Balancer bolt issues. Need help

#1

Alright guys I did my 2nd cam swap on my vette this past weekend

First off, Screw ARP balancer bolts, never using one again. Im not sure if there is something with the early ls1's but that bolt was definitely too long and almost ruined the threads in my crank.

Basically what happened is I was in the process of torquing the ARP bolt and it just seem to keep spinning/cross threading and never getting tight so before it did damage I decided to pull it out and inspect. Well that bolt was a total bitch to try and get back out. Sure enough, the end of the bolt looked like a mushroom and the threads on the bolt were pretty messed up. I was able to stick a pen magnet in there and get all the metal shavings out and I threaded my old balancer bolt in and out with some bolt blaster on there to clean it as best I could. I probably threaded it in and out 50 times. cleaning off the bolt with a rag every time until the threads came clean. I also use compressed air in the snout. Once I had done all this, the bolt would thread in and out by hand with ease and didnt seem to get hung up or anything.

So I ended up using a new GM bolt but Im worried about 2 things

1. Im worried about the small amount of bolt blaster that may still be in the hole when I was cleaning up the threads.

2. When I installed the new bolt I didnt have access to the torque specs/procedure for installing a new bolt. So I seated the balancer completely and then torqued it to 160ft lbs. This sucker was tight. It would have taken a gorilla with a 5ft pole to be able to get it any tigher and I was NOT about to break a bolt off in my crank and try and go further.

Unfortunately on a vette the crank bolt isnt easily accessed because the steering rack is in the way.

Do you guys think ill be ok? Do you think its tight enough?

Any opinions are welcome

First off, Screw ARP balancer bolts, never using one again. Im not sure if there is something with the early ls1's but that bolt was definitely too long and almost ruined the threads in my crank.

Basically what happened is I was in the process of torquing the ARP bolt and it just seem to keep spinning/cross threading and never getting tight so before it did damage I decided to pull it out and inspect. Well that bolt was a total bitch to try and get back out. Sure enough, the end of the bolt looked like a mushroom and the threads on the bolt were pretty messed up. I was able to stick a pen magnet in there and get all the metal shavings out and I threaded my old balancer bolt in and out with some bolt blaster on there to clean it as best I could. I probably threaded it in and out 50 times. cleaning off the bolt with a rag every time until the threads came clean. I also use compressed air in the snout. Once I had done all this, the bolt would thread in and out by hand with ease and didnt seem to get hung up or anything.

So I ended up using a new GM bolt but Im worried about 2 things

1. Im worried about the small amount of bolt blaster that may still be in the hole when I was cleaning up the threads.

2. When I installed the new bolt I didnt have access to the torque specs/procedure for installing a new bolt. So I seated the balancer completely and then torqued it to 160ft lbs. This sucker was tight. It would have taken a gorilla with a 5ft pole to be able to get it any tigher and I was NOT about to break a bolt off in my crank and try and go further.

Unfortunately on a vette the crank bolt isnt easily accessed because the steering rack is in the way.

Do you guys think ill be ok? Do you think its tight enough?

Any opinions are welcome

Last edited by Jarren_b; 03-30-2015 at 06:53 PM.

#2

TECH Senior Member

iTrader: (25)

