ls2 mp112 killer deal.

#41

TECH Addict

iTrader: (14)

Join Date: Feb 2007

Location: Owasso, OK

Posts: 2,342

Likes: 0

Received 0 Likes

on

0 Posts

It cant be a 3.0 on the rear blower side. Not with out machining it alot. 3.0-3.1 or.2 really is gonna drop the boost more than a lb1/2. I have a 3.0 6 rib and a 2.8 and 2.6 ill sell. I switched to 8 rib pullys.

With a stock motor.. Overdriven rears,stock balancer and a 3.0 youll be around 9lbs. I had all that but with the od crank and was seeing 13lbs with a reg 112.

Before i built my motor i was pushing 10lbs all day long and was making 485whp/502tq

With a stock motor.. Overdriven rears,stock balancer and a 3.0 youll be around 9lbs. I had all that but with the od crank and was seeing 13lbs with a reg 112.

Before i built my motor i was pushing 10lbs all day long and was making 485whp/502tq

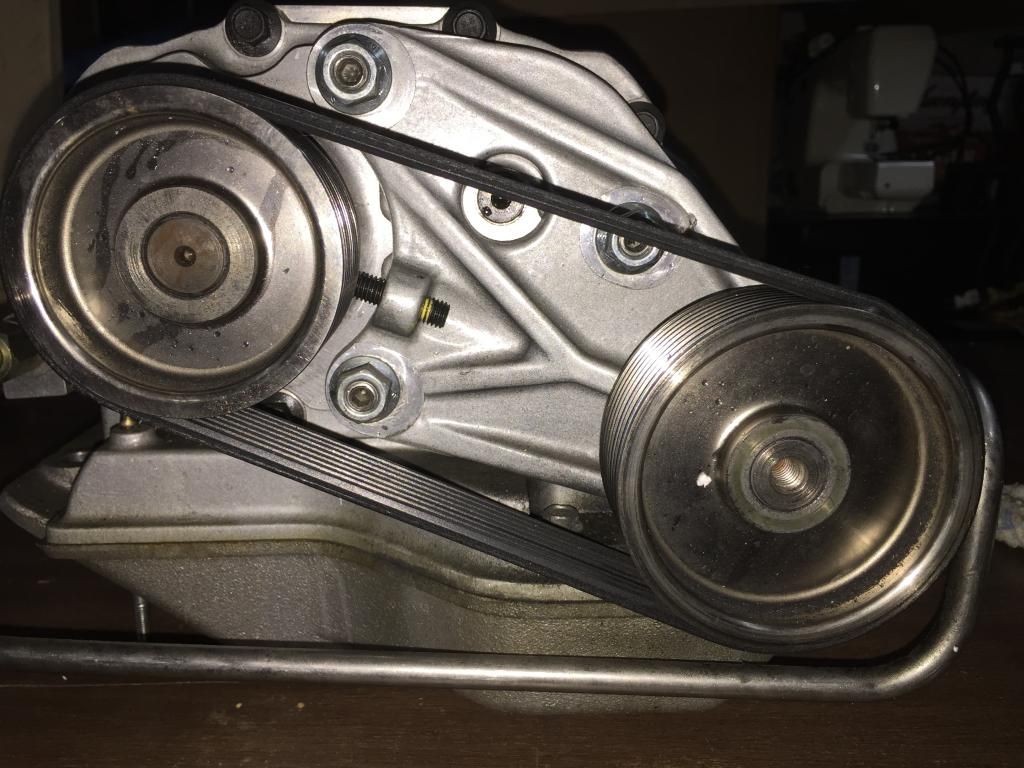

Here is my 3.2 installed the same direction the stockers where.

And here's his flipped. You can see the hub is shorter on the outside of his.

And her you can see the added 1/4" or so of clearance.

I wish I would have noticed this before I cut on my manifold. I've had to remove a lot of material to get this to fit with like 1/64" of clearance.

Last edited by raven154; 02-18-2015 at 01:26 AM.

#43

TECH Addict

iTrader: (14)

Join Date: Feb 2007

Location: Owasso, OK

Posts: 2,342

Likes: 0

Received 0 Likes

on

0 Posts

Nothing other than the pulleys being closer to the firewall. They are flipped for the sole purpose of clearance on the blower side. Just make sure the wire harness that runs behind them once installed is secure and can't move and you should be good.

