One Member's "New" harness woes, PIC HEAVY

#21

I called SSP wiring today and talked with the owner Bill. He told me that the wiring to the coil connector is spec at 22ga and that there may be an issue with the 12v (pink) wire going to the coils. He admitted that in the past they had some wire with too few strands that caused this issue. Iam going to try and run a dedicated wire with 12v to see if it fixes the issue. I have to say after talking to SSP that they are very willing to help out and even offered to bench test the harness for me and replace anything that is wrong.

#23

I called SSP wiring today and talked with the owner Bill. He told me that the wiring to the coil connector is spec at 22ga and that there may be an issue with the 12v (pink) wire going to the coils. He admitted that in the past they had some wire with too few strands that caused this issue. Iam going to try and run a dedicated wire with 12v to see if it fixes the issue. I have to say after talking to SSP that they are very willing to help out and even offered to bench test the harness for me and replace anything that is wrong.

Something else that is VERY important to note is you will notice the wire that feeds S102 is 18AWG, on the harness this customer received the wire feeding S102 is 22AWG. Below is the GM Schematic for an LS1.

__________________

Standalone LS Swap Harnesses IN STOCK!

LSX, LTX Stand alone swap harnesses. S10 LSX conversion PLUG AND PLAY harnesses, 24x conversion PLUG AND PLAY harnesses. LT1 to LSX PLUG AND PLAY Harnesses.

sales@bp-automotive.com

www.bp-automotive.com

1-888-467-4491

Standalone LS Swap Harnesses IN STOCK!

LSX, LTX Stand alone swap harnesses. S10 LSX conversion PLUG AND PLAY harnesses, 24x conversion PLUG AND PLAY harnesses. LT1 to LSX PLUG AND PLAY Harnesses.

sales@bp-automotive.com

www.bp-automotive.com

1-888-467-4491

#24

The ignition circuit that feeds the coils on a 24x LS1 engine is always 20ga. The 6 other circuits are all 18ga. Please see the diagram below. You will notice the wire size for the ignition is .5 which is 20AWG and all of the other circuits are .8 mm2 which is 18AWG.

Something else that is VERY important to note is you will notice the wire that feeds S102 is 18AWG, on the harness this customer received the wire feeding S102 is 22AWG. Below is the GM Schematic for an LS1.

Something else that is VERY important to note is you will notice the wire that feeds S102 is 18AWG, on the harness this customer received the wire feeding S102 is 22AWG. Below is the GM Schematic for an LS1.

#25

he was saying that is true of the older harnesses (early ls engines) but gm has since changed their spec on this. The newer style says 22ga is okay to use. Did he lie? Im just trying to get my facts strait. If I switched these wires out with the correct gauge do you think it might fix the issue? I really dont want to pull the entire harness out and start over. I appreciate your help

Lastly, just because something was used on a newer system does not mean that it automatically supersedes the previous rendition. For example, an LT1 only had 1 coil. Even though it had a 12ga wire supplying it, does that mean because the ls1 only had an 18 ga wire you can just go ahead and update it? Of course not. You should always wire the engine for the generation applicable schematics. Here are the pics for your reference.

__________________

Standalone LS Swap Harnesses IN STOCK!

LSX, LTX Stand alone swap harnesses. S10 LSX conversion PLUG AND PLAY harnesses, 24x conversion PLUG AND PLAY harnesses. LT1 to LSX PLUG AND PLAY Harnesses.

sales@bp-automotive.com

www.bp-automotive.com

1-888-467-4491

Standalone LS Swap Harnesses IN STOCK!

LSX, LTX Stand alone swap harnesses. S10 LSX conversion PLUG AND PLAY harnesses, 24x conversion PLUG AND PLAY harnesses. LT1 to LSX PLUG AND PLAY Harnesses.