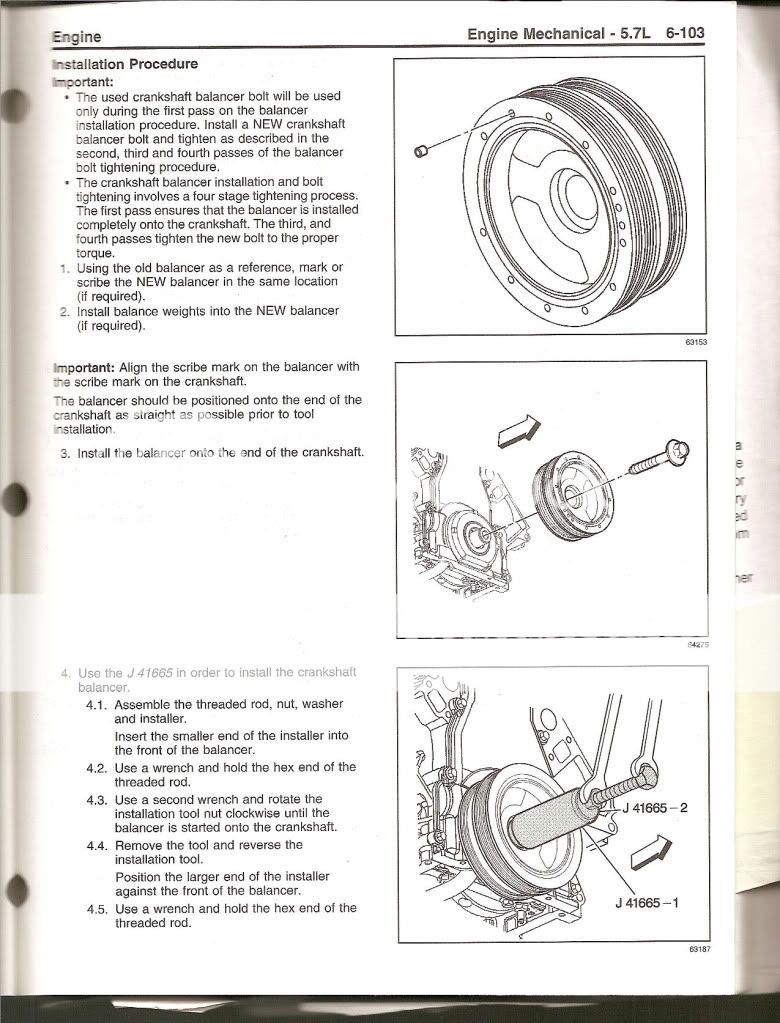

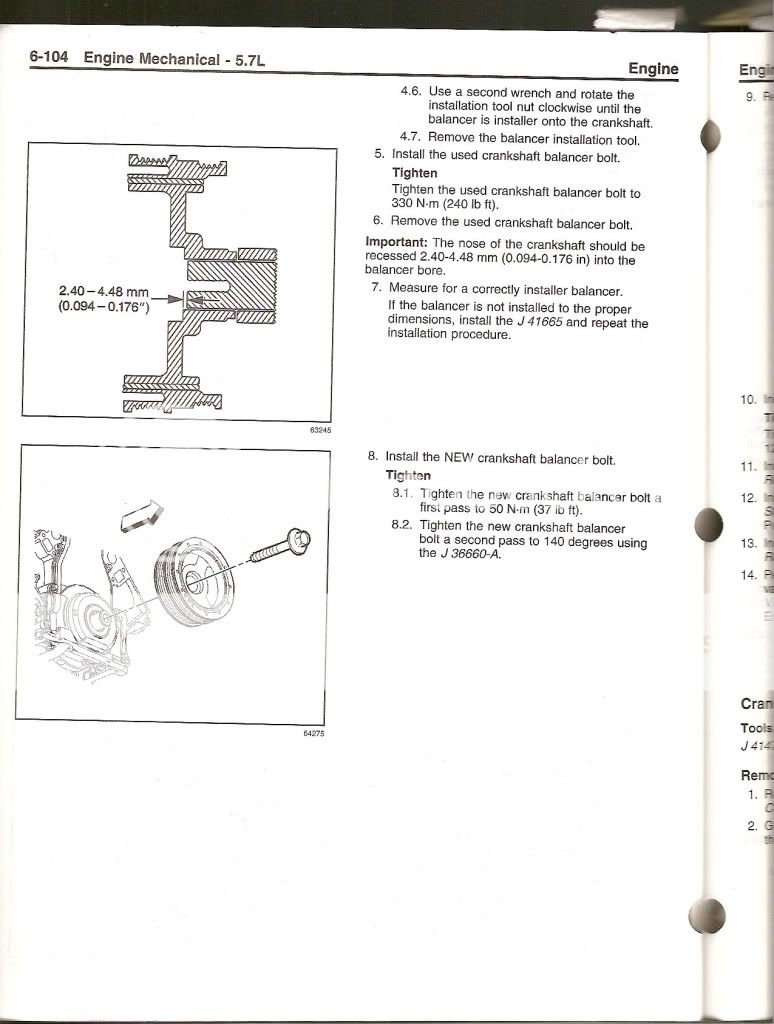

So what if people say it will be OK, it's tight enough, then it backs out. A lot of good those opinions will be, right? The tq specs are tighten to 250 ft lbs with the old bolt to seat the pulley, remove old bolt, then with new bolt, tighten to 37 ft lbs then turn an additional 140 degrees. Would only be a wild *** guess how close to that 160 ft lbs is.

#4

I just used what they sent me so im not sure but its ridiculous if they sent the wrong one. The reason i went to 160 is because that's the highest my torque wrench would go. I mean i could try and go further i guess. I guess i was wondering if anyone had sucess with a standard tq spec on a stock bolt

#6

TECH Senior Member

iTrader: (4)

So what if people say it will be OK, it's tight enough, then it backs out. A lot of good those opinions will be, right? The tq specs are tighten to 250 ft lbs with the old bolt to seat the pulley, remove old bolt, then with new bolt, tighten to 37 ft lbs then turn an additional 140 degrees. Would only be a wild *** guess how close to that 160 ft lbs is.

I don't think you had the correct ARP bolt either.

#7

Rather than hope it doesnt come off Im just going to order another new bolt and reinstall the balancer. I noticed that my timing cover is leaking a little, probably didnt put enough rtv on the bottom so I guess its coming off.. But id be willing to bet that the 160ft lbs I put on that bolt is more than enough. Guess its coming off anyway

Trending Topics

#12

Rather than hope it doesnt come off Im just going to order another new bolt and reinstall the balancer. I noticed that my timing cover is leaking a little, probably didnt put enough rtv on the bottom so I guess its coming off.. But id be willing to bet that the 160ft lbs I put on that bolt is more than enough. Guess its coming off anyway

#13

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,240

Likes: 0

Received 79 Likes

on

