Hi Swirl Piston Design - Soft Heads - Larry Widmer style

#1

LS1tech I have a sad fact for you. If you search for "swirl" all you get are pages of threads from "appearance and detailing".

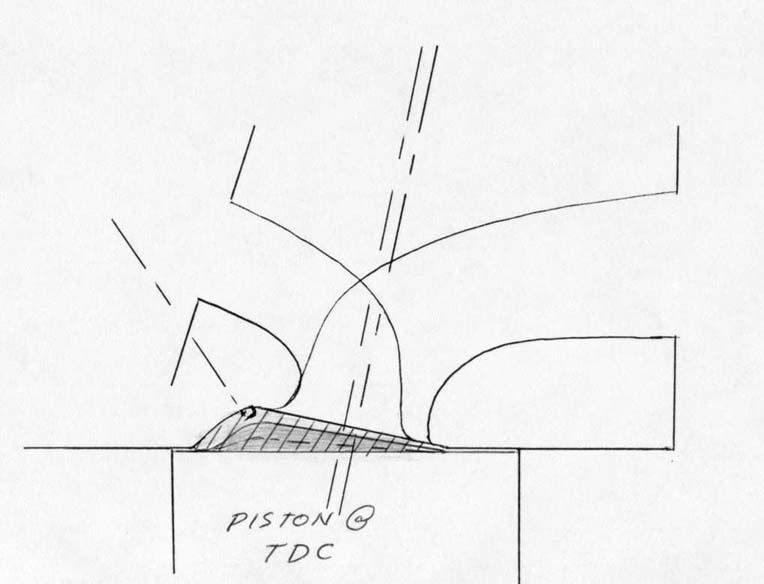

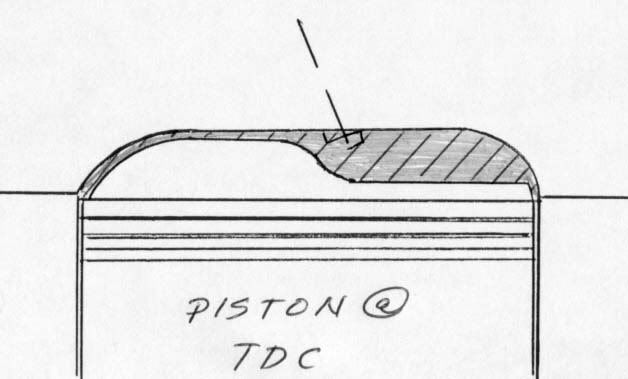

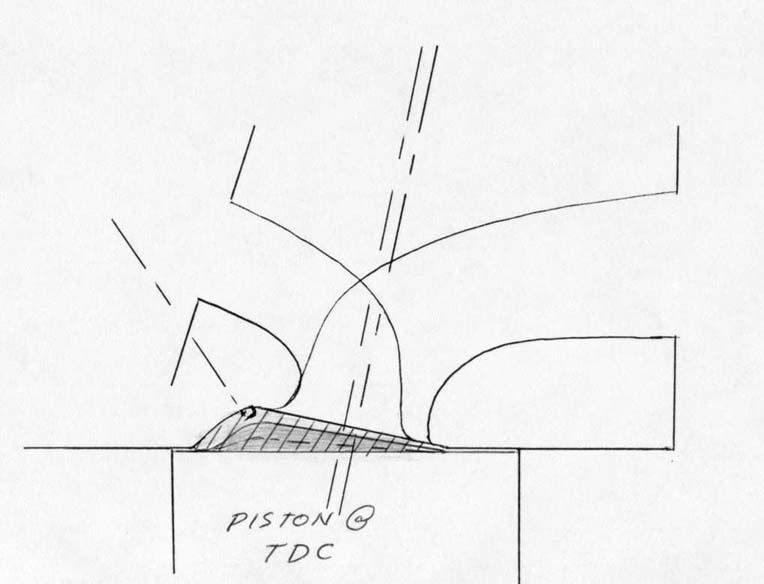

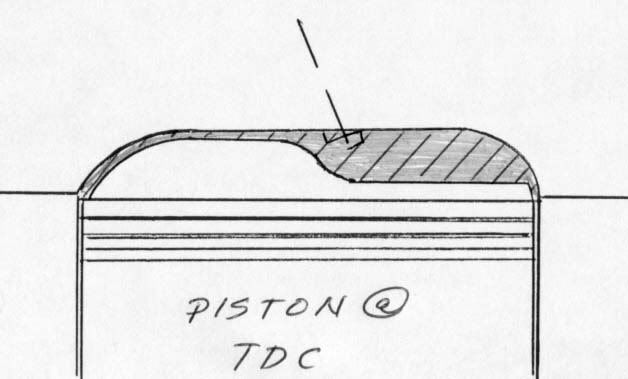

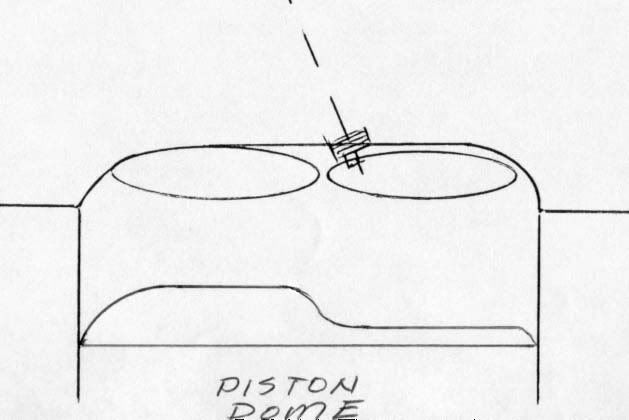

I'm building a new short block and have been reading up on piston design. I've read a few debates on reverse dome vs. traditional circumferential dish. I was leaning towards a reverse dome when I cam across some writings by Larry Widmer of Endyn.

He has some interesting theories about basically building a reverse dome on the exhaust side of the piston with a regular dome on the intake side of the piston in order to mechanically induce swirl and a better/faster/more localized burn. Even more interesting than his theories are his results! His personal street car is running 13.4:1 compression on 92 octane with VERY little ignition advance (down to 10 degrees), and 300 hp out of 2L with incredibly low BSFC. He originally developed his ideas in the 70s while working on 2 valve nascar heads, though Endyn now seems to specialize parts for N/A hondas.

