MMS 220 heads....Info, Pics, and discussion inside

#1

LS1Tech Sponsor

Thread Starter

Guys,

This is the "official" thread discussing the launch of what I feel is a very exciting new product.

I will get the apology out of the way now for the delay in sharing this information.....numerous folks have inquired (some numerous times), but my time is spread extremely thin of late and you juggle the time designing and building the product with the time you would like to spend talking about it....LOL

That being said gets us right to one of the first topics that should come as good news.....the product is available now.....in fact this past week I shipped the first half a dozen sets or so and have more in the works as well. Some of these builds are clearly more long term projects while others I suspect will be done alot sooner. Hoping for some independent results to start rolling in the next 3-6 weeks or so.

I also have a 347 forged shortblock being built for me by Golen Engines (I simply have no time), and I plan to use that engine to showcase the merits of the new design as well (on the engine dyno). I anticipate the lead time on that to be around the same (3-6 weeks) as I'm still awaiting the arrival of the shortblock. I may test a small cam (no flycut) and a more aggressive medium-plus sized cam (mid 230's @ .050) in the same engine to accurately show the trade offs and gains associated with a larger cam in the same exact engine. I may go 10 degrees larger in fact (a 227 intake lobe and a 237 int lobe potentially)....something notable but not over the top where the drivability becomes really poor. The first cam representing a great street/strip cam....the latter a great strip/street cam with enough civility to actually consider it. Pick your poison based on the type of build/application you have in mind knowing that flycutting or aftermarket pistons will be a must for the larger grind.

What was my objective with this design?? A few things come to mind that were permeating my brain during the development of this head. First and foremost, I wanted a head that would really work well on a 3.900 bore which I feel still represents a large chunk of the aftermarket in spite of it not being in production in close to a decade. That means minding the diameter of the intake valve was/is important.....also the cross section of the head needed to be modest to get the air speed where it needed to be at a reasonable RPM (assuming a 346/347 based combination). Having enough flow to also feed the newer crop of larger based 6.0 and 6.2 liter engines as well as the natural growth of a 346 to 383 CID through the use of a relatively affordable stroker crank was also an important design criteria. That meant I was hoping to see a legit 320 CFM's or so through a head with a modest sized valve and a modest cross section. Keep in mind guys a stock LS6 head is 210 - 212 cc.....most OEM ported heads that legitimately flow 300 CFM (not just on paper ), are usually 228 - 240 cc.

), are usually 228 - 240 cc.

The other large bulls eye for me for the 220 project was to create a cylinder head that in out of the box trim would rival a "Mamofied" AFR 215 in flow knowing that head has worked wonders on just about every build I have been privied to the information (my own builds and the independent results of my customers). That head has performed well on 346 all the way to 400+ CID LS2 based stroker engines (knowing how to cam them based on displacement/application making all the difference).

At the end of the day (more like a month and some change), I'm happy to say I hit all my design objectives and a little more. The MMS 220 is not only as good as a much more expensive hand finished AFR 215, it's actually a little better flowing over 320 CFM when tested on a 4" or larger bore (it goes almost 320 on a 3.900 bore!) and does this using only a 2.055 inlet valve. Its a very efficient head that brings a nice blend of substantial peak airflow (enough to comfortably make 600+ at the crank), and combine it with alot of velocity which is just as important as peak airflow numbers. Guys...its important you understand that managing the two of them is the name of the game for a really explosive package (and good valve control to keep all that goodness working the way its supposed to!).

Alot of guys on the phone have asked me whats the right sized engine for this head.....clearly I was focusing on an efficient piece for the venerable 346, but truthfully its the right sized head for alot of engines depending on application, but its sweet spot IMO is a 346 to a 383 based application.

OK....its past 3AM and I would like to wrap this up so let me share some of the flow bench data with you folks....keep in mind all flow equipment is not the same and NOT comparable. I can tell you that the original head I designed for AFR in 2004 which still holds its own today (the AFR 205) on the same bench and the same 3.900 bore, it flowed 298 CFM at .600 (20 less that the MMS 220)....a stock LS1 head flows 230 CFM and a stock LS6 casting around 250-255 CFM. These numbers being shared to get a better handle on the type of CFM gains we are discussing and how they relate to the real world. I have tested alot of "325 CFM" heads that barely mustered 300 on my equipment....see the oldie but goodie stickey in this section I started many years back for some background and good reading in spite of it being dated. Btw, a stock LS3 head with a 2.165 valve at 260 cc's and a raised runner design flows about 320 CFM on a 4" bore (but sadly only 210 CFM on the exhaust). Consider/visualize what a 40 cc difference in size really equates two. A cc (cubic centimeter)....maybe a little smaller than a cube of sugar....but picture 40 of then stacked on your desk in front of you. Its a HUGE difference.....10 cc's easily seen be eye gazing into a port without having to be an expert in cylinder head design.

