Experiment: Cam Motion Low Lash Solid Roller with stock rocker arms

#21

Interesting approach! Just to let others know, all this is completely dependent on many different factors. Heads milled, gasket thickness, base circle, etc. So whatever thunderstruck comes up with for pushrods and shims on his combo will most likely NOT work on a different engine. As you can see, he has done very thorough measuring to get where he is now...

It might be possible to accomplish with stock GM heads, but I have not been able to fully confirm GM tolerance for installed valve stem height. I knew mine had a lot of miles (the heads were bought used here from a failed engine and one chamber even had damage) and a recent valvejob 6000 miles ago. My head guy specifically mentioned he had to cut a few deeper than others due to valve seats being beat up.

This isn't a toss together and run project. But to be fair neither is a solid roller using adjustable rockers...it's just easier to do the adjusting.

But once it is done it should be set it and forget it for many miles. I will be checking to confirm.

Just order this....with everything else you have making things much more challenging you will thank me for the time it saves you by getting the pushrods closer to perfect. Its $49.....no big deal

(Then you can loan it to your buddies when they need it!)

http://www.harborfreight.com/12-inch...per-47261.html

Good luck

-Tony

(Then you can loan it to your buddies when they need it!)

http://www.harborfreight.com/12-inch...per-47261.html

Good luck

-Tony

You could also get this caliper for $30 http://www.harborfreight.com/8-inch-...per-47260.html

#22

#23

Local Harbor Freight has both 12" and 8" calipers in stock for the online prices.

I bought the 8", should make things go a little easier. I intend to check each pushrod and see if they vary. If there is a variance I can move them around to minimize shimming.

I bought the 8", should make things go a little easier. I intend to check each pushrod and see if they vary. If there is a variance I can move them around to minimize shimming.

#24

Originally Posted by thunderstruck507

Local Harbor Freight has both 12" and 8" calipers in stock for the online prices.

I bought the 8", should make things go a little easier. I intend to check each pushrod and see if they vary. If there is a variance I can move them around to minimize shimming.

I bought the 8", should make things go a little easier. I intend to check each pushrod and see if they vary. If there is a variance I can move them around to minimize shimming.

#27

#28

TECH Apprentice

iTrader: (11)

The shims came as a set ranging .010" - .060"

Not trying to take away from thunderstruck407's thread here, as I am very intrigued by what the final monetary investment will be.

#29

Cam Motion had some BTR pushrods drop shipped to me and I got them in today. Regular .080" walls 7.275' advertised length. Of note my old Comp pushrods varied by as much as .012" in length, the BTRs were within about .006". Might be from wear?