I've really enjoyed his articles:

http://www.theoldone.com/articles/

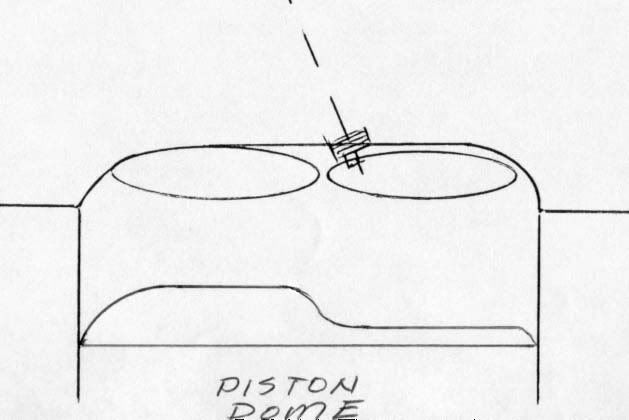

and here are some pics of his ideas on piston design I pilfered from his web site (I hope he doesn't mind)

I have a set of stock CNC LS7 heads that have been milled to a 63cc cumbustion chamber

What's up with the funny button of material in the chamber just above the spark plug between the intake and exhaust halves of the chamber? I hope some of the head porters stop by.

With the cam that I am considering now with a IVC of 43.5/68.5 @ .050"/.006" lift I am going to need a dish of about 16cc to keep my DCR below 9. I think that might be a difficult piston to design. Especially for these LS7 heads which seem to have the majority of their chamber volume below the intake (which Mr. Widmer suggests I eliminate with a partial traditional dome; even at the expense of intake valve lift!).

Has anyone tried "soft head" style design on an LS engine?

I'm building a new short block and have been reading up on piston design. I've read a few debates on reverse dome vs. traditional circumferential dish. I was leaning towards a reverse dome when I cam across some writings by Larry Widmer of Endyn.

