1970 Bug Mid Engine (engine build pg15)

#83

Your thought of running two 2.5" lines is overkill. There are may 914/V8 conversions that run 1 1/4" (actually 1" hot side, and 1 1/4" cold side) lines successfully. They traditionally (unlike mine) vent the exit air into the front wheel wells.

Anyway, 1 1/4' should greatly simplify your problem. Would there perhaps be enough room under the Bug running boards on each side to route the lines?

Andy1

Anyway, 1 1/4' should greatly simplify your problem. Would there perhaps be enough room under the Bug running boards on each side to route the lines?

Andy1

On a side note, what size radiator are you running? It looks like I will end up with a 17" X 27" with two 14" fans. I think that will be big enough for a 2.2 liter....

Bandit -

We are going to meet halfway on this radiator subject. That huge roof scoop had me thinking

, but not going to happen. No it isn't going up front either. I still can't bring myself to do it, but I will take your suggestion on running the intercooler in front of the radiator instead of side by side. If I do have a small lack of air flow, the size of the radiator should take care of cooling the engine.

, but not going to happen. No it isn't going up front either. I still can't bring myself to do it, but I will take your suggestion on running the intercooler in front of the radiator instead of side by side. If I do have a small lack of air flow, the size of the radiator should take care of cooling the engine.

#84

I honestly want to make this my daily driver. Building a car from the ground up (minus the body) has been a dream of mine for years. I want to make it as simple and fail safe as possible. The less I have going on, the less that can go wrong.

#85

Well I haven't had much time to get anything done on the Bug lately. Probably this weekend though. I did however find out some bad news. I got some very nice Manley turbo tuff rods for way too good of a price. They aren't going to work. The big end is way to small, the small end is way too big, and the rod is .120" too long.... I called Manley and they said these were a special order rod from the GM Performance division and that everything about them was custom. Yes I can make them work with some custom pistons and some machine work on the crank but I am not sure if I want to go that route. So I am either dumping those rods and going with Eagle H-beams or getting a set of custom pistons and doing a NA setup. The turbo setup would be faster, 50hp or so more, but I think the powerband of a 300hp NA 2.2 liter would be a blast. It would be like a 8000 rpm 2 stroke! The car doesn't weigh anything so TQ is not necessary. Its going to be about $1000 cheaper going the NA route and I am on a budget! What do you guys think?

#86

TECH Addict

iTrader: (1)

Not sure why I feel obliged to offer so much of my personal opinion, but I wouldn't have gone turbo in the first place. I think NA or supercharger are just more predictable in how the power come on and so typically better for combination street and curvey track use. I'm not saying a turbo can't work great in those applications also, it's just not my preference. I prefer the "geared" feel of NA and supercharged applications because I know exactly what kind of power I'm going to get for a given pedal position and gear without regard for how the turbo is spooling - it just makes me more comfortable going in and out of corners. You will still have great power-to-weight if you build a 300hp NA setup.

#87

A blower was my original plan but after seeing how easy it is to make power with a turbo, I wanted to go that route. It would still have good power below boost and get great MPG. But the I also thought if I was going to road race this thing, forced induction is going to be throwing a lot of heat down that intake manifold and even more stress on the engine and have a powerband with a mind of its own. So that brought me back to NA. I like the idea of having more RPMs in each gear and the sound of a big cam in a 4 cyl. My only downside would be the lack of power down low. Again, the car won't weigh much so I don't think it will be a big deal. I do plan on driving it a lot, so I am hoping it doesn't kill the driveability.

#88

Bandit -

Thank you for all the suggestions. I feel like you have more real life experience with most of the suspension stuff and have probably done more auto X then me. I have been around this kind of stuff all my life, built my first engine at 15, did my first LS conversion at 17, have built over 150 LS engines and 75 Ecotecs by now, but have never built something from the ground up. I have a good idea about what I am doing but not a pro by any means.

I also know there are more of you out there looking at this post who probably know more then Bandit and I combined! I want your inputs! Even the people who like what they see but don't know much about it, if you see something weird, bring it up!

Thank you for all the suggestions. I feel like you have more real life experience with most of the suspension stuff and have probably done more auto X then me. I have been around this kind of stuff all my life, built my first engine at 15, did my first LS conversion at 17, have built over 150 LS engines and 75 Ecotecs by now, but have never built something from the ground up. I have a good idea about what I am doing but not a pro by any means.

