LQ4/T56 into 2001 BMW 540i

#61

Nothing much to report, just little things I'm getting together.

Sold both my BMW diffs (2.81 and 3.15), both MAFs, the base rails of my roof rack, and the Camaro (rear sump) oil pan.

I received my ARP head bolts, GM MLS 6.0 headgaskets, LS1 harmonic balancer, starter, water pump, and GTO oil pan over the last week. The top end of the engine is ready to go back together, but the machine shop lost the dowels in the heads, so I had to special order 3 of those (1 was left in the block). Can't assemble it until they get in this weekend. Once I do get those I can finally put the heads back on and torque them down, as well as replace both front and rear main seals as well as a ton of other gaskets I bought. At that point I can put the intake manifold on, and it'll start to look like a real motor (good timing, because I need to know where I'll have issues for fabbing the motor mounts).

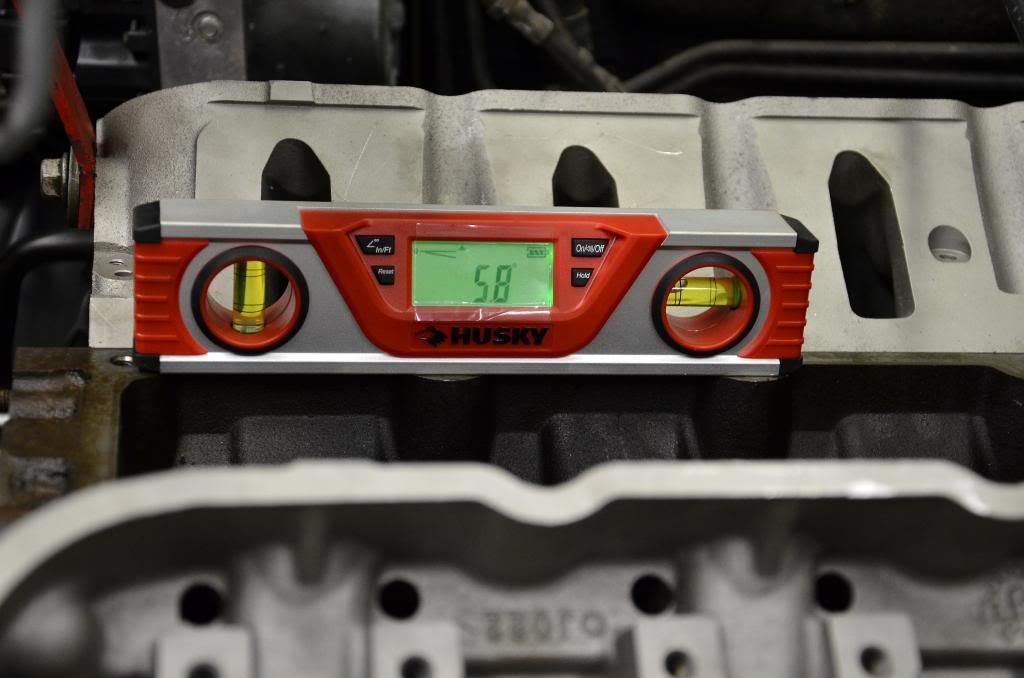

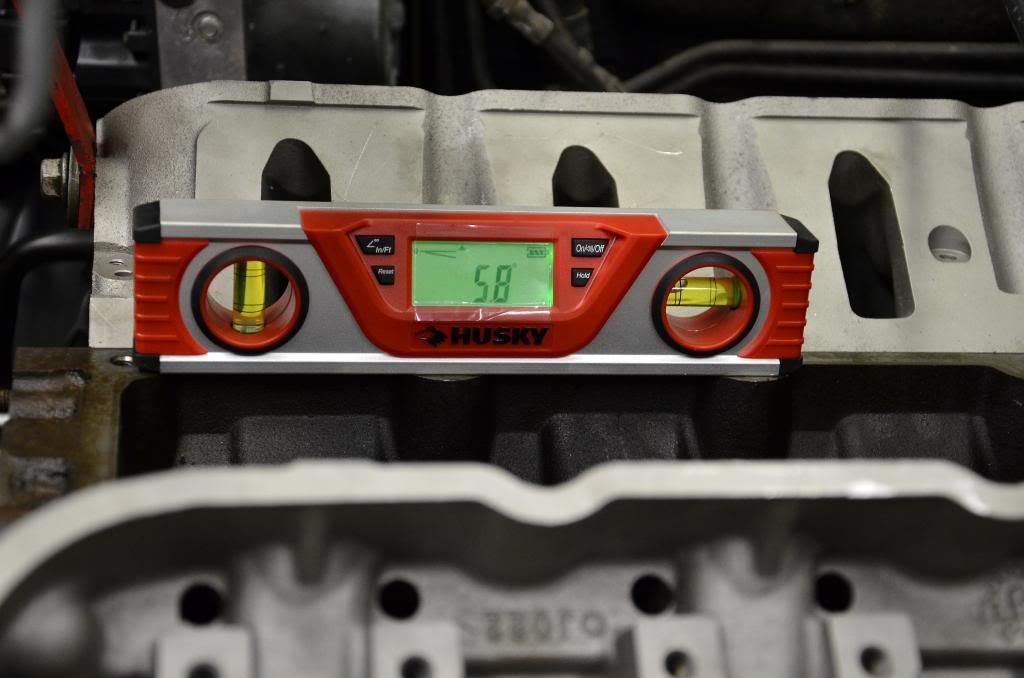

On Saturday, I put the car on some 2x6s I nailed together to raise the car off the ground at all 4 corners. I eyeballed the rough dimensions of the cut on the GTO pan and notched it, test fit, and found that I still need to notch the horizontal portion some more in order for the nose of the motor to come down a few more degrees. With the shifter roughly where it needs to be, the engine is pointing 6* down at the back--I am going for 3*. Having a digital inclinometer accurate to a tenth of a degree is awesome. The motor/pan is resting on a 1" board, so maybe it's a bit overkill as far as spacing from the crossmember, but I am assuming the new stock rubber engine mounts will squish down some when the weight of the drivetrain comes down onto them.

My right angle grinder backing plate fell apart, and Home Depot was already closed, so I wasn't able to finish trimming the pan. Today on lunch I went to the store and picked up the proper backing plate/ring along with an 11/32" drill bit, which I'll need to drill out the boss on the block for the alternator to mount to. I have the LQ4 truck alternator as it came with my motor, but is it the same type as the LS1 style? It looks like any old small car-style alternator. I'll have to see if there's a part number on it and cross reference to see if I can reuse it. I'm still on the hunt for a cheap OEM LS1 alternator bracket.

