Hydraulic Roller Lifters

#1

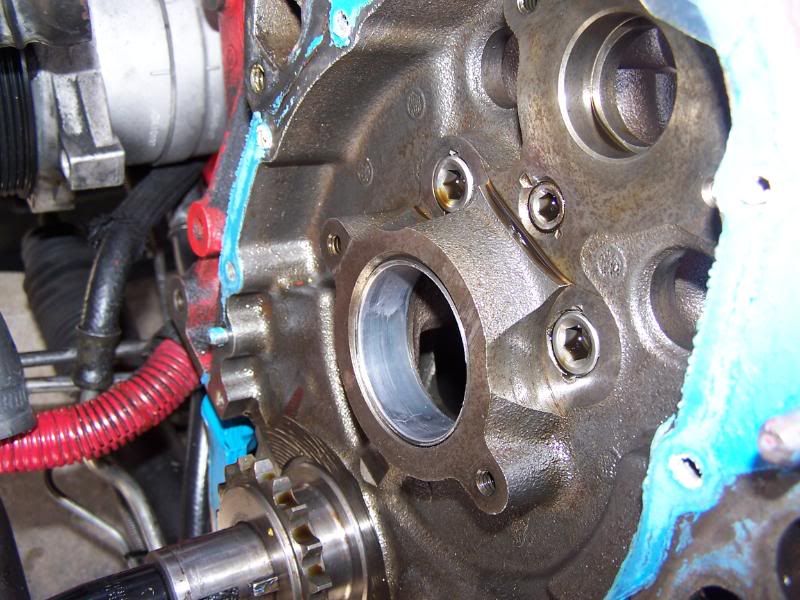

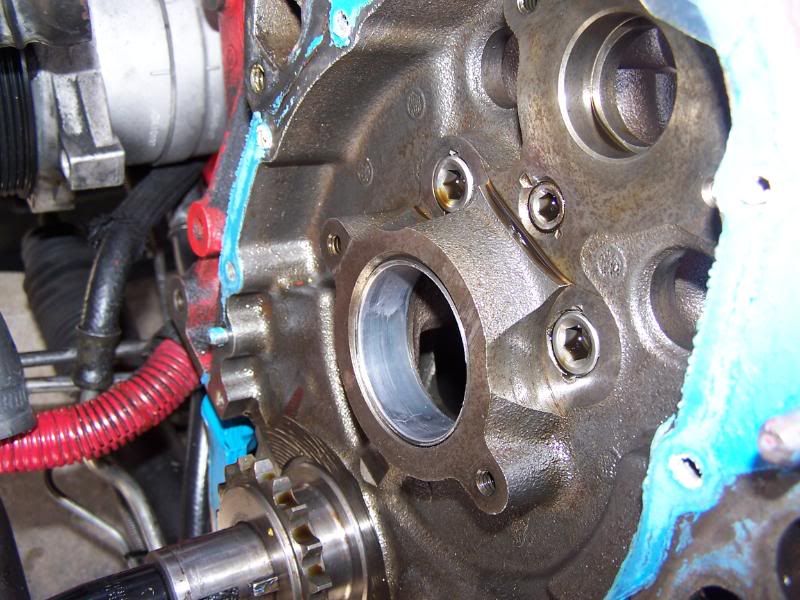

Time for another question. I have a recently rebuilt engine, about 2k miles on it, and there is a slight tick on the drivers side around the middle of of the valve train when it gets hot. I have adjusted the rockers a couple times and it is quiet as a mouse when cold and warming up but when it gets "hot" operating temp after sitting in traffic or half hour or so of driving (not overheating) it ticks. I have the motor pulled apart right now so while it was apart I decided to inspect the lifters. All 16 have what I would consider normal wear

Just slight polished looking areas where the machined surface has worn but no major wear.

However 7 of the 16, almost half have some pitting on the roller the worst of all being the #5 Exhaust. (about where I hear the tick by the way but I know the pitting on the roller won't make a tick)

Most have only a few pits on them. To me this looks like there was some contaminants present when the engine was assembled. Especially since 9 of the rollers are perfect, 5 have two or three pits, 1 is moderate and 1 (the one I showed in the photo) looks severe. Plus the oil was changed at 500 miles break in, 1000 miles and once more around 1700 miles on the engine. It was broke in, first 1000 miles with conventional oil (changed once at 500) and changed to Mobil 1 fully synthetic at 1000 miles and 1700 miles (only because I had torn the engine down partially)

I tried to push in on the inner spring with an old pushrod after they had been drained of oil for a couple days and I couldn't budge any of them by hand. I am assuming this means they are all still strong as far as the spring goes but I am not sure how to go about testing the hydraulic lifters. Do I need to replace any, some or all of the roller lifters? Also I never got a part number from the shop as to which roller lifters these are so does anyone recognize them? I think they may be the GM stock LS lifters but not sure. If I only need to replace the ones with pitting on the rollers I obviously need to figure out which lifters I have. If I have to replace all the lifter what would be a good replacement lifter? I am making moderate hp (400-500) N/A not planning to boost and primarily street driven.

