Disappointing dyno results

#61

Launching!

iTrader: (5)

Join Date: Dec 2014

Location: Jim Thorpe Pa

Posts: 211

Likes: 0

Received 0 Likes

on

0 Posts

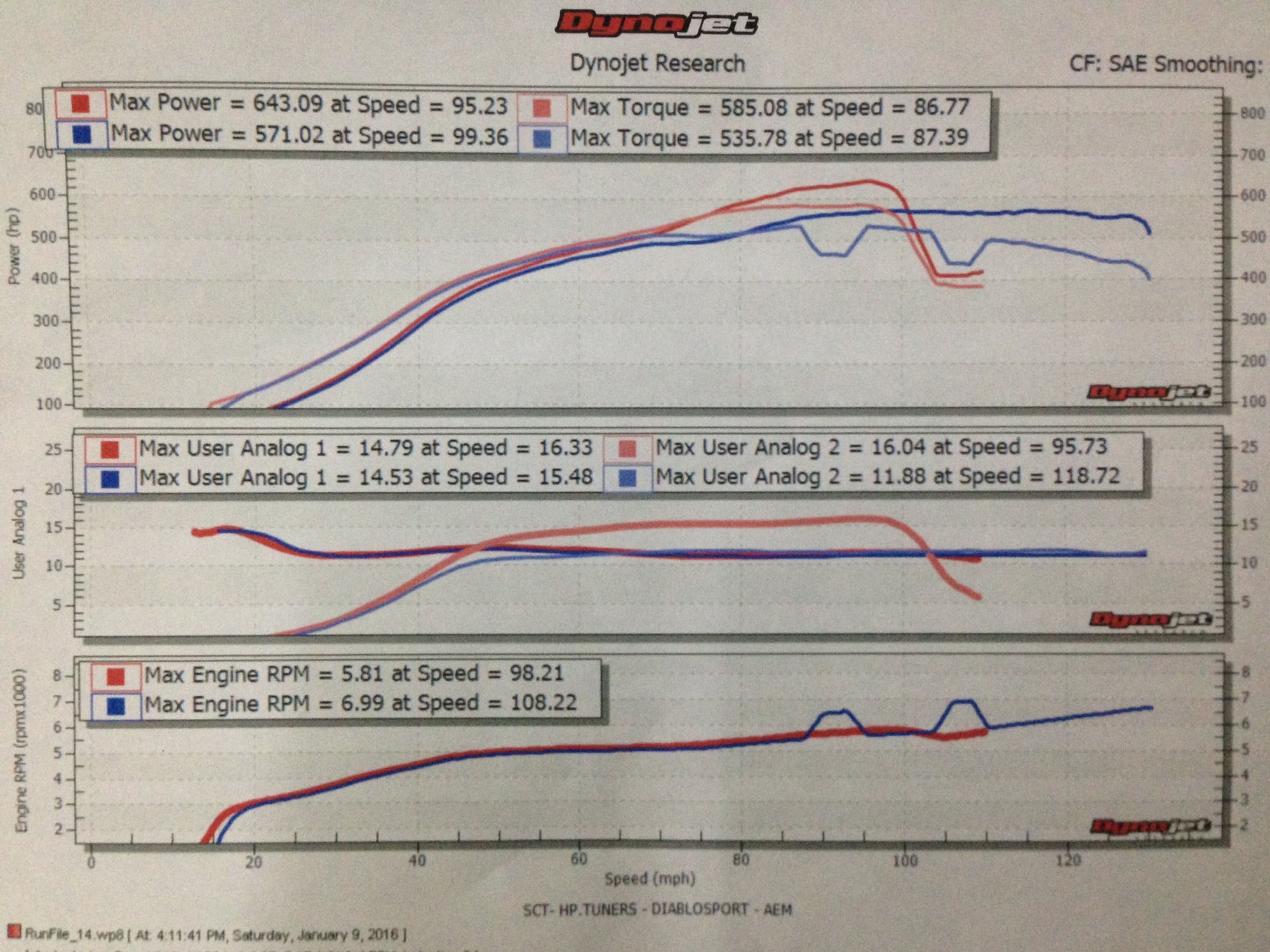

I didn't look back to see if u mentioned these things but assuming the car has a 28 inch tire and mid 3 something gears and that the pull is in a trans gear that is 1 to 1 that thing is slipping bad. Its not even getting 130 Mph at 6800 rpms.

