2" piping too small?

#41

8 Second Club

iTrader: (4)

It's a sealed pressure system. All pressure in the system is equal before the bottle neck. The exit in the volute of a .96 T4 twin scroll is much smaller than 1 7/8". I'd assume an open scroll would be too but I'm not 100% certain. There is no location in the system that will reduce back pressure more than another when the turbo is the restriction.

Twin 38's are more than enough to control the system pressure. It's like having single 76mm WG. I run a 2" hotside on a 370" engine around 1000hp with twin 38mm gates. I can run 7lbs (or less with a smaller spring in the WG.) They are more than enough to control boost on a 700ish hp 5.3.

I agree spool-up won't be an issue either way. You are talking very minimal gains between 2" is and 1 7/8". Doubt you'd be able to tell a difference without some nice test equipment. But if you have the 1 7/8 piping to use for free I wouldn't hesitate with your goals.

Twin 38's are more than enough to control the system pressure. It's like having single 76mm WG. I run a 2" hotside on a 370" engine around 1000hp with twin 38mm gates. I can run 7lbs (or less with a smaller spring in the WG.) They are more than enough to control boost on a 700ish hp 5.3.

I agree spool-up won't be an issue either way. You are talking very minimal gains between 2" is and 1 7/8". Doubt you'd be able to tell a difference without some nice test equipment. But if you have the 1 7/8 piping to use for free I wouldn't hesitate with your goals.

#42

Logging back pressure would still be neat on this system

And for reference, twin 38mm gates equals a single 57mm gate in surface area. I've seen single 60's control systems with great success

And for reference, twin 38mm gates equals a single 57mm gate in surface area. I've seen single 60's control systems with great success

Last edited by Nathaninwa; 11-27-2016 at 06:20 PM.

#43

8 Second Club

iTrader: (4)

Was talking about running a divided system, each with it's own 38mm gate. This is going to double the WG capacity. More than enough gate for what he is needing. I've run 1 38mm gate placed properly on a 5.3 and was able to control boost just fine. Lots of folks place the gates in horrible positions and then think they need 60mm WG's is my point.

Last edited by Forcefed86; 11-28-2016 at 07:32 AM.

#46

On The Tree

iTrader: (3)

Join Date: Aug 2013

Location: st paul mn

Posts: 105

Likes: 0

Received 0 Likes

on

0 Posts

I'm running a T6 twin scroll. 2.25 tubing fits nicely into each scroll. I'm running 44mm gates on each bank about 10 inches in front of the turbo flange. I have ran 4psi Wastegate pressure with no issues before. Still need to measure back pressure, but the turbine is the ultimate restriction in the system

I've been 168mph in a 2750lb car, puts it close to 1100whp, and I'll tell you what, spool time is not really an issue on the street

I've been 168mph in a 2750lb car, puts it close to 1100whp, and I'll tell you what, spool time is not really an issue on the street

#47

Wonder if it is divided all the way to the WG valve? Or if it merges just before and is open that few inches before the WG?

