04 LM7 Cylinder Head Port/Polish- atomization area?

#1

Teching In

Thread Starter

Join Date: Dec 2013

Location: Chicago burbs

Posts: 26

Likes: 0

Received 0 Likes

on

0 Posts

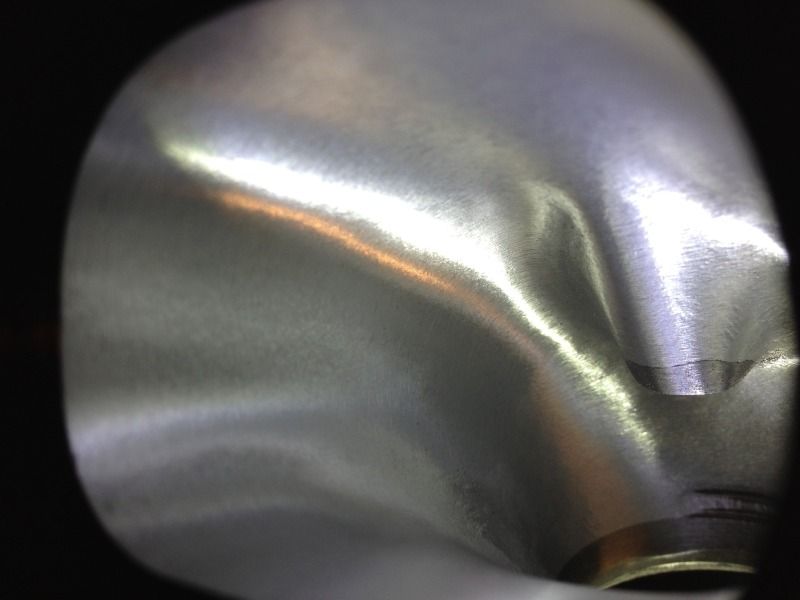

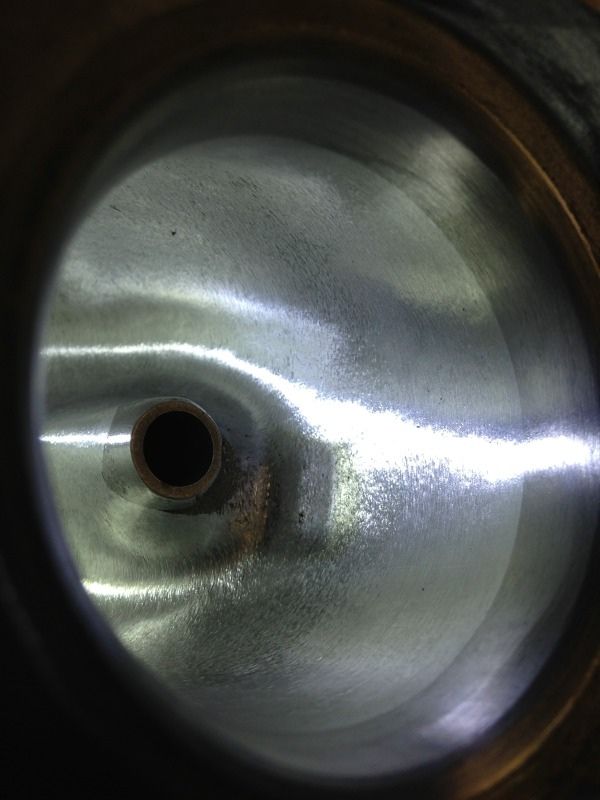

I have the valves and springs out and I have ported a couple of the exhaust ports to about 1/16th smaller than the OEM gasket size (I did not want to grind the exhaust port larger than the gasket size so I left some safety net room). I will be finishing the exhaust side soon and will then start on the intake side. I remember reading something about porting these heads that said to leave a certain area rough on the intake as it helps with atomization. However, the reading was not at all specific as to where this area is located. Based on the context of the reading I was fairly certain that they were not referring to the combustion chamber of the head but somewhere in the lower side of the intake port- near the valve seat maybe. (I know to be very careful not to touch the valve seat with the grinder)

Any ideas where the atomization area referenced is located? Also is there specific guidance for how much area to leave "rough"?

Any ideas where the atomization area referenced is located? Also is there specific guidance for how much area to leave "rough"?

#2

Teching In

Join Date: Dec 2013

Location: North Carolina

Posts: 11

Likes: 0

Received 0 Likes

on

0 Posts

I'm not so sure how accurate that information is? I'm not a porting expert by no means, but any aftermarket head you buy is completely ported and polished in every single area that air/fuel flows..

What causes atomization is your injector, it has nothing to do with the intake port. The mixing of fuel and air I suppose could be effected by the intake port, but once again this is all mainly determined by the injector, proper sizing, duty cycle, transient fueling, tune. But mainly the injector.

I am a design engineer for fuel injectors for Continental (formerly siemens) and everything depends on your injector, the spray pattern, the bend angle, the spray angle etc..

For example LS9 injectors will not work very well on a ls2 or ls3 because the injector is aimed at the port wall instead of the intake valve due to the boosted application. Can it be tuned to work? Yes.. But the tuner will have issues with wall wetting and transient fueling.

So I'm not sure where you read that, but I would port and polish every area, or you are going to have a turbulence pocket in the port that will hamper flow. Polish and port all of it man.

What causes atomization is your injector, it has nothing to do with the intake port. The mixing of fuel and air I suppose could be effected by the intake port, but once again this is all mainly determined by the injector, proper sizing, duty cycle, transient fueling, tune. But mainly the injector.

I am a design engineer for fuel injectors for Continental (formerly siemens) and everything depends on your injector, the spray pattern, the bend angle, the spray angle etc..

For example LS9 injectors will not work very well on a ls2 or ls3 because the injector is aimed at the port wall instead of the intake valve due to the boosted application. Can it be tuned to work? Yes.. But the tuner will have issues with wall wetting and transient fueling.

So I'm not sure where you read that, but I would port and polish every area, or you are going to have a turbulence pocket in the port that will hamper flow. Polish and port all of it man.

#3

11 Second Club

iTrader: (18)

most people say to leave the entire intake ports "rougher" than a fine grit cleanup or full polish like you can do on the exhaust

this really just means do your porting and you can sandpaper roll the whole port just keep the grit rough (60grit, 80 grit, something like that)

on the exhaust you can go 120grit or finer if you like

this really just means do your porting and you can sandpaper roll the whole port just keep the grit rough (60grit, 80 grit, something like that)

on the exhaust you can go 120grit or finer if you like