#45

Update:

I've had the maggie on for a couple weeks now, but haven't been able to run it to redline because I was waiting on an HD tensioner bracket (which finally came in and I installed this morning) and I have to get an exhaust leak before the O2's fixed. Also have to pin the crank to my ATI Super Damper. Everything else is done and I've been driving it but only pushing to about 3500rpm.

Recall that this is an mp112hh with overdriven rears (not 1 to 1, overdriven with the pulleys swapped positions) and a 3.1 front pulley, on an ls6 (with ls2TB.) I was seeing the most boost on my mechanical gauge under load in fifth gear, up to about 8 psi at 3500rpm. Today I took it for a test drive with the HD tensioner and pushed it a little harder, somewhere between 4-5k RPM, and saw 11 psi on the boost gauge. I'm concerned this is too much for my otherwise stock ls6. I think my only option to bring down the boost is a 3.2 or larger pulley on the front. Thoughts? The motor is otherwise stock with 112k miles.

I've had the maggie on for a couple weeks now, but haven't been able to run it to redline because I was waiting on an HD tensioner bracket (which finally came in and I installed this morning) and I have to get an exhaust leak before the O2's fixed. Also have to pin the crank to my ATI Super Damper. Everything else is done and I've been driving it but only pushing to about 3500rpm.

Recall that this is an mp112hh with overdriven rears (not 1 to 1, overdriven with the pulleys swapped positions) and a 3.1 front pulley, on an ls6 (with ls2TB.) I was seeing the most boost on my mechanical gauge under load in fifth gear, up to about 8 psi at 3500rpm. Today I took it for a test drive with the HD tensioner and pushed it a little harder, somewhere between 4-5k RPM, and saw 11 psi on the boost gauge. I'm concerned this is too much for my otherwise stock ls6. I think my only option to bring down the boost is a 3.2 or larger pulley on the front. Thoughts? The motor is otherwise stock with 112k miles.

#46

TECH Enthusiast

iTrader: (4)

Join Date: Apr 2014

Location: San Jose, CA

Posts: 602

Likes: 0

Received 0 Likes

on

0 Posts

I think 10lb is a safe number to stick around on a stock blocks. However you can easily push beyond that, it's done all the time. You hadn't mentioned much about tune, i would focus on that before going any harder.

Maybe set it up for 3.2 and tune it. Then if it looks like there is room for more then try the 3.1

A overdrivven 112 isn't a plug and play and needs some fine tuning to be safe but still nasty

That's just my two cents

Maybe set it up for 3.2 and tune it. Then if it looks like there is room for more then try the 3.1

A overdrivven 112 isn't a plug and play and needs some fine tuning to be safe but still nasty

That's just my two cents

#48

Good to hear that you have it up and running. How about that 12 pack

Update:

I've had the maggie on for a couple weeks now, but haven't been able to run it to redline because I was waiting on an HD tensioner bracket (which finally came in and I installed this morning) and I have to get an exhaust leak before the O2's fixed. Also have to pin the crank to my ATI Super Damper. Everything else is done and I've been driving it but only pushing to about 3500rpm.

Recall that this is an mp112hh with overdriven rears (not 1 to 1, overdriven with the pulleys swapped positions) and a 3.1 front pulley, on an ls6 (with ls2TB.) I was seeing the most boost on my mechanical gauge under load in fifth gear, up to about 8 psi at 3500rpm. Today I took it for a test drive with the HD tensioner and pushed it a little harder, somewhere between 4-5k RPM, and saw 11 psi on the boost gauge. I'm concerned this is too much for my otherwise stock ls6. I think my only option to bring down the boost is a 3.2 or larger pulley on the front. Thoughts? The motor is otherwise stock with 112k miles.

I've had the maggie on for a couple weeks now, but haven't been able to run it to redline because I was waiting on an HD tensioner bracket (which finally came in and I installed this morning) and I have to get an exhaust leak before the O2's fixed. Also have to pin the crank to my ATI Super Damper. Everything else is done and I've been driving it but only pushing to about 3500rpm.