Anyway....lets get into the numbers

First on the 3.900 bore

Lift.....Int.....Exh

.200....151....126

.300....214....183

.400....260....217

.500....296....234

.550....311....239

.600....318....243

Now the 4.060 bore

.200....152....130

.300....216....184

.400....266....222

.500....302....239

.550....315....245

.600....323....249

Solid numbers on both bore sizes.....but seeing how the 3.900 chokes alot of the better flowing heads, I'm especially pleased with those results. Really strong for a modest sized head with a modest sized intake valve. Like I said earlier, a great compromise of peak flow and high velocity which really means its just a well designed port more than anything else....that's the trick to getting both. With a larger less efficient design (a stock LS3 for example), it relies on sheer size (both in valve and port size) to achieve similar peak airflow figures (on the intake side at least), but your completely missing the inertia and extra cylinder fill available from the velocity portion of the equation. It also takes longer to activate a larger valve/larger port design which also delays/hampers some of the cylinder fill. Now I don't want this thread to turn into a cathedral versus square port thread....I could use the old school oval port BBC versus rect port but its easier to discuss the LS3 only as most of you are familiar with and can relate to it. There are tricks to getting everything to work OK (reducing some of the certain handicap), but at the end of the day a more efficient design is always more desirable if your focused on the scope of the entire power delivery.....especially when discussing part throttle and roll on seat of the pants stuff....a larger less efficient design really hurts you in that department due to almost zero inertia from the slower moving column of air.

So I have to break this retarded long post into two parts....typical for a topic I'm trying to be thorough with (another reason I conveniently avoided tackling it....LOL).

-Tony

This is the "official" thread discussing the launch of what I feel is a very exciting new product.

I will get the apology out of the way now for the delay in sharing this information.....numerous folks have inquired (some numerous times), but my time is spread extremely thin of late and you juggle the time designing and building the product with the time you would like to spend talking about it....LOL

That being said gets us right to one of the first topics that should come as good news.....the product is available now.....in fact this past week I shipped the first half a dozen sets or so and have more in the works as well. Some of these builds are clearly more long term projects while others I suspect will be done alot sooner. Hoping for some independent results to start rolling in the next 3-6 weeks or so.

I also have a 347 forged shortblock being built for me by Golen Engines (I simply have no time), and I plan to use that engine to showcase the merits of the new design as well (on the engine dyno). I anticipate the lead time on that to be around the same (3-6 weeks) as I'm still awaiting the arrival of the shortblock. I may test a small cam (no flycut) and a more aggressive medium-plus sized cam (mid 230's @ .050) in the same engine to accurately show the trade offs and gains associated with a larger cam in the same exact engine. I may go 10 degrees larger in fact (a 227 intake lobe and a 237 int lobe potentially)....something notable but not over the top where the drivability becomes really poor. The first cam representing a great street/strip cam....the latter a great strip/street cam with enough civility to actually consider it. Pick your poison based on the type of build/application you have in mind knowing that flycutting or aftermarket pistons will be a must for the larger grind.

What was my objective with this design?? A few things come to mind that were permeating my brain during the development of this head. First and foremost, I wanted a head that would really work well on a 3.900 bore which I feel still represents a large chunk of the aftermarket in spite of it not being in production in close to a decade. That means minding the diameter of the intake valve was/is important.....also the cross section of the head needed to be modest to get the air speed where it needed to be at a reasonable RPM (assuming a 346/347 based combination). Having enough flow to also feed the newer crop of larger based 6.0 and 6.2 liter engines as well as the natural growth of a 346 to 383 CID through the use of a relatively affordable stroker crank was also an important design criteria. That meant I was hoping to see a legit 320 CFM's or so through a head with a modest sized valve and a modest cross section. Keep in mind guys a stock LS6 head is 210 - 212 cc.....most OEM ported heads that legitimately flow 300 CFM (not just on paper

), are usually 228 - 240 cc.

), are usually 228 - 240 cc.The other large bulls eye for me for the 220 project was to create a cylinder head that in out of the box trim would rival a "Mamofied" AFR 215 in flow knowing that head has worked wonders on just about every build I have been privied to the information (my own builds and the independent results of my customers). That head has performed well on 346 all the way to 400+ CID LS2 based stroker engines (knowing how to cam them based on displacement/application making all the difference).

At the end of the day (more like a month and some change), I'm happy to say I hit all my design objectives and a little more. The MMS 220 is not only as good as a much more expensive hand finished AFR 215, it's actually a little better flowing over 320 CFM when tested on a 4" or larger bore (it goes almost 320 on a 3.900 bore!) and does this using only a 2.055 inlet valve. Its a very efficient head that brings a nice blend of substantial peak airflow (enough to comfortably make 600+ at the crank), and combine it with alot of velocity which is just as important as peak airflow numbers. Guys...its important you understand that managing the two of them is the name of the game for a really explosive package (and good valve control to keep all that goodness working the way its supposed to!).

