Why are my bearings tore up?

#1

So a little history on the backround on the motor. It was built in 2007 has Scat rods, and Diamond Pistons, set up for boost and a stock crank, in 2011 oil pressure dropped (it made it to about 22K miles seeing DD duty and about 100 passes at the track at 580 rwhp) so I pulled it and found it had wiped the main bearings I chalked it up as normal wear and tear for a high horsepower engine, had the crank turned +10 to clean it up and put it back together early this year. Since then it has made about 40 1/8th mile passes and had about 2K miles put on it.

I used clevitte H series bearings and checked clearances on the mains and all were .0020-.0023 using plastiguage, rods were about the same. Don't remember the exact numbers but they were between .0020-.0025.

Crank shaft end play was .0060

I broke it in easy for the first 500 miles, never beat on it. changed the oil. I run VR-1 racing 20-50. Ive changed the oil at least 6 times this year with no issues. I also run a AN 10 oil cooler using a lingenfelter oil block.

Last month I took it to the local 1/8th for some TNT to try out the new S480, got it to run a 6.25 @ 110 on 10psi first pass but on the return road I noticed the oil pressure had dropped about 15 psi from the normal and was like 35 psi at 2K rpm, and the top end was making some noise. So I parked it and let it cool checked the oil, dip stick had it about 1/8" from the max fill then fired it up, Oil pressure was still down. So I put it up on the trailer and took it home. Dropped the oil the next day and cut the filter open and found babbit in the filter. I have since pulled it and this is what I have found.

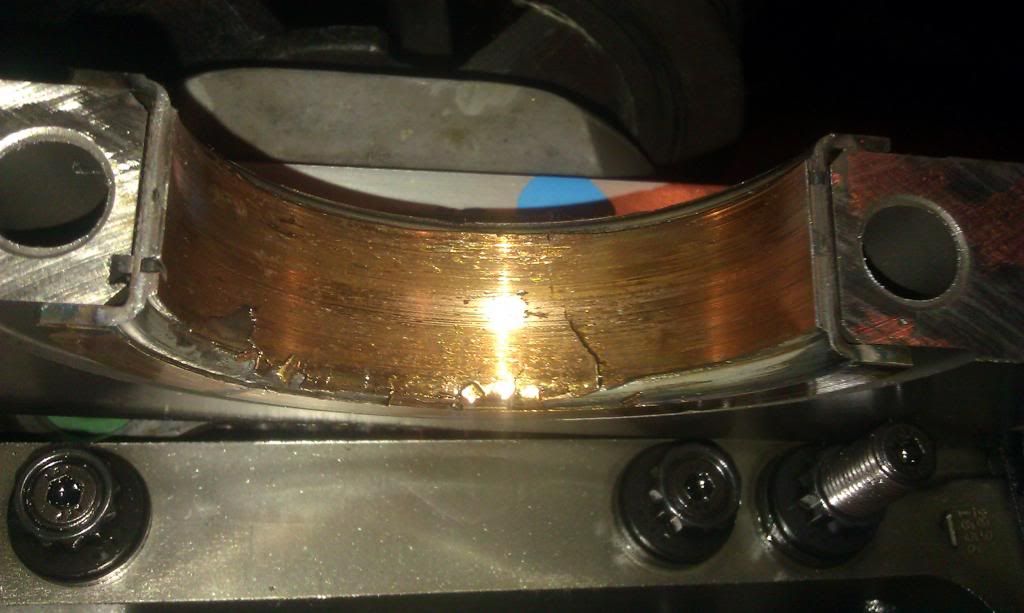

Main/Thrust bearing

[IMG] [/IMG]

[/IMG]