#63

Staging Lane

Thread Starter

Join Date: Sep 2012

Location: Saint Petersburg, FL

Posts: 79

Likes: 0

Received 0 Likes

on

0 Posts

This run may have been the pull that the coupler at the throttle body / inlet tube blew under boost and he let off. I wasn't present when that happened ( left to go grab lunch)

#64

Staging Lane

Thread Starter

Join Date: Sep 2012

Location: Saint Petersburg, FL

Posts: 79

Likes: 0

Received 0 Likes

on

0 Posts

The pulls were done in 3rd gear. Don't know what the rear gear ratio is?? I know the rearend had been upgraded but neither myself or the owner knows the gearing. I'm guessing 3:23 or 3:42?? I'll have to measure tire height - they're 22" dia rims.

This run may have been the pull that the coupler at the throttle body / inlet tube blew under boost and he let off. I wasn't present when that happened ( left to go grab lunch)

This run may have been the pull that the coupler at the throttle body / inlet tube blew under boost and he let off. I wasn't present when that happened ( left to go grab lunch)

#65

Launching!

iTrader: (5)

Join Date: Dec 2014

Location: Jim Thorpe Pa

Posts: 211

Likes: 0

Received 0 Likes

on

0 Posts

The pulls were done in 3rd gear. Don't know what the rear gear ratio is?? I know the rearend had been upgraded but neither myself or the owner knows the gearing. I'm guessing 3:23 or 3:42?? I'll have to measure tire height - they're 22" dia rims.

This run may have been the pull that the coupler at the throttle body / inlet tube blew under boost and he let off. I wasn't present when that happened ( left to go grab lunch)

This run may have been the pull that the coupler at the throttle body / inlet tube blew under boost and he let off. I wasn't present when that happened ( left to go grab lunch)

Last edited by vinceI; 01-13-2016 at 08:30 AM.

#66

8 Second Club

iTrader: (4)

You need to know what gear is in the car.

http://www.how-to-build-hotrods.com/gear-ratio.html

Rim size doesn’t help us. We need the tire diameter. What does the tire say? 255/30 R-22 etc…

http://www.discounttire.com/dtcs/infoTireMath.do

Coupler wouldn’t matter. The MPH is WAY off. Honestly if your “tuner” didn’t see this I’d be looking for another shop. Not saying anything bad about his tuning ability, but I’d want a shop familiar with racing in general. Should throw up a red flag immediately when a 1000+hp car is at 118mph near redline. You should be at 160-170ish if you are geared properly IMO.

http://www.how-to-build-hotrods.com/gear-ratio.html

Rim size doesn’t help us. We need the tire diameter. What does the tire say? 255/30 R-22 etc…

http://www.discounttire.com/dtcs/infoTireMath.do

Coupler wouldn’t matter. The MPH is WAY off. Honestly if your “tuner” didn’t see this I’d be looking for another shop. Not saying anything bad about his tuning ability, but I’d want a shop familiar with racing in general. Should throw up a red flag immediately when a 1000+hp car is at 118mph near redline. You should be at 160-170ish if you are geared properly IMO.

#67

Don't live in denial like I did. Find out your rear gear/tire diameter and calculate your slippage for sure. The reason I have been fighting my issue for so long is I was sure I must have been doing something else wrong when the data was staring me right in the face.

I will regurgitate some advice forcefed gave me before. What are your trans temps and what does the fluid look like. If it's the Trans slipping you will know from that.