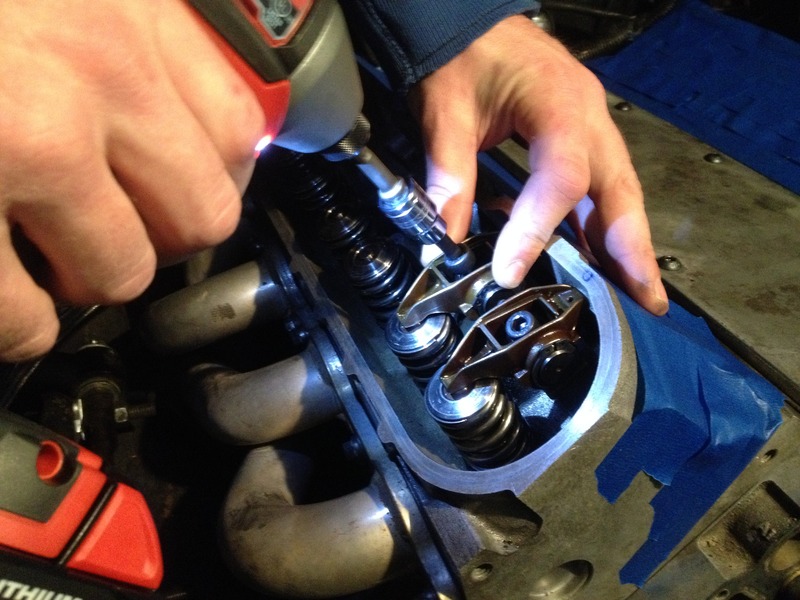

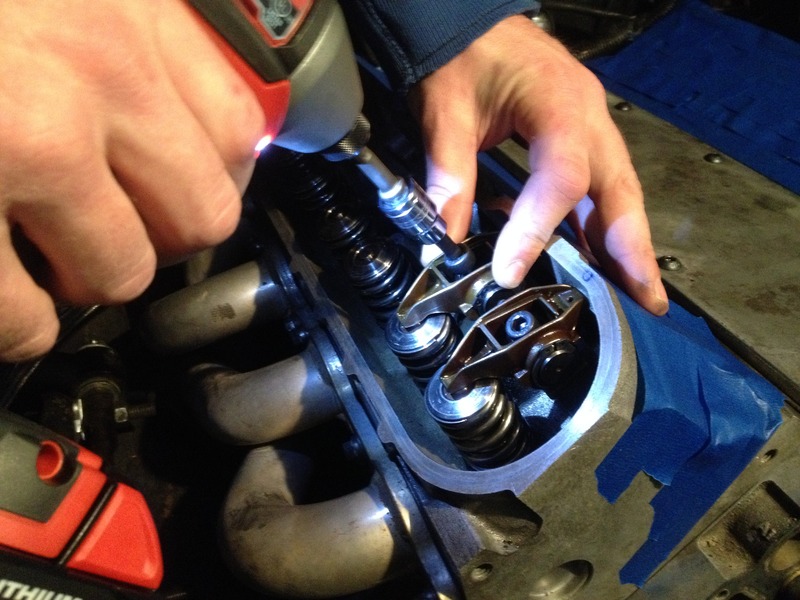

Shimming turned out to be an easy task, just time consuming. The key here being the cut pedestals and an extra set of hands helped too.

Patience is key. Shim thickness does not directly correlate to lash at the tip. This means it becomes straight trial and error.

Prepare for detailed post outlining the procedure as soon as I get photobucket to cooperate.

Shimming turned out to be an easy task, just time consuming. The key here being the cut pedestals and an extra set of hands helped too.

Patience is key. Shim thickness does not directly correlate to lash at the tip. This means it becomes straight trial and error.

Prepare for detailed post outlining the procedure as soon as I get photobucket to cooperate.

#30

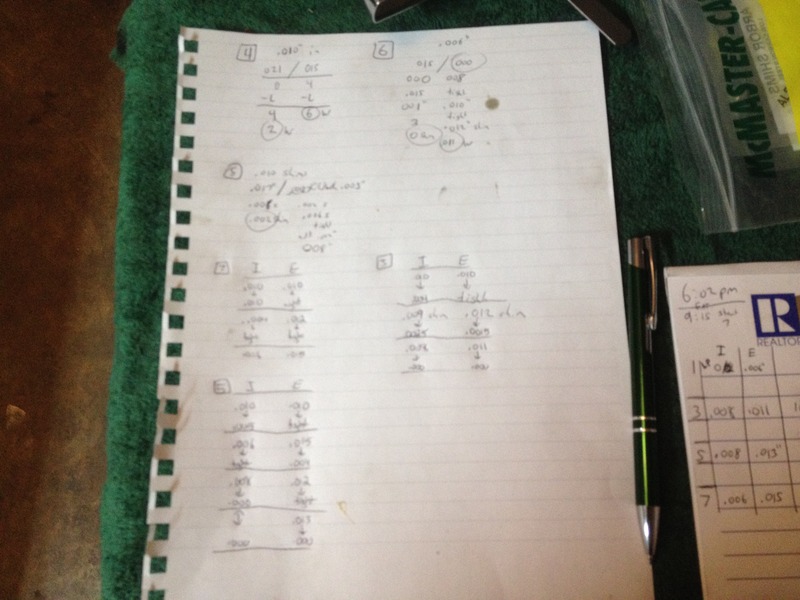

Process for shimming rockers:

So the basic principle here is you order a pushrod that it close, but too long. This creates preload on the valvetrain...enough to open the valves in some cases. So you then shim under the pedestal to relieve the preload and get to 0 lash or slightly over tight.

