tcc problems again

#1

Ok guys, I am about at y witts end here. I am yet again having tcc lockup trouble. I finished this 2006 AWD Suburban rebuild Wednesday evening. When I got the truck, it would move for a little ways then stop moving. Reverse or forward gears went completely away. Having let the truck sit for a few weeks, I went out and drove it around the yard and into my garage. Wasn't exactly where i wanted it so I backed it out and repositioned it. This time it would only move at idle and very slowly. So once it hit the needed position I stopped and started my teardown. I noticed that the fluid was heavily mixed with water so I advised the owner to install a cooler that bypassed the radiator. He was going to put a radiator in later he says. Got the trans out and torn down. Much rusty parts found inside so I had to replace a bunch of things. Spring cages and what not. After cleaning the case and deleting the 4th accumulator, I blew out the orifices and reseated and drip checked the checkball capsule. Then I assembled the lower portion of the geartrain and snapped the output shaft in place. The case bushing was also replaced. Along with the sungear and reaction shaft bushings. The input drum was pressure checked for leaks at 135 psi and for the first time in a while, there were zero leaks. not even the pistons leaked. Took it apart and changed the lower spring cage and pistons. green oring too. The clutches all looked ok just old and worn. No evidence of excessive heat. Oh this was also a 4L65E with the 7 clutch pack and 5 pinion planitaries. Reassembly went well and the post pressure check was satisfactory. Reverse drum was changed out due to the old one just having too much rust damage despite being perfectly flat. Next came the pump. Took it apart and cleaned it. Then vacuum checked the valves. All came out in spec. installed a sonnax late style boost valve anyway and moved on. Nothing but a slight shadow where the old pump had ridden. Still had all of the blueing on the pump slide. Changed it all out for new pump hardware anyway and then checked the bushings. No slop in the pump bushings at all. Literally felt like brand new so I opted for not replacing them. Cleaned the valve body and oddly enough, none of the springs were rusty. Vacuum checked all of the spot on the sonnax sheet and only had issues with one end plug and one abuse bore plug. AFL, TCC, Abuse Valves and 3-2 were all good to go. I did the checkball mod to the tcc valve train to lock it in place and put an oringed end plug in that bore for good measure. Put it all back together and back in the truck and went for a test drive. I had a pronounced 2-3 shift flare and no tcc lockup. Naturally I was deflated but went back and decided to drop the pan. Double checked the valve body again and found nothing. Pulled the tcc valve and installed the sonnax valve. Pulled the boost valve and the upper oring came out in two pieces. I was like HIZZA!!!! I found the issue. Replaced the oring and installed a drop in transgo PR valve for good measure and went back for another test drive. Now the shifts are good but there is no tcc lockup. Well actually there is a small amount of apply but I mean a very small amount. You have to be watching the data to catch it. It will knock about 100 rpm off of the converter slip but never go lower than 45 rpm and the lightest of throttle. After a bit of drivin(less than 5 minuets) the epc maxes out and the tcc stops trying to apply. Code for component slippage pops up. So Now I am really deflated. Take it out to check the oring. Perfect. Take the pump out to check the teflon rings. Perfect. Double check the vacuum on the pump. Perfect. Decided to change the stator pushing and my driver slipped and damaged the inside of the stator. Replaced it from another pump with the same speed sensor hole and checked the bushing for clearance. Felt great so I left in. Did not want a repeat of the last deal. I wnt through and check all of the passages in the pump for converter feed flow and nothing is clogged. Put everything back together but I a hesitant to try it again. I have found nothing to cause the tcc not to apply. This is also a new converter so I dont know what to do now. Last time I had delayed converter charge which illuminated the issue after getting some education for Mr. Frank. This time I have perfect converter charge and perfect stall speed. No delay in first or reverse engagement. No wrong gear starts. No overly soft shifts or anything. Even the temps are agreeable. I don't know what to check now.

#2

TECH Enthusiast

That's a decently long paragraph ya got there.

