Torque the intake bolts

#1

Staging Lane

Thread Starter

iTrader: (3)

Join Date: Apr 2012

Location: NWI

Posts: 82

Likes: 0

Received 0 Likes

on

0 Posts

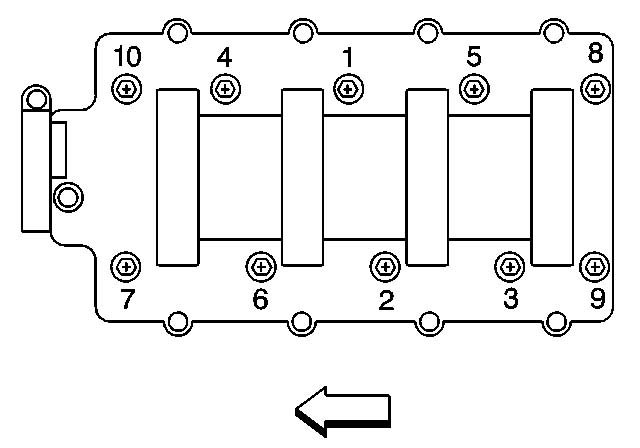

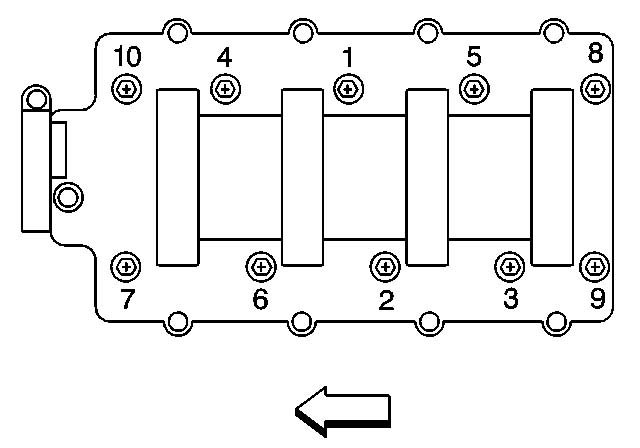

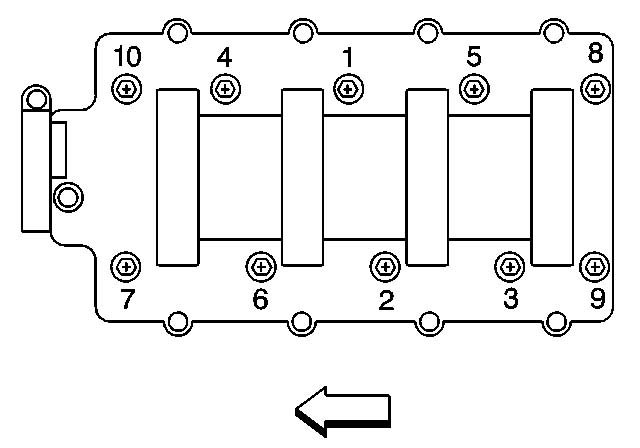

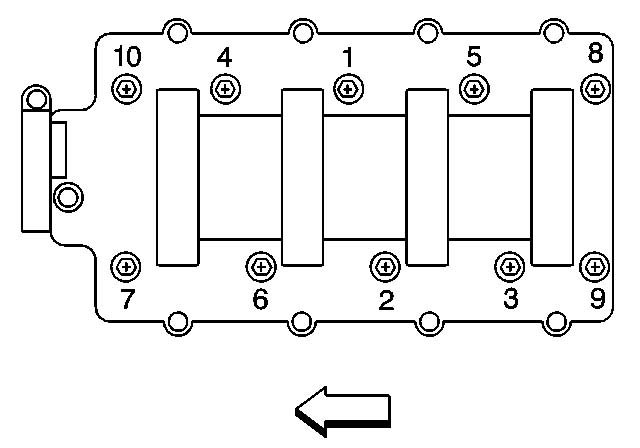

Im about to finish my ls6 intake swap and found out i need to torque the intake bolts 44in lbs then 89 inlbs in a sequence. The wrench i have goes as low as 20ftlbs so its useless in this application.

Can i just tighten them with a 1/4 ratchet and not get too crazy with it or should i buy a 1/4 inlb torque wrench. i was looking at the harbor freight one( dont have a lot of cash) its 15 bucks, Its something i would not use much at all after this one use. I use craftsman most of the time but they dont have a small inlb wrench.

What should i do? i need to get this done today

Can i just tighten them with a 1/4 ratchet and not get too crazy with it or should i buy a 1/4 inlb torque wrench. i was looking at the harbor freight one( dont have a lot of cash) its 15 bucks, Its something i would not use much at all after this one use. I use craftsman most of the time but they dont have a small inlb wrench.

What should i do? i need to get this done today

#2

TECH Junkie

iTrader: (11)

I always buy tools, but can understand why others don't/can't. You can use the 1/4" drive stuff you have, just follow the pattern. I use three different torque steps (30, 60, 90 in/lbs) and go around in this pattern 3 times per step or until they all are even. You may have trouble feeling "even" as well as a wrench...

#3

10 Second Club

Join Date: Jan 2010

Location: Houston Tx

Posts: 195

Likes: 0

Received 0 Likes

on

0 Posts

Be careful 89" lbs is only about 7 ft lbs. Even with a 1/4" drive you will over tighten them. If you can get a torque wrench it will be worth the money especially if you accidentally break a bolt off in the head.

#4

I used a beam wrench. It only went to 60in pounds, but its not detrimental. You want it tight enough the seal are compressed enough to seal, but not so tight you break a bolt, strip a thread, or crack the intake. Tons of people here just snug them down. Just re-check every now and then.

#5

Staging Lane

Thread Starter

iTrader: (3)

Join Date: Apr 2012

Location: NWI

Posts: 82

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the advice guys. I bought the harbor freight special lol 20 bucks. It seems like a nice piece actually, it felt consistent and i read they are spot on with snap ons when tested against each other for accuracy. Seems to have sealed well cant complain.

#6

10 Second Club

iTrader: (41)

I always buy tools, but can understand why others don't/can't. You can use the 1/4" drive stuff you have, just follow the pattern. I use three different torque steps (30, 60, 90 in/lbs) and go around in this pattern 3 times per step or until they all are even. You may have trouble feeling "even" as well as a wrench...

Just make sure and dont over torque them. I had one break on me VERY easily on my old 98z while doing the ls6 swap. I had to drill out the bolt and get a cheap extractor kit to back it out.