Making an 8.8 work

#21

TECH Addict

iTrader: (22)

The tubes wont separate. Weld them to the diff if it worries you

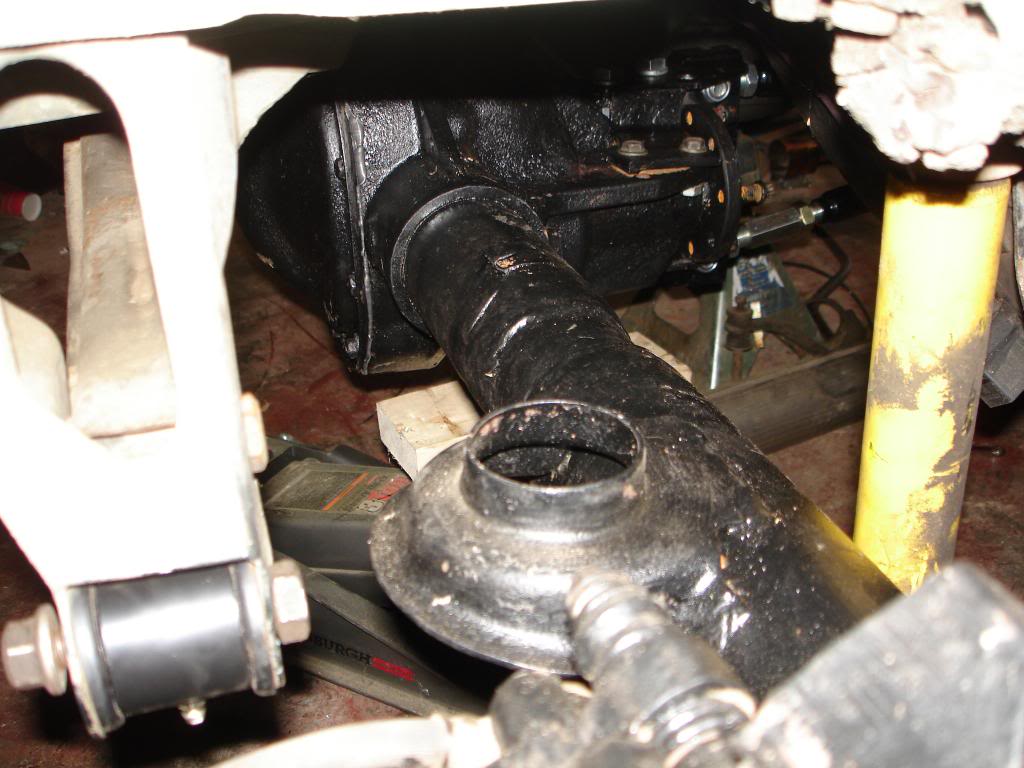

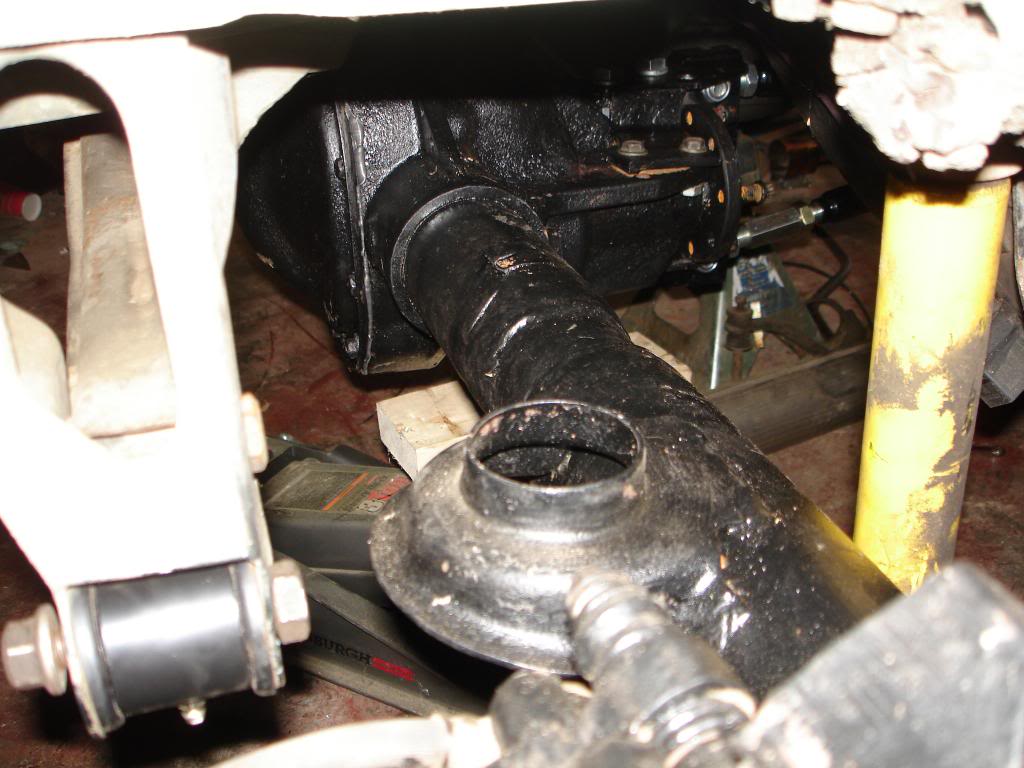

Heres a ranger 28sp 8.8 with Fbody axle tubes and stock Fbody axles. I later updated the design from a pair of tubes to a solid piece of angle

31sp explorer unit using two drivers side explorer axles. Pass tube extended via internal sleeve. 4"x5/16" angle from drivers tube for TA mount

Sleeve. 10 bolt mounts were cut off a junk housing and welded on the 8.8. Will fabricate the brackets from scratch the next time. That sucked

Heres a ranger 28sp 8.8 with Fbody axle tubes and stock Fbody axles. I later updated the design from a pair of tubes to a solid piece of angle

31sp explorer unit using two drivers side explorer axles. Pass tube extended via internal sleeve. 4"x5/16" angle from drivers tube for TA mount

Sleeve. 10 bolt mounts were cut off a junk housing and welded on the 8.8. Will fabricate the brackets from scratch the next time. That sucked

#24

As far as why engineering companies such as moser/trick etc. don't sell these I'm not too sure, but if someone could get a good method down that had a quick completion time, I'm sure a good majority of tech members would line up.

#25

Once I'm done with mine and I write up a build thread (and if people are pleased and confident with the results) I'd have no problem making some for tech members. If I get supplied with the donor axle and the 8.8 I don't see why I couldn't make some for a few hundred dollars in labor.

#27

10 Second Club

iTrader: (37)

I want one that keeps 4ch ABS, stock e-brake cables, and stock width that dosent use the small 10 bolt axle bearings. I want to keep my wheels and not have to buy new ones. If someone has a formula for this I can cut and weld perfect and have all the shop tools to do it with.

I want one that keeps 4ch ABS, stock e-brake cables, and stock width that dosent use the small 10 bolt axle bearings. I want to keep my wheels and not have to buy new ones. If someone has a formula for this I can cut and weld perfect and have all the shop tools to do it with.

#28

TECH Senior Member

iTrader: (11)

I don't know what you mean by the small axle bearings. That's usually not a major failure component.

Sounds like you might as well just get a 12 bolt, S60, or 9 inch if you're looking to beef everything up. The goal of this though is to just get a stronger center section (and maybe a higher spline axle set).

Sounds like you might as well just get a 12 bolt, S60, or 9 inch if you're looking to beef everything up. The goal of this though is to just get a stronger center section (and maybe a higher spline axle set).

#29

10 Second Club

iTrader: (37)

I don't know what you mean by the small axle bearings. That's usually not a major failure component.

Sounds like you might as well just get a 12 bolt, S60, or 9 inch if you're looking to beef everything up. The goal of this though is to just get a stronger center section (and maybe a higher spline axle set).

Sounds like you might as well just get a 12 bolt, S60, or 9 inch if you're looking to beef everything up. The goal of this though is to just get a stronger center section (and maybe a higher spline axle set).

#32

TECH Addict

iTrader: (22)

Considering this for my car. It seems too good to be true. Why isnt this more popular?

Someone could make a killing off these.

Someone could make a killing off these.

This is a budget axle, always has been. Throw a company fabbing them in and it's no longer a budget axle. Then you might as well go aftermarket

The f150 or any heavy truck axle is out. Look at the axle flange. If you can find a shop willing to red roll the lug pattern, the tulip is still too big. The explorer axle is the heaviest axle with the small flanges, but it's the small ford bolt pattern of 5 on 4.5"

IMHO, the only two routes I would consider would be:

Use 28sp car/ranger 8.8 and slide the 10 bolt axles/tubes in. 9/10 cars on this forum will not break this setup and it can be built for around $100. Weak link are the axles. 4ch abs is all stock parts, same brakes, everything

2) explorer 31sp 8.8 using two drivers side axles, extend the pass tube, fab new brackets, use ford brakes and 1.5" adapters for the wheels or run mustang wheels. Weak link is the differential

Do whatever you want for the TA mount. I prefer the wing from the drivers tube. Hiltys mount is solid, but requires disassembling the diff. If you can properly setup a gear pattern and properly weld cast, use his mount 100%. If you can't do both, use the wing

#33

10 Second Club

iTrader: (37)

Lots of liability with used axle parts. For a company, it'd cost about the same to build a fab9 as an 8.8. Who would shell out the same money for a weaker axle?

This is a budget axle, always has been. Throw a company fabbing them in and it's no longer a budget axle. Then you might as well go aftermarket

The f150 or any heavy truck axle is out. Look at the axle flange. If you can find a shop willing to red roll the lug pattern, the tulip is still too big. The explorer axle is the heaviest axle with the small flanges, but it's the small ford bolt pattern of 5 on 4.5"

IMHO, the only two routes I would consider would be:

Use 28sp car/ranger 8.8 and slide the 10 bolt axles/tubes in. 9/10 cars on this forum will not break this setup and it can be built for around $100. Weak link are the axles. 4ch abs is all stock parts, same brakes, everything

2) explorer 31sp 8.8 using two drivers side axles, extend the pass tube, fab new brackets, use ford brakes and 1.5" adapters for the wheels or run mustang wheels. Weak link is the differential

Do whatever you want for the TA mount. I prefer the wing from the drivers tube. Hiltys mount is solid, but requires disassembling the diff. If you can properly setup a gear pattern and properly weld cast, use his mount 100%. If you can't do both, use the wing

This is a budget axle, always has been. Throw a company fabbing them in and it's no longer a budget axle. Then you might as well go aftermarket

The f150 or any heavy truck axle is out. Look at the axle flange. If you can find a shop willing to red roll the lug pattern, the tulip is still too big. The explorer axle is the heaviest axle with the small flanges, but it's the small ford bolt pattern of 5 on 4.5"

IMHO, the only two routes I would consider would be:

Use 28sp car/ranger 8.8 and slide the 10 bolt axles/tubes in. 9/10 cars on this forum will not break this setup and it can be built for around $100. Weak link are the axles. 4ch abs is all stock parts, same brakes, everything

2) explorer 31sp 8.8 using two drivers side axles, extend the pass tube, fab new brackets, use ford brakes and 1.5" adapters for the wheels or run mustang wheels. Weak link is the differential

Do whatever you want for the TA mount. I prefer the wing from the drivers tube. Hiltys mount is solid, but requires disassembling the diff. If you can properly setup a gear pattern and properly weld cast, use his mount 100%. If you can't do both, use the wing