He has some interesting theories about basically building a reverse dome on the exhaust side of the piston with a regular dome on the intake side of the piston in order to mechanically induce swirl and a better/faster/more localized burn. Even more interesting than his theories are his results! His personal street car is running 13.4:1 compression on 92 octane with VERY little ignition advance (down to 10 degrees), and 300 hp out of 2L with incredibly low BSFC. He originally developed his ideas in the 70s while working on 2 valve nascar heads, though Endyn now seems to specialize parts for N/A hondas.

I've really enjoyed his articles:

http://www.theoldone.com/articles/

and here are some pics of his ideas on piston design I pilfered from his web site (I hope he doesn't mind)

I have a set of stock CNC LS7 heads that have been milled to a 63cc cumbustion chamber

What's up with the funny button of material in the chamber just above the spark plug between the intake and exhaust halves of the chamber? I hope some of the head porters stop by.

With the cam that I am considering now with a IVC of 43.5/68.5 @ .050"/.006" lift I am going to need a dish of about 16cc to keep my DCR below 9. I think that might be a difficult piston to design. Especially for these LS7 heads which seem to have the majority of their chamber volume below the intake (which Mr. Widmer suggests I eliminate with a partial traditional dome; even at the expense of intake valve lift!).

Has anyone tried "soft head" style design on an LS engine?

#3

At first, that's what i thought. But the little pad above the spark plug looks like it would work against flow going from the intake side of the head towards the exhaust. Also the majority of the volume in the head's chamber looks like it is around the intake valve, so I don't know. The low angle of the intake valve (12 degrees) is definitly a part of soft head design though.

#4

TECH Senior Member

iTrader: (23)

Join Date: Aug 2005

Location: Watertown, NY

Posts: 8,797

Likes: 0

Received 0 Likes

on

0 Posts

Thats part above the plug looks to be a potenial spot for detonation.

Swirl is also associated with quench, search here for quench and you will find a good bit of info on chamber design and how quench plays a large part in combustion.

Swirl is also associated with quench, search here for quench and you will find a good bit of info on chamber design and how quench plays a large part in combustion.

#6

TECH Addict

iTrader: (24)

Join Date: Oct 2006

Location: Webb City, MO...out in the garage

Posts: 2,610

Likes: 0

Received 0 Likes

on

0 Posts

i can't remember where i read it, but the little 'nub' by the spark plug was deliberately left there. it has something to do with, well....something important  i can't remember, but i do recall reading that taking it off showed no benefits whatsoever...there's a reason it's on there, SOMEBODY knows...i wanna say it deflected the ignited air/fuel in such a way that it more efficiently forced the piston down...but i honestly can't remember for certain.

i can't remember, but i do recall reading that taking it off showed no benefits whatsoever...there's a reason it's on there, SOMEBODY knows...i wanna say it deflected the ignited air/fuel in such a way that it more efficiently forced the piston down...but i honestly can't remember for certain.

Trending Topics

#8

TECH Senior Member

iTrader: (23)

Join Date: Aug 2005

Location: Watertown, NY

Posts: 8,797

Likes: 0

Received 0 Likes

on

0 Posts

Right and the trade off for swirl is a big *** hot spot for detonation, exactly what you dont want in any high compression high HP engine. I really would not want that sticking out in my chamber especially since I run a 11:8ish nitrous motor.

Maybe it has its advantage in stock form but once you deck the heads and plan on having a motor thats going to make some power I wouldnt want that nub there.

Now maybe one of our cylinder head experts can comment on it though since I am sure they know much more than I about this.

Maybe it has its advantage in stock form but once you deck the heads and plan on having a motor thats going to make some power I wouldnt want that nub there.

Now maybe one of our cylinder head experts can comment on it though since I am sure they know much more than I about this.

#9

If it was a regular quench pad I would think that it would be flush with the deck surface of the head. Instead it's ill-machined with multiple sharp edges and sits down about .100" after I had the heads shaved .045".