#3

LS1Tech Sponsor

Ok you will hate me , But put a stock early TCC enable valve in it and springs , by early Do not mean pre PWM but the 95 up and before they changed them to the new stye . If it works I will tell you why ,

__________________

Frank formerly of Performabuilt, Now just me, What can I build for you today? Call or message me. Click sig pic for my facebook

Frank formerly of Performabuilt, Now just me, What can I build for you today? Call or message me. Click sig pic for my facebook

Last edited by FranksCustomTrans; 08-23-2024 at 05:37 PM.

The following users liked this post:

reubone (08-23-2024)

#4

ok would this be the style with the recessed lower valve that the spring fits into or the style with the little nipples on both ends? I also have some fitzall valves if you think that might do the same thing. Iíll look through my stock and see what I have. Thank you for the suggestion.

#6

LS1Tech Sponsor

We are talking about different valve. I assume you have already dealt with the converter regulator valve, I am speaking of the TCC enable valve in the pump

#7

Trending Topics

#9

LS1Tech Sponsor

#10

ok so no that didn't work, or at least it doesn't seem to have worked. The vehicle is still raised and I cannot force the tcc solenoid to engage to the converter clutch to any noticeable degree. I have stalled other vehicles fine doing this method with working converter clutches so I know the operation is sound. Also the readout on the data log is not correct. The tcc slip reading is in negativce rpm after 2nd gear. I can force each gear and track its mph increase as well as sudden rpm drop as each gear engages. Possibly it is a faulty reading from the vss due not all wheels spinning the same. AWD was not designed specifically to operate with all four wheels off the ground. Now I have to start digging back into this issue so the first thing is to drop a check ball into the tcc solenoid to check hydraulic integrity if that is a thing. If it fails Im not sure what that will really be telling me other than there is a problem somewhere in the hydraulics or the converter.

#11

Ooook sooo the checkball thing diagnostic test didn't work either. Or not how I had hoped. I'm guessing that have a hydraulic circuitry failure, at some level, somewhere. The test went as follows. Drain pan and remove. Remove PWM solenoid and tcc solenoid. Remove solenoid filter and drop in checkball. Just for kicks I poked the filter back in to see if it would install and it would not. Reinstall the solenoid, Tighten the bolts. Reinstall the PWM, Pan and fill with fluid. Start the truck an lock the breaks. Drop into reverse and we got instant reverse engagement(tires not spinning), a little drop in rpm that quickly recovered and it settled into a nice steady idle. Moved to neutral, then to drive. Same deal. So now I guess the pump or converter or a bushing somewhere or a valve. Or something.

I just don't know what to do. These last two really have shaken my confidence in all this testing equipment I have invested in. I am vacuum testing everything and anything lower than 16 inches gets addressed. Either in after market solutions or by installing o-rings. I used to just order rebuilt valvebodies and pumps for every rebuild but started getting units that were missing parts or didn't vacuum check up to spec. If I had to fix supposed rebuilt units then what is the point I thought. Hence my current situation. I have nothing close by for transmission parts or service and have to order and wait for everything. I was hoping to make a fruitful business and change that in my area but dang this hard.

Back to the current issue. What would you guys do to chase this problem down? Thank you

I just don't know what to do. These last two really have shaken my confidence in all this testing equipment I have invested in. I am vacuum testing everything and anything lower than 16 inches gets addressed. Either in after market solutions or by installing o-rings. I used to just order rebuilt valvebodies and pumps for every rebuild but started getting units that were missing parts or didn't vacuum check up to spec. If I had to fix supposed rebuilt units then what is the point I thought. Hence my current situation. I have nothing close by for transmission parts or service and have to order and wait for everything. I was hoping to make a fruitful business and change that in my area but dang this hard.