#48

#49

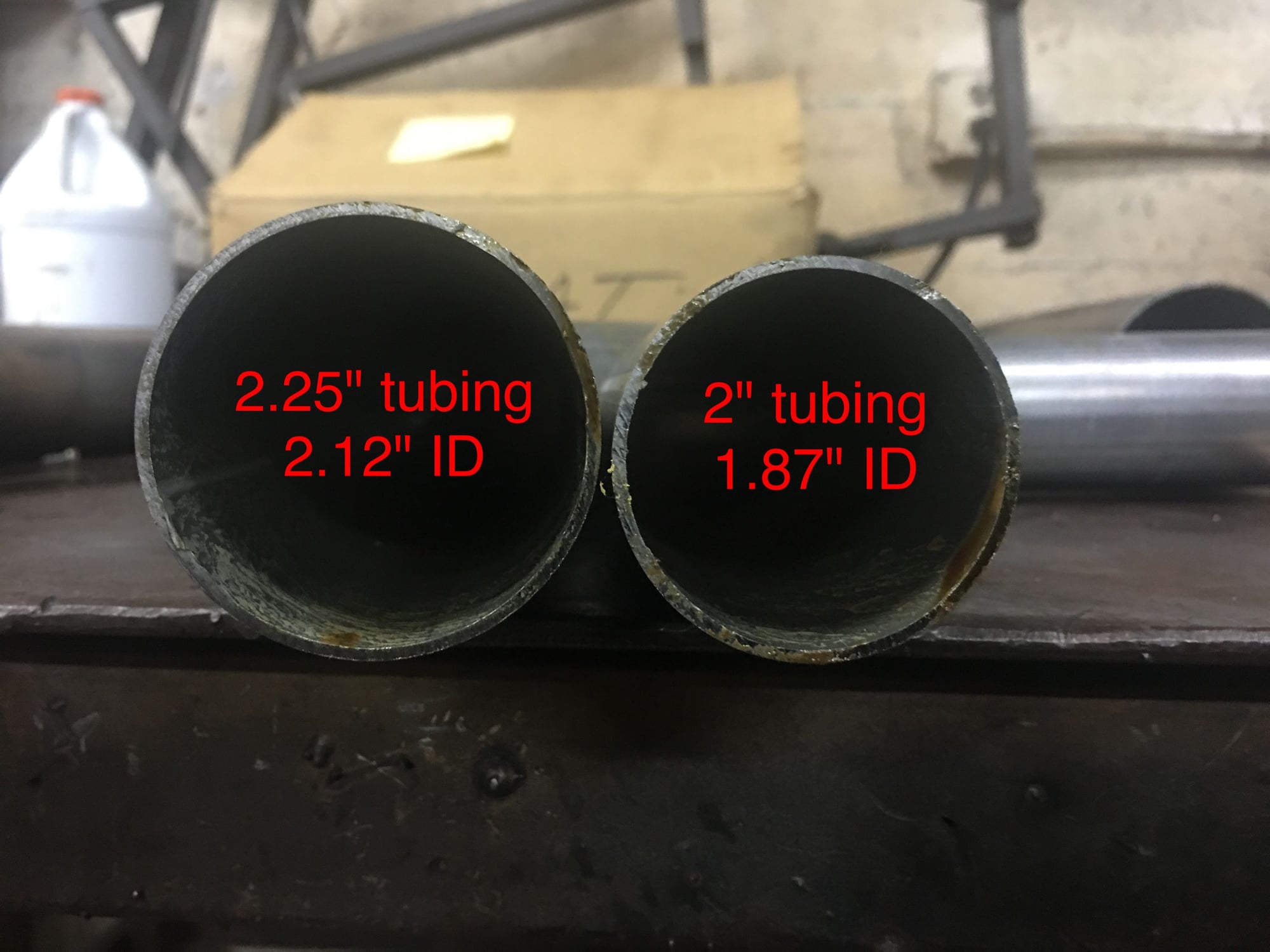

Just wanted to pass this on to you guys. After reading this thread and with the help of other members I decided to go with 2" pipe for my hot pipes. I went to my local muffler shop and asked for 2 inch pipe . They gave me the pipe that's marked 2 inches and off I went .. I realized that the ID was smaller then 2" .. so if you decide to go with 2" pipe you need to buy 2.25" pipe.

#51

Just wanted to pass this on to you guys. After reading this thread and with the help of other members I decided to go with 2" pipe for my hot pipes. I went to my local muffler shop and asked for 2 inch pipe . They gave me the pipe that's marked 2 inches and off I went .. I realized that the ID was smaller then 2" .. so if you decide to go with 2" pipe you need to buy 2.25" pipe.

Same is true with headers, there measure od, so my 1-3/4 primary's are actually 1-5/8 and 1-5/8 headers are really only 1-1/2 id

#54

On The Tree

iTrader: (1)

my buddy self fabbed his whole system/truck including the headers, except for that one piece. I've been doing that design on single systems for years, he brought me his merge and asked if i'd make that one piece for him. I sent him this pic while I was fitting it.

Last edited by nxfirebird; 11-30-2016 at 10:55 PM.

with the 2.25 pipe

with the 2.25 pipe