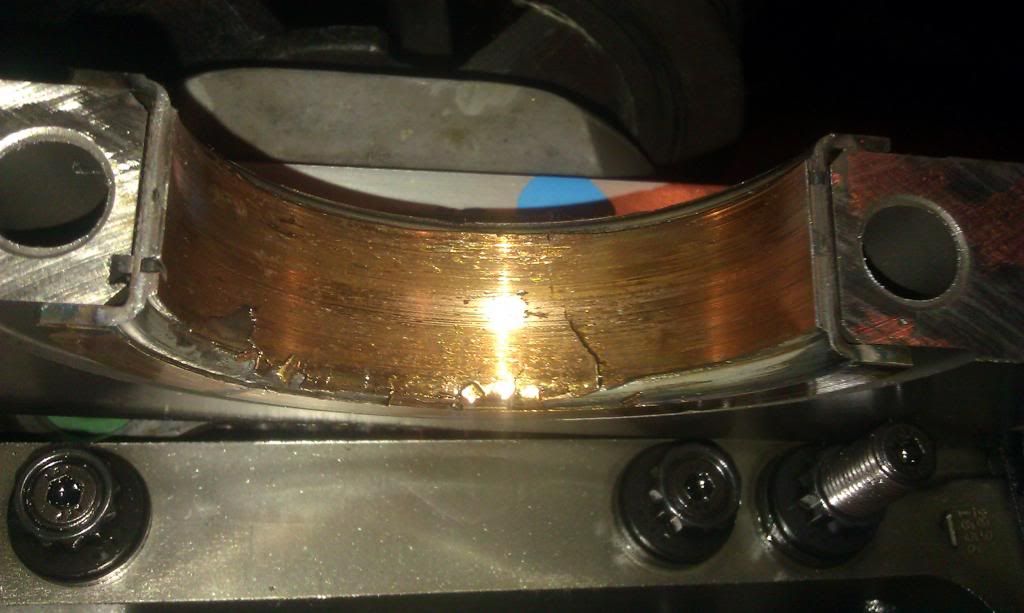

Main Journal

[IMG] [/IMG]

[/IMG]

Rod bearing looks like some babitt ran through here

Rod journal looks fine polish looks great

Not a expert but I was thinking it must have been a foreign contamination issue but this looks like oil starvation to me. What do you guys think, need some LS savy builders to give me some pointers. Pump oil ring is in perfect shape no pinches or rips. Pump is a ported LS6. Rods journals look and feel perfect but the main journals will need at least a polish if not turned again.

Sorry about the length of the post just really am confused as to why this has happened. I plan on replacing the pump this go around also had someone tell me the plunger could have caused this since it is from the original 5.7 that was in the car and not the new style.

Also if one of you sponsors wants to have a crack at the short block shoot me a PM, on what you can do to check it out and put it back together right as I am questioning my capabilities with these LS's motors, and on a budget. The motor was not knocking and does not have a spun bearing.

This damage is almost identical to what I saw in January, only there is more babbit on the bearings this time as I didn't kid myself and try and trouble shoot the gauge so something is wrong with it only I don't know what, and I hate throwing parts at it if I am not sure its the problem.

I used clevitte H series bearings and checked clearances on the mains and all were .0020-.0023 using plastiguage, rods were about the same. Don't remember the exact numbers but they were between .0020-.0025.

Crank shaft end play was .0060

I broke it in easy for the first 500 miles, never beat on it. changed the oil. I run VR-1 racing 20-50. Ive changed the oil at least 6 times this year with no issues. I also run a AN 10 oil cooler using a lingenfelter oil block.

Last month I took it to the local 1/8th for some TNT to try out the new S480, got it to run a 6.25 @ 110 on 10psi first pass but on the return road I noticed the oil pressure had dropped about 15 psi from the normal and was like 35 psi at 2K rpm, and the top end was making some noise. So I parked it and let it cool checked the oil, dip stick had it about 1/8" from the max fill then fired it up, Oil pressure was still down. So I put it up on the trailer and took it home. Dropped the oil the next day and cut the filter open and found babbit in the filter. I have since pulled it and this is what I have found.