But then again, in one of Widmer's articles he calls for the dome under the intake valve to come within .100" of the head. And my understanding is that he's using the dome for an extra quench pad, so maybe it is?

But then again, in one of Widmer's articles he calls for the dome under the intake valve to come within .100" of the head. And my understanding is that he's using the dome for an extra quench pad, so maybe it is?

#11

Yeah, anybody who can sell heads to nascar team for near 5 figures is doing something right. And pulling 300 hp out of 2 liters as a hobby is pretty damn amazing.

I've got to find somebody on here who has messed with partial/intake side domes. Maybe we can drag the wiseco and/or diamond guys in here. Brian Nutter from wiseco has been a source of info for me more than once.

Something else I've been wondering. For me to beable to have a streetable compression ratio (though one wonders what that is considering Widmer is well over 13:1 on 92 octane in his DD) I would have to have a traditional dish/reverse dome under the exhaust valve to balance out the cc's that would be removed from my chamber with the dome under the intake valve.

Would this odd unbalance in the piston (the intake side of the piston would be significantly heavier) cause any reliability issues? or neccesitate more stout piston pins?

I've got to find somebody on here who has messed with partial/intake side domes. Maybe we can drag the wiseco and/or diamond guys in here. Brian Nutter from wiseco has been a source of info for me more than once.

Something else I've been wondering. For me to beable to have a streetable compression ratio (though one wonders what that is considering Widmer is well over 13:1 on 92 octane in his DD) I would have to have a traditional dish/reverse dome under the exhaust valve to balance out the cc's that would be removed from my chamber with the dome under the intake valve.

Would this odd unbalance in the piston (the intake side of the piston would be significantly heavier) cause any reliability issues? or neccesitate more stout piston pins?

Last edited by GIGAPUNK; 09-18-2008 at 12:16 PM.

#12

David Vizard had a hand at MTI in the development of their LS7 head porting program. He wrote a short article about it here:

http://www.gofastnews.com/board/tech...oved-upon.html

They obviously removed the little pad above the spark plug! If it works for David Vizard...

http://www.gofastnews.com/board/tech...oved-upon.html

They obviously removed the little pad above the spark plug! If it works for David Vizard...

#13

The soft head concept is valid, but there are some things you need to consider. Larry Widmer is a good friend of mine and a good customer. We do the pistons for his 420+ crank horsepower naturally aspirated Honda 4 cylinders. At the same time, you've got to look at Cup and Pro stock engines today for the most advanced 2v technology. These are the people who know the most, but they aren't going to talk about it on a forum. I've seen the CFD combustion analysis they do and it's incredible. Efficiencies well beyond F1 due to them developing against a standard that remains in place for longer than a couple years. Larry certainly stands as a person that got many of these people to start Studying and Thinking about the art.

Most of the present high end N/A engines do not enhance swirl in the intake port. In general, we don't want swirl at the expense of flow and tumble designs are better. To this end, Larry has some interesting features in the Venturi area that act as a vortex generator and induces the air to stick around the short turn of the intake runner.

Where swirl can be accomplished without hurting flow is in the combustion chamber. A Pro Stock engine COULD use a smaller chamber and get a flat top to net the needed compression, but they don't. What does that tell you about mixture motion? We build up dome around the intake side without shrouding the valve (made easier by the cant of the intake valve used on those heads, and the exhaust side of the dome is smaller-but still above the deck a fair amount. I'd say this area is "funnel like" in the chamber and the dome that matches it.

For guys that are truly gluttons for punishment, we've built pistons that had a dome on the intake side and a Reverse dome on the exhaust. It was a nightmare to engineer, machine, and I hope the customer had an easier time of getting it into the engine than we did building them. The pistons were VERY heavy because of the Mass could not be removed underneath the intake side, yet the crown had to be thick enough under the reverse dome side. All in all, it's an excellent exercise, but the heads and pistons almost need to be designed around each other from the start to not shrowd the valves.

