Pre-Turbo Dual Widebands

#21

ForceFed - Thanks for the calibration curve, this is what I wanted to see. I just ordered my MS3 Gold Box setup, so I do not know the capabilities yet...but it seems that you could create a correction factor to be calculated for the lambda being observed and recorded, read a pressure transducer pre-turbo, and set up an IF statement: IF Lambda >1 use K=0.47 and IF Lambda and use the calculation to give a new lambda value.

I wonder if narrowband O2 sensors are more durable? I could potentially use narrowbands for part throttle closed loop and resort to a wideband downstream of the turbo for initial tuning and CL WOT corrections, as well as engine shut down safety int he event it goes lean.

I wonder if narrowband O2 sensors are more durable? I could potentially use narrowbands for part throttle closed loop and resort to a wideband downstream of the turbo for initial tuning and CL WOT corrections, as well as engine shut down safety int he event it goes lean.

#23

9 Second Club

#24

8 Second Club

iTrader: (4)

Narrow band would be fine.

This is the one I got.

http://www.ebay.com/itm/Innovate-372...NS~t2C&vxp=mtr

This is the one I got.

http://www.ebay.com/itm/Innovate-372...NS~t2C&vxp=mtr

#27

thanks for the input stevie. seems like we're having a tussle here haha I like it. I always try and keep my mind open so I can learn and maybe come up with new things to help my builds. I checked out that 02 sensor extender you guys posted on here, looks like a decent product that I could use on my post turbo wideband since I have mine kinda close to my turbo (bumper exhaust). my only question is does this affect sensor sampling any since the sensor no longer dips into the exhaust like it normally would.?

#29

9 Second Club

And if people would open their eyes and read. That's exactly what you can use a sampling chamber for which takes the pressure aspect away which is why his comment about the use of a sampling chamber was complete and utter nonsense. And that's me being polite about it.

#31

8 Second Club

iTrader: (4)

And if people would open their eyes and read. That's exactly what you can use a sampling chamber for which takes the pressure aspect away which is why his comment about the use of a sampling chamber was complete and utter nonsense. And that's me being polite about it.

#32

Maybe Iím misunderstanding your ďchamberĒ? Any area pre-turbo (regardless of the orifice size leading to it) will have the same amount of pressure as anywhere else in the system. Thatís how all sealed pressure systems work. How are you suggesting it would work otherwise? Maybe Iím missing something? Draw us a diagram of what youíre talking about.

#33

9 Second Club

Maybe Iím misunderstanding your ďchamberĒ? Any area pre-turbo (regardless of the orifice size leading to it) will have the same amount of pressure as anywhere else in the system. Thatís how all sealed pressure systems work. How are you suggesting it would work otherwise? Maybe Iím missing something? Draw us a diagram of what youíre talking about.

It is NOT a sealed system, air will always move from an area of high pressure to low pressure. You control that movement via orifice size, exactly as you do with your boost control.

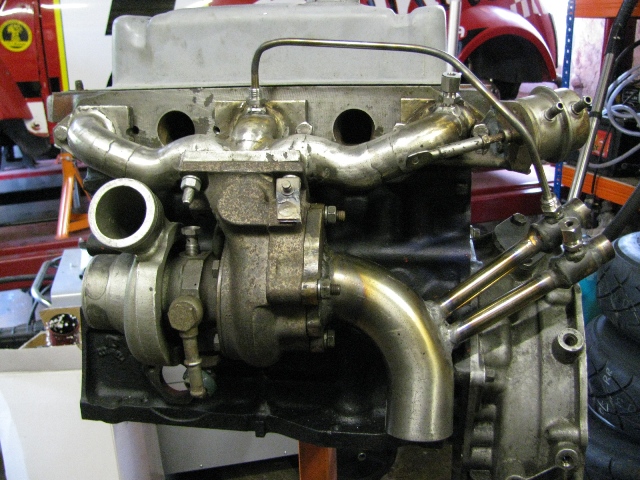

Here is one install ( not mine ). Small line to the chamber, larger discharge back into main exhaust. This results in NO pressure build up in the chamber.

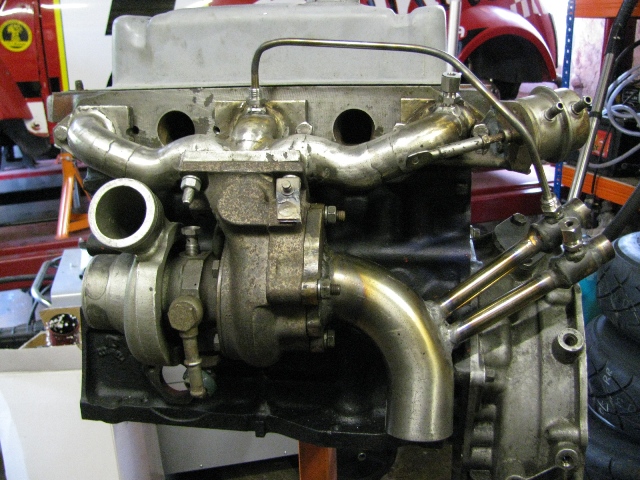

And another

[/quote]

[/quote]And another

#34

TECH Fanatic

iTrader: (11)

If you believe this, may as well rip out your entire boost control setup, as it will never work. Same principals apply

It is NOT a sealed system, air will always move from an area of high pressure to low pressure. You control that movement via orifice size, exactly as you do with your boost control.

Here is one install ( not mine ). Small line to the chamber, larger discharge back into main exhaust. This results in NO pressure build up in the chamber.

