Barry Grant Heat Sink Fuel Cooler

#1

Hi guys

I have a 68 camaro with LS6 engine and I installed the Aeromotive EFI fuel tank which has an in tank fuel pump and the fuel system is plumbed as follows:

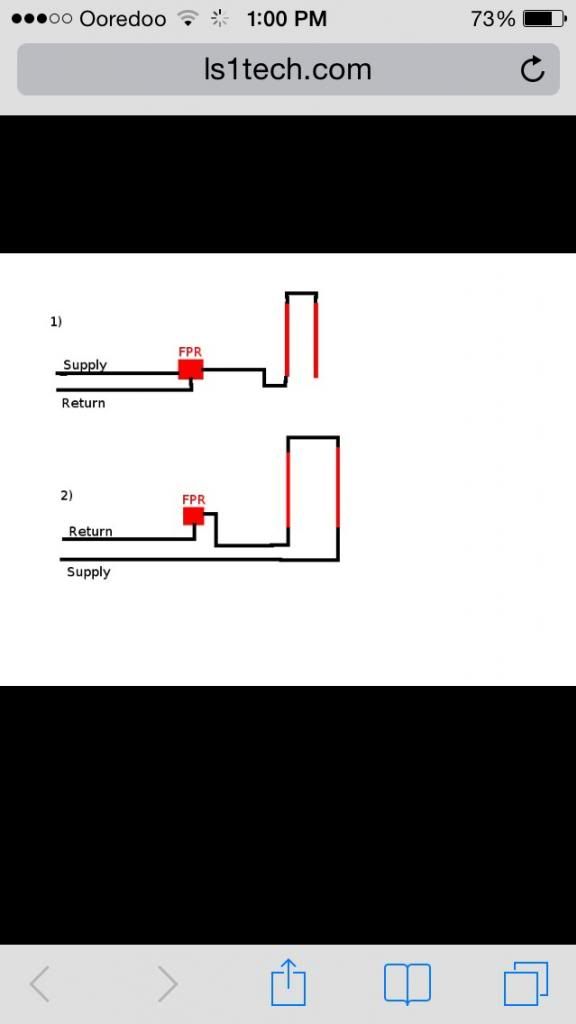

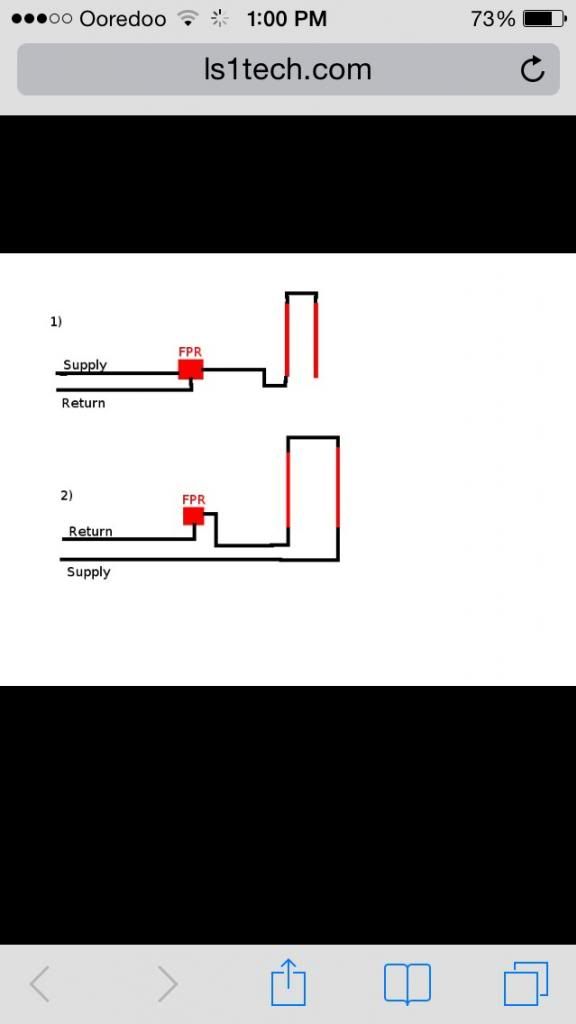

Feed line to passenger side fuel rail going to the second fuel rail, then returing through the Aeromotive fuel pressure regulator (mounted on the firewall) back to the the tank similar to the below photo

I was about a bit concerned about hot fuel and vapor lock issues so I bought a brand new Barry Grant fuel cooler with 8AN fittings as shown below

Once I received the fuel cooler, I noticed as per the instruction is this fuel cooler works well with flow-through-style fuel pumps.

I was planning to install the cooler in the return line to cool down the fuel going back to the tank.