Thanks again for the help I know several of you have been helping me on several issues here lately and I appreciate your experience and time.

Just slight polished looking areas where the machined surface has worn but no major wear.

However 7 of the 16, almost half have some pitting on the roller the worst of all being the #5 Exhaust. (about where I hear the tick by the way but I know the pitting on the roller won't make a tick)

Most have only a few pits on them. To me this looks like there was some contaminants present when the engine was assembled. Especially since 9 of the rollers are perfect, 5 have two or three pits, 1 is moderate and 1 (the one I showed in the photo) looks severe. Plus the oil was changed at 500 miles break in, 1000 miles and once more around 1700 miles on the engine. It was broke in, first 1000 miles with conventional oil (changed once at 500) and changed to Mobil 1 fully synthetic at 1000 miles and 1700 miles (only because I had torn the engine down partially)

I tried to push in on the inner spring with an old pushrod after they had been drained of oil for a couple days and I couldn't budge any of them by hand. I am assuming this means they are all still strong as far as the spring goes but I am not sure how to go about testing the hydraulic lifters. Do I need to replace any, some or all of the roller lifters? Also I never got a part number from the shop as to which roller lifters these are so does anyone recognize them? I think they may be the GM stock LS lifters but not sure. If I only need to replace the ones with pitting on the rollers I obviously need to figure out which lifters I have. If I have to replace all the lifter what would be a good replacement lifter? I am making moderate hp (400-500) N/A not planning to boost and primarily street driven.

Thanks again for the help I know several of you have been helping me on several issues here lately and I appreciate your experience and time.

Last edited by AirborneZ28; 04-29-2011 at 05:18 PM. Reason: wrong part mentioned

#3

Looks like dirt to me, what does the cam look like? Block the oil filter by-pass when you put it back together. It's in the thing the filter screws on. Just knock out the metal flapper and thread the hole for a plug, go from the top down, base of the plug towards the filter.

Al 95 Z28

Al 95 Z28

#4

Well yeah, that is what I meant by contaminants, dirt, sand, grit or anything else that somehow got in there during assembly. If it was something in the oil like dirt falling into the oil filler on the valve cover then getting circulated through the engine you wouldn't expect to see 9 of the 16 looking brand new. If it was something that got into the head area when the covers were off for adjusting valves you would think the worst ones would all be near each other and the worst was #5 ex and next worse #8 ex. I looked at the cam through the lifter hole with a flashlight and mirror and then got out the inspection camera and the surface looks good but I am going to pull the cam out to really inspect it better.

I had thought about eliminating the stock oil cooler which would also obviously eliminate the oil filter by-pass and putting an after market oil cooler on it. Is this just a waste of time and money then?

I had thought about eliminating the stock oil cooler which would also obviously eliminate the oil filter by-pass and putting an after market oil cooler on it. Is this just a waste of time and money then?

#5

Well regardless of the cause, is the damage on that roller too severe and need to be replaced? If the pitting calls for a new lifter, is there any amount of pitting that is ok? Out of the 7 that have pitting only 2 have pitting like this the other 5 have just a few very small pits. I have searched for articles about the comp cams LT LS style lifter the 850 and 875 magnum series and have heard good things, bad things and yes, even ugly things. I looked at the Morel Lifters which apparently are one of the best for these engines but they are more than twice the cost of the comp cams lifters and seem to be for engines that will see higher hp and stress. I did find some photos of the Comp 875 lifters that looked like mine and other photos of the 875 lifters that looked very different. Is there a new style, old style thing going on here? Any help from someone who knows lifters would be appreciated.

#6

Village Troll

iTrader: (2)

Absolutely replace the lifters. If the cam lobes look anything like that it should be replaced too. No amount of pitting on the rollers or lobes is acceptable wear. From what I understand LS7 lifters are very reasonably priced and are just fine for any hyd. roller application. The spring pressure w/in the lifter has no engine operational value while other than to keep the plunger at the top of the lifter body when there is no preload.

#7

Surprised as I am the cam looks like new. I found no pitting anywhere but I was a bit surprised after taking off the timing gear. Before I took the front plate loose that holds the cam in, I pulled the cam forward and it moved quite a distance. I put the dial guage on it and the total travel from fully back to fully forward was just under .2" on the guage, litterally about 3/16 inch movement. Is this normal play when the timing gear and chain are off or is the thrust bearing severly worn? I can find information of measuring the lobe wear by measuring lift with the dial guage but nothing on measuring end thrust.

Also, when you say LS7 lifters do you mean the LT / LS style lifters (as they are described by comp cams) part number 850 or 875 or is there a different lifter I should be looking for as a LS7 lifter. If you are talking about the 850 or 875 which would be better for my application? I know the 875 magnum series is supposed to help limit improper positioning of the internal piston as the lifter gets "pumped up" (yes that is directly from comp cams description) but I have seen some threads where people say they are trouble and you are much better off going with the 850.

Final question I noticed when I was cleaning the cam bearing at the front and to me it looks like wear, when you see the different colored metal from the top layer being worn off in certain areas. The bearing journal on the cam look great so would this be just normal wear for 2k miles? I can take a picture and post it if necessary.

