4l60 valve body gaskets ??

#21

TECH Enthusiast

iTrader: (1)

My rebuild thread titled "another 4l60e rebuild thread" has a lot of pictures, including ones relating to to the pump, stator, reverse input drum, plastic tab, etc.:

https://ls1tech.com/forums/automatic...-thread-4.html

https://ls1tech.com/forums/automatic...-thread-4.html

Last edited by mrvedit; 05-05-2015 at 08:41 PM. Reason: Inserted the thread link

#22

Teching In

Thread Starter

Join Date: Apr 2015

Location: calif

Posts: 41

Likes: 0

Received 0 Likes

on

0 Posts

yes ive looked at the awhile back ...see the last pic in post #50 that is what im doin with the drums , set on a table just like that but theres a gap between the plastic thrust and the reverse drum yours has no gap , my plastic thrust well fall off the stator ... on to the drum ...

#23

TECH Enthusiast

iTrader: (1)

That's really odd. The stator sits on nothing but the spacer and needle bearing.

A couple things I would double check:

-Are the pump and reverse input drum fully seated past all 6 teflon rings?

-Bushings driven in to the correct depth. I don't remember if any of those bushings could potentially cause your problem, but it wouldn't hurt to check. Some of the bushings are very picky about their depth.

And of course, when mrvedit returns, he can tell you if 3/16 is within tolerance for the gap. It's possible you're just fine.

A couple things I would double check:

-Are the pump and reverse input drum fully seated past all 6 teflon rings?

-Bushings driven in to the correct depth. I don't remember if any of those bushings could potentially cause your problem, but it wouldn't hurt to check. Some of the bushings are very picky about their depth.

And of course, when mrvedit returns, he can tell you if 3/16 is within tolerance for the gap. It's possible you're just fine.

#24

Moderator

As bbond105 wrote, the reverse drum will fit into and snug up to the prongs in the sun shell. That will lift it significantly from a simple mock-up where it is resting on the input drum. When fully assembled I suspect it only has .030 of end play which will keep the plastic thrust washer seated on the stator shaft.

I have never measured reverse drum end-play , but after you install the pump, you can see the reverse drum through various holes in the case and could use a screwdriver to move it back and forth to estimate its end-play.

If you are really concerned, do a test-assembly without the band to confirm that the reverse drum has very limited end-play.

I have never measured reverse drum end-play , but after you install the pump, you can see the reverse drum through various holes in the case and could use a screwdriver to move it back and forth to estimate its end-play.

If you are really concerned, do a test-assembly without the band to confirm that the reverse drum has very limited end-play.

#26

Teching In

Thread Starter

Join Date: Apr 2015

Location: calif

Posts: 41

Likes: 0

Received 0 Likes

on

0 Posts

ok here it is , like bbond said the sun shell pushes the reverse drum closer to the plastic thrust washer.the reverse drum will fit into and snug up to the prongs in the sun shell..went by a trans shop and thats what they showed me ...got a new drum so almost ready to go need a outer lip seal for the reverse piston the one in the kit was cut bad , it was wavy .... so what i was looking at was a waste, sorry ... but i didnt know ... only reason i saw that, was checkin the stator ....hopefully thats right ... now should i trust that the endplay is right or check it ??? if i check it whats the easiest or best way ? thanks again ... might have more questions .....

#28

TECH Addict

As mrvedit said, you should always check the end play, but especially after replacing the stator support and reverse drum. Just leave the O-ring off the pump, but be sure to install the gasket. You don’t even have to install the reverse drum. Don’t forget to install the selective washer and bearing on the input drum.

Set up a dial indicator to the end of the input shaft and push all the way in. Zero the dial indicator and pull out on the input shaft. The reading on the dial indicator will be your end play. Disassemble and adjust accordingly and recheck.

Set up a dial indicator to the end of the input shaft and push all the way in. Zero the dial indicator and pull out on the input shaft. The reading on the dial indicator will be your end play. Disassemble and adjust accordingly and recheck.

