Forged Piston to bore clearance?

#41

Moderator

iTrader: (20)

Pistons do not "get shrunk". They are what they are. They can expand from cracking/breakage/warpage, but not the other way around. You would have to wear off an obscene amount of material to make them small. It could have been mixboxed and not the right size, but that is more likely than anything else. But still highly unlikely.

#47

Wrong size hole....end of story.

Let not sugar coat this deal....the only good news is you found your noise issues.

Measure with a dial bore guage to get the proper measurement spec but the fact you can slide a .010 feeler gauge in between the skirt and the bore tells me you are SOL and likely have more than .010

Whether its .010.....012....it doesn't matter.....you have over 2X and heading for 3X the amount of clearance those pistons require.

And the fact you told your machinist you can slide a .010 feeler guage in there and they somehow justified it is also scary.

They need to make this right for you which at the least will require new pistons....likely custom at this point to take up the extra room and I would be scared to see how straight the bores are right now as well.

The biggest problem is can you trust these guys to do it right assuming they are willing to stand up and admit they screwed the pooch on the bore job.

Bad situation....perfect example of why some situations warrant spending more money with shops/people you trust. Avoiding this type of a disaster saves the end user thousands in the end and a bunch of aggrevation.

Good luck....keep us posted on the outcome of the situation. I hope they stand up and make it right for you.

Regards,

Tony

PS.....For most performance applications you should have .0035 - .004 piston to wall by the way....about .001 per inch of bore is a good rule of thumb....some pistons can even be run tighter but they will never make noise at .001 per inch of bore (a 4" bore motor requires .004 clearanace in this quick rule of thumb just as an example....but always consult the pistons manufacturers specs however).

Let not sugar coat this deal....the only good news is you found your noise issues.

Measure with a dial bore guage to get the proper measurement spec but the fact you can slide a .010 feeler gauge in between the skirt and the bore tells me you are SOL and likely have more than .010

Whether its .010.....012....it doesn't matter.....you have over 2X and heading for 3X the amount of clearance those pistons require.

And the fact you told your machinist you can slide a .010 feeler guage in there and they somehow justified it is also scary.

They need to make this right for you which at the least will require new pistons....likely custom at this point to take up the extra room and I would be scared to see how straight the bores are right now as well.

The biggest problem is can you trust these guys to do it right assuming they are willing to stand up and admit they screwed the pooch on the bore job.

Bad situation....perfect example of why some situations warrant spending more money with shops/people you trust. Avoiding this type of a disaster saves the end user thousands in the end and a bunch of aggrevation.

Good luck....keep us posted on the outcome of the situation. I hope they stand up and make it right for you.

Regards,

Tony

PS.....For most performance applications you should have .0035 - .004 piston to wall by the way....about .001 per inch of bore is a good rule of thumb....some pistons can even be run tighter but they will never make noise at .001 per inch of bore (a 4" bore motor requires .004 clearanace in this quick rule of thumb just as an example....but always consult the pistons manufacturers specs however).

#48

LS1Tech Sponsor

iTrader: (14)

Those scuff marks do show signs of considerable piston rock at the bottom and/or top though.

#49

Wrong size hole....end of story.

Let not sugar coat this deal....the only good news is you found your noise issues.

Measure with a dial bore guage to get the proper measurement spec but the fact you can slide a .010 feeler gauge in between the skirt and the bore tells me you are SOL and likely have more than .010

Whether its .010.....012....it doesn't matter.....you have over 2X and heading for 3X the amount of clearance those pistons require.

And the fact you told your machinist you can slide a .010 feeler guage in there and they somehow justified it is also scary.

They need to make this right for you which at the least will require new pistons....likely custom at this point to take up the extra room and I would be scared to see how straight the bores are right now as well.

The biggest problem is can you trust these guys to do it right assuming they are willing to stand up and admit they screwed the pooch on the bore job.

Bad situation....perfect example of why some situations warrant spending more money with shops/people you trust. Avoiding this type of a disaster saves the end user thousands in the end and a bunch of aggrevation.

Good luck....keep us posted on the outcome of the situation. I hope they stand up and make it right for you.

Regards,

Tony

PS.....For most performance applications you should have .0035 - .004 piston to wall by the way....about .001 per inch of bore is a good rule of thumb....some pistons can even be run tighter but they will never make noise at .001 per inch of bore (a 4" bore motor requires .004 clearanace in this quick rule of thumb just as an example....but always consult the pistons manufacturers specs however).

Let not sugar coat this deal....the only good news is you found your noise issues.

Measure with a dial bore guage to get the proper measurement spec but the fact you can slide a .010 feeler gauge in between the skirt and the bore tells me you are SOL and likely have more than .010

Whether its .010.....012....it doesn't matter.....you have over 2X and heading for 3X the amount of clearance those pistons require.

And the fact you told your machinist you can slide a .010 feeler guage in there and they somehow justified it is also scary.

They need to make this right for you which at the least will require new pistons....likely custom at this point to take up the extra room and I would be scared to see how straight the bores are right now as well.

The biggest problem is can you trust these guys to do it right assuming they are willing to stand up and admit they screwed the pooch on the bore job.

Bad situation....perfect example of why some situations warrant spending more money with shops/people you trust. Avoiding this type of a disaster saves the end user thousands in the end and a bunch of aggrevation.

Good luck....keep us posted on the outcome of the situation. I hope they stand up and make it right for you.

Regards,

Tony

PS.....For most performance applications you should have .0035 - .004 piston to wall by the way....about .001 per inch of bore is a good rule of thumb....some pistons can even be run tighter but they will never make noise at .001 per inch of bore (a 4" bore motor requires .004 clearanace in this quick rule of thumb just as an example....but always consult the pistons manufacturers specs however).

Its not easy to find a machine that doesn't know the difference between finnish honing the cylinders to size OR doubling the measuement perfectly...BUT YOU FOUND THEM!

Good Luck but honestly if were you i'd be fuming about now. I got screwed on a engine last year by a "CHRISTAIN FRIEND" someone who supposedly i could trust. Now only did he lie his *** off but he got others involved that lied too. In the end it cost me about 7k! Still frosts my *** to think about it.

Last edited by HotSilverBird; 08-24-2010 at 11:49 PM.