So what's a guy to do?: You'll find the easiest way to get good results is to mill the heads enough that a small reverse dome is necessary. Be careful because you CAN hurt flow and that almost always hurts more than the enhanced combustion helps. Speak to your cylinder head manufacturer as the best have flowed the heads at different chamber volumes. Back to the reverse dome- The wall created with this reverse image actually reflects the combustion back to the center of the cylinder for a split second longer resulting in a more complete burn. I have seen this in CFD and in burn patterns on pistons. As always, there are other things that can offset the gains...deep valve pockets may require lowering the top ring and creating more crevice area. Where does it stop! It doesn't!

Our three part numbers k462,k463, and k464 use something we call the Wiseco flow dome. When we went to a multifit pocket to accomodate different heads, it made it hard to hit the negative -3cc volume necessary for many applications. We designed a nifty little dome that mirrored the face of the valves on the intake and exhaust...this left a natural flame slot around the plug area. In theory, it may promote flow around the valves when the piston is around tdc. Because the intake dome is larger than the exhaust, it could promote movement toward the exhaust side, but the PERFECT combination would require a cylinderhead and dome be built in conjuction....literally minimal piston to valve clearance and the chamber sized to net the compression ratio in conjuction with the dome. We have some visuals of this if you want to email me at bnutter@wiseco.com . Larry and I have spoken about him doing flow testing with the piston under the cylinder head in the bore fixture and the valves opened up as they would be around tdc with typical camshafts. For now though, it's unproven to help or hurt. Some day I'll retire and mess with this stuff every day. Until then, take anything I say with a grain of salt

Most of the present high end N/A engines do not enhance swirl in the intake port. In general, we don't want swirl at the expense of flow and tumble designs are better. To this end, Larry has some interesting features in the Venturi area that act as a vortex generator and induces the air to stick around the short turn of the intake runner.

Where swirl can be accomplished without hurting flow is in the combustion chamber. A Pro Stock engine COULD use a smaller chamber and get a flat top to net the needed compression, but they don't. What does that tell you about mixture motion? We build up dome around the intake side without shrouding the valve (made easier by the cant of the intake valve used on those heads, and the exhaust side of the dome is smaller-but still above the deck a fair amount. I'd say this area is "funnel like" in the chamber and the dome that matches it.

For guys that are truly gluttons for punishment, we've built pistons that had a dome on the intake side and a Reverse dome on the exhaust. It was a nightmare to engineer, machine, and I hope the customer had an easier time of getting it into the engine than we did building them. The pistons were VERY heavy because of the Mass could not be removed underneath the intake side, yet the crown had to be thick enough under the reverse dome side. All in all, it's an excellent exercise, but the heads and pistons almost need to be designed around each other from the start to not shrowd the valves.

So what's a guy to do?: You'll find the easiest way to get good results is to mill the heads enough that a small reverse dome is necessary. Be careful because you CAN hurt flow and that almost always hurts more than the enhanced combustion helps. Speak to your cylinder head manufacturer as the best have flowed the heads at different chamber volumes. Back to the reverse dome- The wall created with this reverse image actually reflects the combustion back to the center of the cylinder for a split second longer resulting in a more complete burn. I have seen this in CFD and in burn patterns on pistons. As always, there are other things that can offset the gains...deep valve pockets may require lowering the top ring and creating more crevice area. Where does it stop! It doesn't!

Our three part numbers k462,k463, and k464 use something we call the Wiseco flow dome. When we went to a multifit pocket to accomodate different heads, it made it hard to hit the negative -3cc volume necessary for many applications. We designed a nifty little dome that mirrored the face of the valves on the intake and exhaust...this left a natural flame slot around the plug area. In theory, it may promote flow around the valves when the piston is around tdc. Because the intake dome is larger than the exhaust, it could promote movement toward the exhaust side, but the PERFECT combination would require a cylinderhead and dome be built in conjuction....literally minimal piston to valve clearance and the chamber sized to net the compression ratio in conjuction with the dome. We have some visuals of this if you want to email me at bnutter@wiseco.com . Larry and I have spoken about him doing flow testing with the piston under the cylinder head in the bore fixture and the valves opened up as they would be around tdc with typical camshafts. For now though, it's unproven to help or hurt. Some day I'll retire and mess with this stuff every day. Until then, take anything I say with a grain of salt

Last edited by briannutter; 09-19-2008 at 08:10 PM.

