Truck 10 bolt in an Fbody (yes we can)

#63

Launching!

Thread Starter

Join Date: Sep 2007

Location: Surrey, BC

Posts: 230

Likes: 0

Received 0 Likes

on

0 Posts

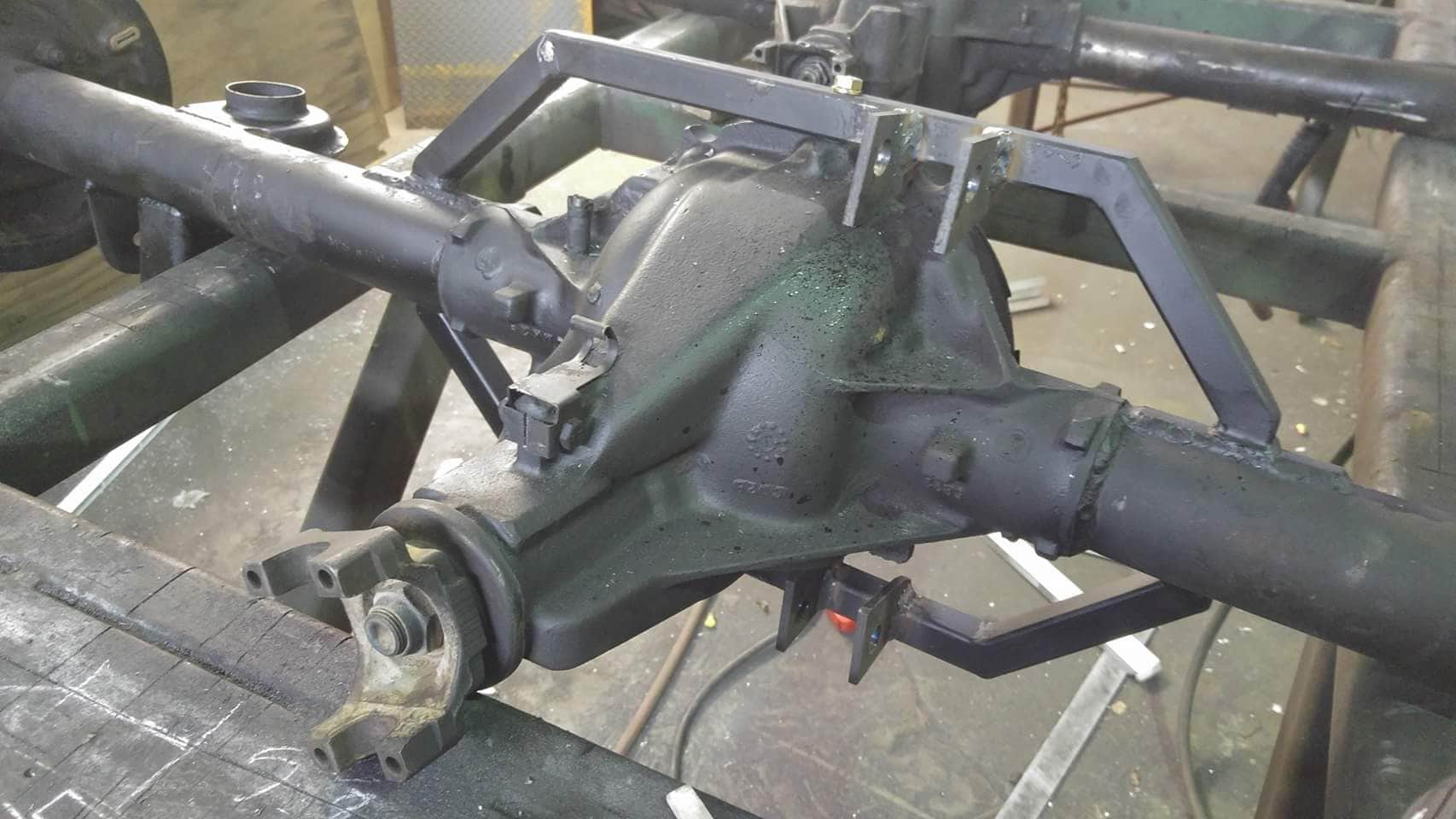

It's held up well since we put it in in the summer. Took it to the track twice. No issues. Next summer it's slicks and spray. Its a little wider than the factory rear but it fits fine. Only problem is the 6 bolt hubs... (it's what we had laying around)

#65

Launching!

Thread Starter

Join Date: Sep 2007

Location: Surrey, BC

Posts: 230

Likes: 0

Received 0 Likes

on

0 Posts

Those are the best I've got of the rear end in the car. It belongs to a friend of mine in Canada. I can ask him to take some more pictures of there's anything you need to see. We had to build our own torq arm too.

#67

Teching In

Join Date: Apr 2011

Location: Cloverdale, BC, Canada

Posts: 4

Likes: 0

Received 0 Likes

on

0 Posts

This is actually my car, I can try and get some shots of it installed this weekend. It wasn't that bad labour wise, we actually put more effort into taking the 8.5 out of the truck in the scrap yard. As far as I recall we spent 3 nights working on it to get it ready to go under the car... so like 6 hours of work and 6 hours of drinking beer

#69

Teching In

Join Date: Apr 2011

Location: Cloverdale, BC, Canada

Posts: 4

Likes: 0

Received 0 Likes

on

0 Posts

Actually, we simply took the control arm brackets and spring perches off the original rear, modified them to fit the larger diameter axle tube, welded them in place, and put it back in. We were able to use the stock components except the torque arm

#70

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,240

Likes: 0

Received 79 Likes

on

70 Posts

I just bit the bullet on a new spooled S60.. I figured," done once, done 8's " .. well I know at least the rear axle will be good for an 8 sec 1/4 pass.. the rest of the car will now have to play catch up to the over grown S60.