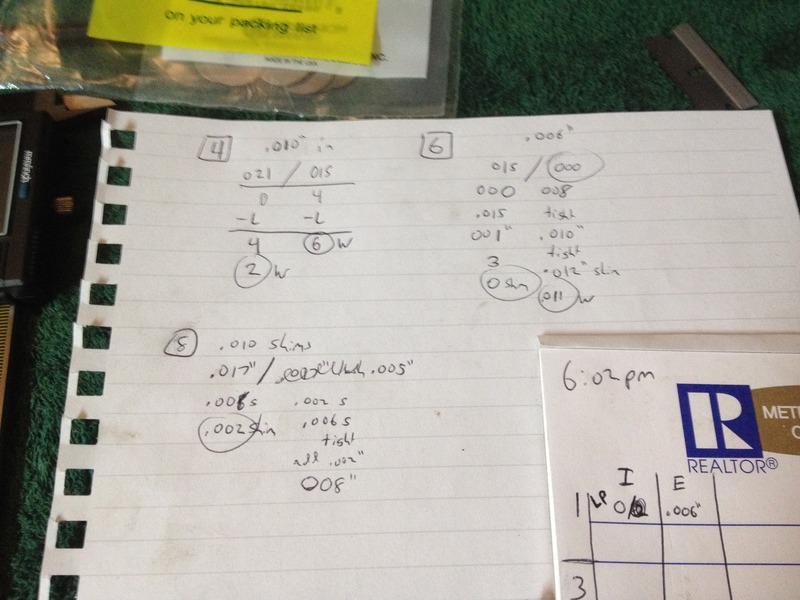

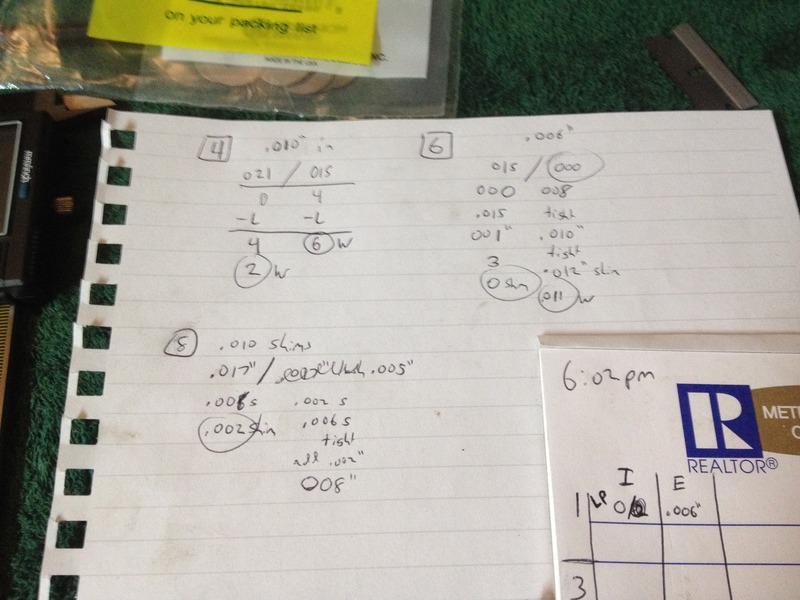

I started by tossing a .010" shim under both intake and exhaust rockers. This is typically too much so then you can measure lash with a set of standard parts store feeler gauges. If it's not enough to create lash you can add a thicker shim to that rocker.

Assemble the set and carefully tilt it onto the head. The shims are thin enough they don't have much issue hanging on to the threads.

CAUTION: make 100% sure your intake ports are covered!!!!

Once the threads are started and run down some you should be able to tell if the valve is going to be open or not. Rotate the engine until both valves seem closed and tighten the rocker arm bolts. They don't need to be 22 ft/lbs....just good and tight. Then roll the engine over until one valve is full open (spring compressed) and check it's neighbor. Once you have your measurement spin it until the other is open and repeat. I'm sure there are several ways to skin that cat but this seemed to give me the most accurate results.

Now take your measurements and record them. Decide what you need to add/subtract and write that down. Repeat and note the change. Do this until with the rocker arm bolt tight you can barely move the rocker arm body side to side on the pedestal with NO lash at the tip. If you can get a .0015" (1.5 thousandth, should be your thinnest feeler gauge blade) between the tip and the valve it's probably too loose. Drop another .001" from your shim.