Buying a used LS1 power steering pump was ehhhhhhhhh, so I found a nice cheap one on Rockauto and grabbed that. I still have to find a pulley. Might yank the pulley off the truck PS pump (if I even still have that in the piles of parts) and see if it's the same diameter (I would assume so).

I had the sheet metal shop at work punch me out a few engine plates, bolted those to the motor. I also grabbed some short lengths of 2" square thick wall tube steel out of the scrap bin, those will be used to make up the driver's side mount around the steering box. I did a rough "from memory" sketch on CAD at work of the driver's side mount. The passenger side will be easier, should be just one length (straight shot from the engine plate to the rubber isolator). My little farmhand MIG welder is wayyyy too shitty to actually weld all the way through and get full penetration so I'll just be tacking the **** out of it and having the shop at work weld it all up for me. exhaust should be okay to weld due to the thinner wall pipe, I'm just a crappy welder, but this will be good practice.

Should have some spare time tomorrow on my day off to finish trimming the GTO pan, maybe start to cut up the tube steel to make the mounts.

Sold both my BMW diffs (2.81 and 3.15), both MAFs, the base rails of my roof rack, and the Camaro (rear sump) oil pan.

I received my ARP head bolts, GM MLS 6.0 headgaskets, LS1 harmonic balancer, starter, water pump, and GTO oil pan over the last week. The top end of the engine is ready to go back together, but the machine shop lost the dowels in the heads, so I had to special order 3 of those (1 was left in the block). Can't assemble it until they get in this weekend. Once I do get those I can finally put the heads back on and torque them down, as well as replace both front and rear main seals as well as a ton of other gaskets I bought. At that point I can put the intake manifold on, and it'll start to look like a real motor (good timing, because I need to know where I'll have issues for fabbing the motor mounts).