Recall that this is an mp112hh with overdriven rears (not 1 to 1, overdriven with the pulleys swapped positions) and a 3.1 front pulley, on an ls6 (with ls2TB.) I was seeing the most boost on my mechanical gauge under load in fifth gear, up to about 8 psi at 3500rpm. Today I took it for a test drive with the HD tensioner and pushed it a little harder, somewhere between 4-5k RPM, and saw 11 psi on the boost gauge. I'm concerned this is too much for my otherwise stock ls6. I think my only option to bring down the boost is a 3.2 or larger pulley on the front. Thoughts? The motor is otherwise stock with 112k miles.

#49

TECH Fanatic

Update:

I've had the maggie on for a couple weeks now, but haven't been able to run it to redline because I was waiting on an HD tensioner bracket (which finally came in and I installed this morning) and I have to get an exhaust leak before the O2's fixed. Also have to pin the crank to my ATI Super Damper. Everything else is done and I've been driving it but only pushing to about 3500rpm.

Recall that this is an mp112hh with overdriven rears (not 1 to 1, overdriven with the pulleys swapped positions) and a 3.1 front pulley, on an ls6 (with ls2TB.) I was seeing the most boost on my mechanical gauge under load in fifth gear, up to about 8 psi at 3500rpm. Today I took it for a test drive with the HD tensioner and pushed it a little harder, somewhere between 4-5k RPM, and saw 11 psi on the boost gauge. I'm concerned this is too much for my otherwise stock ls6. I think my only option to bring down the boost is a 3.2 or larger pulley on the front. Thoughts? The motor is otherwise stock with 112k miles.

I've had the maggie on for a couple weeks now, but haven't been able to run it to redline because I was waiting on an HD tensioner bracket (which finally came in and I installed this morning) and I have to get an exhaust leak before the O2's fixed. Also have to pin the crank to my ATI Super Damper. Everything else is done and I've been driving it but only pushing to about 3500rpm.

Recall that this is an mp112hh with overdriven rears (not 1 to 1, overdriven with the pulleys swapped positions) and a 3.1 front pulley, on an ls6 (with ls2TB.) I was seeing the most boost on my mechanical gauge under load in fifth gear, up to about 8 psi at 3500rpm. Today I took it for a test drive with the HD tensioner and pushed it a little harder, somewhere between 4-5k RPM, and saw 11 psi on the boost gauge. I'm concerned this is too much for my otherwise stock ls6. I think my only option to bring down the boost is a 3.2 or larger pulley on the front. Thoughts? The motor is otherwise stock with 112k miles.

Your biggest problem I can see at the moment is that you may exceed the factory fueling hard limit within the PCM, which occurs at 512 grams/sec of airflow which equates into a bit over 500 whp on our platforms. Even if everything else is spot on, this hard limit will bite you in the end. The solution here would be to scale the tune (scale the injector size and airflow) to make the PCM think there is less airflow through the motor, which does work quite well, however you will lose resolution at the lower end of the spectrum which can affect daily drivability. A 2 BAR OS would get around this, but that has its own consequences (emissions testing, etc) which we have already discussed.

Also, you really need a boost pump for your fuel system. You replaced the OE 24 lb injectors with 60 lb injectors (note: these are the advertised 3 BAR ratings) which will make it harder for the fuel pump to maintain pressure at the rail at higher RPM. Now that you have boost, the fuel must overcome this manifold pressure as well since the OE system anticipates the fuel is being injected to a vacuum up to ambient atmospheric pressure at WOT. When the manifold is pressurized, it's equivalent to removing that amount of fuel pressure from the rail (ex: 58 psi of fuel being injected into 10 lbs of boost = 48 PSI). One last consideration is the inertial effect of the fuel column in the fuel line. As you accelerate, the fuel pump must be able to overcome the weight of the fuel pushing against it in addition maintaining adequate supply (maintaining adequate supply is the primary consideration). While not usually a consideration, this could be one of those things that breaks the camels back so to speak.

You're also on borrowed time with the crank...the supercharger probably requires 80hp+ at 10 lbs of boost, and once the friction bond of the press on balancer is exceeded it may not ever be right again and require a new crankshaft.

As a last thought, I would scale it back for the simple fact that out of a 10 mile strip of road, it'll probably see max boost for at least 7.8 of those

No offense buddy, but I've ridden with you hahaha!

I got extended so I likely won't be back until next week. Looking forward to see what you've got going on with the V.

Last edited by DMM; 04-12-2015 at 09:03 PM.