The Barry Grant cooler has a check valve with defined inlet and outlet ports

My question is can I use this fuel cooler with in tank fuel pump or it works only with flow through stye fuel pump

I have a 68 camaro with LS6 engine and I installed the Aeromotive EFI fuel tank which has an in tank fuel pump and the fuel system is plumbed as follows:

Feed line to passenger side fuel rail going to the second fuel rail, then returing through the Aeromotive fuel pressure regulator (mounted on the firewall) back to the the tank similar to the below photo

I was about a bit concerned about hot fuel and vapor lock issues so I bought a brand new Barry Grant fuel cooler with 8AN fittings as shown below

Once I received the fuel cooler, I noticed as per the instruction is this fuel cooler works well with flow-through-style fuel pumps.

I was planning to install the cooler in the return line to cool down the fuel going back to the tank.

The Barry Grant cooler has a check valve with defined inlet and outlet ports

My question is can I use this fuel cooler with in tank fuel pump or it works only with flow through stye fuel pump

Last edited by 72Z/28; 05-13-2014 at 08:20 AM.

#3

TECH Enthusiast

iTrader: (17)

Join Date: Sep 2007

Location: Southern NJ

Posts: 634

Likes: 0

Received 0 Likes

on

0 Posts

I will cover several issues here so if it seems jumbled I apologize.

Heat soak and vapor lock is more common on low pressure dead head fuel systems. Also it normally does not happen when running but when the engine is off and the fuel near the engine gets hot. This was a real problem with carbs and the fuel sitting in the bowls. With the higher pressure efi systems the risk is greatly reduced. The return style system in diagram 2 would pretty much guarantee that you won't have vapor lock issues.

When the engine is running do you know what the fuel temp is? Or are you just assuming that it is excessively hot?

If you are running a stock size fuel tank I'm not sure you would really raise the temp in the tank very much. I believe the concern with raising the temp of the stems from drag racers using small fuel cells. I am not aware of any proof of this being an issue. I have never heard of any one doing dyno tests with different fuel temps and how it impacts HP. I have also never heard of anyone that actually measured the fuel temps in the fuel lines or fuel tank.

I know Roger Penske would super cool his fuel back in the 60's when he raced TransAm cars. This was done to reduce the volume so more fuel would fit in the cell not for any performance advantage. Also Smokey Yunick was working on HEATING the fuel to increase the fuel economy and performance of cars.

All that being said make sure you have a problem before you spend time and money fixing it.

In line pumps generally have stronger motors. Not sure if this is the reason.

Contact Barry Grant and ask them.

Just remember that heat sinks can work both ways (add or remove heat) so placement is critical. Also with high pressure systems the fuel can pass thru the cooler to quickly to transfer heat.

Although I do not use them aluminum fuel line could perform some of the same function.

Good luck.

Heat soak and vapor lock is more common on low pressure dead head fuel systems. Also it normally does not happen when running but when the engine is off and the fuel near the engine gets hot. This was a real problem with carbs and the fuel sitting in the bowls. With the higher pressure efi systems the risk is greatly reduced. The return style system in diagram 2 would pretty much guarantee that you won't have vapor lock issues.

When the engine is running do you know what the fuel temp is? Or are you just assuming that it is excessively hot?

If you are running a stock size fuel tank I'm not sure you would really raise the temp in the tank very much. I believe the concern with raising the temp of the stems from drag racers using small fuel cells. I am not aware of any proof of this being an issue. I have never heard of any one doing dyno tests with different fuel temps and how it impacts HP. I have also never heard of anyone that actually measured the fuel temps in the fuel lines or fuel tank.

I know Roger Penske would super cool his fuel back in the 60's when he raced TransAm cars. This was done to reduce the volume so more fuel would fit in the cell not for any performance advantage. Also Smokey Yunick was working on HEATING the fuel to increase the fuel economy and performance of cars.

All that being said make sure you have a problem before you spend time and money fixing it.

In line pumps generally have stronger motors. Not sure if this is the reason.

Contact Barry Grant and ask them.

Just remember that heat sinks can work both ways (add or remove heat) so placement is critical. Also with high pressure systems the fuel can pass thru the cooler to quickly to transfer heat.

Although I do not use them aluminum fuel line could perform some of the same function.

Good luck.

#4

Thanks for the write up. I am not sure about the fuel temperature of the fuel but I drove the car for about 20 min and noticed the fuel tank was warm. Maybe due to heat transfer from the rails and engine heat to the fuel returning back to the tank.

I got the BG instructions but it seems I got the wrong cooler for the application as this cooler is specificaly to be used with inline fuel pumps and as you stated they have stronger motors.

I believe Barry Grant company is no longer in business as I could not find their website at all. I got the cooler brand new off ebay.

I have russel fuel hose for the feed and return and wrapped the hoses that are kind of close to the tailpipes with heat tape.

I guess I am going to drive the car for a longer time and see how hot the tank gets

I got the BG instructions but it seems I got the wrong cooler for the application as this cooler is specificaly to be used with inline fuel pumps and as you stated they have stronger motors.

I believe Barry Grant company is no longer in business as I could not find their website at all. I got the cooler brand new off ebay.

I have russel fuel hose for the feed and return and wrapped the hoses that are kind of close to the tailpipes with heat tape.