#50

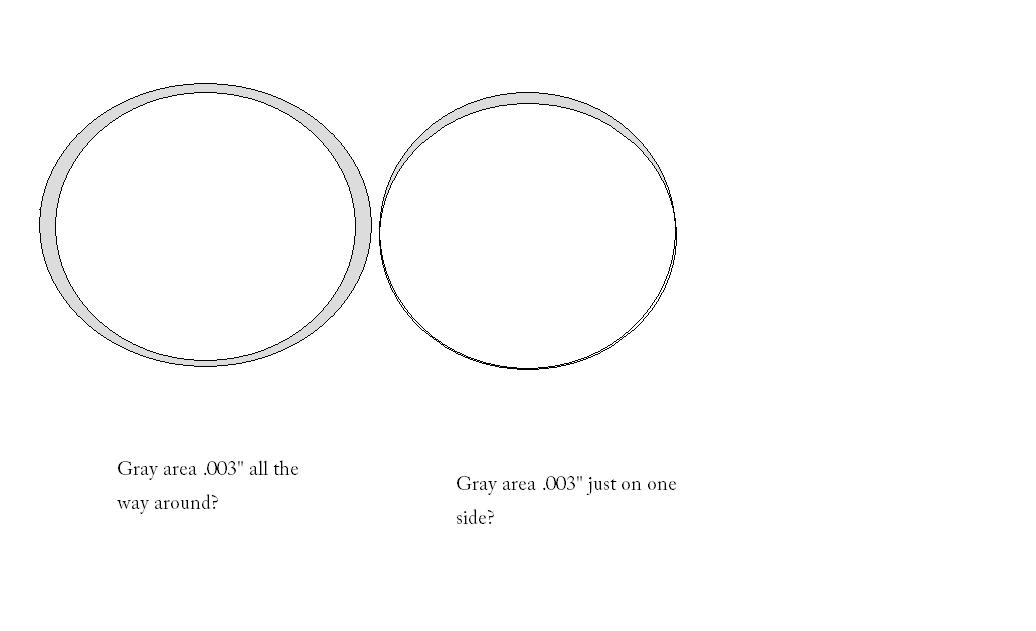

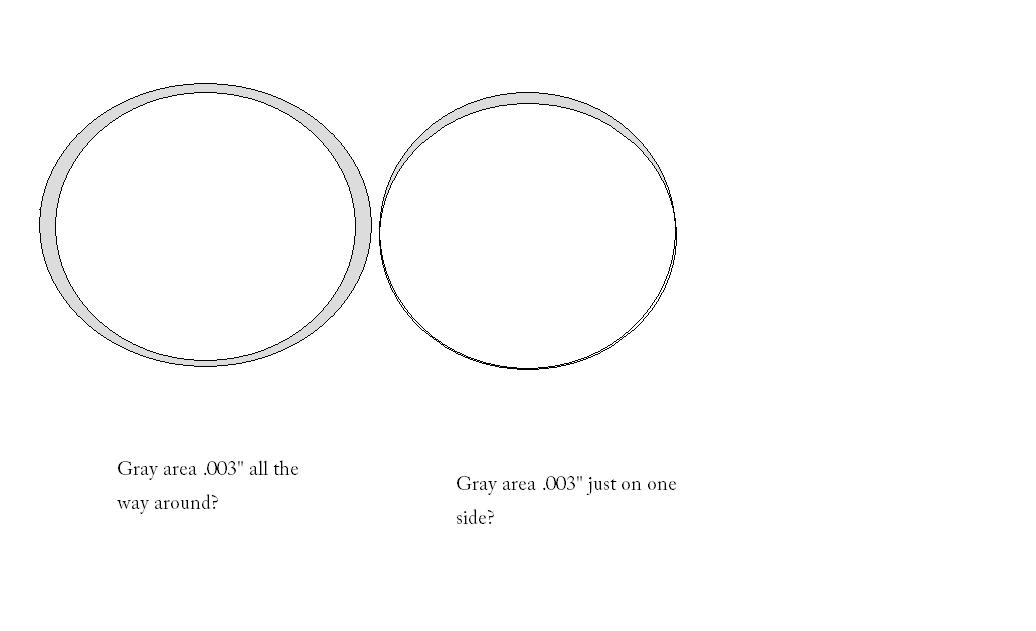

Alright so I am still a little confused on the proper way to measure PTW clearance. You measure with just the skirt of the piston, and with one side of the piston against the wall completely and the number your looking for is measured on the other side? Or do you want the piston centered, and measure for that number to be equal all the way around???

See illustration lol

See illustration lol

#51

Alright so I am still a little confused on the proper way to measure PTW clearance. You measure with just the skirt of the piston, and with one side of the piston against the wall completely and the number your looking for is measured on the other side? Or do you want the piston centered, and measure for that number to be equal all the way around???

See illustration lol

See illustration lol

Your illustration on the left would be .006 piston to wall.....on the right only .003.

Bottom line, how you really measure is with a dial bore gauge.....in fact better than just measuring a bore and then measuring a piston, the best approach is to use a mic to get the skirt dimension of the piston, setting the mic to that dimension, then you zero the bore gauge at the size of the mic (hold the mic in a vise with soft rubber jaws etc.) and drop it in the cylinder so it will now show "net" exactly what you have for clearance. In some respects the size of the piston and the size of the bore doesn't matter....whats most important is the relationship between the two, or how much larger the bore is than the piston. You hope to land extremely close to the .001 thou per inch of bore I mentioned earlier....at least in most N/A applications.

Hope this helps....

-Tony

#52

Moderator

iTrader: (20)

I dont see some heat and a couple thousand miles just doing this. We have run the power pak pistons in quite a few different applications and have never had a problem so far with anything as such.

Those scuff marks do show signs of considerable piston rock at the bottom and/or top though.

Those scuff marks do show signs of considerable piston rock at the bottom and/or top though.

#53

Old School Heavy

iTrader: (16)

Nice pics....LOL

Your illustration on the left would be .006 piston to wall.....on the right only .003.

Bottom line, how you really measure is with a dial bore gauge.....in fact better than just measuring a bore and then measuring a piston, the best approach is to use a mic to get the skirt dimension of the piston, setting the mic to that dimension, then you zero the bore gauge at the size of the mic (hold the mic in a vise with soft rubber jaws etc.) and drop it in the cylinder so it will now show "net" exactly what you have for clearance.

Your illustration on the left would be .006 piston to wall.....on the right only .003.

Bottom line, how you really measure is with a dial bore gauge.....in fact better than just measuring a bore and then measuring a piston, the best approach is to use a mic to get the skirt dimension of the piston, setting the mic to that dimension, then you zero the bore gauge at the size of the mic (hold the mic in a vise with soft rubber jaws etc.) and drop it in the cylinder so it will now show "net" exactly what you have for clearance.