Alot of guys on the phone have asked me whats the right sized engine for this head.....clearly I was focusing on an efficient piece for the venerable 346, but truthfully its the right sized head for alot of engines depending on application, but its sweet spot IMO is a 346 to a 383 based application.

OK....its past 3AM and I would like to wrap this up so let me share some of the flow bench data with you folks....keep in mind all flow equipment is not the same and NOT comparable. I can tell you that the original head I designed for AFR in 2004 which still holds its own today (the AFR 205) on the same bench and the same 3.900 bore, it flowed 298 CFM at .600 (20 less that the MMS 220)....a stock LS1 head flows 230 CFM and a stock LS6 casting around 250-255 CFM. These numbers being shared to get a better handle on the type of CFM gains we are discussing and how they relate to the real world. I have tested alot of "325 CFM" heads that barely mustered 300 on my equipment....see the oldie but goodie stickey in this section I started many years back for some background and good reading in spite of it being dated. Btw, a stock LS3 head with a 2.165 valve at 260 cc's and a raised runner design flows about 320 CFM on a 4" bore (but sadly only 210 CFM on the exhaust). Consider/visualize what a 40 cc difference in size really equates two. A cc (cubic centimeter)....maybe a little smaller than a cube of sugar....but picture 40 of then stacked on your desk in front of you. Its a HUGE difference.....10 cc's easily seen be eye gazing into a port without having to be an expert in cylinder head design.

Anyway....lets get into the numbers

First on the 3.900 bore

Lift.....Int.....Exh

.200....151....126

.300....214....183

.400....260....217

.500....296....234

.550....311....239

.600....318....243

Now the 4.060 bore

.200....152....130

.300....216....184

.400....266....222

.500....302....239

.550....315....245

.600....323....249

Solid numbers on both bore sizes.....but seeing how the 3.900 chokes alot of the better flowing heads, I'm especially pleased with those results. Really strong for a modest sized head with a modest sized intake valve. Like I said earlier, a great compromise of peak flow and high velocity which really means its just a well designed port more than anything else....that's the trick to getting both. With a larger less efficient design (a stock LS3 for example), it relies on sheer size (both in valve and port size) to achieve similar peak airflow figures (on the intake side at least), but your completely missing the inertia and extra cylinder fill available from the velocity portion of the equation. It also takes longer to activate a larger valve/larger port design which also delays/hampers some of the cylinder fill. Now I don't want this thread to turn into a cathedral versus square port thread....I could use the old school oval port BBC versus rect port but its easier to discuss the LS3 only as most of you are familiar with and can relate to it. There are tricks to getting everything to work OK (reducing some of the certain handicap), but at the end of the day a more efficient design is always more desirable if your focused on the scope of the entire power delivery.....especially when discussing part throttle and roll on seat of the pants stuff....a larger less efficient design really hurts you in that department due to almost zero inertia from the slower moving column of air.

So I have to break this retarded long post into two parts....typical for a topic I'm trying to be thorough with (another reason I conveniently avoided tackling it....LOL).

-Tony

__________________

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

#2

LS1Tech Sponsor

Thread Starter

You guys still with me....I commend you if you are! (Really sorry for the lengthy post....just wanted to share my personal "mission" with this new head).