#68

Staging Lane

Thread Starter

Join Date: Sep 2012

Location: Saint Petersburg, FL

Posts: 79

Likes: 0

Received 0 Likes

on

0 Posts

Coupler won't effect the slip if anything being down on power would help the looseness of the converter... Either the trans is slipping or the converter is way too loose. 3rd gear should be w to 1 so if the tires are in the 27 to 28 inch area your up at 20 % slip or more and you would want it down around 5 %. I would bet it would make the same power on 5 or 6 psi.

When the tuner was doing light initial pulls at 7psi boost it was only around 500whp. I thought it seemed weird that at 14psi it was only making around 650whp.

#69

Staging Lane

Thread Starter

Join Date: Sep 2012

Location: Saint Petersburg, FL

Posts: 79

Likes: 0

Received 0 Likes

on

0 Posts

Boy this looks familiar ehh forcefed?

Don't live in denial like I did. Find out your rear gear/tire diameter and calculate your slippage for sure. The reason I have been fighting my issue for so long is I was sure I must have been doing something else wrong when the data was staring me right in the face.

I will regurgitate some advice forcefed gave me before. What are your trans temps and what does the fluid look like. If it's the Trans slipping you will know from that.

Don't live in denial like I did. Find out your rear gear/tire diameter and calculate your slippage for sure. The reason I have been fighting my issue for so long is I was sure I must have been doing something else wrong when the data was staring me right in the face.

I will regurgitate some advice forcefed gave me before. What are your trans temps and what does the fluid look like. If it's the Trans slipping you will know from that.

Btw - tire size is 295/30 - 22 which puts it at 29" tall

#70

Launching!

iTrader: (5)

Join Date: Dec 2014

Location: Jim Thorpe Pa

Posts: 211

Likes: 0

Received 0 Likes

on

0 Posts

Your welcome. 500 at 7 seems pretty low too. I'm guessing the trans is slipping or the converter is hurt not just to loose. A 3.42 gear, 29 inch tire, going 130 mph at 6800 is 24% slip. That's were your problem is. You just need to figure out if its the trans or converter.

#71

Staging Lane

Thread Starter

Join Date: Sep 2012

Location: Saint Petersburg, FL

Posts: 79

Likes: 0

Received 0 Likes

on

0 Posts

Your welcome. 500 at 7 seems pretty low too. I'm guessing the trans is slipping or the converter is hurt not just to loose. A 3.42 gear, 29 inch tire, going 130 mph at 6800 is 24% slip. That's were your problem is. You just need to figure out if its the trans or converter.

#72

TECH Resident

iTrader: (2)

I've been there done that with my 4L80. If it's been a few years since the 800 whp pull I'd definitely be suspect to the trans and converter. It doesn't take much to hurt a trans with 800+ whp in a big boat like this. I'd have someone go through the trans and get a good triple disc converter for it (Yank, Circle D, Jakes, etc.) Someone that knows 4L80's. Good luck with it, and keep us posted.

#73

Banned

iTrader: (1)

I didn't get the timing/ AF ratio graph printout from him. The AF was pretty much in the 11:1 range during boost.

Injectors are Injector Dynamics ID1300. I spoke to tech at ID at length about the engine combination, turbo size, fuel delivery, etc.. Before those size injectors were purchased to make sure I had more than adequate size along with the fuel delivery was plumbed for more than the HP requirements this motor will make. One thing I do is over engineer & build it for more than what it needs so I don't have to worry about breaking stuff. Fuel system is plumbed to support 2000HP.

Injectors are Injector Dynamics ID1300. I spoke to tech at ID at length about the engine combination, turbo size, fuel delivery, etc.. Before those size injectors were purchased to make sure I had more than adequate size along with the fuel delivery was plumbed for more than the HP requirements this motor will make. One thing I do is over engineer & build it for more than what it needs so I don't have to worry about breaking stuff. Fuel system is plumbed to support 2000HP.

just saying its easier to check your fuel pressure and the number on the injector than it is to change a trans.