#30

Moderator

The spec in the ATSG manual is .015 to .036. I personally aim for the low end as I don't want parts hammering each other in my high HP setup. A local builder told me that even .010 is enough after a complete rebuild, especially with new parts, as the play will increase a bit as parts settle into their final position while driving. Parts will expand with heat and the static end play ensures you never reach zero end play during hot operation.

#33

Teching In

Thread Starter

Join Date: Apr 2015

Location: calif

Posts: 41

Likes: 0

Received 0 Likes

on

0 Posts

i checked the endplay it was at .021 .. so i changed it to .014 ... i put the reverse drum in and set the stator shaft in , theres still a gap between the plastic thrust washer and the reverse drum ... the more endplay you take out (make tighter) the bigger the gap gets .... so whats at the other end of the end play or what would hold the sun shell up closer to the reverse drum .. replacing all the thrust bearings help??? and theres end play in the output shaft , you can push the output shaft in and out about a snap ring gap ... is there a way to adjust output endplay .. i cant think theres that much slop in the reverse drum ... im i missin something???

#34

Moderator

The output shaft end play sounds OK. IIRC Sonnax has a (thin) shim set for reducing output shaft end play, but you have to remove the entire low/reverse section to install them.

Like Mr Bond I have never measured the reverse drum gap. Since you think it is excessive, did you replace the sun shell and/or reverse drum. If not both, perhaps the tabs have bent or worn, letting the reverse drum sit in deeper than it should.

There is nothing wrong with a .021 end play either. I keep it lower because I'm running 600+ HP.

Like Mr Bond I have never measured the reverse drum gap. Since you think it is excessive, did you replace the sun shell and/or reverse drum. If not both, perhaps the tabs have bent or worn, letting the reverse drum sit in deeper than it should.

There is nothing wrong with a .021 end play either. I keep it lower because I'm running 600+ HP.

#35

Teching In

Thread Starter

Join Date: Apr 2015

Location: calif

Posts: 41

Likes: 0

Received 0 Likes

on

0 Posts

is the a number for output shaft end play? it had a beast sun shell with 50,000 miles on it that shouldnt be bad , i got a reverse drum from the trans shop that they refurbished they said they are checked out and trued that they are good , thats all they offered when i asked for one ...since everything is riding on thrust bearings replacing those might tighten things up ?? if i put thinner selective washers that moves the stator shaft closer to the reverse drum but makes more end play . the pins that hold the plastic thrust to the stator shaft almost come out of there holds, are there thicker plastic thrust washers?? sorry for all the questions but it just doesnt look right ... thanks . because the reverse drum rubbed on the stator shaft at the sealing rings i want to make sure that theres nothing wrong ... is there something worn thats lets the input drum move down in the case ?? thanks !

#36

Moderator

Perhaps the Trans shop will let you borrow a different reverse drum.

No such thing as a thicker plastic thrust washer as this is an unusual problem.

The selective washer will compensate for any wear in the torrington bearings, although they should be replaced during a major rebuild.

Can you post a picture of how far the reverse drum fits into the tabs of the sun shell?

I have a Beast and an old reverse drum and will compare with your picture.