#14

It's guys like you that make this site, and guys like you that build brand loyalty in guys like me.

Thank you so much for that reply! I'm glad you didn't find a good place to stop!

It's strange that you mentioned the reverse domes under the valves only. I was day dreaming today of what would be the most efficient use of a positive dome (because I think I'm going to be limited by compression) and that's exactly what I thought up. And like you postulated, it made sense to my imagination that you could design these "sub valve domes" (just made that up) to enhance flow, if they could be made to look like a continuation of the valve to the air. I'm going to keep reading, asking questions and day dreaming.

Thank you so much for that reply! I'm glad you didn't find a good place to stop!

It's strange that you mentioned the reverse domes under the valves only. I was day dreaming today of what would be the most efficient use of a positive dome (because I think I'm going to be limited by compression) and that's exactly what I thought up. And like you postulated, it made sense to my imagination that you could design these "sub valve domes" (just made that up) to enhance flow, if they could be made to look like a continuation of the valve to the air. I'm going to keep reading, asking questions and day dreaming.

#15

One other thing with Larry's daily. All Honda 4v small bore -84-89mm engines run easily at 11.5, with many of them regularly running 12.5 now. Several people have purported to be in the low 13's (as are MANY o.e. crotchrockets)-but it's tricky because .005" worth of decking really changes compression and I'm not sure some of those people are really lower than they think they are. Crankcase breathing aids to keep oil out of the chamber allows some of these into the low 13's. Larry greatest talent is exploration to do things others say you can't.

You guys are going to start seeing more direct injection engines out over the next few years. If you look at the solstice gxp engine, it has a centered dome with a little "sugar scoop" in the center of the piston that takes the stream of fuel and causes it to reverse direction for some serious atomization. Think about being in a carwash and hitting the spot in the spokes that causes water to come back at you violently This dome isn't there for any purpose other than to hold the sugar scoop in place, but it's neat to look at.

This dome isn't there for any purpose other than to hold the sugar scoop in place, but it's neat to look at.

You guys are going to start seeing more direct injection engines out over the next few years. If you look at the solstice gxp engine, it has a centered dome with a little "sugar scoop" in the center of the piston that takes the stream of fuel and causes it to reverse direction for some serious atomization. Think about being in a carwash and hitting the spot in the spokes that causes water to come back at you violently

This dome isn't there for any purpose other than to hold the sugar scoop in place, but it's neat to look at.

This dome isn't there for any purpose other than to hold the sugar scoop in place, but it's neat to look at.

#16

I've been dreading the direct injection revolution solely because there's no such thing as an aftermarket direct injector/ecu controller. There's probably going to be a lag as the aftermarket catches up. But the advantages seem so real that it's just a matter of time.

And talking about Larry willing to do things that people say can't be done, reminds me about the difference between a good theoretical engineer and a good practical engineer. Larry is obviously both. While for guys like me, it's a lot easier to sit on the internet and pontificate, order up the best parts I can and then cross my fingers, then it is to trash a couple heads figuring out that I can, or can not run some crazy compression number on 93. I sure do appreciate the practical guys though, they are the ones that really keep us moving forward.

And talking about Larry willing to do things that people say can't be done, reminds me about the difference between a good theoretical engineer and a good practical engineer. Larry is obviously both. While for guys like me, it's a lot easier to sit on the internet and pontificate, order up the best parts I can and then cross my fingers, then it is to trash a couple heads figuring out that I can, or can not run some crazy compression number on 93. I sure do appreciate the practical guys though, they are the ones that really keep us moving forward.

#19

Moderator

iTrader: (20)

Right and the trade off for swirl is a big *** hot spot for detonation, exactly what you dont want in any high compression high HP engine. I really would not want that sticking out in my chamber especially since I run a 11:8ish nitrous motor.

Maybe it has its advantage in stock form but once you deck the heads and plan on having a motor thats going to make some power I wouldnt want that nub there.

Now maybe one of our cylinder head experts can comment on it though since I am sure they know much more than I about this.