Main/Thrust bearing

[IMG]

[/IMG]

[/IMG]Main Journal

[IMG]

[/IMG]

[/IMG]Rod bearing looks like some babitt ran through here

Rod journal looks fine polish looks great

Not a expert but I was thinking it must have been a foreign contamination issue but this looks like oil starvation to me. What do you guys think, need some LS savy builders to give me some pointers. Pump oil ring is in perfect shape no pinches or rips. Pump is a ported LS6. Rods journals look and feel perfect but the main journals will need at least a polish if not turned again.

Sorry about the length of the post just really am confused as to why this has happened. I plan on replacing the pump this go around also had someone tell me the plunger could have caused this since it is from the original 5.7 that was in the car and not the new style.

Also if one of you sponsors wants to have a crack at the short block shoot me a PM, on what you can do to check it out and put it back together right as I am questioning my capabilities with these LS's motors, and on a budget. The motor was not knocking and does not have a spun bearing.

This damage is almost identical to what I saw in January, only there is more babbit on the bearings this time as I didn't kid myself and try and trouble shoot the gauge so something is wrong with it only I don't know what, and I hate throwing parts at it if I am not sure its the problem.

Last edited by Preston99WS6; 11-16-2012 at 08:10 PM. Reason: added more info

#2

I know there is only .0005-.0008 babbit material on the clevite H bearings. Depending on whether it is an aluminum or iron block would depend on what gap works best accounting for block expansion. Other things to consider is whether you're road racing it which could cause oil starvation.

Also i have never been a fan of plastigauge. You have to account for the error of your measurement tool based on its calibration. So if the error is .0005+/- and you measure .0025, then you have .0020-.0030 tolerance realistically with normal measurement methods. For safety reasons you gauge based on the lower tolerance. However what you really meant to do was get the difference of the measurements. A dial bore gauge and a micrometer is what i recommend. You measure the crank journal with the micrometer, zero the dial bore gauge to the micrometer and then measure the installed bearing with the dial bore gauge. This will allow you to get the difference which is what you were originally after.

I would also check to make sure the block and caps were line bore honed originally which assures proper mains centricity.

Also i have never been a fan of plastigauge. You have to account for the error of your measurement tool based on its calibration. So if the error is .0005+/- and you measure .0025, then you have .0020-.0030 tolerance realistically with normal measurement methods. For safety reasons you gauge based on the lower tolerance. However what you really meant to do was get the difference of the measurements. A dial bore gauge and a micrometer is what i recommend. You measure the crank journal with the micrometer, zero the dial bore gauge to the micrometer and then measure the installed bearing with the dial bore gauge. This will allow you to get the difference which is what you were originally after.

I would also check to make sure the block and caps were line bore honed originally which assures proper mains centricity.

#3

I know there is only .0005-.0008 babbit material on the clevite H bearings. Depending on whether it is an aluminum or iron block would depend on what gap works best accounting for block expansion. Other things to consider is whether you're road racing it which could cause oil starvation.

Also i have never been a fan of plastigauge. You have to account for the error of your measurement tool based on its calibration. So if the error is .0005+/- and you measure .0025, then you have .0020-.0030 tolerance realistically with normal measurement methods. For safety reasons you gauge based on the lower tolerance. However what you really meant to do was get the difference of the measurements. A dial bore gauge and a micrometer is what i recommend. You measure the crank journal with the micrometer, zero the dial bore gauge to the micrometer and then measure the installed bearing with the dial bore gauge. This will allow you to get the difference which is what you were originally after.

I would also check to make sure the block and caps were line bore honed originally which assures proper mains centricity.

Also i have never been a fan of plastigauge. You have to account for the error of your measurement tool based on its calibration. So if the error is .0005+/- and you measure .0025, then you have .0020-.0030 tolerance realistically with normal measurement methods. For safety reasons you gauge based on the lower tolerance. However what you really meant to do was get the difference of the measurements. A dial bore gauge and a micrometer is what i recommend. You measure the crank journal with the micrometer, zero the dial bore gauge to the micrometer and then measure the installed bearing with the dial bore gauge. This will allow you to get the difference which is what you were originally after.

I would also check to make sure the block and caps were line bore honed originally which assures proper mains centricity.

