What causes spun bearings? How to fix it?

#1

Had a very loud knock in my LS1, pulled it down and a rod bearing spun. Now I'm wondering why this happened, and how do i prevent it in the future? Even after it spun there was decent oil pressure. Is it from over powering what the rod bolts can handle, they stretch and allow the bearing to spin? Maybe some trash got in the bearing?

My other question is do they make oversize rod bearings? I quickly measured the crank with a set of calipers, and it looks like the diameter of the crank is about .010" smaller where the bearing ground into it. I plan on going with aftermarket rods and pistons, but I'm wondering if i can have the crank ground down and polished, then run oversize bearings? If so, does this weaken the crank?

My other question is do they make oversize rod bearings? I quickly measured the crank with a set of calipers, and it looks like the diameter of the crank is about .010" smaller where the bearing ground into it. I plan on going with aftermarket rods and pistons, but I'm wondering if i can have the crank ground down and polished, then run oversize bearings? If so, does this weaken the crank?

#3

Old School Heavy

iTrader: (16)

Had a very loud knock in my LS1, pulled it down and a rod bearing spun. Now I'm wondering why this happened, and how do i prevent it in the future? Even after it spun there was decent oil pressure. Is it from over powering what the rod bolts can handle, they stretch and allow the bearing to spin? Maybe some trash got in the bearing?

My other question is do they make oversize rod bearings? I quickly measured the crank with a set of calipers, and it looks like the diameter of the crank is about .010" smaller where the bearing ground into it. I plan on going with aftermarket rods and pistons, but I'm wondering if i can have the crank ground down and polished, then run oversize bearings? If so, does this weaken the crank?

My other question is do they make oversize rod bearings? I quickly measured the crank with a set of calipers, and it looks like the diameter of the crank is about .010" smaller where the bearing ground into it. I plan on going with aftermarket rods and pistons, but I'm wondering if i can have the crank ground down and polished, then run oversize bearings? If so, does this weaken the crank?

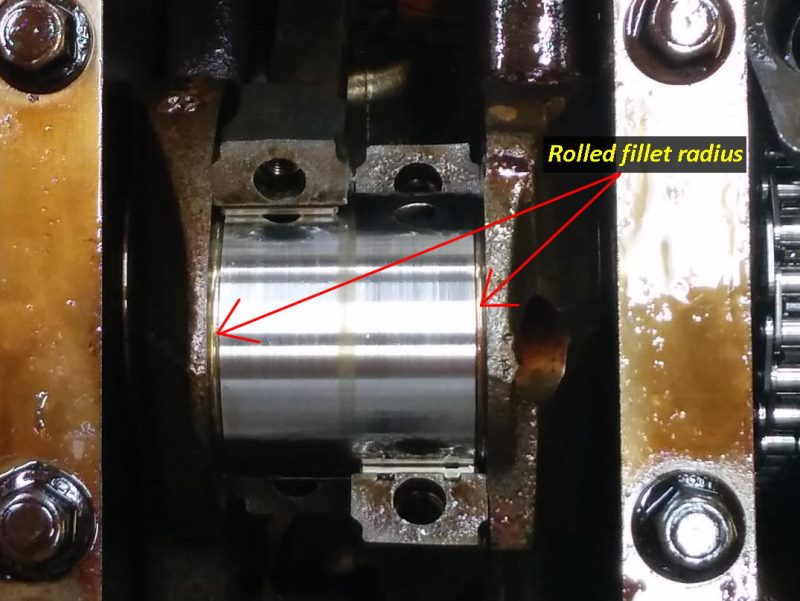

Crankshafts can be ground to smaller journal size to correct surface damage. The LS1 crankshaft can be ground down for use with undersize bearings. Just be sure that the rolled fillet radius on the sides of the journal were not damaged when the bearing failed. Here is a picture that depicts the rolled fillet radius:

Also, make sure that whomever grinds your crank has the proper knowledge and correctly radiused grinding stone so that this area is not ground during the refinishing of the crankshaft.

If that area of the crank is damaged, I would get another.