70 Posts

To properly torque a stock bolt its going to take more then 150ish foot pounds. To get to the degree that they want you to it takes a heck of a cheater pipe and you still gotta pull like hell. I recently did a diesel and the figure was around 250 for the crank bolt and it was very similar to doing an fbody stretch bolt so im guessing its in that neighborhood of 250.

#14

Its 250 to reinstall the balancer. The ARP bolt requires 180ft lbs if I remember correctly. So basically there is no way the stock one requires 250.

#15

To properly torque a stock bolt its going to take more then 150ish foot pounds. To get to the degree that they want you to it takes a heck of a cheater pipe and you still gotta pull like hell. I recently did a diesel and the figure was around 250 for the crank bolt and it was very similar to doing an fbody stretch bolt so im guessing its in that neighborhood of 250.

#17

Fully aware of the correct way to do it. and yes ill live with the consequences of not going clear to 140 degrees. ill get close but if it requires a breaker bar and a floor jack handle to get me there than ill take the chance so that I dont break a bolt and have to pull my motor to replace the crank.

#18

Fully aware of the correct way to do it. and yes ill live with the consequences of not going clear to 140 degrees. ill get close but if it requires a breaker bar and a floor jack handle to get me there than ill take the chance so that I dont break a bolt and have to pull my motor to replace the crank.

#19

TECH Enthusiast

iTrader: (3)

Fully aware of the correct way to do it. and yes ill live with the consequences of not going clear to 140 degrees. ill get close but if it requires a breaker bar and a floor jack handle to get me there than ill take the chance so that I dont break a bolt and have to pull my motor to replace the crank.

Also, it shouldn't take you a cheater bar to hit 250 ft/lbs. Get a 300 ft/lb torque wrench, the handle is plenty long to get the leverage.