sales@bp-automotive.com

www.bp-automotive.com

1-888-467-4491

#26

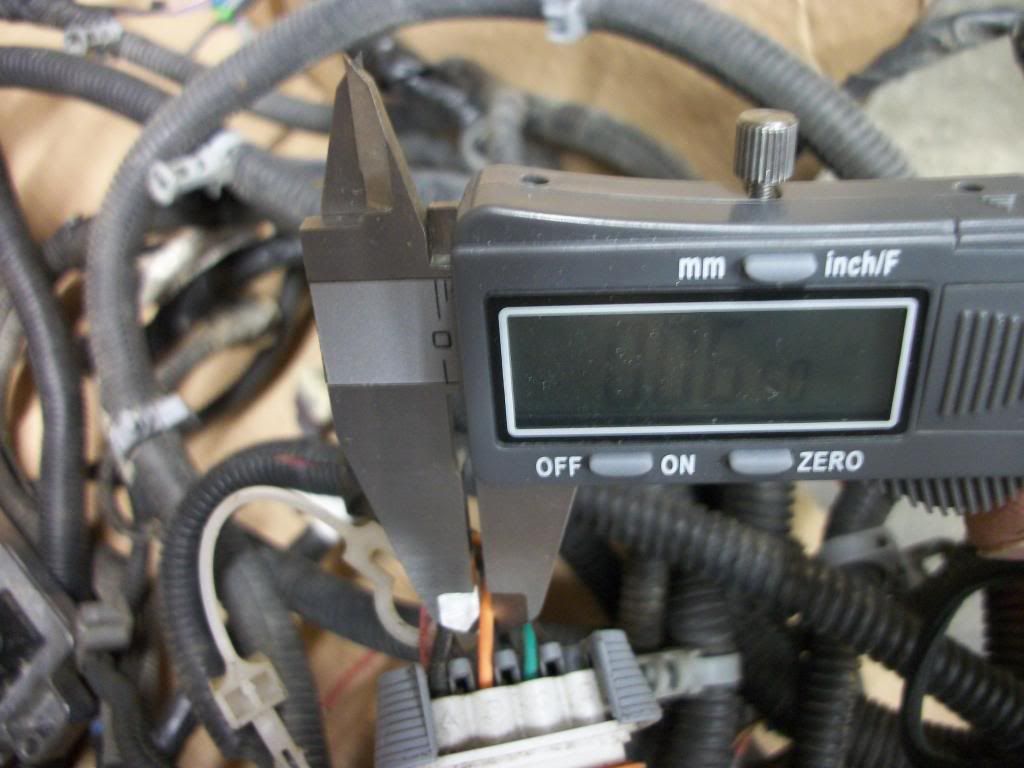

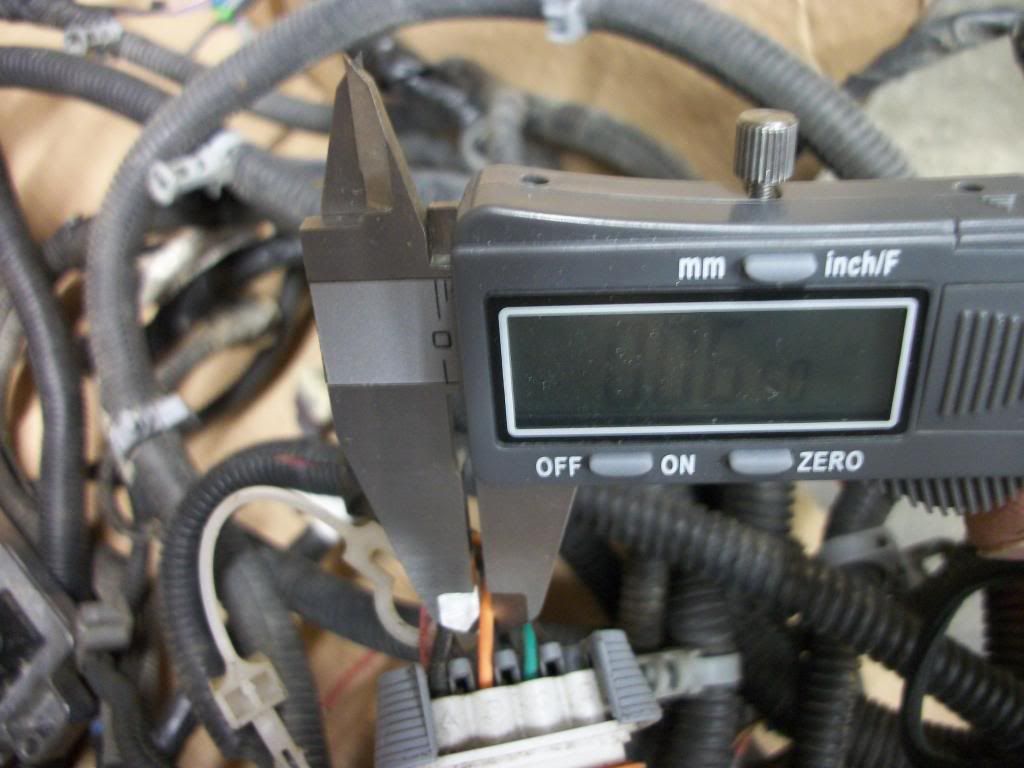

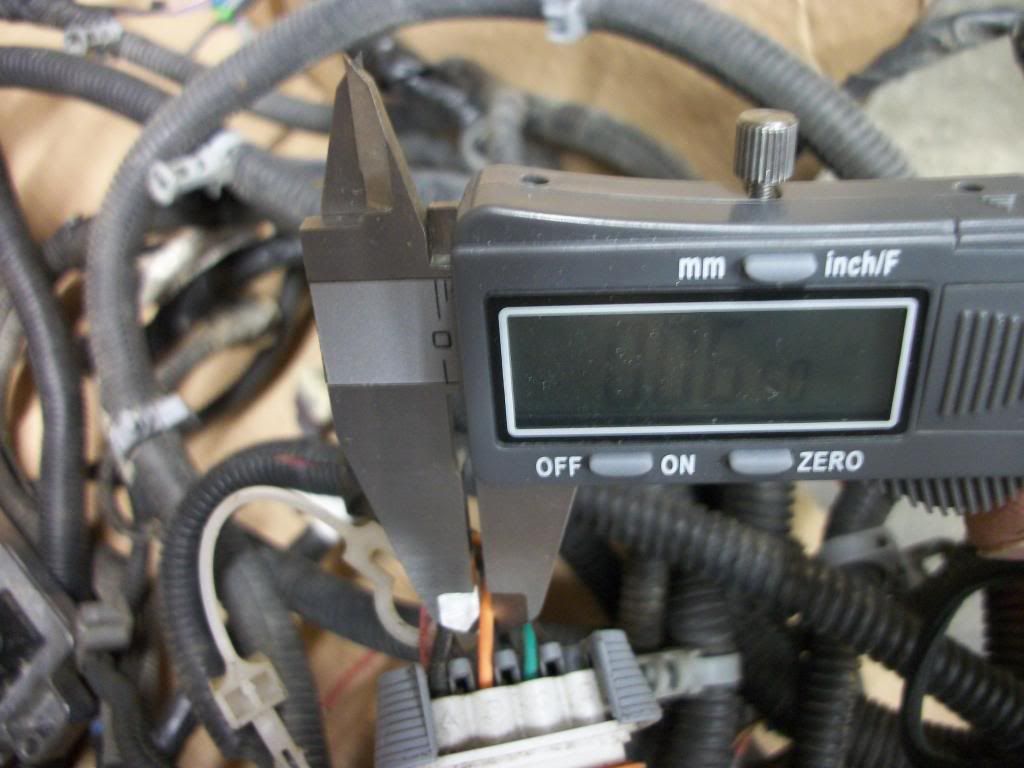

GM did change the specs on the GEN 4 engines. However, this is a GEN 3 harness. Moreover, GM went to 20 AWG on the ignition control and coil control wires, not 22. The newer schematics do not have the gauges listed, so I broke out the digital caliper and took some pics for you. The harness I measured is the harness from a 09 truck application sent to me to be fixed after it was sent somewhere else. The power supply wiring (ignition and ground) are both 18 ga.. Even then you will not find a 22 AWG wire supplying the injector and coil splice.

Lastly, just because something was used on a newer system does not mean that it automatically supersedes the previous rendition. For example, an LT1 only had 1 coil. Even though it had a 12ga wire supplying it, does that mean because the ls1 only had an 18 ga wire you can just go ahead and update it? Of course not. You should always wire the engine for the generation applicable schematics. Here are the pics for your reference.

Lastly, just because something was used on a newer system does not mean that it automatically supersedes the previous rendition. For example, an LT1 only had 1 coil. Even though it had a 12ga wire supplying it, does that mean because the ls1 only had an 18 ga wire you can just go ahead and update it? Of course not. You should always wire the engine for the generation applicable schematics. Here are the pics for your reference.