#5

Cannot remember the exact tolerance differences of plastigauge but they are worse - they can be used beside the tools to check against your work but i would not depend on it myself - this is all in opinion though.

Are you accounting for block expansion? Did you wipe the bearings with a lint free cloth and acetone before installation? I know the clevite H's are pure tin and do not have the coating that the other P series/passenger series have which exists simply to help extend shelf life.

If the machine work is spot on and the bearing clearances are correct then i cannot think of anything else.

Are you accounting for block expansion? Did you wipe the bearings with a lint free cloth and acetone before installation? I know the clevite H's are pure tin and do not have the coating that the other P series/passenger series have which exists simply to help extend shelf life.

If the machine work is spot on and the bearing clearances are correct then i cannot think of anything else.

#6

Last i understood was that the H series could be ordered with different widths and have one side that is shorter to account for aftermarket crank fillets. The thinner bearing is less friction/drag than the passenger series.

#7

Cannot remember the exact tolerance differences of plastigauge but they are worse - they can be used beside the tools to check against your work but i would not depend on it myself - this is all in opinion though.

Are you accounting for block expansion? Did you wipe the bearings with a lint free cloth and acetone before installation? I know the clevite H's are pure tin and do not have the coating that the other P series/passenger series have which exists simply to help extend shelf life.

If the machine work is spot on and the bearing clearances are correct then i cannot think of anything else.

Are you accounting for block expansion? Did you wipe the bearings with a lint free cloth and acetone before installation? I know the clevite H's are pure tin and do not have the coating that the other P series/passenger series have which exists simply to help extend shelf life.

If the machine work is spot on and the bearing clearances are correct then i cannot think of anything else.

I know that plastigauge is no where near as good as micing, but I have never had a problem with it in the past, built a couple poncho motors, a olds rocket, and a few Gen 1 small blocks (that were used for circle track racing) with it and never had a problem. This was my first and only attempt at freshening a LS up to date.

Trending Topics

#8

TECH Senior Member

iTrader: (39)

You said your thrust bearing was wiped out. Do you think your converter is ballooning under boost pushing the crank forward?

Also in the first pic that bearing looks like its been hammered. What I mean is I have seen it on rod bearings on cylinders that had detonation that pounded the bearing but haven't seen it on a main.

Hopefully some people way smarter than me will post in here so you can get this figured out.

Also in the first pic that bearing looks like its been hammered. What I mean is I have seen it on rod bearings on cylinders that had detonation that pounded the bearing but haven't seen it on a main.

Hopefully some people way smarter than me will post in here so you can get this figured out.

#9

You said your thrust bearing was wiped out. Do you think your converter is ballooning under boost pushing the crank forward?

Also in the first pic that bearing looks like its been hammered. What I mean is I have seen it on rod bearings on cylinders that had detonation that pounded the bearing but haven't seen it on a main.

Hopefully some people way smarter than me will post in here so you can get this figured out.

Also in the first pic that bearing looks like its been hammered. What I mean is I have seen it on rod bearings on cylinders that had detonation that pounded the bearing but haven't seen it on a main.

Hopefully some people way smarter than me will post in here so you can get this figured out.

The thrust/Main is once piece here but there is copper showing in the thrust part of it, as far as the babbit goes looks like it got hot, melted and started running out of the journal to me.

#10

Could be, but every pass has been data logged at the track and it saw some rich knock several months ago. It was only on 12 degrees of timing at 10 psi 93 and meth 11.3 AFR no knock the last night at the track when it developed this issue seen a lot of street driving in between.

The thrust/Main is once piece here but there is copper showing in the thrust part of it, as far as the babbit goes looks like it got hot, melted and started running out of the journal to me.

The thrust/Main is once piece here but there is copper showing in the thrust part of it, as far as the babbit goes looks like it got hot, melted and started running out of the journal to me.

Usually converter expansion happens due to increased line pressures.

#11

TECH Addict

iTrader: (83)

You had a oiling issue.