On Saturday, I put the car on some 2x6s I nailed together to raise the car off the ground at all 4 corners. I eyeballed the rough dimensions of the cut on the GTO pan and notched it, test fit, and found that I still need to notch the horizontal portion some more in order for the nose of the motor to come down a few more degrees. With the shifter roughly where it needs to be, the engine is pointing 6* down at the back--I am going for 3*. Having a digital inclinometer accurate to a tenth of a degree is awesome. The motor/pan is resting on a 1" board, so maybe it's a bit overkill as far as spacing from the crossmember, but I am assuming the new stock rubber engine mounts will squish down some when the weight of the drivetrain comes down onto them.

My right angle grinder backing plate fell apart, and Home Depot was already closed, so I wasn't able to finish trimming the pan. Today on lunch I went to the store and picked up the proper backing plate/ring along with an 11/32" drill bit, which I'll need to drill out the boss on the block for the alternator to mount to. I have the LQ4 truck alternator as it came with my motor, but is it the same type as the LS1 style? It looks like any old small car-style alternator. I'll have to see if there's a part number on it and cross reference to see if I can reuse it. I'm still on the hunt for a cheap OEM LS1 alternator bracket.

Buying a used LS1 power steering pump was ehhhhhhhhh, so I found a nice cheap one on Rockauto and grabbed that. I still have to find a pulley. Might yank the pulley off the truck PS pump (if I even still have that in the piles of parts) and see if it's the same diameter (I would assume so).

I had the sheet metal shop at work punch me out a few engine plates, bolted those to the motor. I also grabbed some short lengths of 2" square thick wall tube steel out of the scrap bin, those will be used to make up the driver's side mount around the steering box. I did a rough "from memory" sketch on CAD at work of the driver's side mount. The passenger side will be easier, should be just one length (straight shot from the engine plate to the rubber isolator). My little farmhand MIG welder is wayyyy too shitty to actually weld all the way through and get full penetration so I'll just be tacking the **** out of it and having the shop at work weld it all up for me. exhaust should be okay to weld due to the thinner wall pipe, I'm just a crappy welder, but this will be good practice.

Should have some spare time tomorrow on my day off to finish trimming the GTO pan, maybe start to cut up the tube steel to make the mounts.

#64

finished cutting up the pan, it clears the crossmember now.

slapped it on the block.

placed a 1" thick piece of wood under the pan to simulate space between pan and crossmember, and a 1"x1" piece under the pan on top of the steering linkage.