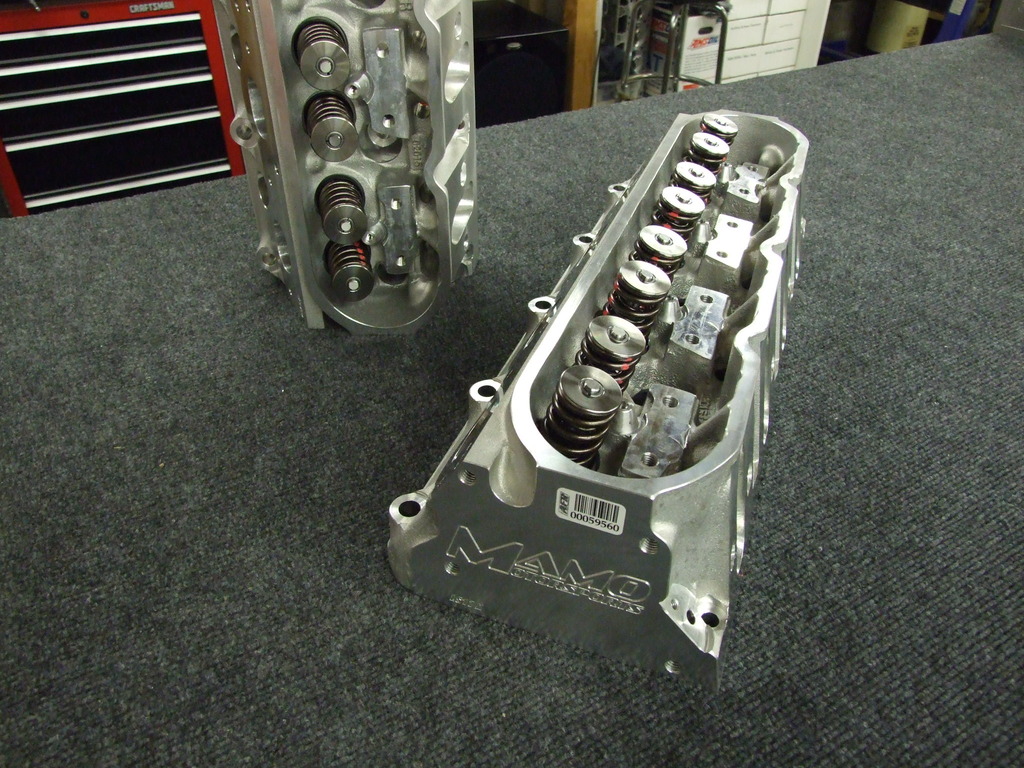

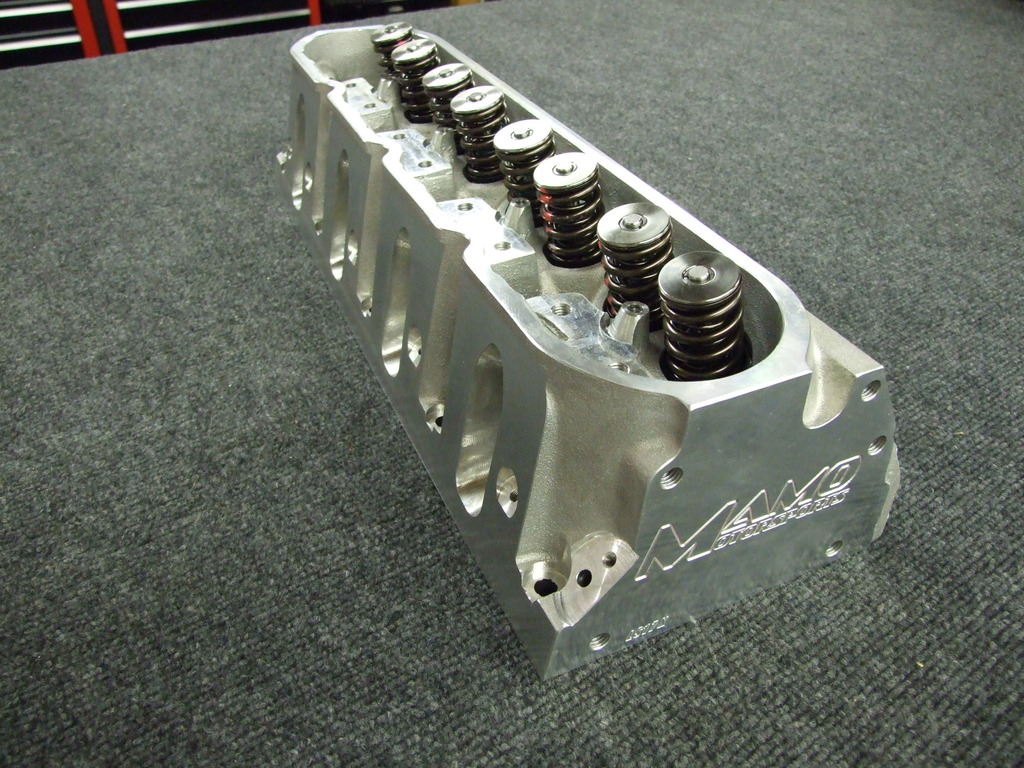

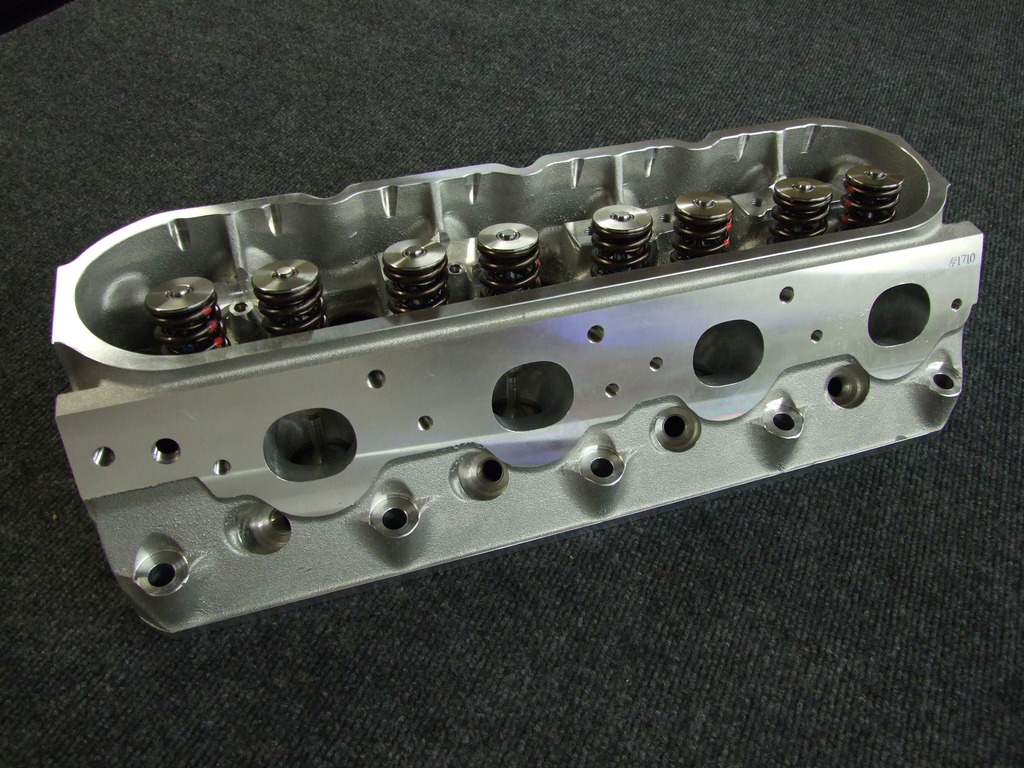

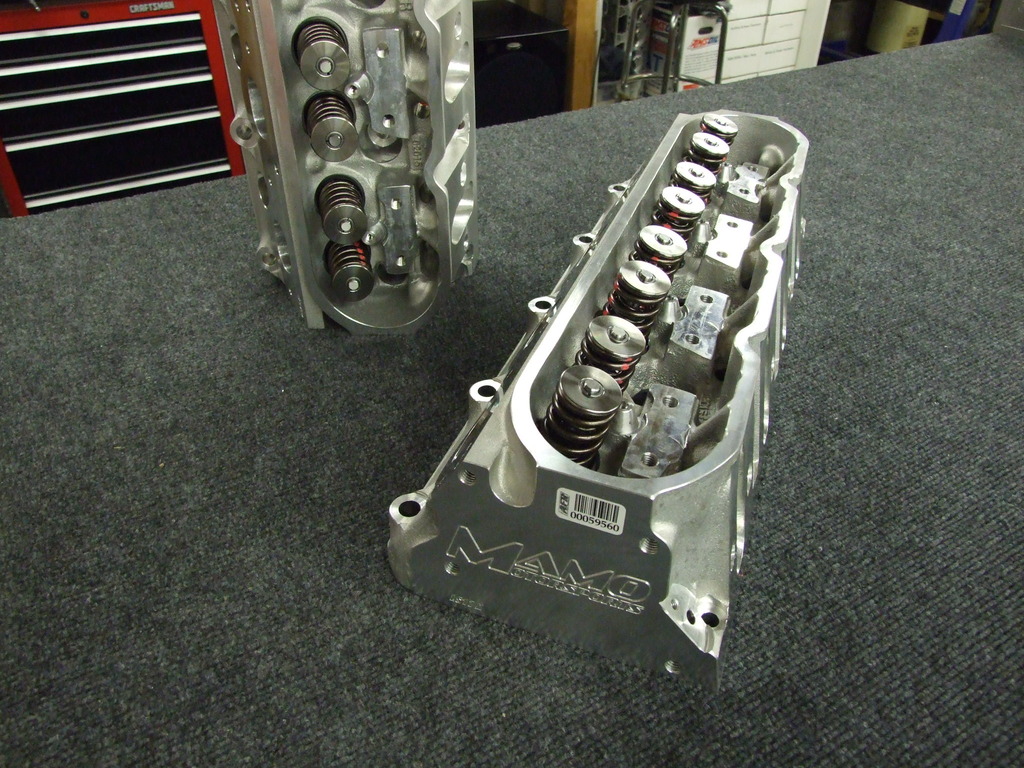

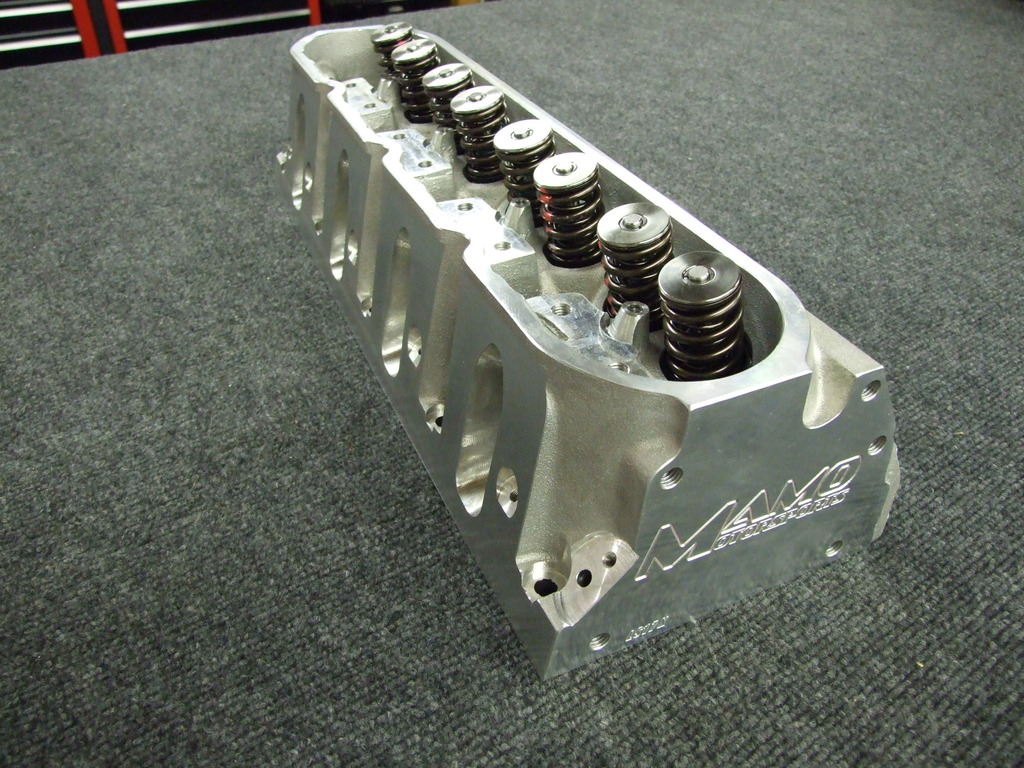

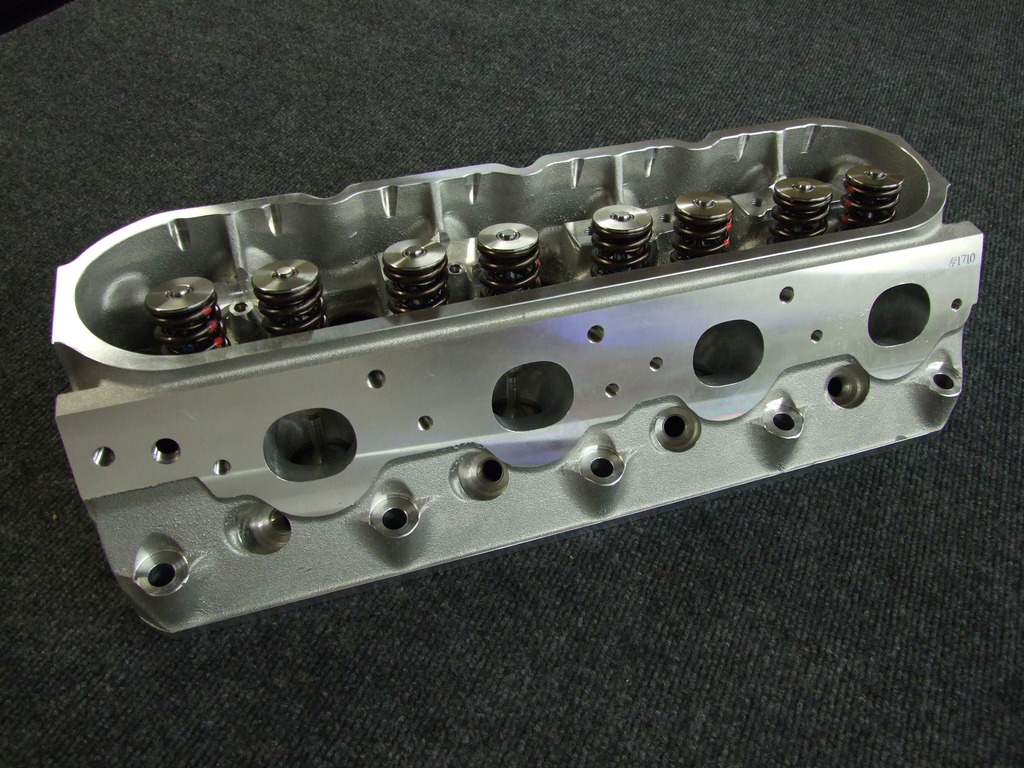

I don't have alot of pics but I did take the time to snap a few.....some of them you likely saw in a few other threads I mentioned the head in but for the sake of those who may have missed them I will include them here as well.

Guys, regarding pricing I would like to get into more detail in one of my next posts, but I would quickly mention the base price of the new MMS 220's with a 150lb (seat pressure) high quality HR spring and a titanium retainer (fully assembled) is $2650

In wrapping up I really want to convey that the level of execution of the CNC and valvejob integration into the chamber and bowl is really well done....my best work to date. This is what helped this head be such a winner in out of the box trim. While hand finishing it will no doubt improve it a notch further (no mass produced CNC part can be perfect.....not yet at least), its not required to punch a big number....but for the guys with a larger budget looking for ALL the money, its still something worth considering.

That said I will also include a pic of a "Mamofied" 220 I shipped last week....its "aluminum art" meets a cylinder head.....LOL. While Its impossible to get that type of seat, bowl, and chamber transition off a machine (at this price level at least), the out of the box 220 is very impressive I assure you

I'm sure you guys will have questions etc....will do my best to get back to this thread as quickly as possible and get everyone handled.