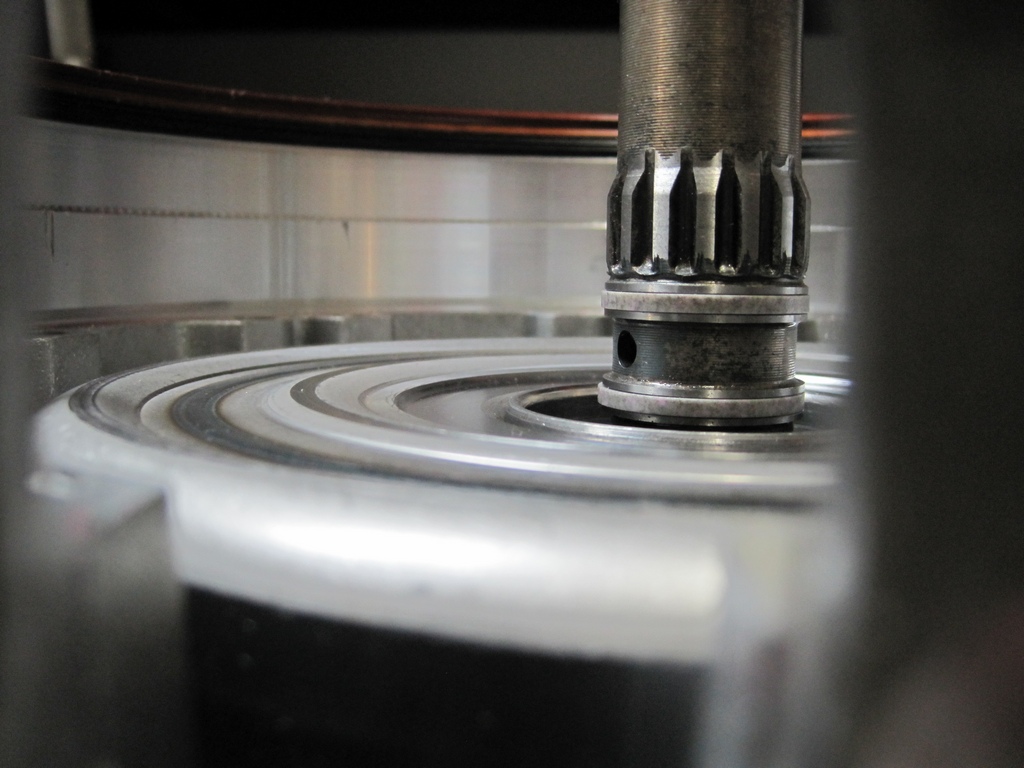

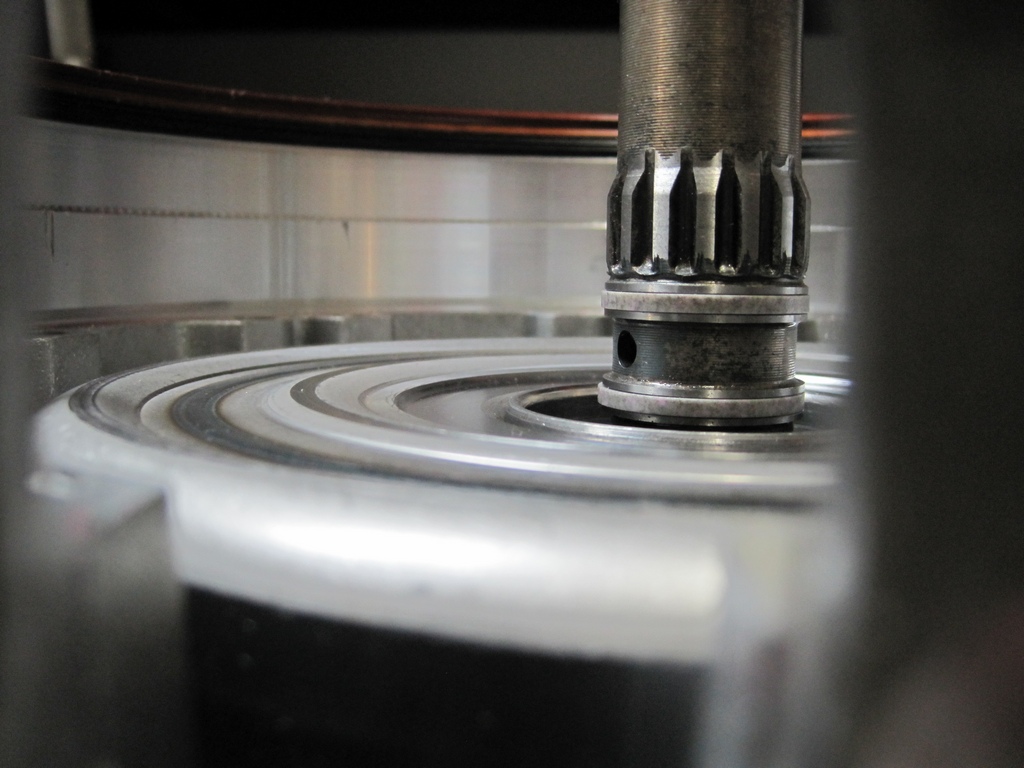

This pictures shows that my reverse drum sits just below the case lip that holds the pump:

No such thing as a thicker plastic thrust washer as this is an unusual problem.

The selective washer will compensate for any wear in the torrington bearings, although they should be replaced during a major rebuild.

Can you post a picture of how far the reverse drum fits into the tabs of the sun shell?

I have a Beast and an old reverse drum and will compare with your picture.

This pictures shows that my reverse drum sits just below the case lip that holds the pump:

#37

Moderator

Thinking about it some more, the thickness of the selective washer should not affect the reverse drum position. If it does, then it is hitting the input drum which is a serious NO-NO! Only the sunshell should be holding it up. You should be able to lift the input drum/shaft about 1/10" before the reverse drum starts to lift.

I am starting to wonder if your sun shell is sitting too low due to missassembly.

Try to measure exactly how much end play your output shaft has.

I am starting to wonder if your sun shell is sitting too low due to missassembly.

Try to measure exactly how much end play your output shaft has.

#38

TECH Addict

That’s what I am thinking also. Maybe a thrust washer in the gear set is very worn, wrong one or left out. This would make the sun shell sit too deep or low in the case. If you did not replace all of the thrust washers in the gear set you may want to go ahead and replace them now.

I have never used the Beast sunshell, I prefer the Sonnax Smart Shell, but doesn’t the Beast shell use a different thickness thrust washer than stock?

Did you ever compare your new parts to your olds ones like I suggested in post #20?

I have never used the Beast sunshell, I prefer the Sonnax Smart Shell, but doesn’t the Beast shell use a different thickness thrust washer than stock?