I also know there are more of you out there looking at this post who probably know more then Bandit and I combined! I want your inputs! Even the people who like what they see but don't know much about it, if you see something weird, bring it up!

Last edited by CBM Motorsports; 06-06-2014 at 05:48 PM.

#89

TECH Addict

iTrader: (1)

CBM I am blowing a lot of smoke if you think I have a wealth of experience. I have only auto-crossed a few times. I have driven both NA and turbocharged, OEM and modified vehicles and I'm drawing on my limited experience and reading knowledge, but by no means am I experienced or an expert. I just love to read about this stuff. With regards to suspension, I am a mechanical engineer and took some vehicle dynamics courses in school which I have followed up on by calculating a few things for my car and others, but have very little experience in the real world. I read about and see a lot of different designs and I do talk to people who do have real world experience which is why I am pointing things out here and there. Take what I say with a grain of salt - this is the Internet and EVERYBODY is going to be an expert on here, especially an arrogant guy like me

#90

TECH Apprentice

Throw the turbo on there and get going! Yes N/A is more predictable in a road racing application, but hey, unpredictable is a little more fun right? Plus, if you want more power, turn a couple of clicks on a boost controller and hold on! Thats my $0.02 I love the build though!

#93

Hurry up and get this thing done, LOL. Keep up the great work!!!

Jim

Jim

#95

I wish I could hurry up and get this thing done! I told myself I don't want to use any money out of the bank account to fund it. So that means I have to sell parts on the side and junk laying around the garage to fund it. Sure I could buy everything I need right now and get this thing done in a month, but I can't bring myself to do it. I can wait.