#34

TECH Addict

iTrader: (22)

Possibly, you're looking at $400 in axles though, so its not that appealing

I posted pics of the old and revised mounts. Old was two pieces of roll bar tubing, new was a single 5"x5/16" piece of angle. Both located the TA mount close to the snout and used 2"x1/4" steel stock to wrap a loop around the snout and bolt to the flange on the pass side. Point of the "wing" is to control the up/down forces from the axle. The strap controls the L/R of the TA attempting the fish tail under load. All welding is done on the drivers mild steel axle tube, not the cast diff

I do not sell anything for the axle. The parts are simple to make

I posted pics of the old and revised mounts. Old was two pieces of roll bar tubing, new was a single 5"x5/16" piece of angle. Both located the TA mount close to the snout and used 2"x1/4" steel stock to wrap a loop around the snout and bolt to the flange on the pass side. Point of the "wing" is to control the up/down forces from the axle. The strap controls the L/R of the TA attempting the fish tail under load. All welding is done on the drivers mild steel axle tube, not the cast diff

I do not sell anything for the axle. The parts are simple to make

#36

Update:

Broken clutch slave cylinder bleed valve had my spare time tied up lately. Everything is ok now and the rear end project resumes. I'm having some trouble locating an ideal donor axle (10bolt or 8.8) and that seems to be my only remaining obstacle. I'm following up a lead this weekend that might land me the 8.8.

A build thread will be started as soon as both axles are purchased and begin to be cut apart.

Broken clutch slave cylinder bleed valve had my spare time tied up lately. Everything is ok now and the rear end project resumes. I'm having some trouble locating an ideal donor axle (10bolt or 8.8) and that seems to be my only remaining obstacle. I'm following up a lead this weekend that might land me the 8.8.

A build thread will be started as soon as both axles are purchased and begin to be cut apart.

#37

10 Second Club

iTrader: (37)

Update:

Broken clutch slave cylinder bleed valve had my spare time tied up lately. Everything is ok now and the rear end project resumes. I'm having some trouble locating an ideal donor axle (10bolt or 8.8) and that seems to be my only remaining obstacle. I'm following up a lead this weekend that might land me the 8.8.

A build thread will be started as soon as both axles are purchased and begin to be cut apart.

Broken clutch slave cylinder bleed valve had my spare time tied up lately. Everything is ok now and the rear end project resumes. I'm having some trouble locating an ideal donor axle (10bolt or 8.8) and that seems to be my only remaining obstacle. I'm following up a lead this weekend that might land me the 8.8.

A build thread will be started as soon as both axles are purchased and begin to be cut apart.

#38

12 Second Club

Join Date: Sep 2005

Location: Bucks County, Pa.

Posts: 4,273

Likes: 0

Received 0 Likes

on

0 Posts

One of the advantages of the 8.8 center/r&p for those of us who road race/open track their f bodies is that there is a STRONG version of the very high bias, Torsen T2R diff available for these (through FRPP).

Whereas the version for the 7.5 10 bolts has a very weak case and is prone to cracking.

This diff is NOT made for 9" or S60s of ANY kind/company.

Whereas the version for the 7.5 10 bolts has a very weak case and is prone to cracking.

This diff is NOT made for 9" or S60s of ANY kind/company.

#39

10 bolt purchased w/ panhard and springs for $60. I'm heading over to a junkyard today to check out an 8.8. They said if they have one it will be $100.

Cost to build:

10 bolt donor: $60

8.8" full assm: $100

Flange yoke: ~$20

Materials: ~$20

__________________________

Total so far: $200

Not bad considering it will be a major leap above the 10 bolt towards the strength of a 9" or 12 bolt.

Cost to build:

10 bolt donor: $60

8.8" full assm: $100

Flange yoke: ~$20

Materials: ~$20

__________________________

Total so far: $200

Not bad considering it will be a major leap above the 10 bolt towards the strength of a 9" or 12 bolt.