changing pinion yoke?

#21

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,240

Likes: 0

Received 79 Likes

on

70 Posts

Crush sleeve is there to keep the inner race from rotating and to insure proper torque readings when checking rotating preload, it also holds the nut tight against the bearing assembly. Without the crush collar there is no force against the nut, think about it. This is a precision setup assembly, wheel bearings are not.

Wheel bearings you mentioned are not torqued to such a spec and don't require precision set up BUT they do require a lock of some type to retain the adjustment nut.

I have something else to mention, when you go through engineering school and are hired to design such a assembly and are qualified to make such statements DO SO. Till then please don't sway anyone to follow you into HELL.

Wheel bearings you mentioned are not torqued to such a spec and don't require precision set up BUT they do require a lock of some type to retain the adjustment nut.

I have something else to mention, when you go through engineering school and are hired to design such a assembly and are qualified to make such statements DO SO. Till then please don't sway anyone to follow you into HELL.

I have that 3 or 4 piece prybar set from harbor freight. You can fit one (i use one of the longer ones) and the socket inside the front of the yoke, position it where it will hit the ground or the underside of the car and start turning your torque wrench and make sure its stable then get your torque. Done it this way many times.

#22

TECH Fanatic

iTrader: (1)

but why do we measure stretch on them ?

when you tighten the lug nuts on your wheels, do you know the wheel studs stretch?

when you tighten the pinion nut, and you are applying 500+ lb/ft of torque to overcome and crush the crush sleeve, you are stretching the pinion shaft. I can even provide you the math behind it and relatively exact amount of elongation of the pinion shaft if you like.

torque-tension and hooke's law is not fancy.

#23

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,240

Likes: 0

Received 79 Likes

on

70 Posts

Dude stop, Its not a constant 500lbs on holding pressure and a pinion nut is a **** of a lot bigger then a rod bolt. Jesus. An even if it did stretch it would stretch ONLY the threaded section first and its naturally gonna be the smallest and weakest.

#24

TECH Fanatic

iTrader: (1)

keep taking the tech out of ls1tech.

and you guys wonder why your **** breaks or vibrates like hell.

once i correct the bullshit sold to me by you ******* guys car is sold and i'm gone and you can keep driving your junk in one direction.

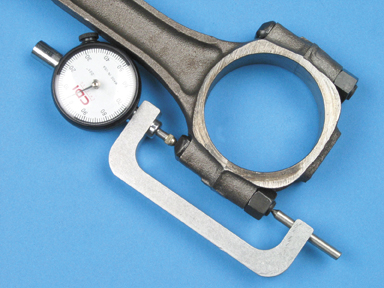

i dare someone ask me why the backing plate is bent in the attached pic, let's make this really interesting.

and you guys wonder why your **** breaks or vibrates like hell.

once i correct the bullshit sold to me by you ******* guys car is sold and i'm gone and you can keep driving your junk in one direction.

i dare someone ask me why the backing plate is bent in the attached pic, let's make this really interesting.

#26

keep taking the tech out of ls1tech.

and you guys wonder why your **** breaks or vibrates like hell.

once i correct the bullshit sold to me by you ******* guys car is sold and i'm gone and you can keep driving your junk in one direction.

i dare someone ask me why the backing plate is bent in the attached pic, let's make this really interesting.

and you guys wonder why your **** breaks or vibrates like hell.

once i correct the bullshit sold to me by you ******* guys car is sold and i'm gone and you can keep driving your junk in one direction.

i dare someone ask me why the backing plate is bent in the attached pic, let's make this really interesting.

NOTHING you have ever posted up is truth, being such YOU must be dreaming this crap up. Good Luck Dood

#27

Yes do what he says, I have built hundreds of rear ends and that is how I would do it in this case, and don't believe the stretch dude, the only thing getting stretched is the truth.