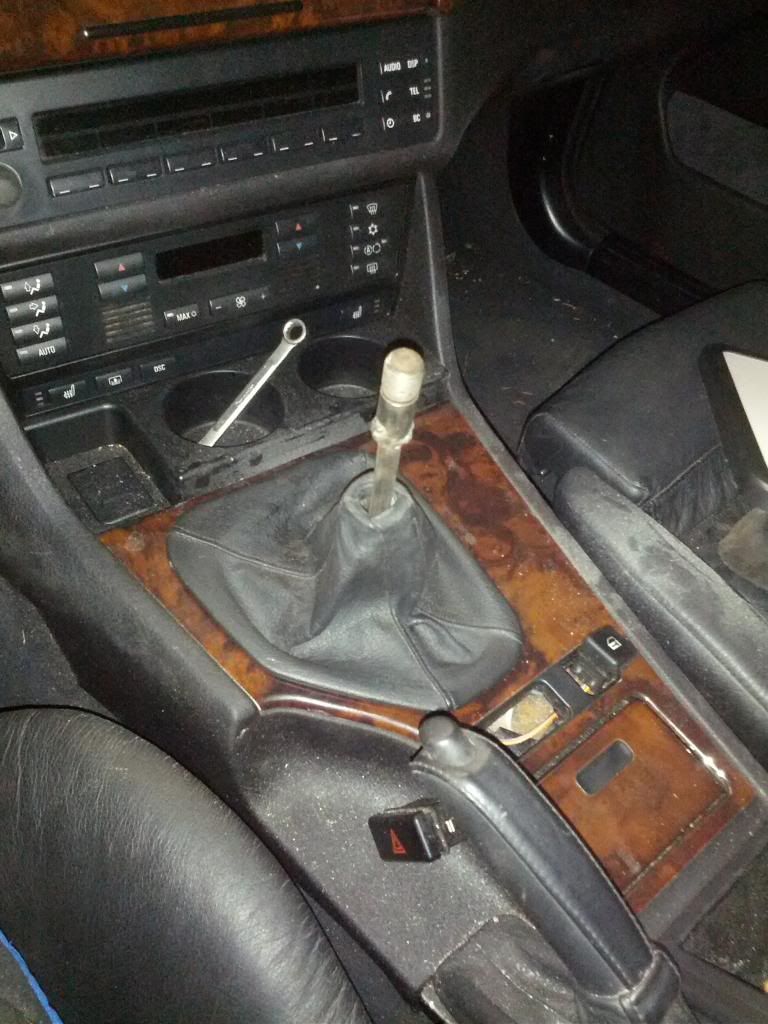

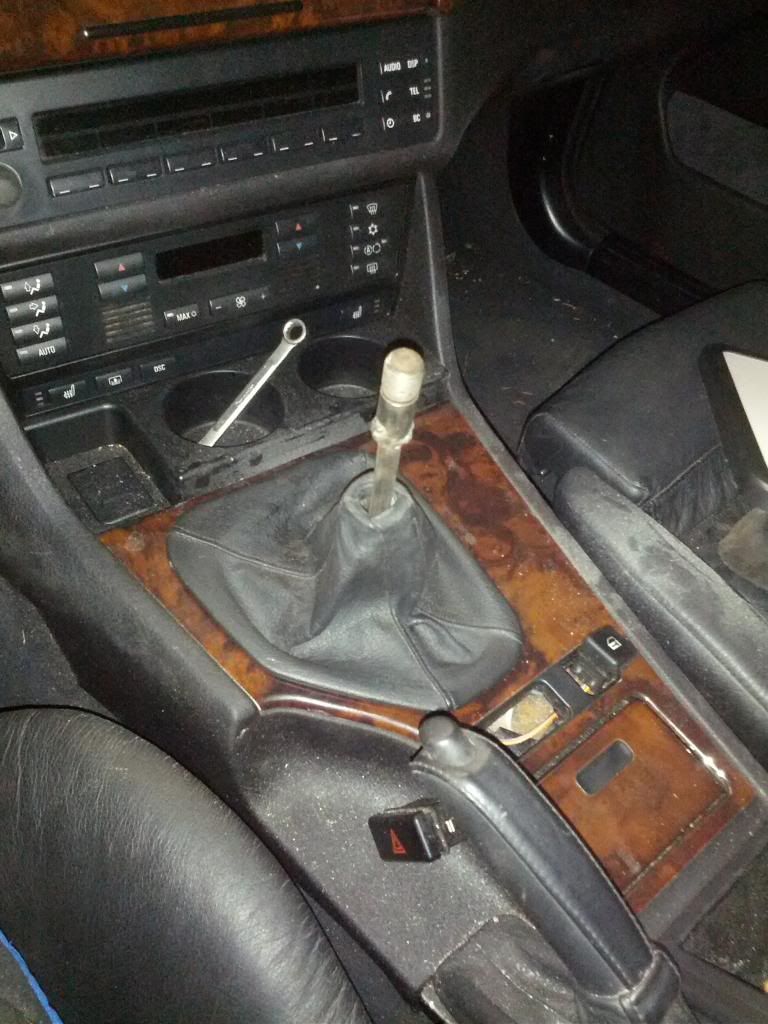

unfortunately, the motor needs to be forward enough to make the oil pan happy above the crossmember, but this makes the shifter pissed off. it's about 3" forward of the shifter hole in the unibody. had to modify the stock shifter to allow the rear of the trans to come up vertically as much as possible, to give me the right driveline angle. it was hitting the inside of the trans tunnel, making the rear of the trans point down at a 8* angle. i might use a GTO shifter (offset to the rear by a bit compared to the Camaro one).

stock:

moved the shifter rod down "one hole"

cut a top inch or so off, bought me some room.

slapped it on the block.

placed a 1" thick piece of wood under the pan to simulate space between pan and crossmember, and a 1"x1" piece under the pan on top of the steering linkage.

unfortunately, the motor needs to be forward enough to make the oil pan happy above the crossmember, but this makes the shifter pissed off. it's about 3" forward of the shifter hole in the unibody. had to modify the stock shifter to allow the rear of the trans to come up vertically as much as possible, to give me the right driveline angle. it was hitting the inside of the trans tunnel, making the rear of the trans point down at a 8* angle. i might use a GTO shifter (offset to the rear by a bit compared to the Camaro one).

stock:

moved the shifter rod down "one hole"

cut a top inch or so off, bought me some room.

