What tools used to tap out head bolt threads??

#1

I just removed a stud and I'm having a difficult time placing it back in and I wanted to know if anyone made a long tap or a tap extension to clear the threads out?

Trending Topics

#8

TECH Addict

iTrader: (49)

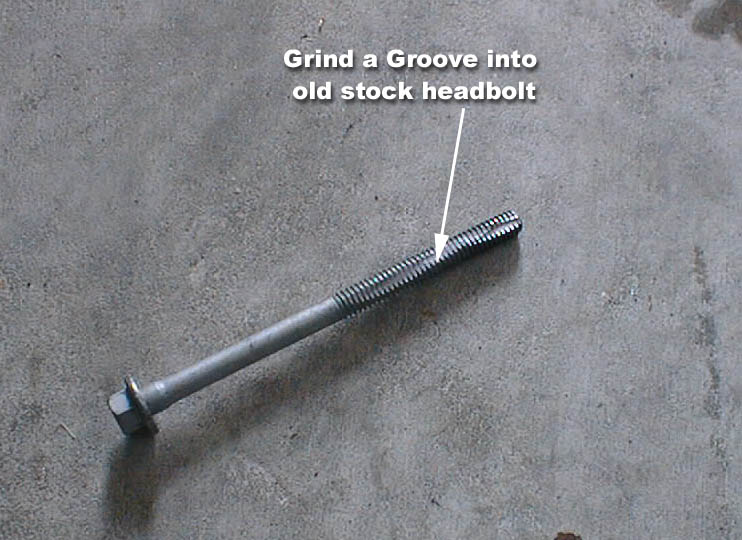

A lot of guys have done it this way, but I never have. Go to http://www.ls1howto.com/index.php?article=2 and scroll 1/2 way down, they talk about using the grinded down head bolt method.

#9

TECH Senior Member

iTrader: (4)

If he has any threads that may be partially damaged, I would not use this method, rather the ARP thread chased in post #2. This method could make things worse depending on the existing thread condition.

A lot of guys have done it this way, but I never have. Go to http://www.ls1howto.com/index.php?article=2 and scroll 1/2 way down, they talk about using the grinded down head bolt method.

#11

Ok...that seems easy enough. I just couldn't get the stud to seat as far down in the block as It needed to be. hopefully this method will help, unless some of the threads are damaged, then I might need a tap. If so, does anyone know where to find a tap that long?