Did you ever compare your new parts to your olds ones like I suggested in post #20?

#39

Teching In

Thread Starter

Join Date: Apr 2015

Location: calif

Posts: 41

Likes: 0

Received 0 Likes

on

0 Posts

yes compared all the parts they are the same , selective washer doesnt hold up the reverse drum i can see that and can lift up on the input till it hits the reverse drum but it moves more then 1/10" .. more like an 1/8 to 3/16 .. as for thrush bearing all in there none felt bad .. but what it does do is let the stator shaft move down closer to the reverse drum , taking up that gap .... the reverse drum does rest on the sun shell ... looks like something needs to come up , sun shell or input drum ... but not sure !!! i do have two different thickness plastic thrust washers , one that was in, the thicker of the two and one that came in a washer kit ...im using the thick one ... il get more infor and be back .... i could prob send pic direct to you but cant post here ... sorry

#40

Moderator

I just estimated the 1/10" from memory; if you have 3/16" that is fine; they just has to be some. Your statement that the selective washer was changing the reverse drum location confused, but I guess you have retracted that.

Currently think your sun shell is sitting a bit on the low side and the prongs on your reverse drum are worn; combined your reverse drum is sitting quite low. If needed I should have time tomorrow evening to experiment and measure a trans build.

(I keep a 4L60E disassembled in my basement just to answer questions like this. )

Currently think your sun shell is sitting a bit on the low side and the prongs on your reverse drum are worn; combined your reverse drum is sitting quite low. If needed I should have time tomorrow evening to experiment and measure a trans build.

(I keep a 4L60E disassembled in my basement just to answer questions like this. )