#65

what do you mean? it's all set as far as cutting it up so i'll have the guys at work cut out aluminum patches and TIG it for me.

---------- Post added at 08:43 PM ---------- Previous post was at 08:34 PM ----------

slapped the inclinometer on the bottom of the car on the frame rail, only place where the car was parallel with the ground.

that's with the nose pointing up.

after cutting the shifter i got this.

rough height in the bay. rotation along the crank axis is a bit off obviously but i'll fix that the next time i work on the car.

---------- Post added at 08:43 PM ---------- Previous post was at 08:34 PM ----------

slapped the inclinometer on the bottom of the car on the frame rail, only place where the car was parallel with the ground.

that's with the nose pointing up.

after cutting the shifter i got this.

rough height in the bay. rotation along the crank axis is a bit off obviously but i'll fix that the next time i work on the car.

#66

so, let's begin with tonight's pleasant atmosphere! before i fired up the heater it was 32, as i finished up for the evening i snapped this.

i really wasn't happy with the pinion angle, and the only thing that could give was the shifter moving up into the tunnel. so i enlarged the shifter hole forward about 3-4".

fun fact....burning tunnel insulation smells like pickles

so this places the engine fore/aft roughly where it will be, give or take half an inch.

head to AC line:

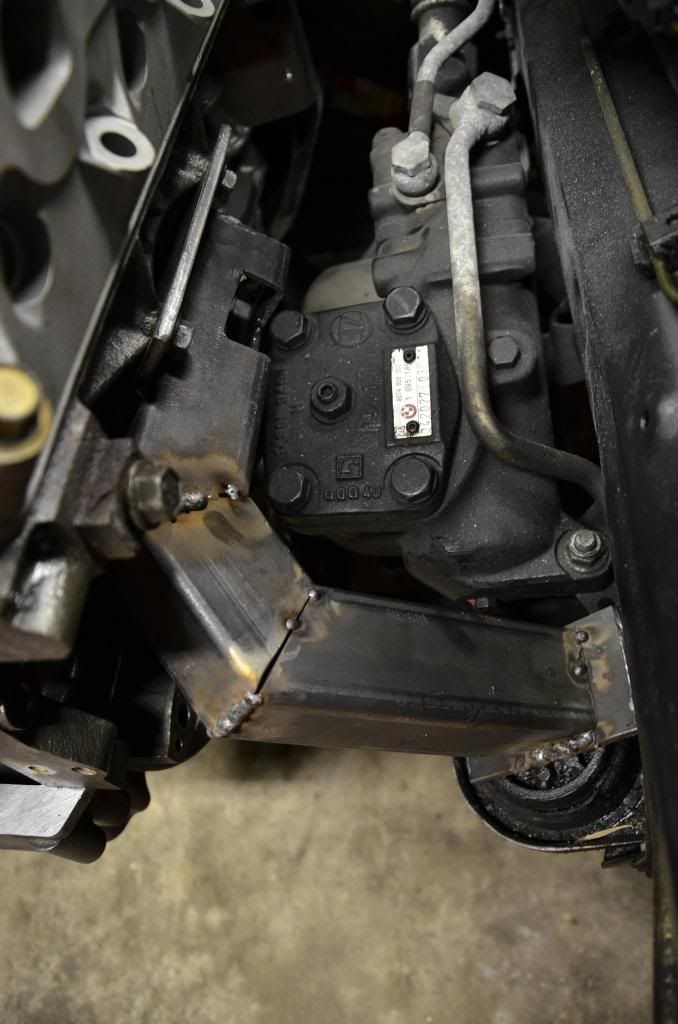

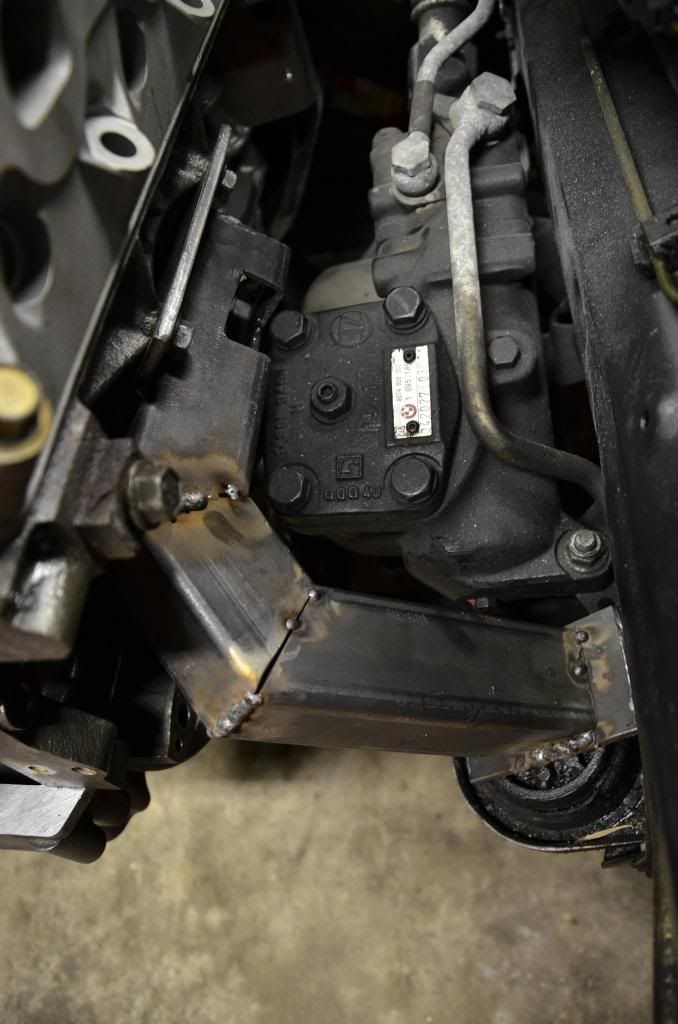

tight spot by the steering box, 2" square tube is very very tight, i will end up notching the mount around there to avoid any contact if/when the motor moves back and forth.

this gave us a better angle than last night. remember that i'm subtracting 1.2 degrees of the car's nose pointing up.

grabbed some stock from the scrap bin at work and put a 90* bend in it with the vise. cut up the stock shifter rod (where the **** threads on) and welded on the threaded portion to the stock. i purposely left it tall so i can cut it down later to my liking. i actually really like it tall, gives it that old muscle car feel.