I guess I am going to drive the car for a longer time and see how hot the tank gets

I will cover several issues here so if it seems jumbled I apologize.

Heat soak and vapor lock is more common on low pressure dead head fuel systems. Also it normally does not happen when running but when the engine is off and the fuel near the engine gets hot. This was a real problem with carbs and the fuel sitting in the bowls. With the higher pressure efi systems the risk is greatly reduced. The return style system in diagram 2 would pretty much guarantee that you won't have vapor lock issues.

When the engine is running do you know what the fuel temp is? Or are you just assuming that it is excessively hot?

If you are running a stock size fuel tank I'm not sure you would really raise the temp in the tank very much. I believe the concern with raising the temp of the stems from drag racers using small fuel cells. I am not aware of any proof of this being an issue. I have never heard of any one doing dyno tests with different fuel temps and how it impacts HP. I have also never heard of anyone that actually measured the fuel temps in the fuel lines or fuel tank.

I know Roger Penske would super cool his fuel back in the 60's when he raced TransAm cars. This was done to reduce the volume so more fuel would fit in the cell not for any performance advantage. Also Smokey Yunick was working on HEATING the fuel to increase the fuel economy and performance of cars.

All that being said make sure you have a problem before you spend time and money fixing it.

In line pumps generally have stronger motors. Not sure if this is the reason.

Contact Barry Grant and ask them.

Just remember that heat sinks can work both ways (add or remove heat) so placement is critical. Also with high pressure systems the fuel can pass thru the cooler to quickly to transfer heat.

Although I do not use them aluminum fuel line could perform some of the same function.

Good luck.

Heat soak and vapor lock is more common on low pressure dead head fuel systems. Also it normally does not happen when running but when the engine is off and the fuel near the engine gets hot. This was a real problem with carbs and the fuel sitting in the bowls. With the higher pressure efi systems the risk is greatly reduced. The return style system in diagram 2 would pretty much guarantee that you won't have vapor lock issues.

When the engine is running do you know what the fuel temp is? Or are you just assuming that it is excessively hot?

If you are running a stock size fuel tank I'm not sure you would really raise the temp in the tank very much. I believe the concern with raising the temp of the stems from drag racers using small fuel cells. I am not aware of any proof of this being an issue. I have never heard of any one doing dyno tests with different fuel temps and how it impacts HP. I have also never heard of anyone that actually measured the fuel temps in the fuel lines or fuel tank.

I know Roger Penske would super cool his fuel back in the 60's when he raced TransAm cars. This was done to reduce the volume so more fuel would fit in the cell not for any performance advantage. Also Smokey Yunick was working on HEATING the fuel to increase the fuel economy and performance of cars.

All that being said make sure you have a problem before you spend time and money fixing it.

In line pumps generally have stronger motors. Not sure if this is the reason.

Contact Barry Grant and ask them.

Just remember that heat sinks can work both ways (add or remove heat) so placement is critical. Also with high pressure systems the fuel can pass thru the cooler to quickly to transfer heat.

Although I do not use them aluminum fuel line could perform some of the same function.

Good luck.

#5

Barry grant got bought by Holley so they still exist

http://www.demoncarbs.com/Index.asp

That cooler isn't going to care what sort of pump is feeding it. Fuel goes through and either picks up or sheds heat through the fins. All depends on if the air surrounding the fins is hotter or colder than the fuel. The device seems a little BS to me, but I suppose in the right application where you can get that thing out in the breeze it could help.

ss performance gave a pretty complete answer, although the fuel pressure really has no bearing on how quickly the fuel will pass through the cooler.

http://www.demoncarbs.com/Index.asp

That cooler isn't going to care what sort of pump is feeding it. Fuel goes through and either picks up or sheds heat through the fins. All depends on if the air surrounding the fins is hotter or colder than the fuel. The device seems a little BS to me, but I suppose in the right application where you can get that thing out in the breeze it could help.

ss performance gave a pretty complete answer, although the fuel pressure really has no bearing on how quickly the fuel will pass through the cooler.

#6

TECH Enthusiast

iTrader: (17)

Join Date: Sep 2007

Location: Southern NJ

Posts: 634

Likes: 0

Received 0 Likes

on

0 Posts

Remember that when you drive you are on hot concrete or asphalt so some of the temp of the tank could be from that.

You're right, in a dead head system the pressure has no bearing on how quickly the fuel travels, but in a return system, generally, the fuel moves faster in a high pressure system.

The strength of the pump could come into play overcoming the by-pass valve in the cooler.

Good luck.

You're right, in a dead head system the pressure has no bearing on how quickly the fuel travels, but in a return system, generally, the fuel moves faster in a high pressure system.

The strength of the pump could come into play overcoming the by-pass valve in the cooler.

Good luck.

#7

I was thinking primarily carb vs. EFI. A big carb pump at 6 psi is going to move a lot more fuel than a small EFI pump at 55 psi.

Last edited by Pop N Wood; 05-14-2014 at 03:54 PM.