Gear install help

#1

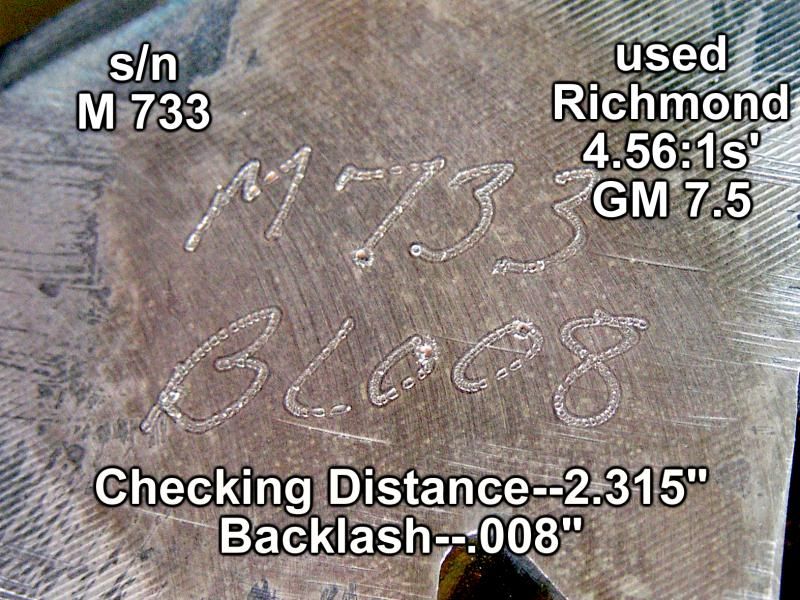

I had a 2 series Auburn Posi laying around so picked up a Thick set of 4.11 gears to stuff into a 7.5 10 bolt. I have a Pinion depth tool and it measured 2.313 on Pinion depth with the original shim that was on the original 3.42 gear. On the new pinion, it has CD 2.311 so that's .002 thicker pinion shim. Though it also has + 8 so if that's the case, that means + .008 on the Shim ? Been a long time since I installed a R & P, attached is a pic of the pattern I now have. It's looks like it's not deep enough into the ring gear ? Thx 4 any help

#2

Heres a site that has a lot of good info to refresh your memory . I have used this from time to time . It also has a + - chart for the pinion depth . + 8 seems like a lot . I would add the .002 and run a pattern check at the 2.311 and another at 2.299 and see which one looks better of the three all using the same backlash , maybe trying a couple different backlashes on all three to see the affect . Cant tell much about your pattern . Best to use the yellow marking paint . It shows up better in pictures .

http://www.pirate4x4.com/tech/billavista/Gear_Setup/

http://www.pirate4x4.com/tech/billavista/Gear_Setup/

Last edited by homemade87; 03-09-2015 at 11:28 AM.

#3

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,240

Likes: 0

Received 79 Likes

on

70 Posts

I always start with a stock shim and adjust from that pattern. I always have a set of hollowed out setup bearings to make changing shims simple. Ive never measured pinion depth and my rear ends always handle lots of abuse.