with das boot on it:

tomorrow i'd like to finalize the location of the motor and start to make the mounts.

i really wasn't happy with the pinion angle, and the only thing that could give was the shifter moving up into the tunnel. so i enlarged the shifter hole forward about 3-4".

fun fact....burning tunnel insulation smells like pickles

so this places the engine fore/aft roughly where it will be, give or take half an inch.

head to AC line:

tight spot by the steering box, 2" square tube is very very tight, i will end up notching the mount around there to avoid any contact if/when the motor moves back and forth.

this gave us a better angle than last night. remember that i'm subtracting 1.2 degrees of the car's nose pointing up.

grabbed some stock from the scrap bin at work and put a 90* bend in it with the vise. cut up the stock shifter rod (where the **** threads on) and welded on the threaded portion to the stock. i purposely left it tall so i can cut it down later to my liking. i actually really like it tall, gives it that old muscle car feel.

with das boot on it:

tomorrow i'd like to finalize the location of the motor and start to make the mounts.

#69

decided to not use a GTO shifter since using a steel bar gives me the flexibility to bend the shifter however i want as well as shorten and lengthen it.

final engine placement. measured pinion angle for the final time, centered motor left to right both at the crank snout and at the trans output.

compound angle i'll have to cut

beginning of driver's side mount. the notch is to clear the steering box bolts. it's 2" tube steel.

final engine placement. measured pinion angle for the final time, centered motor left to right both at the crank snout and at the trans output.

compound angle i'll have to cut

beginning of driver's side mount. the notch is to clear the steering box bolts. it's 2" tube steel.

Last edited by LQ4-E39; 01-03-2013 at 10:09 PM.