I read that in the day Chrysler had the dana 60 as a "fix" for 4 speed stick big block cars that were lucky to put out 500hp. Some would break dodge 8 3/4 rears. They never had the power or 60ft times back then many cars do these days.. so how overkill is the S60 really. People seem afraid of it like it'll weigh their car down 1/2 second in the 1/4. That is not the case. A spooled S60 from Strange with race brakes, is barely heavier than the stock 93-02 10 bolt with lt1 or ls1 stock brakes.. so how bad can it be?????

Strange S60 lightweight 35 spline spool - 13.2 lbs

Im sure a stock posi unit from the POS stock 10 bolt is heavier than that. So again, all the internet hype about the Dana 60 being so much overkill, I don't see it. At least not when it has a spool. SO I decided I will try one.

No I don't work for Strange. I've just being weighing up the differences between 9" or S60 and I don't see an S60 w/ spool vs 9" w/spool being any noticeable ET loss or gain if both are running the same length/spline axles and brakes.

#71

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,240

Likes: 0

Received 79 Likes

on

70 Posts

I read over all the weight info in the past (from my own weights to various other reputable sources), and even read a back to back to back dyno comparison of 9, 12, s60. I can't remember everything exactly bc I quite frankly have too much info in my head and some gets lost over time. There is no doubt in my head that all are within reason of each other, weight wise and parasitic loss wise. 9 inch has the disadvantage due to the gear mesh is worse (but stronger), and s60 is THE heaviest out of the group we are talking about. 12 and 8.8 are favorable for their attributes. I mean I think they all have advantages/disadvantages. I have a Strange 12 bolt because I think I can make it live (smallest ring gear of the group). If I can, it will probably provide me with least drag (and no fabrication hassles of the 8.8) and its going to be the lightest other then a Fab9 which can beat it by a little bit. In retrospect, due to my frequent gear changes I wish I would have bought a 9 inch just for convenience, but other then that I actually think most times a 12 or 8.8 can get the job done on 99% of cars here. I know why most buy the s60 and thats because it is one of the cheapest, and biggest options, seems like a no brainer. In my eyes, if there is any way budget allows, if I'm gonna outgrow a 12/8.8, Id go straight to a 9 inch, an s60 wouldnt even be a consideration. But again, thats opinion. Also, I mean anything you can do to one like spool or lightweight brakes you can do to another to gain the same advantage. Your smaller rears like the 12/8.8 are capped in axle spline size due to the carrier bearings I.D. They simply only allow so much room to grow.

#73

Old School Heavy

iTrader: (16)

The problem that I had with the 8.5 is, that once I got to a certain power level, it started eating ring and pinions. It did fine until my full weight car started into the 9s. I think it was a housing flex problem. Also, there are no really strong posi units for the 8.5 like there is for the S60 and 9".

#74

TECH Addict

iTrader: (17)

The problem that I had with the 8.5 is, that once I got to a certain power level, it started eating ring and pinions. It did fine until my full weight car started into the 9s. I think it was a housing flex problem. Also, there are no really strong posi units for the 8.5 like there is for the S60 and 9".

To speedtigger, I like what you've said. You didn't have problem until our heavy car hit 9's. Which sounds about right. And means this.... and 8.5 is significantly stronger than a 7.5 and is just fine for probably 90% of people in general. A 7.5 is a junk rear end. A 8.5 is a decent one with limitations. There hundreds of thousands of these things behind small and big block performance cars all over the country. Trucks too obviously. Ever since I bought my current Transam I've been curious about putting an 8.5 in it. I'm never going to run 10's even. I rarely go the track. It seems like an economical - power and weight and parasitic power loss - choice.

Let's get back on topic. The OP did a good job of getting a stronger rear end in his car on the cheap. It's interesting and fun. 6 lug, additional width, obviously not ideal. He knows that. Just doing it because he/they thought about and thought they could. And did. Probably while having fun.

#76

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,240

Likes: 0

Received 79 Likes

on

70 Posts

#78

LS1Tech Administrator

iTrader: (3)

Join Date: Nov 2001

Location: Schiller Park, IL Member: #317

Posts: 32,046

Likes: 0

Received 1,493 Likes

on

1,075 Posts

I wouldn't quite go that far. While it's true that the 7.5" is often overwhelmed in manual trans applications, this isn't so much the case for a properly setup auto car. Here's an interesting thread that might be an eye opener for you, regarding just how much a 7.5" can take:

https://ls1tech.com/forums/gears-axl...ock-7-5-a.html

I've seen similar results locally with the 7.5, when I was regularly at the track with these cars. We had zero issues with several auto cars 60-footing in the 1.5x-1.7x range for years, unless they had uncontrolled wheel hop. Granted, the 1.5x cars had plenty of weight reduction, but there were several of us with full weight cars that did 1.6-1.7 for TONS of passes without rear issues.

There is a lot of truth to 01ssreda4's post below....

#80

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,240

Likes: 0

Received 79 Likes

on

70 Posts

GM guys around here know me as THE guy who can make a rear end live while being raced. Yes I have certain ways I like to set each one up, but I'm still self taught and my very first 7.5 I built hasn't broken yet. While everything mechanical has limits, if you call that rear junk, you're a keyboard mechanic nothing more, and not even a good one.