Chasing down vibrations at freeway speeds with UMI/Strano parts

#21

TECH Fanatic

iTrader: (5)

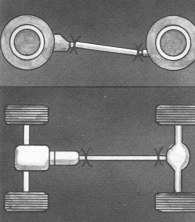

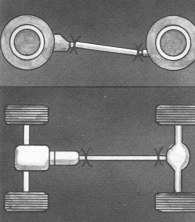

demonstrated with a working model. Imagine the pinion on the left, and the tailshaft on the right. This demo is plan view only, but the same principles apply with top view.

If you have an angle in planview and top view (and most cars would, that's a compound angle) that's ok as long as all the center lines of the driving (transmission out put shaft) and driven (pinion) components are parallel (it's ok with in reason, at too great an angle, even compensating angles won't cancel vibration). U-joint equiped shafts work best with no angle on them at all.

#22

Launching!

Thread Starter

iTrader: (5)

Join Date: Apr 2004

Location: Tucson, AZ

Posts: 227

Likes: 0

Received 0 Likes

on

0 Posts

I changed my drive line angle completely. I put shims under my tailshaft to push it up to 0°. I then set my pinion to the same. You don't have to do this.

For a stick axle car, driven on the street, I'm a firm believer in the equal opposite angle at either end of the drive line. Most likely your tailshaft is sloping down between 2° and 3°, therefore your pinion should be sloping up an equal amount. There is flex in the torque arm, in the bushing or the arm itself, and in the tailshaft, some change in the angles is to be expected.

Equal angles as this video points out, cancels vibration.

Universal Joint Related Problems (problemas relacionados a juntas universais) - YouTube

Remember too, you have angles in plan view and top view. Top view usually isn't an issue unless you've got one control arm much different in length than the other, or your engine and trans are skewed in such a way that the center line of them is not parallel with the center line of the pinion.

For a stick axle car, driven on the street, I'm a firm believer in the equal opposite angle at either end of the drive line. Most likely your tailshaft is sloping down between 2° and 3°, therefore your pinion should be sloping up an equal amount. There is flex in the torque arm, in the bushing or the arm itself, and in the tailshaft, some change in the angles is to be expected.

Equal angles as this video points out, cancels vibration.

Universal Joint Related Problems (problemas relacionados a juntas universais) - YouTube

Remember too, you have angles in plan view and top view. Top view usually isn't an issue unless you've got one control arm much different in length than the other, or your engine and trans are skewed in such a way that the center line of them is not parallel with the center line of the pinion.

1) I changed the instant-center of the car by adjusting the front torque arm mount down from the 2nd set of holes on the top (UMI torque arm relocation kit) to the 3rd, which is what's recommended for lowered cars. No effect on the vibrations, nor was one expected, just documenting changes.

2) I measured the tailshaft angle in the following place; this is a stock picture I pulled off Google, I obviously measured my tailshaft on the car. For reference, the top of the image is the output to the driveshaft, and to the right points downward when installed on the car.

I obtained an angle of -3 (running downhill to the rear of the car). So I adjusted the rearend angle such that it was +3 (running uphill towards the front of the car) as measured on the lower torque arm mount, the flat part directly beneath the lower torque arm pivot point, as shown here (this is a view from the drive side of the car):

This created a driveshaft angle of approximately 1.5 degrees running uphill toward the rear of the car. These measurements correspond pretty closely with the drivetrain angle picture you posted. My concern is whether having the driveshaft run uphill toward the rear of the car is a problem in any way. Another note - this brought the top of the torque arm mount fairly close to the transmission tunnel; I wedged a spare rubber grommet between the corner of the mount and where it looked like it could potentially come into contact with the tunnel.

Driving the car at the problem speeds of 70-85, the vibrations seems to have improved, but is still present, just to a lesser degree. I noted previously that it seems to come and go, and now it comes and goes at a slower frequency, and is less harsh when it does occur.

The problem could be one a few things:

1) Inaccuracy (or user error) with the analog magnetic angle finder I have; the needle has a tendency to bounce with the slightest movement, so I may re-measure the angles using a digital angle finder.

2) The places I chose to measure (pictured above) may not be representative of the "true" driveline angles. If there are better places to measure transmission and rearend angles from, I'd appreciate any input on where.

In any event, I seem to be on the right track, but wanted to get LS1tech's opinion again on whether my measured transmission and rearend angles seem appropriate (particularly the effect it's had on the operating angle of the driveshaft) and if I should be measuring the angles from other locations. Thanks all.

#23

TECH Fanatic

iTrader: (5)

I measure right off the output shaft on the transmission with a digital angle finder, and then the yoke on the pinion (means removing the driveshaft). I find the cheap analog angle finders at Lowes/Home Depot to be a pain to get an accurate reading from. You want to keep the angles with in .5° of each other ideally.

Don't worry about the angle of the driveshaft, its the center lines of the output shaft and input shaft that are relevant. As I said in an earlier post, the drive shaft angle matters depending on application, but for a car not so much. With in the suspension travel available and the usual angles at each component (transmission and rearend) of 1°-3° the driveshaft angle just doesn't matter. Measuring that just confuses the matter.

Don't worry about the angle of the driveshaft, its the center lines of the output shaft and input shaft that are relevant. As I said in an earlier post, the drive shaft angle matters depending on application, but for a car not so much. With in the suspension travel available and the usual angles at each component (transmission and rearend) of 1°-3° the driveshaft angle just doesn't matter. Measuring that just confuses the matter.

Last edited by lees02WS6; 04-20-2013 at 08:05 PM.