And another

It is NOT a sealed system, air will always move from an area of high pressure to low pressure. You control that movement via orifice size, exactly as you do with your boost control.

Here is one install ( not mine ). Small line to the chamber, larger discharge back into main exhaust. This results in NO pressure build up in the chamber.

And another

[/QUOTE]

[/QUOTE]Very interesting thanks for posting Stevie.

#35

Banned

iTrader: (1)

seems like an unnecessary excessively complicated apparatus which requires several additional holes and fittings to be added to parts which already have a tendency to leak.

Might have a racing application, but even then I would want things much simpler than that. thumbs down for daily drivers thats for sure. And FWIW if you isolate something from the temp of the exhaust like that, then it technically is no longer installed directly to the manifold (the question was/is: can I install a wideband to the manifold directly, answer is NO: You must isolate it somehow, to a cooler/lower pressure area, so this really just proves that same original issue is true, they will not tolerate well being directly bolted into an manifold.)

its like saying "hey guise, can I run a lawnmower with ethanol?" and half say "yes" and half say "no", the "yes" people are right because of course it will work, provided that certain conditions are met (apparatus is provided). The no people are also right because, those conditions have not been met in their eyes yet, without the additional apparatus. So no, you cant just put ethanol in the tank, and no, you cant just bolt a wideband into a pre-turbo manifold and expect it to work like that either.

Might have a racing application, but even then I would want things much simpler than that. thumbs down for daily drivers thats for sure. And FWIW if you isolate something from the temp of the exhaust like that, then it technically is no longer installed directly to the manifold (the question was/is: can I install a wideband to the manifold directly, answer is NO: You must isolate it somehow, to a cooler/lower pressure area, so this really just proves that same original issue is true, they will not tolerate well being directly bolted into an manifold.)

its like saying "hey guise, can I run a lawnmower with ethanol?" and half say "yes" and half say "no", the "yes" people are right because of course it will work, provided that certain conditions are met (apparatus is provided). The no people are also right because, those conditions have not been met in their eyes yet, without the additional apparatus. So no, you cant just put ethanol in the tank, and no, you cant just bolt a wideband into a pre-turbo manifold and expect it to work like that either.

Last edited by kingtal0n; 05-12-2016 at 05:46 PM.

#36

9 Second Club

What parts have a tendency to leak ?

If you build it ****, then yes I guess it could leak.

And no, nowhere was it asked "can I install a wideband to the manifold directly"

Which goes back to my comment about people opening their ******* eyes and reading.

If you build it ****, then yes I guess it could leak.

And no, nowhere was it asked "can I install a wideband to the manifold directly"

Which goes back to my comment about people opening their ******* eyes and reading.

#37

8 Second Club

iTrader: (4)

If you believe this, may as well rip out your entire boost control setup, as it will never work. Same principals apply

It is NOT a sealed system, air will always move from an area of high pressure to low pressure. You control that movement via orifice size, exactly as you do with your boost control.

Here is one install ( not mine ). Small line to the chamber, larger discharge back into main exhaust. This results in NO pressure build up in the chamber.

It is NOT a sealed system, air will always move from an area of high pressure to low pressure. You control that movement via orifice size, exactly as you do with your boost control.

Here is one install ( not mine ). Small line to the chamber, larger discharge back into main exhaust. This results in NO pressure build up in the chamber.

For one, those are all post turbo, none of them are pre-turbo which is what we are talking about... Those are setup to reduce flow/temperature, and will have zero effect on a pressure reading pre-turbo.

The WG controls the entire systems pressure pre-turbo. It takes X pressure to make Y boost. What ever that pressure is, it will be a constant through out the entire hot side pre-turbo. I don't care if you run a 10ft length of pipe of the manifold and put a pressure sensor in it. It will read the same as the rest of the system.

Just like my 1/4 brass line with 20 coils in it leading to my turbine drive pressure sensor would read the same as if it were tapped directly into the manifold runner.

#38

Banned

iTrader: (1)

Now, My real concern is that this setup is completely unnecessary. A single wideband 3-5 feet behind a turbine is good enough for the majority of high output engines, even at 2000rwhp I would be ok with one in the car and one off the dyno for accuracy comparison.... I would never intentionally add a bunch of holes/plumbing to my already complicated turbo system. Not when a single hole/sensor mounted 5 feet away is good enough.

#39

It seems to me that the sample chambers would work, since the orifice is smaller on the inlet than the outlet, and the chamber itself should pull some vacuum from being dumped in the post turbo exhaust no? Wouldn't that eliminate most of the heat/pressure concerns?

#40

9 Second Club

Forcefed seems to think...

Exhaust manifold pressure pre w/g, ie before the control orifice is the same as the w/g discharge either to atmosphere or into the DP, which of course is nonsense.

He also seems to think in a basic boost control setup, manifold pressure is the same as that applied to the w/g chamber to blow it open after the control orifice bleeds some off.....which is also totally incorrect. If he was correct, none of our systems that vent air after a control orifice would ever allow us to alter boost over basic mechanical spring settings.

Hopefulyl he'll take a minute or more to read what he just wrote and realise how wrong he is.

Even more baffling is why he seems to think something is post turbo, when the connecting lines to the exhaust manifold...ie pre-turbo are there in all their nasty glory for those with eyes to see.

And if someone really wanted to mount them "directly" onto the hotside, they could also do this, just extend the sensor up a couple of inches from the hotside, and as you've said a small orifice to supply air to the sensor then route the larger diameter discharge back into the DP.

It's SIMPLE, SIMPLE, SIMPLE.