EFI University Shows Off 11,000 RPM LS7 Engine

EFI University works magic with a big RPM, big displacement LS7 engine.

High-RPM LS-engines exist, but usually are limited to destroking and reducing their displacement. What if you could get over ten-thousand-RPM with a LS7 block and displacement?

It seems like the impossible dream. Getting 427-cubic-inches to spin above 7,000 RPM without slinging parts out of the block seems like the perfect dream. A reliable small block Chevy spinning over 8,500 revs doesn’t even seem like a reality. Well, the students and teachers over at EFI University decided it was time to make that change in an LS7 engine they built for a drag race project known as ‘Spinal Tap.’ EFI University, as the name implies, is an automotive trade school that promises to be a step above others. They offer specialty classes geared towards the aftermarket performance parts industry.

Their ‘Spinal Tap’ engine endured a two-year development, so it’s not like this has been something that was done overnight just to say “look at what we did” and it blows up the next day. Instead, this has seen multiple simulated runs on their dyno and on the Spintron of COMP Cams Research and Development Department. However, you’ll notice there wasn’t any mention of extreme work done to the bottom end. That’s because it’s not the rotating assembly there that poses the issues at 11,000 revs, it’s rotating assembly that controls the engines breathing and the heads.

How did they do it?

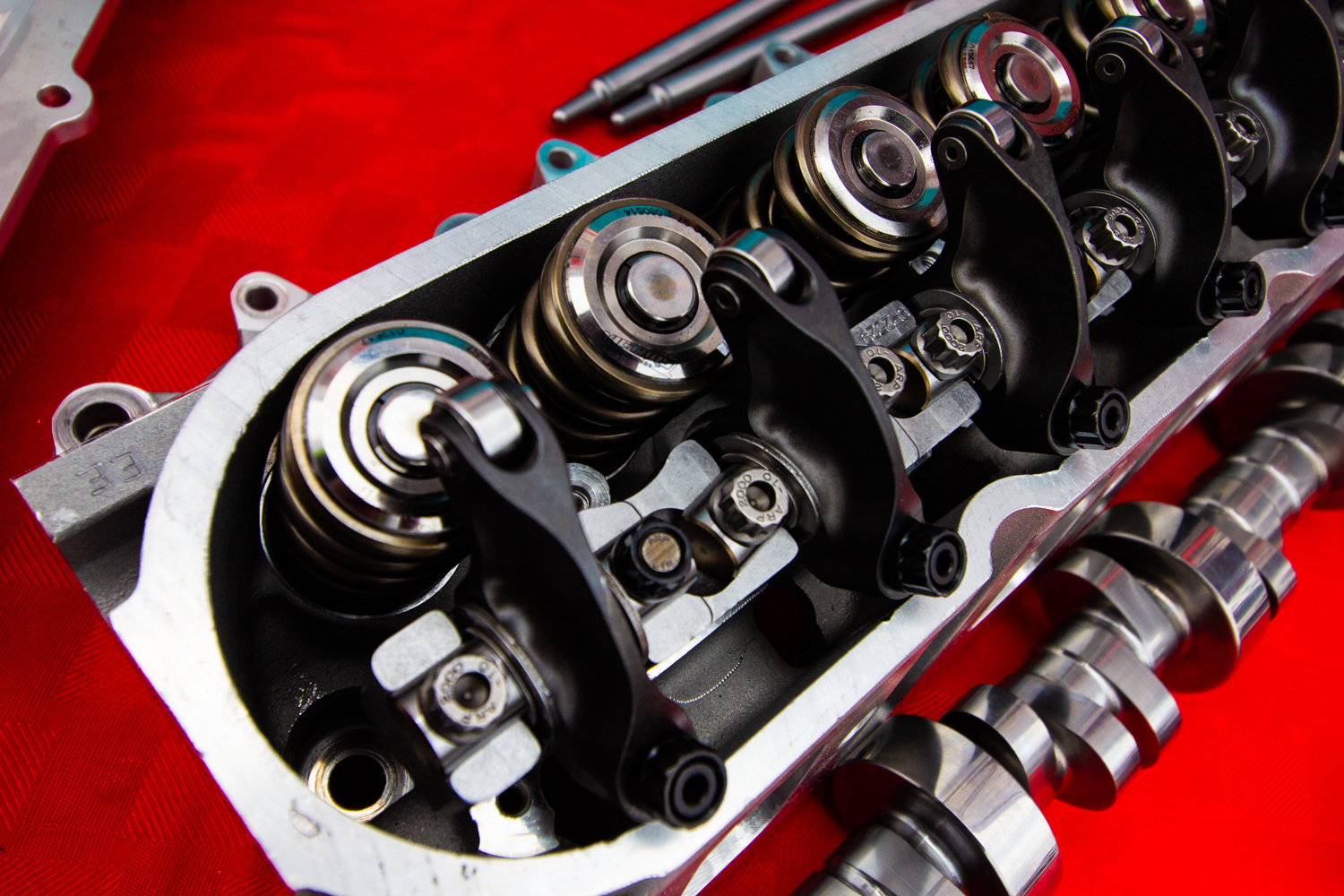

The camshaft is a big, beefy 60mm core compared to the stock LS7 bumpstick. This is a requirement when you see that it’s running a dual valve spring the requires 1,250-pounds of pressure to open the valve. With a standard LS Camshaft with .842-inch lifters, they lost .046-thousandths of an inch of lift because of the bending in the system.

Yes, system, not just the camshaft, either. If you think your pushrods are big, the 11,000 RPM LS7 is using a Manton 8.550-inch over all length, .188-inch thick wall pushrod. It’s nearly the diameter of the average teenager’s finger.

The lifter is a hydraulic roller, but it’s a Jesel 0.937-inch diameter keyway lifter. Which means the block had to be modified to fit that. It also doesn’t use tie-bars as the keyway prevents the lifter from rotating in its bore. Turns out, even standard upgrade parts for the LS lifters squeeze out enough oil they begin to gall and even weld themselves to the bore.

ALSO SEE: Driving the Camaro SS Hybrid of the Future

You also can’t use a set stock standard LS rocker arms, either. So Jesel made these adjustable units and they claim that these are “the most stable valvetrain system they have ever made for a LS platform.” The rockers are twisted just enough to allow the pushrod to clear the narrow opening of the LS heads. These sit inside a set of RHS Pro Eliete LS7 cylinder heads capable of moving 307ccs of air.

The valves are titanium units but utilize a cap with a dual locking retainer. So, the retainer locks both the cap and the stem to the spring retainer. These valves are also custom as they allow for one-inch of lift without hitting the valve stem seals.

This was all verified on a testing device known as a Spintron, a 75-horsepower electric motor that moves a crankshaft inside a modified block. Modified to allow a laser to be installed into the cylinder and monitor the movement of the valve to 11,000-RPM and above. That’s why the valve is painted white, so that the laser can be detected by the Spintron’s sensor. During a Facebook live stream on the EFI University page they spun this assembly to nearly 12,000-RPM as a “see if it breaks” run. Though, it was rather “angry” at 11,700-RPM, so we won’t see anything above 11. For now.

Photos for LS1Tech by Justin Banner