#54

LS1Tech Sponsor

iTrader: (14)

Yah, thats why I said some. Things happen so differently in applications where you artificially change cyl pressure, that really anything can happen. I have seen pistons turn into laffy taffy and not crack even, rings weld to pistons, etc.

What seems to be the root cause is not having control over the entire situation and/or not knowing what was used to build the engine.

First things first, find out what piston/material it is. Then move on from there. Then measure the bore size.

What seems to be the root cause is not having control over the entire situation and/or not knowing what was used to build the engine.

First things first, find out what piston/material it is. Then move on from there. Then measure the bore size.

#55

Piston clearance means just that. There is no mystery or doubling the measument of any other voodoo invovled. If the piston calls for .004 max that means you measure the slug add .004 max and thats the size the bore gotta be. NO OTHER VOODOO doubling etc cenetering the piston pushing piston to dside askin yer momma NUTTIN.

I'm not sure why even machine shops screw this up?

I'm not sure why even machine shops screw this up?

#56

Piston clearance means just that. There is no mystery or doubling the measument of any other voodoo invovled. If the piston calls for .004 max that means you measure the slug add .004 max and thats the size the bore gotta be. NO OTHER VOODOO doubling etc cenetering the piston pushing piston to dside askin yer momma NUTTIN.

I'm not sure why even machine shops screw this up?

I'm not sure why even machine shops screw this up?

#59

say what? I tried helping this guy from the start.........if you can't handle a little funny its not my fault.

Just explain to the guy there is no voodoo involved and get on with it! GEEZ

why do i get the feeling you don't understand it either!

There is NO good reason to critisize my english ...why start bs ??? TWTF is wrong you people? This site is getting fucked up! getting sick of all the KIDDY BS.

GROW UP!

Oh look he typed something I don't like................ i gotta say start STUPID SHITnpw like a 2 yearold..........**** OFF

Just explain to the guy there is no voodoo involved and get on with it! GEEZ

why do i get the feeling you don't understand it either!

There is NO good reason to critisize my english ...why start bs ??? TWTF is wrong you people? This site is getting fucked up! getting sick of all the KIDDY BS.

GROW UP!

Oh look he typed something I don't like................ i gotta say start STUPID SHITnpw like a 2 yearold..........**** OFF

Last edited by HotSilverBird; 08-25-2010 at 11:34 AM.

#60

Hotsilverbird-Your fine man, you have been helpful.

Alright so I talked to Mahle once again today, and he said that the particular pistons I have (LS11050905s, which are actually for a 3.905 bore) are 4032 alloy. They require .003" of PTW clearance, and they will inspect them for free if I send them in. They also said they will throw in a new set of rings for free if my pistons are still use able. So with that being said, has anyone ever seen a stock LS1 block honed out to 3.912+"s???? If my pistons are for a 3.905" bore, and I can still fit at least a .010" feeler gauge in there, that means my cylinders are huge! Also I think I am going to give up trying to get the Machine shop who did this to pay for it because no matter what evidence I give them or tell them, they won't fix it unless they have the engine there to inspect.

Another question I had is how much of a difference will the torque plates make when measuring? Since this engine was supposedly torque plate honed, do I HAVE to have them bolted up to measure and get the proper cylinder size?

One more thing....what causes a main bearing with less than 5k miles to look like this??? Poor install I'm guessing.

Alright so I talked to Mahle once again today, and he said that the particular pistons I have (LS11050905s, which are actually for a 3.905 bore) are 4032 alloy. They require .003" of PTW clearance, and they will inspect them for free if I send them in. They also said they will throw in a new set of rings for free if my pistons are still use able. So with that being said, has anyone ever seen a stock LS1 block honed out to 3.912+"s???? If my pistons are for a 3.905" bore, and I can still fit at least a .010" feeler gauge in there, that means my cylinders are huge! Also I think I am going to give up trying to get the Machine shop who did this to pay for it because no matter what evidence I give them or tell them, they won't fix it unless they have the engine there to inspect.

Another question I had is how much of a difference will the torque plates make when measuring? Since this engine was supposedly torque plate honed, do I HAVE to have them bolted up to measure and get the proper cylinder size?

One more thing....what causes a main bearing with less than 5k miles to look like this??? Poor install I'm guessing.