Holley LS Valve covers

#1

Recently bought black crinkle Holley LS valve covers - 241-91. They get rid of the unsightly factory coil brackets. All went well -- except -- I have a high mount alternator and the covers supply a small bracket that moves the #1 coil rearward to clear the alternator. The bracket will relocate the coil so it clears the alternator - that's the good news. Bad news is that the coil won't fit on the supplied bracket -- significant interference between the back of the coil and the bracket.

Any of you using the Holley covers run into this? The engine is a new GM crate LS3 bought in Jan., 2016. Looks to me like the Holley bracket was designed for a different coil than the ones that come on the new crate motors. Few pics below.

Any of you using the Holley covers run into this? The engine is a new GM crate LS3 bought in Jan., 2016. Looks to me like the Holley bracket was designed for a different coil than the ones that come on the new crate motors. Few pics below.

#2

#4

Thanks for the replies guys.

jontall - yeah, the alternator-clearing bracket was clearly designed for a different type coil. The valve covers accept the LS3 coils perfectly though. To paraphrase Meatloaf - 7 out of 8 ain't bad....LOL.

JayTS - yup, it was clear pretty quickly to me that's one solution. Just a bit irritating that a common high-alt application (Corvettes with LS3) can't use the bracket as designed. Someone dropped the ball.

No matter -- I've reached out to Holley and Jeg's just for grins. But if they don't have an alternative bracket, I'll cut this one.

jontall - yeah, the alternator-clearing bracket was clearly designed for a different type coil. The valve covers accept the LS3 coils perfectly though. To paraphrase Meatloaf - 7 out of 8 ain't bad....LOL.

JayTS - yup, it was clear pretty quickly to me that's one solution. Just a bit irritating that a common high-alt application (Corvettes with LS3) can't use the bracket as designed. Someone dropped the ball.

No matter -- I've reached out to Holley and Jeg's just for grins. But if they don't have an alternative bracket, I'll cut this one.

#5

Yup, ran into the same issue. I'm running the Holley Acc drive brackets with the high mount alternator - I can get the coil/plug wire on the coil but it touches the rear of the alternator. I'm worried that it's a potential issue so I'll probably modify the bracket to move it slightly.

Trending Topics

#8

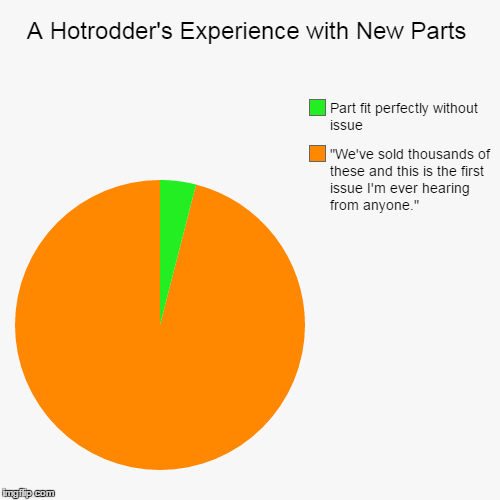

That is the quick and easy way to the solution. Looks like it was designed that way when all said and done. IMHO that is hot rodding. I don't know how many times I have had to modify a part over the years to get it to work.

#9

It's one of many small pieces that adds up to a sad state of affairs with many aftermarket suppliers.

Rant over.

#11

After test fit/the pics ya'll saw above - I painted them yesterday afternoon. And the washers.... And the tan epoxy part of the coils..... And removed the GM bar code stickers..... And soon the motor comes back out so I can tidy up wiring and repaint the engine bay.... And.....it never ends....

Last edited by Michael Yount; 05-24-2016 at 05:26 AM.

#12

TECH Fanatic

#16

Well - thinking about it will get you in trouble. I think I've got plenty of room for a low mount alternator. So I'm searching for a low mount alt bracket for the Corvette pulley/belt spacing - several available. And I believe, if my research is correct, that will work with the CTS-V LSA power steering bracket. I already have the short pump, and the LSA pump bracket uses the Corvette pulley spacing. Lower CG and polar moment, cleaner look under the hood - and I can mount the coil as designed. I'd contemplated the low mount before, but the Kwik bracket was easy, well designed and fit. But, perhaps not the best mouse trap for this application. We'll see. Worth it to get it the way I'd like the first time. And it won't be the first time I had to sell a brand new, perfectly good part because I decided to go another way.

Thanks for all the help guys.

Thanks for all the help guys.

Last edited by Michael Yount; 05-26-2016 at 06:19 AM.