Back to the current issue. What would you guys do to chase this problem down? Thank you

#12

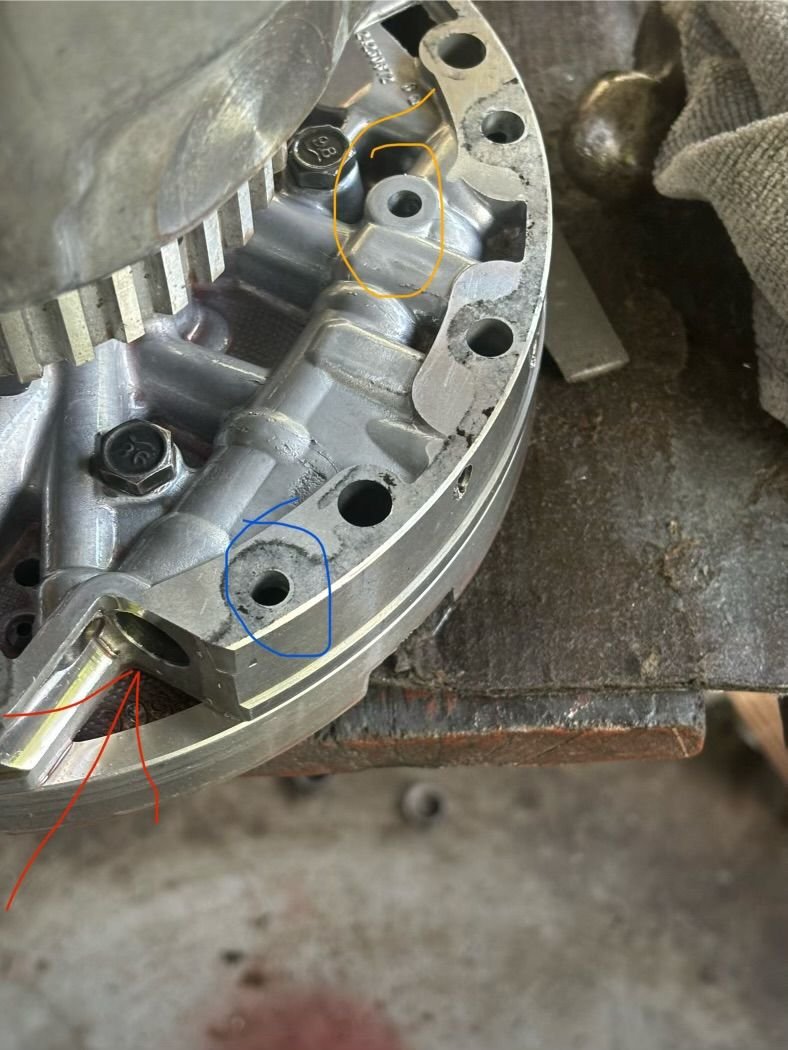

Ok, so if I blow air here or here I get nothing out of the input shaft. If I stroke this valve as far as I can hold it, I get air from the input shaft from hereand here. Only here do I get any push back on the valve. Is this normal or do I need to check something else?

#13

LS1Tech Sponsor

Ok sorry that didn't do it, What I had into a one time was he late valve and the sonnax valve both would actually travel to far in bore and vent the converter apply oil , So it would be like lockup for a split second then it was gone.

Sorry that was not it ,

A few things

Since you have it out . Disassemble pump check that orifice to the TCC solenoid area in pump is not restricted or blocked , It is very tiny and the smallest thing can block . that is whY I aM so very meticulous about all being clean. But even so I have been trying to figure some way to put a fine screen here , I know how but have yet to find a source for the small screens, They in the VB of my ford escort trans and I have seen them in nissans too but they do not see to eb a servacle part buy themselves.

Shine a flashlight into the solenoid bore see if you see light or anything obstructing the tiny hole. If so use a wire or tiny drill bit or pin to clear. Do not dril larger as that will cause random lockup at high line even when not commanded. Ideally you should be able to apply 30ish pounds of air to that orifice and with solenoid in bore turned on or with ball in it you should see valve move.

Wish I had seen that the valve swap failed and a pressure test can tell alot to. If you engage the solenoid you should see a corresponding movement of line pressure with it

You have the Converter regulator valve blocked forward so that is not the issue.You have oringed the cap at end of it so that is not the issue.

So we are left with one of 4 possibilities , The orifice is blocked or restricted in pump and the TCC ENABLE valve is not moving when solenoid applied. The solenoid is bad, The converter is bad, Bad erosion of pump at the orifice (least likely)

Me since you already have it out I would check that orifice as I described. Replace converter . Put it back in and see what happens.

. Put it back in and see what happens.