Also, when you say LS7 lifters do you mean the LT / LS style lifters (as they are described by comp cams) part number 850 or 875 or is there a different lifter I should be looking for as a LS7 lifter. If you are talking about the 850 or 875 which would be better for my application? I know the 875 magnum series is supposed to help limit improper positioning of the internal piston as the lifter gets "pumped up" (yes that is directly from comp cams description) but I have seen some threads where people say they are trouble and you are much better off going with the 850.

Final question I noticed when I was cleaning the cam bearing at the front and to me it looks like wear, when you see the different colored metal from the top layer being worn off in certain areas. The bearing journal on the cam look great so would this be just normal wear for 2k miles? I can take a picture and post it if necessary.

Trending Topics

#8

Sorry I had a minor surgical proceedure on Monday so I have been out of the loop for a couple days. Here is the photo of the cam bearing. To me it looks worn and most likely contaminated with dirt or some other debris during installation based on the speckled and scratched looking areas and what looks to me as excessive wear for less than 2000 miles since rebuild. I am planning on replacing the cam bearings, hopefully myself.

Amazingly to me the cam bearing journals look brand new. I know that is because they are made of a much harder metal but with this much wear on the bearing and roller lifters I was still pleasantly surprised.

Also I found there was no thrust bearing on the cam when I pulled it out. The total amount of play was 0.19" after the timing gear was removed. I figured since there was no thrust bearing on the cam then it must not use one but I contacted my local chevy dealer service department anyway to see if I could get confirmation one way or another. I was told by the service manager that he didn't know but suggested doing a search online and when I did a search for 93 Camaro LT1 engine cam thrust bearing I found that there is indeed such a bearing. The part number I found was Cloyes Gear 9-220 wear plate cam thrust bearing or 9-220B for the bronze version and the thickness was 0.15", which would obviously cut my play from 0.19" to a much more reasonable sounding 0.04". I contacted Crane Cams e-mail tech support as that is who made my cam and they responded saying that the LT1 engine does not use a cam thrust bearing and the end play is supposed to be measured with the timing gear on. I know alot of you, just like myself, had someone else build your engine for you but if there are any LT1/LT4 engine builders out there that can help shed some light on this I would greatly appreciate it.

Also if anyone has a part number for those LS7 lifters I am still trying to sort that part out. Comp Cams lists the 850 and 875 as LT/ LS1, LS2 LS6 hydraulic roller lifters but when I search on Jegs, Summit, eBay or even Google search for LS7 lifters it still comes up as Comp Cams 850 or 875. I was contacted by private message and offered a new set of really nice ones for a very reasonable price by another member here but unfortunately they were still outside my budget. The LS style lifters I found from Comp Cams is less than $200 shipped and with all this other stuff I am finding that I have to replace I just don't have the budget for another $150 for the lifters alone. I am pushing 500 or less N/A power and plan to use it primarily for street and shows and I have already put way too much into this build thanks to a less than honest shop owner. I do greatly appreciate the offer though and I know they are great lifters and a very reasonable price.

Amazingly to me the cam bearing journals look brand new. I know that is because they are made of a much harder metal but with this much wear on the bearing and roller lifters I was still pleasantly surprised.

Also I found there was no thrust bearing on the cam when I pulled it out. The total amount of play was 0.19" after the timing gear was removed. I figured since there was no thrust bearing on the cam then it must not use one but I contacted my local chevy dealer service department anyway to see if I could get confirmation one way or another. I was told by the service manager that he didn't know but suggested doing a search online and when I did a search for 93 Camaro LT1 engine cam thrust bearing I found that there is indeed such a bearing. The part number I found was Cloyes Gear 9-220 wear plate cam thrust bearing or 9-220B for the bronze version and the thickness was 0.15", which would obviously cut my play from 0.19" to a much more reasonable sounding 0.04". I contacted Crane Cams e-mail tech support as that is who made my cam and they responded saying that the LT1 engine does not use a cam thrust bearing and the end play is supposed to be measured with the timing gear on. I know alot of you, just like myself, had someone else build your engine for you but if there are any LT1/LT4 engine builders out there that can help shed some light on this I would greatly appreciate it.

Also if anyone has a part number for those LS7 lifters I am still trying to sort that part out. Comp Cams lists the 850 and 875 as LT/ LS1, LS2 LS6 hydraulic roller lifters but when I search on Jegs, Summit, eBay or even Google search for LS7 lifters it still comes up as Comp Cams 850 or 875. I was contacted by private message and offered a new set of really nice ones for a very reasonable price by another member here but unfortunately they were still outside my budget. The LS style lifters I found from Comp Cams is less than $200 shipped and with all this other stuff I am finding that I have to replace I just don't have the budget for another $150 for the lifters alone. I am pushing 500 or less N/A power and plan to use it primarily for street and shows and I have already put way too much into this build thanks to a less than honest shop owner. I do greatly appreciate the offer though and I know they are great lifters and a very reasonable price.