#24

11 Second Club

iTrader: (1)

Join Date: Mar 2006

Location: Simpsonville, SC

Posts: 349

Likes: 0

Received 0 Likes

on

0 Posts

This makes alot of sense. Myself and a few other friends with F-bodies have been having this same issue also. I am going to try this when i get my car out. I kept just measuring the rear yoke angle and didn't think about measuring the trans yoke angle. Just need to make sure that when you are measuring/making adjustments that they are done on a drive on hoist like an alignment rack.

#26

TECH Fanatic

iTrader: (5)

Newer cars (bmw's, camaro's and mustang's), use two piece shafts that do have at least one cv-joint on at least one piece of their two piece shafts. All in the name of cutting vibration.

#27

TECH Addict

iTrader: (6)

Join Date: Jul 2007

Location: Ringoes/Flemington, New Jersey

Posts: 2,856

Likes: 0

Received 1 Like

on

1 Post

I have the same issue with my car. It's random and its over 65-70. Its REAL BAD when you push the clutch in, or put the car in neutral. It almost goes away when you give it some gas in gear. I set my pinion angle at the rear to -1 (UMI adj T/A). I didn't account for the transmission. I am going to do that this friday and report back. I have literally thrown every part at my car like an idiot.

#28

TECH Fanatic

iTrader: (5)

If you find yourself, as csxfbird did, with a potential clearance issue you can move the tailshaft up by shimming between the tailshaft bushing and the trans cross member. Then lower the pinion angle to get yourself in more comfortable territory. I'm assuming of course that you do NOT have solid motor mounts.

As I said, the less angle on the joint the better they work. You can also try accounting for pinion climb in acceleration by leaving the pinion .5° lower than the tailshaft. Keep playing with the tailshaft and/or pinion angle until you get the vibrations out, but keep the joints at equal angles within .5° of each other.

As I said, the less angle on the joint the better they work. You can also try accounting for pinion climb in acceleration by leaving the pinion .5° lower than the tailshaft. Keep playing with the tailshaft and/or pinion angle until you get the vibrations out, but keep the joints at equal angles within .5° of each other.

#31

11 Second Club

iTrader: (1)

Join Date: Mar 2006

Location: Simpsonville, SC

Posts: 349

Likes: 0

Received 0 Likes

on

0 Posts

Ok so I measured my pinion angle at the u-joint and measured the angle of the yoke on the transmission. The trans yoke was at +3º and I had my rear pinion angle was at -2º. I adjusted the rear pinion to +1º and the vibration on the way home was much better. Not perfect but a lot better. Think I might adjust it up to +2.5º and see how it does then. Only thing I am wondering is what this is going to do for traction for drag racing?? What do you guys think??

#32

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,240

Likes: 0

Received 79 Likes

on

70 Posts

Its the relo cross member. I have the same vibe. I've tried 2 different driveshafts, 2 rear ends, 2 different sets of wheels, multiple pinion angles etc. Nothing changes it one bit. I'm going to shim the trans up, bet that fixes it.

#33

Launching!

Thread Starter

iTrader: (5)

Join Date: Apr 2004

Location: Tucson, AZ

Posts: 227

Likes: 0

Received 0 Likes

on

0 Posts

Having done all the fixes I have and played with multiple pinion angles, I'm starting to think this same thing. Debating going back to my stock, tailshaft torque arm mount but leaving the UMI torque arm in.

#34

I to have the same problem.......between 70 and 75 unless im going uphill or on the gas. When stock with 2in drop spring and LCA it was fine untill i added either the strano kit 1st and or the 2nd sphon adj torque arm. I have tried adjusting the ARM twice but no improvement.

#35

TECH Enthusiast

iTrader: (11)

Join Date: Jul 2008

Location: edmond,ok

Posts: 623

Likes: 0

Received 0 Likes

on

0 Posts

Bump this thread as im having similar problem after moser 9" with bmr non afj torque arm. Im debating if the relo bracket is worth it since ive seen some people said that the relo bracket will introduce additional noise/vibration to the cabin.

Any update op?

Any update op?

#36

TECH Addict

iTrader: (6)

Join Date: Jul 2007

Location: Ringoes/Flemington, New Jersey

Posts: 2,856

Likes: 0

Received 1 Like

on

1 Post

I shimmed my trans so it was -1 (pointing down) and I adjusted my torque arm to be +1 (pointing up). vibration is still there, but I think it got a little better. I wonder if I just keep changing the rear angle and see what happens...

#38

11 Second Club

iTrader: (1)

Join Date: Mar 2006

Location: Simpsonville, SC

Posts: 349

Likes: 0

Received 0 Likes

on

0 Posts

Has anyone tried putting the pinion angle the same as the tail shaft angle?? I know that all the suspension companies say to have the rear pinion angle set at -2deg for racing/traction purposes but if i am reading and watching these videos correctly it looks like they need to be the same angle to stop vibration. Like i said further up, i adjusted my pinion angle to +1deg and vibration got alot better. I mean the car felt like it was going to come apart when i would get around 125-130mph and i would have to let out but after i adjusted the pinion angle up to +1deg i had very slight vibration and went to 145mph and it felt much better with alot less vibration. The vibration at regular highway speed was much better also.

#40

Launching!

Thread Starter

iTrader: (5)

Join Date: Apr 2004

Location: Tucson, AZ

Posts: 227

Likes: 0

Received 0 Likes

on

0 Posts

Frankly, I don't really do any drag racing anyways, so I don't know how much gain I'll get long-term from the torque arm relocation mount, but if it means having a livable freeway ride back, I'm all for it.