Project: Street Smallblock

#41

Oh so now its just the "SMALL TIME engine rebuilders.". With your vague instructions the OP wont be able to find any shop for even machine work let alone a short block rebuild. The truth is regardless of which shop it is u gonna get what the shop wants to do and what it can do which is not always what the owner wants. I have to wonder how many owners are charged for torque plate boring and honing and theres not a torque plate in the shop. And how many main saddles are align bored and honed just because the shop has the equipment even though the stock crank is reused and turns freely as is.

Your back and forth in every post. One line u state "There's also a much smaller margin for error when it comes to performance motor" then the next to suggest used 80k mi B-body engines with and AI top end. Well which is it. Stock B-body blocks never torque plate honed and using stock rod bolts or "the monty"???

Im saying if the OP wants a reliable DD and is on the learning curve then rebuilding the short block with good used and reconditioned parts will get him there. Finding a 80k mi engine after sitting in the boneyard for a couple of years he wont know how the engine got there or why its there or whats been poured inside it. Asking for another loser if u cant hear it run or look inside. Even if the boneyard has guaranteed useable the time to take it home and inspect and then have to return it is a lot more effort down the drain.

U want me to stop the name calling but u were first to start the trashing with "a lot of morons out there". Again which is it?

Your back and forth in every post. One line u state "There's also a much smaller margin for error when it comes to performance motor" then the next to suggest used 80k mi B-body engines with and AI top end. Well which is it. Stock B-body blocks never torque plate honed and using stock rod bolts or "the monty"???

Im saying if the OP wants a reliable DD and is on the learning curve then rebuilding the short block with good used and reconditioned parts will get him there. Finding a 80k mi engine after sitting in the boneyard for a couple of years he wont know how the engine got there or why its there or whats been poured inside it. Asking for another loser if u cant hear it run or look inside. Even if the boneyard has guaranteed useable the time to take it home and inspect and then have to return it is a lot more effort down the drain.

U want me to stop the name calling but u were first to start the trashing with "a lot of morons out there". Again which is it?

#42

11 Second Club

iTrader: (1)

Those of us with EXPERIENCE have had good luck with "junkyard" engines. GM is really good at building engines, they build millions and millions and millions of them.

In many cases while a junkyard engine might be a gamble it is a safer gamble than many local shops.

A friend gave me a bunch of grief for getting topend work done 800miles away when "there are good shops right here" after using what he thought were great shops and paying extra for plateau hone and such I don't think he was happy with the performance, so the following winter he tore it down. He had clayed the corners and the PTV was fine there but some of the inner cylinders had valves that varied I think .030 in valvejob depth, he finally had a real professional 800miles away go through the engine and the hone was a hack job too.

The other popular "RACE" engine builder sold a friend a stockish rebuild with an $80 set of pistons, hasn't been fired yet but it is harder to rotate without plugs than my engine is with plugs and 245psi cranking compression, sold him non-SA rockers to go with the iron b-boy heads with pressed studs that he had rebuilt and had ripped my friend off putting aftermarket stock sized stainless valves in which was a complete waste of money.

Another shop my friends tried to use 3 hours away trying to find someone decent uses a hammer to remove pressed pin pistons that are going to be reused.

"Gambling" on a used GM piece is less gamble than most local shops. Many shops have good reputations only because their customers don't know any better.

In many cases while a junkyard engine might be a gamble it is a safer gamble than many local shops.

A friend gave me a bunch of grief for getting topend work done 800miles away when "there are good shops right here" after using what he thought were great shops and paying extra for plateau hone and such I don't think he was happy with the performance, so the following winter he tore it down. He had clayed the corners and the PTV was fine there but some of the inner cylinders had valves that varied I think .030 in valvejob depth, he finally had a real professional 800miles away go through the engine and the hone was a hack job too.

The other popular "RACE" engine builder sold a friend a stockish rebuild with an $80 set of pistons, hasn't been fired yet but it is harder to rotate without plugs than my engine is with plugs and 245psi cranking compression, sold him non-SA rockers to go with the iron b-boy heads with pressed studs that he had rebuilt and had ripped my friend off putting aftermarket stock sized stainless valves in which was a complete waste of money.

Another shop my friends tried to use 3 hours away trying to find someone decent uses a hammer to remove pressed pin pistons that are going to be reused.