#70

been busy over the last few days.

3 cutoff wheels, a lot of 2" tube steel, lots of trial and error, and we have mounts!

everything as of now is just tacked into place for 2 reasons:

1: my 115V welder doesn't have the ***** to penetrate the thick wall steel

2: i'm a really shitty welder

i will be grinding down the mounts and wirewheeling them to prep them for full welding, which i'll have one of the guys at work do.

looking at it now, that trans mount looks a bit crooked. tomorrow i will realign it and re-tack.

3 cutoff wheels, a lot of 2" tube steel, lots of trial and error, and we have mounts!

everything as of now is just tacked into place for 2 reasons:

1: my 115V welder doesn't have the ***** to penetrate the thick wall steel

2: i'm a really shitty welder

i will be grinding down the mounts and wirewheeling them to prep them for full welding, which i'll have one of the guys at work do.

looking at it now, that trans mount looks a bit crooked. tomorrow i will realign it and re-tack.

#71

test fit mounts, driver's side

passenger side

ready for welding. my little pea shooter 115V MIG wouldn't even penetrate at all so i had it done by a pro at work.

prepped the block for heads. scraped them of all material and cleaned with mineral spirits.

new OEM GM MLS 6.0 headgaskets, nice pieces. new head/block dowels since the old ones disappeared. new ARP head bolts torqued down in 3 passes to their specs, not GM's.

figured i'd put the intake manifold on too since there was no reason not to.

i had the mounts fully welded today at work and they came out awesome.

the motor still needs to come out to get all new front and rear cover gaskets and main seals, as well as to have the pan welded up and GTO pickup installed with windage tray. but, it's in.

well of course there's a goddamn problem...i was so concerned with clearing the steering arm (which is a moving part about 3/4" underneath the oil pan) that i totally disregarded hood clearance. it's not terrible but i may need to figure out something creative.

room for days in the rear.

truck manifolds didn't fit on either side...but i'm keeping them, since i might boost this sucker at one point.

have to start the headers next. i have a pair of used shorties i can hack up and modify. i also have an old tubular stainless header left over from my SE-R Spec V that i can chop up. Always prefer to use what i have rather than buy new.

junkyard engine, transmission out of a wrecked Camaro, mounts made out of steel that was pulled from a scrap bin...i'm sensing a trend here

passenger side

ready for welding. my little pea shooter 115V MIG wouldn't even penetrate at all so i had it done by a pro at work.

prepped the block for heads. scraped them of all material and cleaned with mineral spirits.

new OEM GM MLS 6.0 headgaskets, nice pieces. new head/block dowels since the old ones disappeared. new ARP head bolts torqued down in 3 passes to their specs, not GM's.

figured i'd put the intake manifold on too since there was no reason not to.

i had the mounts fully welded today at work and they came out awesome.

the motor still needs to come out to get all new front and rear cover gaskets and main seals, as well as to have the pan welded up and GTO pickup installed with windage tray. but, it's in.

well of course there's a goddamn problem...i was so concerned with clearing the steering arm (which is a moving part about 3/4" underneath the oil pan) that i totally disregarded hood clearance. it's not terrible but i may need to figure out something creative.

room for days in the rear.

truck manifolds didn't fit on either side...but i'm keeping them, since i might boost this sucker at one point.

have to start the headers next. i have a pair of used shorties i can hack up and modify. i also have an old tubular stainless header left over from my SE-R Spec V that i can chop up. Always prefer to use what i have rather than buy new.

junkyard engine, transmission out of a wrecked Camaro, mounts made out of steel that was pulled from a scrap bin...i'm sensing a trend here

#72

Registered User

Join Date: Jan 2013

Location: outside NashVegas

Posts: 4

Likes: 0

Received 0 Likes

on

0 Posts

I am really enjoying your E39 build.

I will be upgrading my modified E34 (315k on tired M30, new suspension /durathane bushings/brakes) with a stock (for now) LS 5.3 & a BW/WC T5 (Frod w/ .69 OD) as I also have lots of "In Stock" parts left over from my SCCA ASEDAN road racing days..

When I get further into my build I will be shooting my pics and posting too...

What are you going to do for a harness? You are doing a MS3X correct?