#27

I hate to hear that. If you have any more questions post up, Ill help the best I can.

__________________

Standalone LS Swap Harnesses IN STOCK!

LSX, LTX Stand alone swap harnesses. S10 LSX conversion PLUG AND PLAY harnesses, 24x conversion PLUG AND PLAY harnesses. LT1 to LSX PLUG AND PLAY Harnesses.

sales@bp-automotive.com

www.bp-automotive.com

1-888-467-4491

Standalone LS Swap Harnesses IN STOCK!

LSX, LTX Stand alone swap harnesses. S10 LSX conversion PLUG AND PLAY harnesses, 24x conversion PLUG AND PLAY harnesses. LT1 to LSX PLUG AND PLAY Harnesses.

sales@bp-automotive.com

www.bp-automotive.com

1-888-467-4491

#28

11 Second Club

iTrader: (11)

Join Date: Jan 2004

Location: Gallitzin, Pa

Posts: 469

Likes: 0

Received 0 Likes

on

0 Posts

I called SSP wiring today and talked with the owner Bill. He told me that the wiring to the coil connector is spec at 22ga and that there may be an issue with the 12v (pink) wire going to the coils. He admitted that in the past they had some wire with too few strands that caused this issue. Iam going to try and run a dedicated wire with 12v to see if it fixes the issue. I have to say after talking to SSP that they are very willing to help out and even offered to bench test the harness for me and replace anything that is wrong.