"Gambling" on a used GM piece is less gamble than most local shops. Many shops have good reputations only because their customers don't know any better.

#43

"Us", "A friend", "my friends", of course the obscure witness population returns.

So there are no reliable machine shops except the ones u use and are 800 miles away? Dealing with u i can understand why as they would rather drill a hole in the side of your block then deal with your distorted ideas.

When i look in the staging lanes at all the 10sec and faster cars with their supporting local machine painted on the side tells me there are shops that can do good work. So maybe all your friends are mostly goof ***** that cant find a good machine shop to do their block work. Who knows what your and your friends problems are?

Gambling on a bone yard engine that may not only be trashed inside but sat without lubricant maybe not even coolant but instead just water through freezing weather? Sounds desperate to me - and that makes more sense.

So there are no reliable machine shops except the ones u use and are 800 miles away? Dealing with u i can understand why as they would rather drill a hole in the side of your block then deal with your distorted ideas.

When i look in the staging lanes at all the 10sec and faster cars with their supporting local machine painted on the side tells me there are shops that can do good work. So maybe all your friends are mostly goof ***** that cant find a good machine shop to do their block work. Who knows what your and your friends problems are?

Gambling on a bone yard engine that may not only be trashed inside but sat without lubricant maybe not even coolant but instead just water through freezing weather? Sounds desperate to me - and that makes more sense.

#44

11 Second Club

iTrader: (1)

I tend to have less cash than my friends and get by on my junkyard crap just fine.

Dedicated race engines don't have to hold up to the kind of use a street/strip car sees. Someone stuborn who drives their race car on the street might put on 1000miles a season, a lot of guys put that on a month in their street/strip car.

I also think some of the problem lay in "race" shops not giving proper respect to street stuff and halfassing it.

Dedicated race engines don't have to hold up to the kind of use a street/strip car sees. Someone stuborn who drives their race car on the street might put on 1000miles a season, a lot of guys put that on a month in their street/strip car.

I also think some of the problem lay in "race" shops not giving proper respect to street stuff and halfassing it.

#45

TECH Fanatic

iTrader: (6)

I'm the one who's back and forth in every post??? Seriously? On one hand you're telling me this build is a low horsepower DD motor and on the other you're suggesting the use of a forged crank that's only really necessary if you plan on doing some serious ****.

The point of view I'm trying to explain isn't that hard to understand. The stock GM shortblocks are of good quality and will take more abuse than what the OP is willing to throw at it for the time being. Opening up a motor is a can of worms and if you're going to do so then it would be a complete waste of time to not go all the way. You're paying a gigantic premium for something that'll be marginally better than a stock motor and have almost all of the same drawbacks when the power and RPM go up from there. Maybe a fresh 355 is great today, but what about tomorrow or the next day? When you get the itch for more power (which happens 99% of the time) it will have to be torn down again which is more money down the drain. If you're going to open up your wallet then you better do things right the first time or you'll be sorry. Saving money on machine work is plain stupid if your motor is that much of an investment.

This is all assuming that the shop you choose is competent and will devote the amount of attention to your seemingly small time build it really needs to not blow apart during it's life on the street.

And I'm not the one who started pointing fingers in this thread first. So you're calling me a hypocrite because you can't read? You fired first, don't put words in my mouth. I was referencing some observations I've made when dealing with a few local shops. I think back to the one that's advertised as being my area's "premiere" race shop that builds circle track motors. Definitely not impressed with their lower horsepower builds that are floating around in my area and on top of that the place looks like it's run out of a shed. I've seen them leave customer's motors outside to get rained on.

The point of view I'm trying to explain isn't that hard to understand. The stock GM shortblocks are of good quality and will take more abuse than what the OP is willing to throw at it for the time being. Opening up a motor is a can of worms and if you're going to do so then it would be a complete waste of time to not go all the way. You're paying a gigantic premium for something that'll be marginally better than a stock motor and have almost all of the same drawbacks when the power and RPM go up from there. Maybe a fresh 355 is great today, but what about tomorrow or the next day? When you get the itch for more power (which happens 99% of the time) it will have to be torn down again which is more money down the drain. If you're going to open up your wallet then you better do things right the first time or you'll be sorry. Saving money on machine work is plain stupid if your motor is that much of an investment.

This is all assuming that the shop you choose is competent and will devote the amount of attention to your seemingly small time build it really needs to not blow apart during it's life on the street.

And I'm not the one who started pointing fingers in this thread first. So you're calling me a hypocrite because you can't read? You fired first, don't put words in my mouth. I was referencing some observations I've made when dealing with a few local shops. I think back to the one that's advertised as being my area's "premiere" race shop that builds circle track motors. Definitely not impressed with their lower horsepower builds that are floating around in my area and on top of that the place looks like it's run out of a shed. I've seen them leave customer's motors outside to get rained on.

#46

What a croc. All those boneyard engines sitting there for years is gonna be a "good quality" safe buy??

And because your area has trash machine shops they're all gonna be so bad the OP should only what?? U dont say what to look for good shops. Or what do the good shops look like if u know? Bogus "premiere shops" everywhere? Get real.

I will say auto machine work is not a lucrative business and better trained machinists are working in aerospace, petrochemical, electrical power generation or the railroad where they pay much better for their skills. U'll find many auto machinists have no formal machinist training and learned their trade from becoming a machine/equipment operator one machine at a time. Again most machine shops will do what they can do and want to do not necessarily what the owner wants.

But they do machine and rebuild engines everyday of the week and most will warranty their work. As with any machine work for performance or even just for reliable overhauls its up to the owner to source out the level of machine work he needs. And if there were no competent shops then no one would be driving bored, stroked and blueprinted engines. U keep scaring the OP like he cant find a good shop and a junkyard boat anchor is his best option. I will say thats possible but not probable.

U still dont get the idea of a used forged crank if hes looking for a used crank. U keep denying it could be a good buy and replacement. Guess thats your problem.

And because your area has trash machine shops they're all gonna be so bad the OP should only what?? U dont say what to look for good shops. Or what do the good shops look like if u know? Bogus "premiere shops" everywhere? Get real.

I will say auto machine work is not a lucrative business and better trained machinists are working in aerospace, petrochemical, electrical power generation or the railroad where they pay much better for their skills. U'll find many auto machinists have no formal machinist training and learned their trade from becoming a machine/equipment operator one machine at a time. Again most machine shops will do what they can do and want to do not necessarily what the owner wants.

But they do machine and rebuild engines everyday of the week and most will warranty their work. As with any machine work for performance or even just for reliable overhauls its up to the owner to source out the level of machine work he needs. And if there were no competent shops then no one would be driving bored, stroked and blueprinted engines. U keep scaring the OP like he cant find a good shop and a junkyard boat anchor is his best option. I will say thats possible but not probable.

U still dont get the idea of a used forged crank if hes looking for a used crank. U keep denying it could be a good buy and replacement. Guess thats your problem.

#47

TECH Fanatic

iTrader: (6)

Yeah, the GM factory shortblocks are pretty damn good for what they are and will definitely get the job done for a fraction of the price. The worst thing that could possibly happen would be that the junker motor is a dud so you part it out and turn a profit in the process, big whoop. Beats spending hundreds/thousands of dollars having a motor built by a questionable shop only to make the same amount of reliable power.

And I never said anything detrimental about the quality of the forged crank. I said it was a WASTE OF TIME and MONEY. More money down the drain having it checked/ground on top of building the motor itself. And for what? Great, now you have a forged crank that will last just as long as a stock cast unit under the RPM and power capabilities of your 2-bolt block.

I'm actually using a 532 forged crank in my build but I'm building a 4-bolt 355 with the intention of boosting it well beyond the level of power OP is looking for.

And I never said anything detrimental about the quality of the forged crank. I said it was a WASTE OF TIME and MONEY. More money down the drain having it checked/ground on top of building the motor itself. And for what? Great, now you have a forged crank that will last just as long as a stock cast unit under the RPM and power capabilities of your 2-bolt block.

I'm actually using a 532 forged crank in my build but I'm building a 4-bolt 355 with the intention of boosting it well beyond the level of power OP is looking for.

#48

Haven't updated in a while. Got a stock '95 block from a buddy for a good price. (Cheaper than paying a machine shop to fix the bad lifter bore) and it came with a crank and oil pan. I've pulled the crank and oil pan (The main bolts had the studs for a windage tray, my buddy is checking to see if he still has the windage tray. If not, I'll buy one)

Gonna try to drop the block off at my machine shop later this week. Plans are as follows:

Once that is done, I plan on having my builder inspect the stock bottom end in the 80k mile motor with the bad valvetrain. If he thinks it is usable I will probably have him install new piston rings and balance the crank and assemble the shortblock.

All of that should be done for $350-500. Once that is complete I will start planning out my top end. Like I stated before, looking at ~360rwhp cam only for now, but when/if I port out the heads in the future I should be over 400. Looking at Ai 226/234 or maybe 230/238 for the top end.

Gonna try to drop the block off at my machine shop later this week. Plans are as follows:

- Magnaflux/Hone block

- Hot Tank

- Cam/Crank Bearings

- Brass Freeze Plugs

Once that is done, I plan on having my builder inspect the stock bottom end in the 80k mile motor with the bad valvetrain. If he thinks it is usable I will probably have him install new piston rings and balance the crank and assemble the shortblock.

All of that should be done for $350-500. Once that is complete I will start planning out my top end. Like I stated before, looking at ~360rwhp cam only for now, but when/if I port out the heads in the future I should be over 400. Looking at Ai 226/234 or maybe 230/238 for the top end.

#49

12 Second Club

iTrader: (3)

You MUST spin your cam PAST the peak, WAYYY past the peak, for it to be worth it. If you refuse to go over 6200rpm, get a smaller cam, I promise it will be faster than short shifting a big cam. With ARP rod bolts you will be fine to 7000rpm. That 226/232 cam will love shifting at 7000, the other one is too big for stock heads IMO.

#50

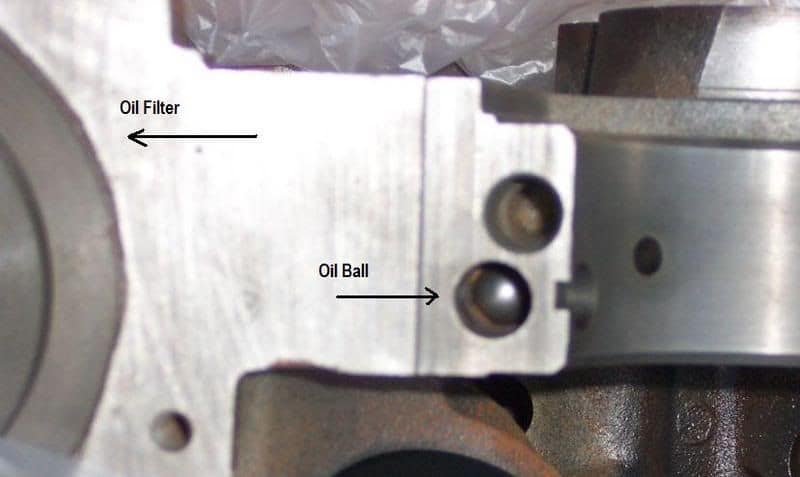

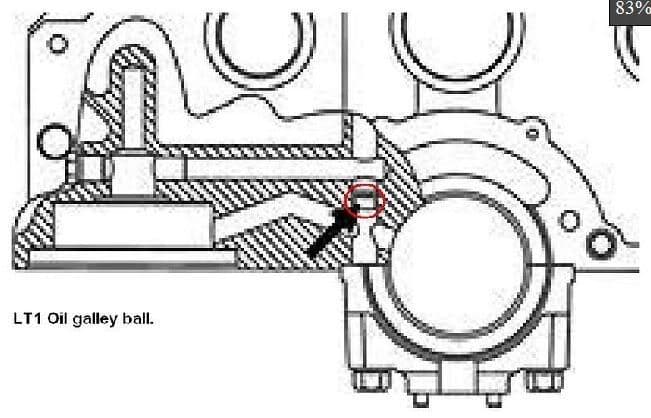

Before u tank the block remove all the plugs and the GEN II block has ball in one of the galleys that needs to come out before tanking also - most engine shops dont know this of the GEN II block. Then after machine work and cleaning that ball has to go back in - dont forget.