Here is what I did with mine and it has worked great.

mains are .002

rods .0024

ls 30 gibbs oil

Get rid of the stock pan it has issues on launch. Oil pump needs some attention also.

I run a Schumanns pump from Tim at the Car Shop Inc.

Another thing to look at is the main bore dimension in the block. I like that as small as possible so the bearing has the proper crush when engine gets up to temp. Then grind the crank to fit.

If the block has been honed then it is prob a little big and when the engine is up to temp the bore gets even bigger you loose bearing crush and clearance. The crush is what holds the bearing in place not the tabs.

The 20-50 is not needed if the pump and clearances are in check.

Another thing is waiting till the oil is up to temp before loading the engine hard. I wait till I see at least 170 even if I have to let the engine run in the lanes to do this.

Tim

Here is what I did with mine and it has worked great.

mains are .002

rods .0024

ls 30 gibbs oil

Get rid of the stock pan it has issues on launch. Oil pump needs some attention also.

I run a Schumanns pump from Tim at the Car Shop Inc.

Another thing to look at is the main bore dimension in the block. I like that as small as possible so the bearing has the proper crush when engine gets up to temp. Then grind the crank to fit.

If the block has been honed then it is prob a little big and when the engine is up to temp the bore gets even bigger you loose bearing crush and clearance. The crush is what holds the bearing in place not the tabs.

The 20-50 is not needed if the pump and clearances are in check.

Another thing is waiting till the oil is up to temp before loading the engine hard. I wait till I see at least 170 even if I have to let the engine run in the lanes to do this.

Tim

#12

Just for grins try bolting all the main caps on and check the bore alignment. Maybe you have a core shift etc. That bearing was overloaded obviously but you don't mention any damage to the rod bearings. I would think an oiling problem would show up with rod bearing failure too.

#13

TECH Junkie

iTrader: (11)

You had a oiling issue.

Here is what I did with mine and it has worked great.

mains are .002

rods .0024

ls 30 gibbs oil

Get rid of the stock pan it has issues on launch. Oil pump needs some attention also.

I run a Schumanns pump from Tim at the Car Shop Inc.

Another thing to look at is the main bore dimension in the block. I like that as small as possible so the bearing has the proper crush when engine gets up to temp. Then grind the crank to fit.

If the block has been honed then it is prob a little big and when the engine is up to temp the bore gets even bigger you loose bearing crush and clearance. The crush is what holds the bearing in place not the tabs.

The 20-50 is not needed if the pump and clearances are in check.

Another thing is waiting till the oil is up to temp before loading the engine hard. I wait till I see at least 170 even if I have to let the engine run in the lanes to do this.

Tim

Here is what I did with mine and it has worked great.

mains are .002

rods .0024

ls 30 gibbs oil

Get rid of the stock pan it has issues on launch. Oil pump needs some attention also.

I run a Schumanns pump from Tim at the Car Shop Inc.

Another thing to look at is the main bore dimension in the block. I like that as small as possible so the bearing has the proper crush when engine gets up to temp. Then grind the crank to fit.

If the block has been honed then it is prob a little big and when the engine is up to temp the bore gets even bigger you loose bearing crush and clearance. The crush is what holds the bearing in place not the tabs.

The 20-50 is not needed if the pump and clearances are in check.

Another thing is waiting till the oil is up to temp before loading the engine hard. I wait till I see at least 170 even if I have to let the engine run in the lanes to do this.

Tim

#14

ModSquad

iTrader: (6)

While its apart, have a shop check the crank for proper balance. If it wasn't balanced, it will chew up bearings like this.

The following users liked this post:

Homer_Simpson (01-28-2022)

#16

If the main housing bore is in tolerance, and the bearing clearance was really at the number you said, there should be no reason to see that kind of main damage without any damage to the rod bearings as well. IMO your main clearance number is not being measured properly, I think you need to take the bottom end into a competent shop to be fully measured out and assembled with bearing clearances checked with mics and bore gauges.

What do the cam bearings look like?

What do the cam bearings look like?