#30

So I checked all the wires going to the coil sub harness. they all check out and I even ran dedicated wires (I used the factory gm wires in a good LS harness I had) to each coil and a good 12v source strait from the battery. Im seriously starting to think this is not an issue with the harness at all but something else. Im going to start simple tomorrow by checking all the grounds etc. I dont know what else to think but bad PCM?? Im seriously out of ideas.....

Last edited by 70TWO NOVA; 03-19-2013 at 09:53 AM.

#31

Curious how one should duplicate the original factory splices then? It was an absolute b!tch to removed the heat shrink that was covering the original splices on the ground wiring or coil pack wiring but it seemed like there were no signs of any kind of solder or small crimp sleeves inside. Looked as if the wires were bunched together then the heat shrink its self shrinked down on the wire strands tight to try and make them become one, for the splice.

Ive tried to duplicate the splices by taking one length of wire, lets just say 6in. Then in the middle I removed about an 1.5in of the jacket from the wire. Then I took two to three more lengths of wire and stripped the ends. I then twisted those around the middle split of the 6in wire as tight as possible. I then solder it all together like the pic above. Mine just looks much cleaner and its not as long as the solder joint above.

After that I used two layers of adhesive heat shrink.

#32

Curious how one should duplicate the original factory splices then? It was an absolute b!tch to removed the heat shrink that was covering the original splices on the ground wiring or coil pack wiring but it seemed like there were no signs of any kind of solder or small crimp sleeves inside. Looked as if the wires were bunched together then the heat shrink its self shrinked down on the wire strands tight to try and make them become one, for the splice.

Ive tried to duplicate the splices by taking one length of wire, lets just say 6in. Then in the middle I removed about an 1.5in of the jacket from the wire. Then I took two to three more lengths of wire and stripped the ends. I then twisted those around the middle split of the 6in wire as tight as possible. I then solder it all together like the pic above. Mine just looks much cleaner and its not as long as the solder joint above.

After that I used two layers of adhesive heat shrink.

Ive tried to duplicate the splices by taking one length of wire, lets just say 6in. Then in the middle I removed about an 1.5in of the jacket from the wire. Then I took two to three more lengths of wire and stripped the ends. I then twisted those around the middle split of the 6in wire as tight as possible. I then solder it all together like the pic above. Mine just looks much cleaner and its not as long as the solder joint above.

After that I used two layers of adhesive heat shrink.

What you are talking about is called a sonic weld. The copper cable is welded together, this the fastest way to achieve a solderless splice. There are two ways that splices have been manufactured in the past 15 years. The newest is the sonic welding, and previously manufacturers used a crimp for the splice. These are the two methods of achieving a solderless splice, unfortunately there isnt any hand tool for achieving a solderless crimp. So if you do it by hand you have to use the crimp, then solder the connection and use delphi adhesive heatshrink.

You should use the delphi or something that becomes hard when it cools, this isolates the splice from all vibration and prevents the splice from breaking.

__________________

Standalone LS Swap Harnesses IN STOCK!

LSX, LTX Stand alone swap harnesses. S10 LSX conversion PLUG AND PLAY harnesses, 24x conversion PLUG AND PLAY harnesses. LT1 to LSX PLUG AND PLAY Harnesses.

sales@bp-automotive.com

www.bp-automotive.com

1-888-467-4491

Standalone LS Swap Harnesses IN STOCK!

LSX, LTX Stand alone swap harnesses. S10 LSX conversion PLUG AND PLAY harnesses, 24x conversion PLUG AND PLAY harnesses. LT1 to LSX PLUG AND PLAY Harnesses.

sales@bp-automotive.com

www.bp-automotive.com

1-888-467-4491

#35

Waiting on my harness from Bill, this is one of the reasons that I chose to go with BP - his attention to detail seems to be top notch.....and he's a helluva guy to deal with.

#36

I would steer clear from SSP... I have been bent hard by Steve Hiltner in the past. Not sure who Bill is but just beware. What a total waste of human space.

http://www.yellowbullet.com/forum/sh...d.php?t=450605

http://www.yellowbullet.com/forum/sh...d.php?t=450605

#39

__________________

Standalone LS Swap Harnesses IN STOCK!

LSX, LTX Stand alone swap harnesses. S10 LSX conversion PLUG AND PLAY harnesses, 24x conversion PLUG AND PLAY harnesses. LT1 to LSX PLUG AND PLAY Harnesses.

sales@bp-automotive.com

www.bp-automotive.com

1-888-467-4491

Standalone LS Swap Harnesses IN STOCK!

LSX, LTX Stand alone swap harnesses. S10 LSX conversion PLUG AND PLAY harnesses, 24x conversion PLUG AND PLAY harnesses. LT1 to LSX PLUG AND PLAY Harnesses.

sales@bp-automotive.com

www.bp-automotive.com

1-888-467-4491