So phase I of the new build is complete. I got the block back from the engine builder where I had him:

- Magnaflux

- Hottank

- Hone cylinders

- Install cam bearings

- Install crank bearings

Phase II will be to finish up the shortblock which brings me to this important question. What are your guys thoughts of using the bottom end out of my spare "80k mile crate motor" where the rods appear to be miss-marked for the cylinders they are in? What should be my approach here? Again I'm trying to do this cheap but I don't want to cut any corners. Should I look at having the bottom end balanced? I assume at bare minimum I will need new main bearings, piston rings, and connecting rod bearings.

#51

11 Second Club

iTrader: (4)

Join Date: Jan 2005

Location: Rowletts,KY

Posts: 1,004

Likes: 0

Received 0 Likes

on

0 Posts

Ive tried to read over most of this post and cant tell What all is going on here. First, if the first engine you bought was a reman crate engine it is a crap shoot what has been done to it. Diffrent cylinder bores, Mixed rods, May have 1 journal turned and the others are standard,ect.

however about the rods, IMO if you are going to have them reconditioned( basicly check for straitness and linebore the big end) then yes, If no then no i would want to put them in mine. If you use a stock set of rods however you go i would replace the studs and nuts. They are cheap and a bad one cost lots of money to fix.

As far as the balanceing if you can afford it it would be a good idea. We dont have a setup to balance but another local shop does, He charges around $250, Unless it needs heavier weight welded in or massive amounts of cutting, but your shouldnt.

however about the rods, IMO if you are going to have them reconditioned( basicly check for straitness and linebore the big end) then yes, If no then no i would want to put them in mine. If you use a stock set of rods however you go i would replace the studs and nuts. They are cheap and a bad one cost lots of money to fix.

As far as the balanceing if you can afford it it would be a good idea. We dont have a setup to balance but another local shop does, He charges around $250, Unless it needs heavier weight welded in or massive amounts of cutting, but your shouldnt.

#52

TECH Addict

iTrader: (3)

Bottom line is how did you come up with the wanted RWHP? If you are looking for something on the cheap with a little more power than stock, then you can do what a this one guy did.

Had the block vated, crank polished for some small nicks

new OE pistons and had the cylinders honed

Rods re-sized

all new bearings

LE cam it was like a 220/228

1.6 RR, new springs

New pushrods

all boltons

exhaust

3200 stall

and a tune

The car is much quicker than stock and is quick enough for him, This was done all on the cheap or much cheaper than buying new rods, forged pistons, new crank ect.

Had the block vated, crank polished for some small nicks

new OE pistons and had the cylinders honed

Rods re-sized

all new bearings

LE cam it was like a 220/228

1.6 RR, new springs

New pushrods

all boltons

exhaust

3200 stall

and a tune

The car is much quicker than stock and is quick enough for him, This was done all on the cheap or much cheaper than buying new rods, forged pistons, new crank ect.

#53

Well congrats on your progress. Block looking clean. But u should have removed the ball before hot tanking. Make sure it installed before assembly.

That ball comes out from the hole in left side in the rear main cap. U have to knock it out from the top of block on the rear china wall with a long thin punch/drift.

As far as swapping bottom ends u may need to have the crank saddles alinehoned - maybe not. Your making it complicated. Why cant u use the original crank and rods? The original crank should install with just a polishing or having it cut for larger bearing then polished. If changing rods then u need them reconditioned/resized and not to install new stronger bolts would be foolish. Myself i would have the rods shot peened also - pretty cheap operation.

Balancing may not be necessary as u would be surprised with what stock engines have for balance. Alot of balance work can be done just by sorting out the parts - heavy pistons with lighter rod ends. If your machine shop does balance work talk it over with them and u may be able to save $$$ by weighting all the parts at home.

Good luck.

That ball comes out from the hole in left side in the rear main cap. U have to knock it out from the top of block on the rear china wall with a long thin punch/drift.

As far as swapping bottom ends u may need to have the crank saddles alinehoned - maybe not. Your making it complicated. Why cant u use the original crank and rods? The original crank should install with just a polishing or having it cut for larger bearing then polished. If changing rods then u need them reconditioned/resized and not to install new stronger bolts would be foolish. Myself i would have the rods shot peened also - pretty cheap operation.

Balancing may not be necessary as u would be surprised with what stock engines have for balance. Alot of balance work can be done just by sorting out the parts - heavy pistons with lighter rod ends. If your machine shop does balance work talk it over with them and u may be able to save $$$ by weighting all the parts at home.