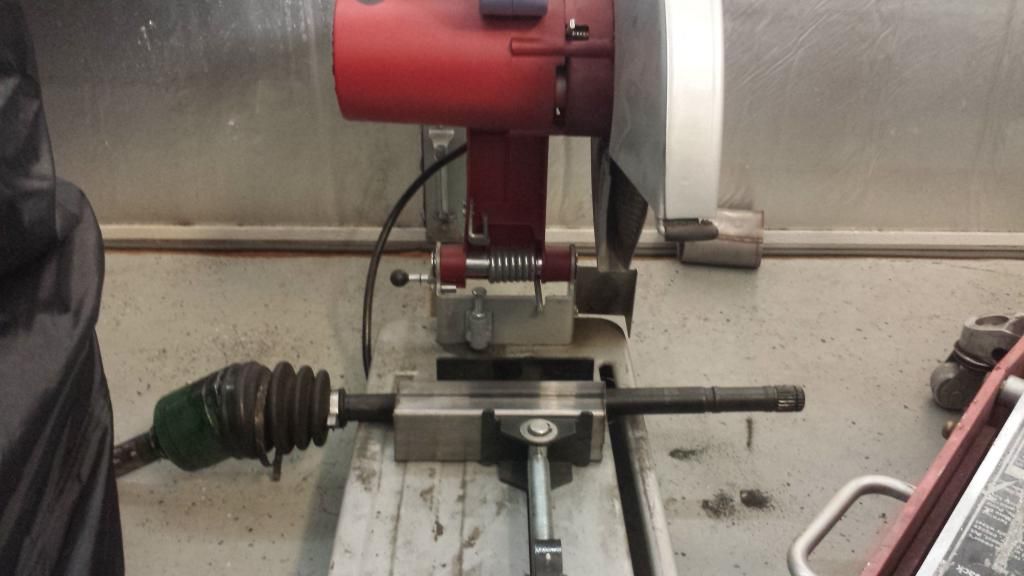

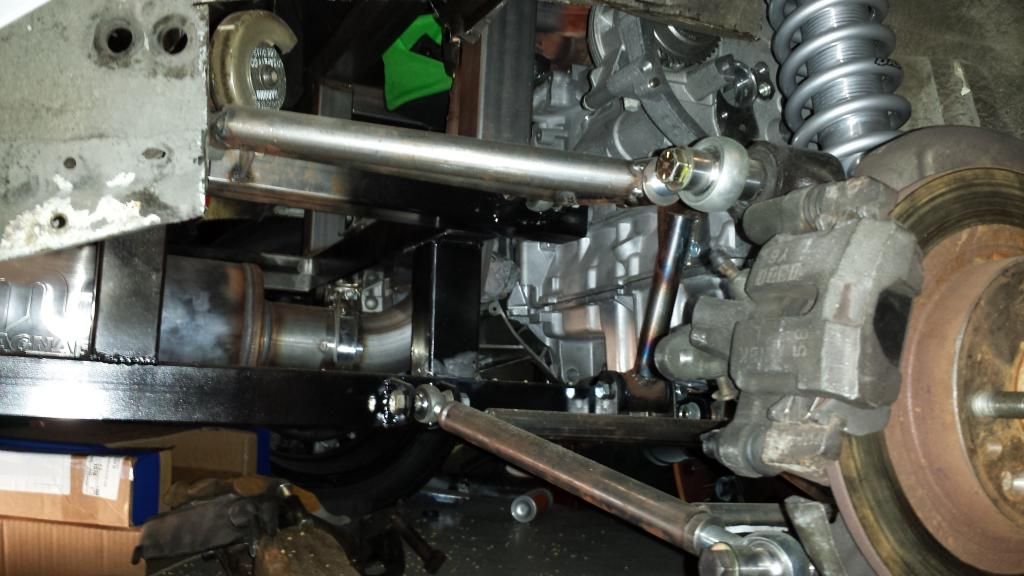

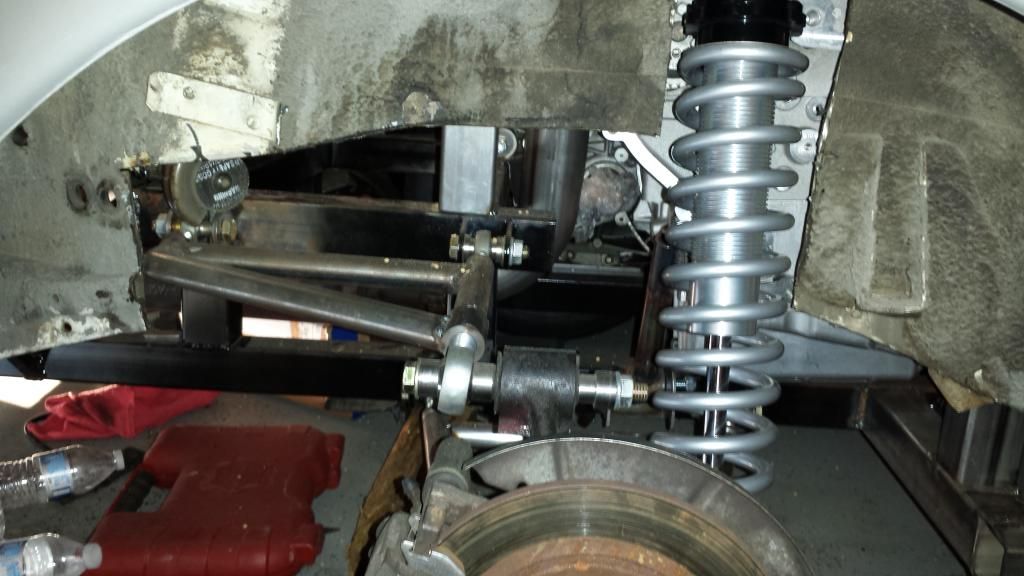

Axles will be here on Monday. They are just stock Cobalt axles. It is sad that I had to buy new axles complete with CVs just to take them and cut them in half and only use half. After I cut those in half, I have to take my Miata axles and cut those in half! Then I have to weld both together at the right length. After that I get to take them all apart again so that I can get the right length axle with the right ends made... So much work for 2 axles. Sure I could just take some measurements and supply both sides of the axle to make, but I would rather hand the axle shop a welded together axle and say clone this but make it twice as strong.

Axles will be here on Monday. They are just stock Cobalt axles. It is sad that I had to buy new axles complete with CVs just to take them and cut them in half and only use half. After I cut those in half, I have to take my Miata axles and cut those in half! Then I have to weld both together at the right length. After that I get to take them all apart again so that I can get the right length axle with the right ends made... So much work for 2 axles. Sure I could just take some measurements and supply both sides of the axle to make, but I would rather hand the axle shop a welded together axle and say clone this but make it twice as strong.

#98

Not much more has happened over the past week or so. I took a little vacation so that didn't help. Went to Vegas and then down to my parents river house. I don't know how people live in 110 degree weather.... Glad to be back! Here is the progress

New bolts are in

Got my new gauge holders. Chose chrome for the smooth finish but only to get painted...