Heres a thought. At 15psi of boost, if your regulator was 45psi to begin with, and there is no reference, you will be at 30psi of fuel pressure, instead of 60. That could easily be your "missing" 500 horsepower worth of fuel.

Last edited by kingtal0n; 01-13-2016 at 04:44 PM.

#75

Staging Lane

Thread Starter

Join Date: Sep 2012

Location: Saint Petersburg, FL

Posts: 79

Likes: 0

Received 0 Likes

on

0 Posts

so basically 1. you have not verified the size of your injectors, and you are taking the word of some guy on the phone that they are the right size, and 2. you have no idea whether the fuel pressure is dropping or not.\

just saying its easier to check your fuel pressure and the number on the injector than it is to change a trans.

Heres a thought. At 15psi of boost, if your regulator was 45psi to begin with, and there is no reference, you will be at 30psi of fuel pressure, instead of 60. That could easily be your "missing" 500 horsepower worth of fuel.

just saying its easier to check your fuel pressure and the number on the injector than it is to change a trans.

Heres a thought. At 15psi of boost, if your regulator was 45psi to begin with, and there is no reference, you will be at 30psi of fuel pressure, instead of 60. That could easily be your "missing" 500 horsepower worth of fuel.

#76

Staging Lane

Thread Starter

Join Date: Sep 2012

Location: Saint Petersburg, FL

Posts: 79

Likes: 0

Received 0 Likes

on

0 Posts

It's not running lean. I never said I didn't know if the fuel pressure was dropping on this run. On the original 800whp pass yes. This is what it's doing for fuel right now - 125lb/hr. 62% X 8 = 620lb/hr. More than plenty of fuel for a 650 pass. Boost reference on the regulator is hooked up and working.

#77

Banned

iTrader: (1)

It's not running lean. I never said I didn't know if the fuel pressure was dropping on this run. On the original 800whp pass yes. This is what it's doing for fuel right now - 125lb/hr. 62% X 8 = 620lb/hr. More than plenty of fuel for a 650 pass. Boost reference on the regulator is hooked up and working.

Also I am not saying the converter is any good, it could also be bad from age and use. The simple diagnosis is your $999 fuel system is returning more of the juice to the tank, its the simplest explanation, should be related to the computer output fuel number. the converter could be old and trans could be shot and all that too-, I would do a compression test and see 160+ even across the board, boost leak it, hit it, lock the converter up when you make the pass to eliminate all this question about converter slippage factoring in, and get a converter that can lockup at WOT (take some of that fuel system money) if you don't have one its practically an essential part of the fundamentals of automatics 101. Transmissions got a set of clutches in it, if you lock the converter clutch and the rpm correlates to wheel speed the way you expect, the clutches aint slipping and you arn't magically dissipating 400 horses. I am not sure how much a torque converter can inefficiently transfer in the case of wear or age, but I can imagine it can be abusive and related to the total output problem if not performing properly as indicated by the desired stall speed range. I don't think anyone calculated how much energy would need to be lost to the fluid to account for 100 horses either, so none of us knows exactly how much delta T (find the heat capacity and convert horses to joules I guess, pretty simply but I am lazy) that is, and if you can do it for 100 you can do it for 300 or 400 and see exactly how much temp rise to expect pretty quick based on how much you think you are losing.

Last edited by kingtal0n; 01-14-2016 at 12:52 AM.

#78

10 Second Club

iTrader: (10)

After I left the engine builder today I went back over to the Dyno/ tuners shop. We went back over the graphs more thorough with curser and saw where the converter /RPMs flashed to 4900 @ 50mph. Definitely a slippage issue. We didn't see this at first. I told y'all I'm dumb sometimes - lol!!

#79

Staging Lane

Thread Starter

Join Date: Sep 2012

Location: Saint Petersburg, FL

Posts: 79

Likes: 0

Received 0 Likes

on

0 Posts

Im not saying the car is running lean, I am saying your pump output and or fuel pressure is the reason your engine looks like it is making 1000 horses when its only putting down anything less, the computer isn't telling you that the engine is using 125lb/hr- the computer is the idiot just shelling out a number based on assumption, it is completely wrong. You have to apply common sense, such as rwhp dyno output results compared to air fuel ratio. The computer has a fuel pressure assumption or injector size assumption. You seem to have a simple regulation or pump problem. Again, I am not saying you did not put enough thousands of dollars into the fuel system, I am not even saying you need a thousand dollar fuel system. We can all do 750 with $350 twin walbros in an OEM tank and get 30 to 50k miles out of that with a great efficiency. If plumbed correctly, that is, I mean you have to make sure the second pump output is nicely correlated with the first, that the other pump comes on only when it is needed, so we conserve many resources such as issues with the return (you want a tiny return when the second pump kicks on to make sure you put the squeeze on the pump without expensive regulators and expensive fuel lines, it is mainly the feed and how much pressure/application we want to run and how much risk at whatever kind of rail/system). You have some fuel system with a regulator that seems to be passing to much to the return, your fuel system is so good and the regulator is so huge and maybe a vacuum line is disconnected for good measure somewhere or insufficient (you DO have a dedicated vacuum source and not a heavily T'd line right?) This is just an example of how you use a proven design (a cookie cutter) if possible for repeatable, reliable results.

Also I am not saying the converter is any good, it could also be bad from age and use. The simple diagnosis is your $999 fuel system is returning more of the juice to the tank, its the simplest explanation, should be related to the computer output fuel number. the converter could be old and trans could be shot and all that too-, I would do a compression test and see 160+ even across the board, boost leak it, hit it, lock the converter up when you make the pass to eliminate all this question about converter slippage factoring in, and get a converter that can lockup at WOT (take some of that fuel system money) if you don't have one its practically an essential part of the fundamentals of automatics 101. Transmissions got a set of clutches in it, if you lock the converter clutch and the rpm correlates to wheel speed the way you expect, the clutches aint slipping and you arn't magically dissipating 400 horses. I am not sure how much a torque converter can inefficiently transfer in the case of wear or age, but I can imagine it can be abusive and related to the total output problem if not performing properly as indicated by the desired stall speed range. I don't think anyone calculated how much energy would need to be lost to the fluid to account for 100 horses either, so none of us knows exactly how much delta T (find the heat capacity and convert horses to joules I guess, pretty simply but I am lazy) that is, and if you can do it for 100 you can do it for 300 or 400 and see exactly how much temp rise to expect pretty quick based on how much you think you are losing.

Also I am not saying the converter is any good, it could also be bad from age and use. The simple diagnosis is your $999 fuel system is returning more of the juice to the tank, its the simplest explanation, should be related to the computer output fuel number. the converter could be old and trans could be shot and all that too-, I would do a compression test and see 160+ even across the board, boost leak it, hit it, lock the converter up when you make the pass to eliminate all this question about converter slippage factoring in, and get a converter that can lockup at WOT (take some of that fuel system money) if you don't have one its practically an essential part of the fundamentals of automatics 101. Transmissions got a set of clutches in it, if you lock the converter clutch and the rpm correlates to wheel speed the way you expect, the clutches aint slipping and you arn't magically dissipating 400 horses. I am not sure how much a torque converter can inefficiently transfer in the case of wear or age, but I can imagine it can be abusive and related to the total output problem if not performing properly as indicated by the desired stall speed range. I don't think anyone calculated how much energy would need to be lost to the fluid to account for 100 horses either, so none of us knows exactly how much delta T (find the heat capacity and convert horses to joules I guess, pretty simply but I am lazy) that is, and if you can do it for 100 you can do it for 300 or 400 and see exactly how much temp rise to expect pretty quick based on how much you think you are losing.

#80

Staging Lane

Thread Starter

Join Date: Sep 2012

Location: Saint Petersburg, FL

Posts: 79

Likes: 0

Received 0 Likes

on

0 Posts