Good luck.

#54

11 Second Club

iTrader: (4)

Join Date: Jan 2005

Location: Rowletts,KY

Posts: 1,004

Likes: 0

Received 0 Likes

on

0 Posts

Well congrats on your progress. Block looking clean. But u should have removed the ball before hot tanking. Make sure it installed before assembly.

That ball comes out from the hole in left side in the rear main cap. U have to knock it out from the top of block on the rear china wall with a long thin punch/drift.

As far as swapping bottom ends u may need to have the crank saddles alinehoned - maybe not. Your making it complicated. Why cant u use the original crank and rods? The original crank should install with just a polishing or having it cut for larger bearing then polished. If changing rods then u need them reconditioned/resized and not to install new stronger bolts would be foolish. Myself i would have the rods shot peened also - pretty cheap operation.

Balancing may not be necessary as u would be surprised with what stock engines have for balance. Alot of balance work can be done just by sorting out the parts - heavy pistons with lighter rod ends. If your machine shop does balance work talk it over with them and u may be able to save $$$ by weighting all the parts at home.

Good luck.

That ball comes out from the hole in left side in the rear main cap. U have to knock it out from the top of block on the rear china wall with a long thin punch/drift.

As far as swapping bottom ends u may need to have the crank saddles alinehoned - maybe not. Your making it complicated. Why cant u use the original crank and rods? The original crank should install with just a polishing or having it cut for larger bearing then polished. If changing rods then u need them reconditioned/resized and not to install new stronger bolts would be foolish. Myself i would have the rods shot peened also - pretty cheap operation.

Balancing may not be necessary as u would be surprised with what stock engines have for balance. Alot of balance work can be done just by sorting out the parts - heavy pistons with lighter rod ends. If your machine shop does balance work talk it over with them and u may be able to save $$$ by weighting all the parts at home.

Good luck.

#55

Do i have pic? Not in my camera. Am i gonna go out into the garage and pop the main cap on my spare LT1, take pics and post them for u? Good guess.

And why do u want a pic? Are u rebuilding an LT1 right now? Then start your own thread for your own questions. Reads like the OP has moved on without any pics.

I dont see whats so hard 'bout taking a look for yourself (if u need to) as there are only 4 holes under the rear main cap - 2 for bolts and 2 for oil. Without the threaded bolt holes your down to 2. As i said its the hole on the left which is the drivers side of block.

And why do u want a pic? Are u rebuilding an LT1 right now? Then start your own thread for your own questions. Reads like the OP has moved on without any pics.

I dont see whats so hard 'bout taking a look for yourself (if u need to) as there are only 4 holes under the rear main cap - 2 for bolts and 2 for oil. Without the threaded bolt holes your down to 2. As i said its the hole on the left which is the drivers side of block.

#56

11 Second Club

iTrader: (4)

Join Date: Jan 2005

Location: Rowletts,KY

Posts: 1,004

Likes: 0

Received 0 Likes

on

0 Posts

Do i have pic? Not in my camera. Am i gonna go out into the garage and pop the main cap on my spare LT1, take pics and post them for u? Good guess.

And why do u want a pic? Are u rebuilding an LT1 right now? Then start your own thread for your own questions. Reads like the OP has moved on without any pics.

I dont see whats so hard 'bout taking a look for yourself (if u need to) as there are only 4 holes under the rear main cap - 2 for bolts and 2 for oil. Without the threaded bolt holes your down to 2. As i said its the hole on the left which is the drivers side of block.

And why do u want a pic? Are u rebuilding an LT1 right now? Then start your own thread for your own questions. Reads like the OP has moved on without any pics.

I dont see whats so hard 'bout taking a look for yourself (if u need to) as there are only 4 holes under the rear main cap - 2 for bolts and 2 for oil. Without the threaded bolt holes your down to 2. As i said its the hole on the left which is the drivers side of block.

#58

Why cant u answer the question dickweed: And why do u want a pic? Are u rebuilding an LT1 right now? Then start your own thread for your own questions. Reads like the OP has moved on without any pics.

I dont see whats so hard 'bout taking a look for yourself (if u need to) as there are only 4 holes under the rear main cap - 2 for bolts and 2 for oil. Without the threaded bolt holes your down to 2. As i said its the hole on the left which is the drivers side of block.