Cheers,

Tony

PS....Keep your eye out for another post addressing the next MMS cylinder head in this cathedral line.....a new 235 cc head aimed squarely at the 4" stroker stock block crowd.....400 - 416 CID. Similar level of detail and efficiency.....larger runner, more flow, and a larger valve to compliment the larger engines it is designed for.

I don't have alot of pics but I did take the time to snap a few.....some of them you likely saw in a few other threads I mentioned the head in but for the sake of those who may have missed them I will include them here as well.

Guys, regarding pricing I would like to get into more detail in one of my next posts, but I would quickly mention the base price of the new MMS 220's with a 150lb (seat pressure) high quality HR spring and a titanium retainer (fully assembled) is $2650

In wrapping up I really want to convey that the level of execution of the CNC and valvejob integration into the chamber and bowl is really well done....my best work to date. This is what helped this head be such a winner in out of the box trim. While hand finishing it will no doubt improve it a notch further (no mass produced CNC part can be perfect.....not yet at least), its not required to punch a big number....but for the guys with a larger budget looking for ALL the money, its still something worth considering.

That said I will also include a pic of a "Mamofied" 220 I shipped last week....its "aluminum art" meets a cylinder head.....LOL. While Its impossible to get that type of seat, bowl, and chamber transition off a machine (at this price level at least), the out of the box 220 is very impressive I assure you

I'm sure you guys will have questions etc....will do my best to get back to this thread as quickly as possible and get everyone handled.

Cheers,

Tony

PS....Keep your eye out for another post addressing the next MMS cylinder head in this cathedral line.....a new 235 cc head aimed squarely at the 4" stroker stock block crowd.....400 - 416 CID. Similar level of detail and efficiency.....larger runner, more flow, and a larger valve to compliment the larger engines it is designed for.

__________________

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

#3

TECH Veteran

JUST SPECTACULAR!! You out of all people that does cylinder heads talk about/mention VELOCITY the most. That tells me that it is a Overlook part of most engine builds but VERY CRITICAL for a street car. VELOCITY- is that how a "flat torque" is obtain? I just figured up the intake/exhaust ratio...... it's Awesome!!

#6

Moderator

iTrader: (4)

Join Date: Jul 2014

Location: My own internal universe

Posts: 10,452

Received 1,852 Likes

on

1,152 Posts

So beautiful. Am I less of a man if I cry?

Trending Topics

#11

Congratulations on getting them up and running mate, hopefully you can finally draw a deep breath and get a bit more sleep now  . They look really impressive, hopefully they are a big success for yourself and your customers.

. They look really impressive, hopefully they are a big success for yourself and your customers.

DB.

P.S. If you happen to be looking for a bunny in Aus to test them out for you, I could possibly be forced to swap you my 210 V2's for a set.

. They look really impressive, hopefully they are a big success for yourself and your customers.

. They look really impressive, hopefully they are a big success for yourself and your customers.DB.

P.S. If you happen to be looking for a bunny in Aus to test them out for you, I could possibly be forced to swap you my 210 V2's for a set.

#14

LS1Tech Sponsor

Thread Starter

See Jake's post above yours....LOL

This casting is no different in geometry than an AFR casting.....in fact it IS an AFR casting and comes with AFR's lifetime warranty which is a nice perk and something I probably should have touched on in my first post.

So back to rockers.....you can run stock or any aftermarket rocker meant to fit a stock LS casting.

My preference is clearly Yella Terra as the wipe pattern is MUCH improved over stock and you increase your effective guide life by triple at least (removing the scrubbing that the stock rocker arm imparts on the guides).

I also offer a beefier 10mm version of that popular rocker arm which is my rocker of choice for the guys that have a little more "creative freedom" with the budget....LOL Its a stouter base and a larger bolt so you get less rocking and flexing of both the rocker arm and the stand and less of that means more action at the valve (higher lift and more effective duration) obviously increasing your bottom line in the power department as well as increasing relaibility. Like the old school guys that use to upgrade from 3/8 SBC studs to 7/16.....not much different or should I say all the same benefits apply (more power and better reliability).

As Jake also mentioned if the heads are ordered thru me I can have them opened up in the CNC machine (to accept the larger bolt/stand configuration) saving you time and money but most importantly the peace of mind of knowing it was done correctly. They are ready to accept the "Pro" version of the Ultralite rocker right out of the box. I ran these on the Vader build and many other customer's builds in the last 1-2 years.

These rockers are only available thru Mamo Motorsports btw as I was deeply involved in the development and original Ultralite rockers many years ago and have a longstanding relationship with management.

Gotta hop.....will check in on this thread tonight before I hit the sack!

Regards,

Tony

This casting is no different in geometry than an AFR casting.....in fact it IS an AFR casting and comes with AFR's lifetime warranty which is a nice perk and something I probably should have touched on in my first post.