I will say looking at post all over that overall quality of converters even by some bigger names has declined over the last while. Not calling any names just noticed from post in various places mostly converter clutch delaminations, Also make sure the little screen in pump is clear if you see little flakes all in it that would point also to converter.

SORRY THE VALVE DIDN'T WORK I WAS HOPEFUL

Sorry that was not it ,

A few things

Since you have it out . Disassemble pump check that orifice to the TCC solenoid area in pump is not restricted or blocked , It is very tiny and the smallest thing can block . that is whY I aM so very meticulous about all being clean. But even so I have been trying to figure some way to put a fine screen here , I know how but have yet to find a source for the small screens, They in the VB of my ford escort trans and I have seen them in nissans too but they do not see to eb a servacle part buy themselves.

Shine a flashlight into the solenoid bore see if you see light or anything obstructing the tiny hole. If so use a wire or tiny drill bit or pin to clear. Do not dril larger as that will cause random lockup at high line even when not commanded. Ideally you should be able to apply 30ish pounds of air to that orifice and with solenoid in bore turned on or with ball in it you should see valve move.

Wish I had seen that the valve swap failed and a pressure test can tell alot to. If you engage the solenoid you should see a corresponding movement of line pressure with it

You have the Converter regulator valve blocked forward so that is not the issue.You have oringed the cap at end of it so that is not the issue.

So we are left with one of 4 possibilities , The orifice is blocked or restricted in pump and the TCC ENABLE valve is not moving when solenoid applied. The solenoid is bad, The converter is bad, Bad erosion of pump at the orifice (least likely)

Me since you already have it out I would check that orifice as I described. Replace converter

. Put it back in and see what happens.

. Put it back in and see what happens.I will say looking at post all over that overall quality of converters even by some bigger names has declined over the last while. Not calling any names just noticed from post in various places mostly converter clutch delaminations, Also make sure the little screen in pump is clear if you see little flakes all in it that would point also to converter.

SORRY THE VALVE DIDN'T WORK I WAS HOPEFUL

The following users liked this post:

reubone (08-24-2024)

#14

Thank you for giving me some more things to check. I will give it a shot and report my findings. I always take a vacuum reading of the orifice to make sure it is less than 10 inches. I sometimes see them close to 20 before blowing them out and getting it back down again. Itís the same one that you vacuum check per the sonnax diagram correct?

#15

LS1Tech Sponsor

Thank you for giving me some more things to check. I will give it a shot and report my findings. I always take a vacuum reading of the orifice to make sure it is less than 10 inches. I sometimes see them close to 20 before blowing them out and getting it back down again. It’s the same one that you vacuum check per the sonnax diagram correct?

__________________

Frank formerly of Performabuilt, Now just me, What can I build for you today? Call or message me. Click sig pic for my facebook

Frank formerly of Performabuilt, Now just me, What can I build for you today? Call or message me. Click sig pic for my facebook

Last edited by FranksCustomTrans; 08-24-2024 at 09:36 PM.

The following users liked this post:

Cory79 (09-01-2024)

#19

LS1Tech Sponsor

Ok It's not clear but I see alot of dull finish area on pump back which points to leaking badly and the Heat marking of the slide would point to a warped leaky pump I think you have a pump issue and yes good test for orifice.

as for to far that is if the valve stokes past the bore at spring side far enough to exhaust that last land. Most do not do it . But have run into a few over the years and will dump the apply oil . Of note when I pointed this out to sonnax they were aware of it. Seems sometimes the bore was drilled deeper in some pumps and with high line and it can push the valve to that point. My solution was a washer to prevent it traveling that far.

So I am leaning to a bad leaky pump in orifice ares and as you can see a little leaky can have large effect here.

as for to far that is if the valve stokes past the bore at spring side far enough to exhaust that last land. Most do not do it . But have run into a few over the years and will dump the apply oil . Of note when I pointed this out to sonnax they were aware of it. Seems sometimes the bore was drilled deeper in some pumps and with high line and it can push the valve to that point. My solution was a washer to prevent it traveling that far.

So I am leaning to a bad leaky pump in orifice ares and as you can see a little leaky can have large effect here.