Toss the connecting rod that had the failed bearing in the recycling bin. Have the remaining 7 connecting rods checked for size and roundness. Since you had a bearing failure, you may consider replacing the rod bolts in the remaining 7 connecting rods. If you do, have them all resized after the rod bolt installation. Some on here may tell you that is not neccessary, but I personally recommend that the connecting rods are always checked and or resized for proper size and roundness after replacing the fasteners.

#4

speedtrigger, thank you for your advice. I will have to check the radius on the crank, but I'm guessing it is bad. The bearing got flattened out and actually widened to the point it got into the rod next to it. Why is this radius so important? is that what controls how much oil can escape from the bearing? thus regulating pressure etc...

You mention close inspection will help figure it out. What do i need to inspect and look for? I will probably be replacing the crank, rods and pistons but am curious to the cause.

When i get home tonight I am going to retorque the rod cap and check to see if it is out of round. Will probably check the other rods as well.

This leads me to more questions, once going with aftermarket rods and bearings (or even aftermarket stroker crank) do I need to increase the clearances? If so what is recommended? Will the crank manufactures have recommendations on their cranks?

Also if the clearances are increased I'd assume I need to upgrade to either a high pressure or high volume pump. What is recommended for which application? If i stick to running stock tolerances, I'd assume run a replacement LS6 pump?

You mention close inspection will help figure it out. What do i need to inspect and look for? I will probably be replacing the crank, rods and pistons but am curious to the cause.

When i get home tonight I am going to retorque the rod cap and check to see if it is out of round. Will probably check the other rods as well.

This leads me to more questions, once going with aftermarket rods and bearings (or even aftermarket stroker crank) do I need to increase the clearances? If so what is recommended? Will the crank manufactures have recommendations on their cranks?

Also if the clearances are increased I'd assume I need to upgrade to either a high pressure or high volume pump. What is recommended for which application? If i stick to running stock tolerances, I'd assume run a replacement LS6 pump?

#5

Old School Heavy

iTrader: (16)

speedtrigger, thank you for your advice. I will have to check the radius on the crank, but I'm guessing it is bad. The bearing got flattened out and actually widened to the point it got into the rod next to it. Why is this radius so important? is that what controls how much oil can escape from the bearing? thus regulating pressure etc...

#6

I finally got some pictures of the crank and the bearings. It looks like the crank radius is find and didn't get touched, so I think the crank is okay to be ground down. Let me know what you think.

Looking around it seems as if most people suggest bearing clearances between .002 and .0025" on the mains and rods for an aluminum block. With the larger clearance I was thinking about running the Meiling 10295 high pressure oil pump. Is this recommended with an f-body oil pan? its not going to drain the oil pain with a high pressure pump is it?

thanks for all the help. I want to make sure going back together this thing is built right and won't have issues in the future.

Looking around it seems as if most people suggest bearing clearances between .002 and .0025" on the mains and rods for an aluminum block. With the larger clearance I was thinking about running the Meiling 10295 high pressure oil pump. Is this recommended with an f-body oil pan? its not going to drain the oil pain with a high pressure pump is it?

thanks for all the help. I want to make sure going back together this thing is built right and won't have issues in the future.

Trending Topics

#11

Looking at the crank and measuring it looks like it will need a .020" cut and polish for it to work properly. I know you can get bearings for this, but at this point I was concerned with the strength and integrity of the crank.....

#12

I got the rest of the motor torn down and found two more rods with bad bearings. However I have never seen a bearing like this. They are pitted instead of scared or scratched. What would cause this? I’d almost think it was detonation, but the top of the pistons looks fine, and if the detonation was bad enough to cause that you would think the stock cast pistons wouldn’t hold up.

The other odd thing is the bearings that look like this almost seems as they shrunk... If you hold the bearing in the rod the bearing is way too small as seen in the picture. It is the oddest thing i have ever seen.

The other odd thing is the bearings that look like this almost seems as they shrunk... If you hold the bearing in the rod the bearing is way too small as seen in the picture. It is the oddest thing i have ever seen.

#15

Moderator

iTrader: (20)

Normally when you have looser bearing clearances, you will want to use a higher volume pump. More oil gets pumped per revolution of the crank, so oil pressure is increased from idle on up the RPM range, unlike a "high pressure" pump which generally just uses a spring to create higher peak oil pressure.