Great job,

roadracer

I will be upgrading my modified E34 (315k on tired M30, new suspension /durathane bushings/brakes) with a stock (for now) LS 5.3 & a BW/WC T5 (Frod w/ .69 OD) as I also have lots of "In Stock" parts left over from my SCCA ASEDAN road racing days..

When I get further into my build I will be shooting my pics and posting too...

What are you going to do for a harness? You are doing a MS3X correct?

Great job,

roadracer

#76

Registered User

Join Date: Jan 2013

Location: outside NashVegas

Posts: 4

Likes: 0

Received 0 Likes

on

0 Posts

Several questions come to mind - do you have access to Motronic expert sw/hw to be able to remap the fuel for the larger displacement and injectors?

I saw that you removed a decent portion of the oil pan - are you going to run a remote system that has more capacity to compensate?

I have an old Earls remote system "In Stock" that I will be using along with the following pan from Jegs: Chevrolet Performance 19212593 - Chevrolet Performance LS Muscle Car Oil Pan Kit

Did you try the Corvette exhaust manifolds? - I got a pair with my boneyard motor, and will have to see how they fit in my E34 that has been lowered 2" (front, 1.5 rear - H&R spring kit, KYB struts & Shocks)

Thanks,

rainracer

I saw that you removed a decent portion of the oil pan - are you going to run a remote system that has more capacity to compensate?

I have an old Earls remote system "In Stock" that I will be using along with the following pan from Jegs: Chevrolet Performance 19212593 - Chevrolet Performance LS Muscle Car Oil Pan Kit

Did you try the Corvette exhaust manifolds? - I got a pair with my boneyard motor, and will have to see how they fit in my E34 that has been lowered 2" (front, 1.5 rear - H&R spring kit, KYB struts & Shocks)

Thanks,

rainracer

#77

Several questions come to mind - do you have access to Motronic expert sw/hw to be able to remap the fuel for the larger displacement and injectors?

I saw that you removed a decent portion of the oil pan - are you going to run a remote system that has more capacity to compensate?

I have an old Earls remote system "In Stock" that I will be using along with the following pan from Jegs: Chevrolet Performance 19212593 - Chevrolet Performance LS Muscle Car Oil Pan Kit

Did you try the Corvette exhaust manifolds? - I got a pair with my boneyard motor, and will have to see how they fit in my E34 that has been lowered 2" (front, 1.5 rear - H&R spring kit, KYB struts & Shocks)

Thanks,

rainracer

I saw that you removed a decent portion of the oil pan - are you going to run a remote system that has more capacity to compensate?

I have an old Earls remote system "In Stock" that I will be using along with the following pan from Jegs: Chevrolet Performance 19212593 - Chevrolet Performance LS Muscle Car Oil Pan Kit

Did you try the Corvette exhaust manifolds? - I got a pair with my boneyard motor, and will have to see how they fit in my E34 that has been lowered 2" (front, 1.5 rear - H&R spring kit, KYB struts & Shocks)

Thanks,

rainracer

Since this will be a street car with no track use, I donít see a need to run a remote system. I will need to calculate how much oil it will take to bring up to ďfullĒ, though.

I am fairly certain the Vette manifolds dump straight down, which on the passenger side isnít so bad, but on the driverís side, will go right into the steering box.

#78

#80

cleaned up the front cover, valve covers, and the coil brackets.

shot them with wrinkle black. just threw them on, it looks ok. i was shooting for a more wrinkly finish, but they may still be curing.

got the shifter all situated. i like the height of it, if it proves to be a PITA to drive with it's 2 bolts to remove it and cut/reweld. the weld ring underneath the **** will be ground down. i also want to use round rod instead of the square stock that i used for a cleaner look in cabin. this was for mock up.

the shifter height and **** is certainly yeehaw!

good news, the hood closes over the intake.

shot them with wrinkle black. just threw them on, it looks ok. i was shooting for a more wrinkly finish, but they may still be curing.

got the shifter all situated. i like the height of it, if it proves to be a PITA to drive with it's 2 bolts to remove it and cut/reweld. the weld ring underneath the **** will be ground down. i also want to use round rod instead of the square stock that i used for a cleaner look in cabin. this was for mock up.

the shifter height and **** is certainly yeehaw!

good news, the hood closes over the intake.