Painted as well as a painted glove box door

Installed. The dash is going to be black. Just need to finish welding some dash holes and pop the window out. Then time for black paint! Don't mind the steering wheel either. It will be gone soon! I still have a ton of work left

New bolts are in

Got my new gauge holders. Chose chrome for the smooth finish but only to get painted...

Painted as well as a painted glove box door

Installed. The dash is going to be black. Just need to finish welding some dash holes and pop the window out. Then time for black paint! Don't mind the steering wheel either. It will be gone soon! I still have a ton of work left

#99

Launching!

Join Date: Jan 2007

Location: Luling TX In the Hot Rod Shop

Posts: 294

Likes: 0

Received 3 Likes

on

3 Posts

Awesome project! This is going to be a sweet little bug and its going to beat the pants off quite a few cars.

I am going to voice my opinion on this one.

Your not making gobs of power like you said but axles and drive shafts suffer from the problem of taking load in both direction. When and part is exposed to twist in one direction and then the counter the life span is normally expected to be 1/4 of the same part only exposed to a single direction worth of load. Carroll Smith talk about it for half a chapter in his stress section of his books. This one if your interested ( )

I would suggest at least taking a piece of tubing, splitting it and making a collar for it. Welded on both side. Most axles are not mild steel so your still likely to break the axle just due to the whole zone being brittle from the heat stressing of the welds but it'll be way stronger than just the butt weld.

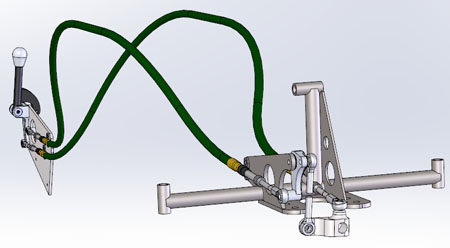

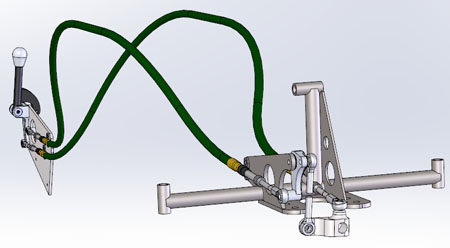

A suggestion for the shifter. Check out this guys page, http://www.dpcars.net/

On the side bar under "PAST" their is a Car Labled "D2", Its the first one under the work past. Click it and then at the top of the page a navigation bar will pop up with number, click page # 6 and look for this photo.

It might make life easier.

Keep up the good work and keep those photos coming! My girlfriend wants to build a bug and this looks like an excellent option for that project.

Later

-Russell

I am going to voice my opinion on this one.

Your not making gobs of power like you said but axles and drive shafts suffer from the problem of taking load in both direction. When and part is exposed to twist in one direction and then the counter the life span is normally expected to be 1/4 of the same part only exposed to a single direction worth of load. Carroll Smith talk about it for half a chapter in his stress section of his books. This one if your interested ( )

I would suggest at least taking a piece of tubing, splitting it and making a collar for it. Welded on both side. Most axles are not mild steel so your still likely to break the axle just due to the whole zone being brittle from the heat stressing of the welds but it'll be way stronger than just the butt weld.

A suggestion for the shifter. Check out this guys page, http://www.dpcars.net/

On the side bar under "PAST" their is a Car Labled "D2", Its the first one under the work past. Click it and then at the top of the page a navigation bar will pop up with number, click page # 6 and look for this photo.

It might make life easier.

Keep up the good work and keep those photos coming! My girlfriend wants to build a bug and this looks like an excellent option for that project.

Later

-Russell

#100

Sorry I didn't clarify this before. The axles I made are for mach up only. They are by no means strong or straight enough to be used. I am going to hand them over to an axle shop to be cloned as a 300m one piece design. I just wanted to have something to simulate the real axle and make sure I have the right end play and good angles.

As for the shifter, it should be a simple thing to get working. I have a stock shifter out of a Cobalt. I am going to buy some different cables then factory and mount them in the stock location. I was also thinking of shortening up the throw (lower mounting on the pivot) to simulate a short throw shifter.

As for the shifter, it should be a simple thing to get working. I have a stock shifter out of a Cobalt. I am going to buy some different cables then factory and mount them in the stock location. I was also thinking of shortening up the throw (lower mounting on the pivot) to simulate a short throw shifter.

[/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL]  [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL]