ARP head bolt 90 after final torque?

#4

LSX Mechanic

iTrader: (89)

NO!!!!

I've seen a lot of people make this mistake and pull the threads right out of the block. One of the beauties of the ARP bolts is that they do not use the angle-Tq'ing procedures like stock bolts.

I go in a 35-55-85ft lb cycle, following the GM sequence. I also let the motor sit for about an hr after the TQ'ing is finished, and hit the bolts one more time @ 85 ft lbs. Some find this unecessary, but I've had bolts budge another 1/8 turn for final TQ according to my calibrated Matco wrench.

I've seen a lot of people make this mistake and pull the threads right out of the block. One of the beauties of the ARP bolts is that they do not use the angle-Tq'ing procedures like stock bolts.

I go in a 35-55-85ft lb cycle, following the GM sequence. I also let the motor sit for about an hr after the TQ'ing is finished, and hit the bolts one more time @ 85 ft lbs. Some find this unecessary, but I've had bolts budge another 1/8 turn for final TQ according to my calibrated Matco wrench.

#6

11 Second Club

iTrader: (6)

Join Date: Feb 2005

Location: middle of nowhere, Kansas

Posts: 1,309

Likes: 0

Received 2 Likes

on

2 Posts

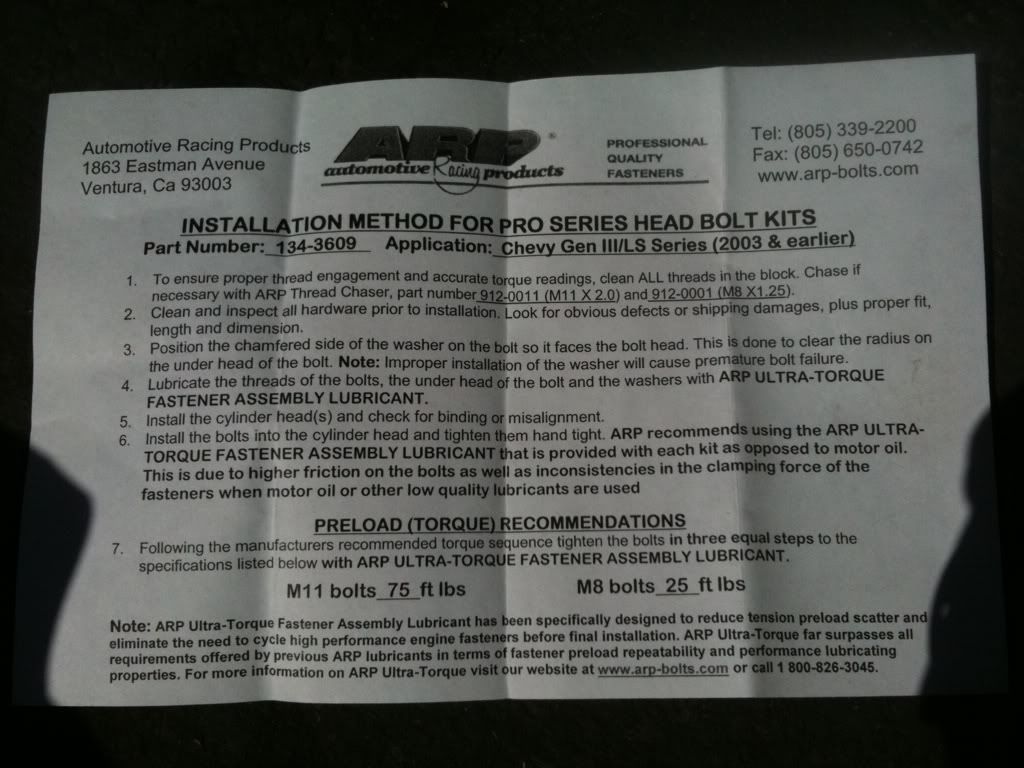

If you use the official ARP assembly lube, torque all 15mm bolts to 30 ft/ibs in the correct torque sequence. Do a second pass at 50 ft/lbs and a third pass at 75 ft/lbs. Install the 5 smaller ARP bolts and torque them to 22 ft/lbs.

If you use engine oil to lube the bolts, I've heard of people using 35/65/85 lb/ft.

If you use engine oil to lube the bolts, I've heard of people using 35/65/85 lb/ft.

#7

TECH Senior Member

iTrader: (39)

If you use the official ARP assembly lube, torque all 15mm bolts to 30 ft/ibs in the correct torque sequence. Do a second pass at 50 ft/lbs and a third pass at 75 ft/lbs. Install the 5 smaller ARP bolts and torque them to 22 ft/lbs.

If you use engine oil to lube the bolts, I've heard of people using 35/65/85 lb/ft.

If you use engine oil to lube the bolts, I've heard of people using 35/65/85 lb/ft.

this is what my instructions said to do.

To the OP, I can't believe you still have threads in your block.

Trending Topics

#8

10 Second Club

Thread Starter

iTrader: (17)

Join Date: Aug 2005

Posts: 620

Likes: 0

Received 0 Likes

on

0 Posts

I did not turn the 90 after final torque. I was in the process of going through the torque sequence 5 times as the ARP web site said and I posted the question during. It is all together and ready to put back in the car. Thanks for the help.

#11

TECH Regular

iTrader: (18)

Join Date: Feb 2005

Location: brunswick, ohio

Posts: 440

Likes: 0

Received 0 Likes

on

0 Posts

http://video.arp-bolts.com/catalog/ARPCatalog.pdf

arp website page 24, 11mm torque to 72/82/92 with molly lube!!!

arp website page 24, 11mm torque to 72/82/92 with molly lube!!!

#12

TECH Junkie

iTrader: (11)

http://video.arp-bolts.com/catalog/ARPCatalog.pdf

arp website page 24, 11mm torque to 72/82/92 with molly lube!!!

arp website page 24, 11mm torque to 72/82/92 with molly lube!!!

- 170,000# fastener = 72 ft-lbs

- 190,000# fastener = 82 ft-lbs

- 220,000# fastener = 92 ft-lbs

#14

TECH Regular

iTrader: (18)

Join Date: Feb 2005

Location: brunswick, ohio

Posts: 440

Likes: 0

Received 0 Likes

on

0 Posts

OK, on pg. 20 the 8740 chrome moly(head stud material), is at yeild strength of 180,000psi, tensile strength 220,000psi. puts you at the top torque table. I will call ARP.

Last edited by sparkwirez06; 08-04-2010 at 08:08 AM.

#16

TECH Regular

iTrader: (18)

Join Date: Feb 2005

Location: brunswick, ohio

Posts: 440

Likes: 0

Received 0 Likes

on

0 Posts

I called ARP told not to use the web chart, final torque on 11mm stud is 80ft.lb.and the 8mm is 25ft.lb. Also FYI, if you order replacement nuts, the 11 mm are 7/16ths-20 nuts, and the 8mm are 5/16-24 nuts.

Last edited by sparkwirez06; 08-04-2010 at 11:27 AM.