TIP: do one set on each engine bank to make sure the pushrod set you have won't be too short on the 2nd bank

TIP: if you are close to zero lash but still have lash with no shims, measure the pushrods with your digital caliper until you find the longest pushrod in your set and try that one, if it works you're good without going to the next pushrod set which will increase length by .025" and mean thicker shims across the board

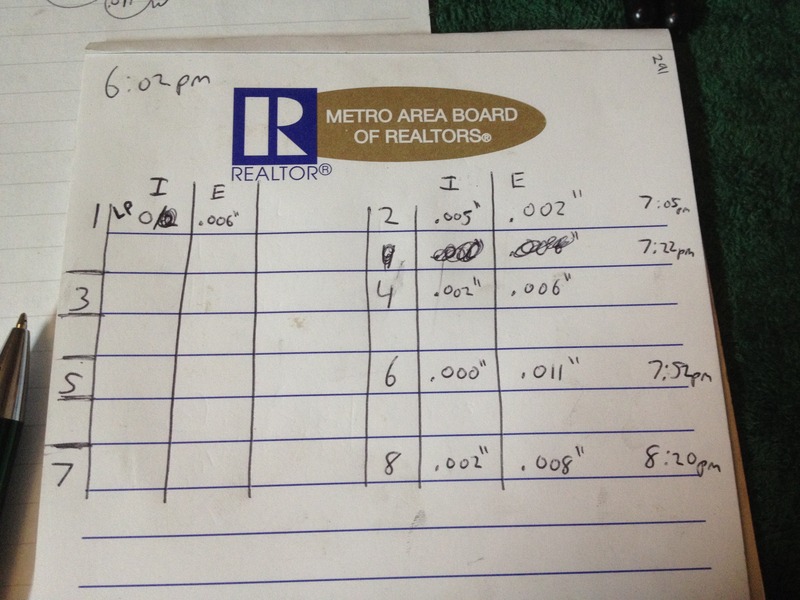

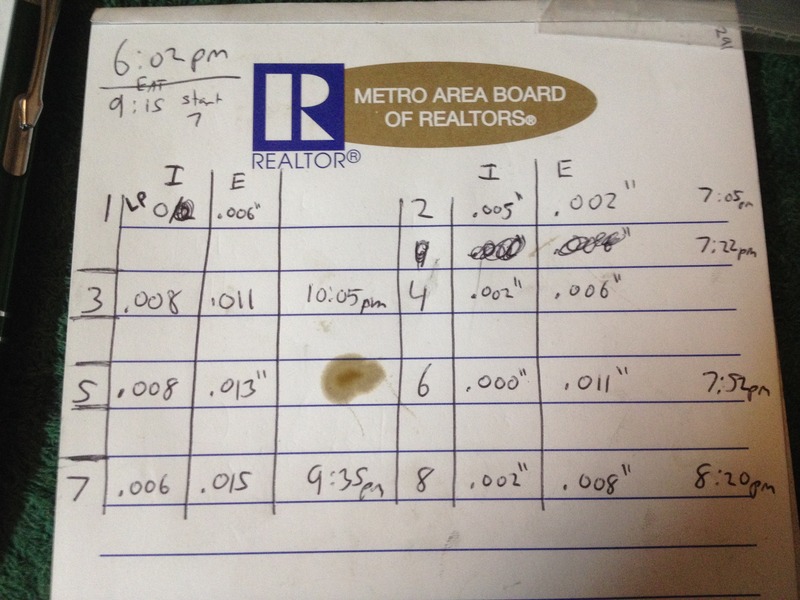

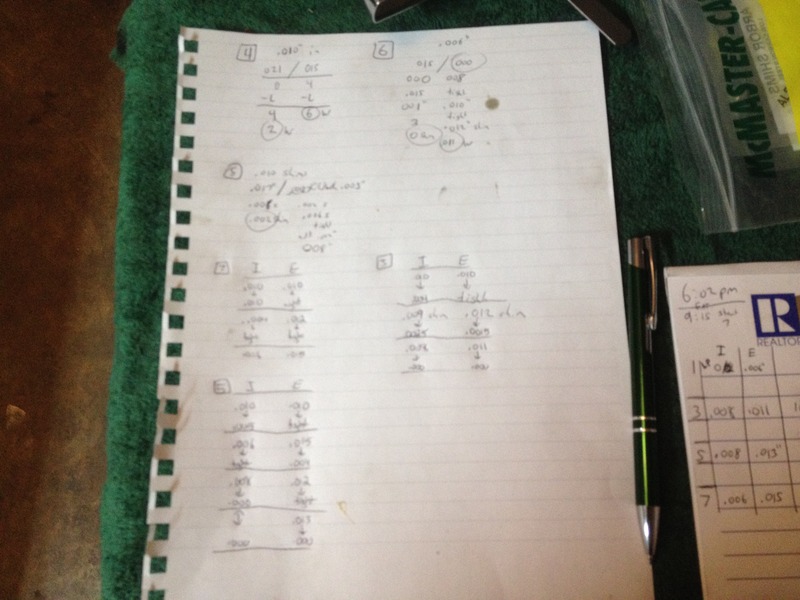

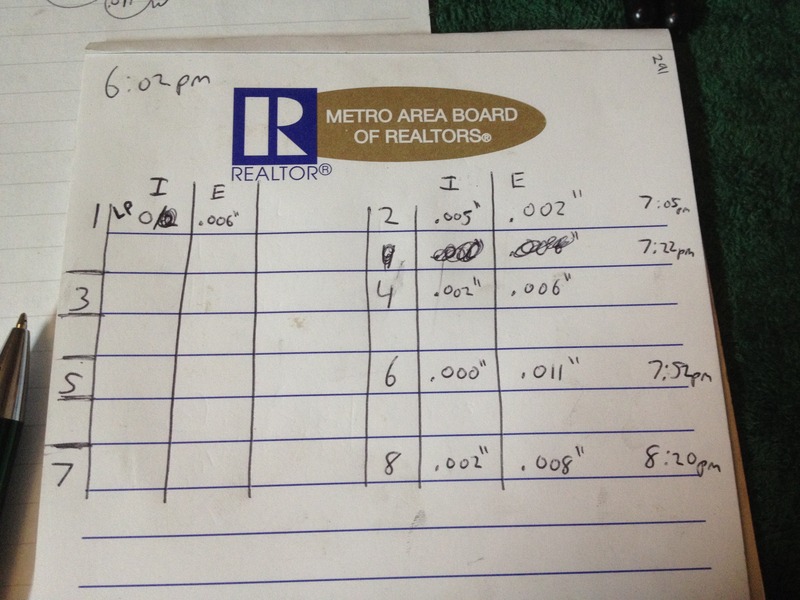

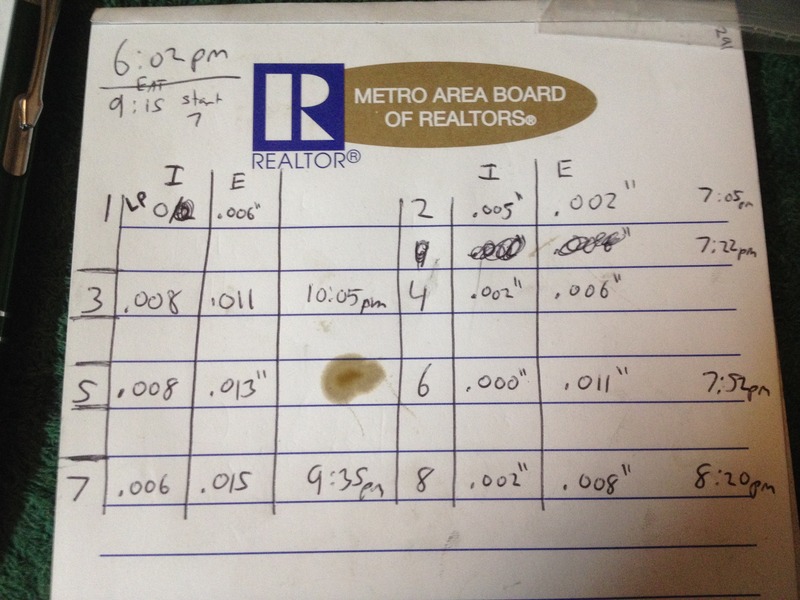

My end result sheet for cold lash shims. Note that 2 rockers have zero shims and were unaffected by shimming the neighboring rocker:

Notice on this sheet how many times some of them had to come off and on...patience

All done! Bank 1 (plus 1 pair on bank 2) took 2 hours and 20 minutes. The remainder of bank 2 was done much faster at just under an hour. It's just one of those projects you have to get a feel for and develop a method.

I'm sure I'm missing some details so I will edit. Feel free to ask questions.

If all goes well I can wrap things up Sat or Sun and light it off to get to operating temp and then check hot lash and hope I don't have to change much. *fingers crossed*

So the basic principle here is you order a pushrod that it close, but too long. This creates preload on the valvetrain...enough to open the valves in some cases. So you then shim under the pedestal to relieve the preload and get to 0 lash or slightly over tight.

I started by tossing a .010" shim under both intake and exhaust rockers. This is typically too much so then you can measure lash with a set of standard parts store feeler gauges. If it's not enough to create lash you can add a thicker shim to that rocker.

Assemble the set and carefully tilt it onto the head. The shims are thin enough they don't have much issue hanging on to the threads.

CAUTION: make 100% sure your intake ports are covered!!!!

Once the threads are started and run down some you should be able to tell if the valve is going to be open or not. Rotate the engine until both valves seem closed and tighten the rocker arm bolts. They don't need to be 22 ft/lbs....just good and tight. Then roll the engine over until one valve is full open (spring compressed) and check it's neighbor. Once you have your measurement spin it until the other is open and repeat. I'm sure there are several ways to skin that cat but this seemed to give me the most accurate results.

Now take your measurements and record them. Decide what you need to add/subtract and write that down. Repeat and note the change. Do this until with the rocker arm bolt tight you can barely move the rocker arm body side to side on the pedestal with NO lash at the tip. If you can get a .0015" (1.5 thousandth, should be your thinnest feeler gauge blade) between the tip and the valve it's probably too loose. Drop another .001" from your shim.

TIP: do one set on each engine bank to make sure the pushrod set you have won't be too short on the 2nd bank

TIP: if you are close to zero lash but still have lash with no shims, measure the pushrods with your digital caliper until you find the longest pushrod in your set and try that one, if it works you're good without going to the next pushrod set which will increase length by .025" and mean thicker shims across the board

My end result sheet for cold lash shims. Note that 2 rockers have zero shims and were unaffected by shimming the neighboring rocker:

Notice on this sheet how many times some of them had to come off and on...patience

All done! Bank 1 (plus 1 pair on bank 2) took 2 hours and 20 minutes. The remainder of bank 2 was done much faster at just under an hour. It's just one of those projects you have to get a feel for and develop a method.

I'm sure I'm missing some details so I will edit. Feel free to ask questions.

If all goes well I can wrap things up Sat or Sun and light it off to get to operating temp and then check hot lash and hope I don't have to change much. *fingers crossed*

Last edited by thunderstruck507; 11-26-2015 at 02:24 PM.

The following users liked this post:

RedWS6 00 (08-19-2022)

#31

Moderator

iTrader: (4)

Join Date: Jul 2014

Location: My own internal universe

Posts: 10,446

Received 1,836 Likes

on

1,145 Posts

Sweet write up! Looks like with some patience and good problem solving skills you've made LLSR possible for more people!

#32

TECH Fanatic

iTrader: (35)

Process for shimming rockers:

....Do this until with the rocker arm bolt tight you can barely move the rocker arm body side to side on the pedestal with NO lash at the tip. If you can get a .0015" (1.5 thousandth, should be your thinnest feeler gauge blade) between the tip and the valve it's probably too loose. Drop another .001" from your shim....

....Do this until with the rocker arm bolt tight you can barely move the rocker arm body side to side on the pedestal with NO lash at the tip. If you can get a .0015" (1.5 thousandth, should be your thinnest feeler gauge blade) between the tip and the valve it's probably too loose. Drop another .001" from your shim....

#34

A guy on yellowbullet claims to have done this on a ls7 and said he picked up around 20hp up top but claims as much as 70hp at some parts in the curve. He didn't provide any details so take all that with a big grain of salt.

I'd be pretty happy to see a gain of .2 in the 1/4 overall. I was getting some lifter bleed off after 1/4 mile passes before so just getting rid of that will make me pleased.

It will be at least February before I can get to the track but I might be able to get some dyno results before then.

#35

Great write-up! You are right on - you want absolutely zero lash cold. I set mine up initially finger-tight cold and ended up with about .010" lash hot (aluminum block). Setup that way I had a little clatter after warm-up. So I adjusted the rockers (T&D) so that I can slide a .007" feeler gage in hot and it's perfect.

My cam sheet says target is .010" hot. Since 2 of mine are zeroed on shims I can't shim tighter without adding a lot more shim thickness to all the other valves. I prefer to avoid this.

Aside from a little tick, would there be any negative consequences to the looser lash?

This is assuming my hot lash comes in close as is. I guess worst case scenario I could run longer pushrods on just those 2

but that would kinda suck....

but that would kinda suck....

#39

Kip said once it set it will be good to go for thousands of miles. My next step is checking hot lash to make sure that is good. Then I will put a bunch of miles on the car and pull the covers and check them again to see if it needs attention.

In theory it is set it and forget it. I'm trying to confirm that as truth.

In theory it is set it and forget it. I'm trying to confirm that as truth.