So back to rockers.....you can run stock or any aftermarket rocker meant to fit a stock LS casting.

My preference is clearly Yella Terra as the wipe pattern is MUCH improved over stock and you increase your effective guide life by triple at least (removing the scrubbing that the stock rocker arm imparts on the guides).

I also offer a beefier 10mm version of that popular rocker arm which is my rocker of choice for the guys that have a little more "creative freedom" with the budget....LOL Its a stouter base and a larger bolt so you get less rocking and flexing of both the rocker arm and the stand and less of that means more action at the valve (higher lift and more effective duration) obviously increasing your bottom line in the power department as well as increasing relaibility. Like the old school guys that use to upgrade from 3/8 SBC studs to 7/16.....not much different or should I say all the same benefits apply (more power and better reliability).

As Jake also mentioned if the heads are ordered thru me I can have them opened up in the CNC machine (to accept the larger bolt/stand configuration) saving you time and money but most importantly the peace of mind of knowing it was done correctly. They are ready to accept the "Pro" version of the Ultralite rocker right out of the box. I ran these on the Vader build and many other customer's builds in the last 1-2 years.

These rockers are only available thru Mamo Motorsports btw as I was deeply involved in the development and original Ultralite rockers many years ago and have a longstanding relationship with management.

Gotta hop.....will check in on this thread tonight before I hit the sack!

Regards,

Tony

__________________

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

#15

TECH Enthusiast

iTrader: (3)

Join Date: Dec 2004

Location: Tulsa OK

Posts: 514

Likes: 0

Received 0 Likes

on

0 Posts

I noticed you said the heads retain the stock geometry. What is your reasoning behind that when most other cylinder head manufacturers change the valve angle from stock? I have absolutely no doubt your heads will perform outstandingly well, I'm just curious.

#19

LS1Tech Sponsor

Thread Starter

Regarding the second port of your question, both essentially....if a customer opts to purchase an out of the box version its a completely CNC ported head....includes my latest and greatest port design....valvejob profiles (and valve profiles as well), and its simply an excellent flowing piece out of the box. Most guys that have followed my career know I also offer hand finishing which takes a really good production piece and makes it into the equivalent of a prototype port in every hole.....small gains are seen at most lift points on both intake and exhaust. To be down right honest the best reason to consider hand finishing (assuming you have the extra coin), is because it eliminates most variables and stacking of tolerances available in every mass produced part. Small lips and steps and CNC transitions that aren't perfect are all optimized and I normally use a slightly different VJ profile in the hand finished stuff cause I know I'm going to hand finish it....LOL It wouldn't be as user friendly in a production piece where I'm trying to account for inevitable small movements in sizing and location from one CNC machine to the next.....a tool change can make a big difference at this level.

If your looking for ALL the money....utter perfection from the flow paths, consistency, and getting the most flow from all 16 holes (int and exh), you go with my CNC+ option.....aka Mamofied.....hand finished.....call it what you like.....LOL

Considering the time I invested to get them as good as they are out of the box, whats all that worth over a stock 220 most of the time....probably about 10 RWHP. And I say most of the time because if you happen to get one off the CNC with a dialed in machine and brand new porting tools it may only be worth 7 RWHP but if you get one of the CNC that might have a few thou run-out in the X and Y axis and the tool is getting close to its expiration in hours you may see 13 HP. That's the real deal honest assessment of what your dealing with no matter what company has their logo on the end pad. Anyone in the industry will tell you the same if they choose to be that straight up with you.

Its nice to have options....for the guys stretching just to get into a head of this caliber and moving away from very inefficient ported OEM castings, out of the box is going to perform excellent.....you would have zero regrets....as I said it's the equivalent of a much more expensive head that has shown to be an excellent performing piece. If your fortunate enough to have a larger budget and your swinging for the fences with the build, my CNC+ option offers decent value for the extra flow and extra ponies it worth when the smoke clears and the peace of mind of knowing you didn't leave a stone unturned in an attempt to provide your engine with every CFM available.

Alright guys.....another loooong day comes to a close

Actually before I sign off I also wanted to say thanks for all the positive commentary and well wishes etc. in this thread....it means alot to me and it makes the time I invest seem a little more worthwhile if you know what I mean.....so again thank you and I'm excited about the upcoming dyno results of these new heads.

Cheers,

Tony

PS....Flowed the upcoming MMS 235's tonight late this evening for the first time.....they are jamming as well. Very pleased....340-345 CFM's thru a 2.100 valve.....about the same level of efficiency as the 220....just a larger version of all its goodness

__________________

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

Last edited by Tony @ Mamo Motorsports; 03-24-2015 at 05:56 AM.

#20

LS1Tech Sponsor

Thread Starter

-Tony

__________________

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

Last edited by Tony @ Mamo Motorsports; 03-24-2015 at 05:57 AM.

That's the best you could do...

That's the best you could do...