Maybe it has its advantage in stock form but once you deck the heads and plan on having a motor thats going to make some power I wouldnt want that nub there.

Now maybe one of our cylinder head experts can comment on it though since I am sure they know much more than I about this.

But IMO, that CNC program (not the All Pro head itself) is the epitome of "garbage in, garbage out" from what we've seen on the flow bench. Hopefully some dyno time can prove this in the future.

#20

LS1tech I have a sad fact for you. If you search for "swirl" all you get are pages of threads from "appearance and detailing".

I'm building a new short block and have been reading up on piston design. I've read a few debates on reverse dome vs. traditional circumferential dish. I was leaning towards a reverse dome when I cam across some writings by Larry Widmer of Endyn.

He has some interesting theories about basically building a reverse dome on the exhaust side of the piston with a regular dome on the intake side of the piston in order to mechanically induce swirl and a better/faster/more localized burn. Even more interesting than his theories are his results! His personal street car is running 13.4:1 compression on 92 octane with VERY little ignition advance (down to 10 degrees), and 300 hp out of 2L with incredibly low BSFC. He originally developed his ideas in the 70s while working on 2 valve nascar heads, though Endyn now seems to specialize parts for N/A hondas.

With the cam that I am considering now with a IVC of 43.5/68.5 @ .050"/.006" lift I am going to need a dish of about 16cc to keep my DCR below 9. I think that might be a difficult piston to design. Especially for these LS7 heads which seem to have the majority of their chamber volume below the intake (which Mr. Widmer suggests I eliminate with a partial traditional dome; even at the expense of intake valve lift!).

Has anyone tried "soft head" style design on an LS engine?

I'm building a new short block and have been reading up on piston design. I've read a few debates on reverse dome vs. traditional circumferential dish. I was leaning towards a reverse dome when I cam across some writings by Larry Widmer of Endyn.

He has some interesting theories about basically building a reverse dome on the exhaust side of the piston with a regular dome on the intake side of the piston in order to mechanically induce swirl and a better/faster/more localized burn. Even more interesting than his theories are his results! His personal street car is running 13.4:1 compression on 92 octane with VERY little ignition advance (down to 10 degrees), and 300 hp out of 2L with incredibly low BSFC. He originally developed his ideas in the 70s while working on 2 valve nascar heads, though Endyn now seems to specialize parts for N/A hondas.

With the cam that I am considering now with a IVC of 43.5/68.5 @ .050"/.006" lift I am going to need a dish of about 16cc to keep my DCR below 9. I think that might be a difficult piston to design. Especially for these LS7 heads which seem to have the majority of their chamber volume below the intake (which Mr. Widmer suggests I eliminate with a partial traditional dome; even at the expense of intake valve lift!).

Has anyone tried "soft head" style design on an LS engine?

This is an old thread, but I was compelled to revive it.

Larry Widmer is a sharp guy, that's a given. But a lot of what he does, is re-gurgitate old tried and true knowledge, and present it as a guru with hidden secret knowledge. He's just not letting you know, where he first found the ideas. The natural response from the public, is assume Larry invented this stuff himself. When in fact, he's just re-creating a very old cylinder head design.

FACT: the "soft head" has been around since the 1930's at least, in the Chevrolet straight 6 engine. Yes, that lowly engine that made like 115 HP. Great for the time. Ford had to create the flathead V8 just to compete with it. The early Chevy 6 had very limited airflow, but a high squeeze head, by that I mean, the intake valve was flat with the deck, the exhaust valve was canted, and the chamber was around the exhaust valve. At TDC, the piston top pushes the mixture into the exhaust valve/chamber area, where it is confined and ignited, to burn efficiently- requiring less spark lead because the charge is so confined in a small space. Here are a couple pictures of the early 1930's Chevy straight 6 head. I saw a couple of these at a junkyard with the valve cover off, and often wondered WTH design they were, as a kid.

Last edited by bigCID; 07-13-2017 at 09:16 AM.

The guy is a freakin genius when it comes to engines. I mean look at some of his head work, its nothing short of amazing.

The guy is a freakin genius when it comes to engines. I mean look at some of his head work, its nothing short of amazing.