L92 H/C package results with cam specs and dyno results

#1

TECH Enthusiast

Thread Starter

I had looked for results for 6 liter motors using the L92 heads and couldnt find any with cam specs. While there are numberous stroker results, very few posted actual specs of the cam (yes, some did) and any other info on using the heads with decent results. I wasnt a fan of these heads when they first came out and I admit I still dont think they are the be-all end-all head. They dont allow the use cams over 228 intake duration while trying to use a DCR of 8.7 since the P/V clearance (again on a 6 liter) is so close. I have seen many 6 liter motors with not so stellar low end results. The ones with great results had secret cam specs.

This is the second posting of this information. The first go-around there were some negative comments from a presumably threatened vendor. Moderators contacted me a wanted me to repost this information for the greater good as both a data point for a cam that worked and as a DIY thread for some people looking to do a package like this. This isnt state of the art nor am I saying there is anything here that cant be easily duplicated. I am retired and dont need a job selling car parts or installs.

I am well aware that many supporting tuners spec cams out for people but there is a big difference between specing a cam and installing one. I was informed this was to be a sticky for DIY info so at least someone thought it was of value. Haters can post away and the comments will be deleted. I hope it helps some on the fence with these heads. In the original post I listed the source for the ported manifold which made a big difference on 3 cars I tried it on and not checking to see if that vendor was a supporting vendor I listed his info which rightfully upset some apple carts when he turned out to not be a supporting vendor on this forum. While it was handled unprofessionaly by that vendor, I was wrong. There will be no parts sources listed for anything used in this build.

As I stated, I havent seen many results (not justspeced cams since I am aware everyone has an opinion) but actual specs and power results for a cam and these heads. I wanted to not use a ported set of heads since the 260cc runner while great for a stroker can have other undesirable results on a small dispalcement like a 6 liter. If anyone else has actual results for this displacement and they are willing to share cam specs, post away. Strokers will make TQ easily but the 3-4k rpm range seems to be troublesome on the 6 liter with these heads. To get past this I used a DCR of 8.7 for the 93 octane fuel available here. The heads were stock except for minor touching-up on the exhaust side. The goal here was that I never bought into the huge split theaory and some tuners using these heads have found that it doesnt do much for the results other than give you more overlap. If the exhausr runner is made to flow a little better, conventional cams can be used with small splits and thus less overlap. The results here with the ported manifold were striking through the midband and made me think the L76 manifold is a big reason for these heads not doing as well as they can. Now keep in mind that to make a decent size cam to fit with such compression and a good stainless set of valves, the P/V clearance was too close and required fly-cutting.

This package was installed on my car first and then two other cars with 3 different cam specs tried.

In this package the cam specs are:

XER Comp cams lobes 228/232 .588/.595 lift 114+2 LSA

The heads are box stock L92’s that were ported on the exhaust side slightly to get rid of the bump near the headers side and to narrow down the valve guide bosses.

Springs are: Patriot gold extreme duals

The intake manifold is ported.

Have a look at the work:

And the stage 2 ported TB:

Note the thinner center shaft that holds the TB blade:

The timing chain is an IWIS and is much stronger than a stock LS2. Held side by side with the stock LS2 it has so much less slack leading me to believe that the stock chain is retarding the cam its used with by 2-3 degrees. Out side of a double roller chain, this is the best there is.

The heads used Manley Race Flow intake and exhaust one piece stainless valves. I am opposed to welded stock valves. These valves eat up an additional .030" due to bigger margins. More on that later.

Powerbond under drive pulley.

Supporting mods were:

Vararam

LG headers-because the heads need the TQ

4.10 gears, remember this lowers the dyno reading.

THE INSTALL

This was done on my friend Craig's car.

Craig’s shop, was 120 degrees. The rip down was done by both of us.

The start:

Sliding the shaft out....thats the stock cam coming out.

FLY_CUTTING:

This is a how-to/DIY part from a different thread on another car I did this exact same install on. Pictures of the current motor's fly-cuts are further down the thread.

HOW TO FLYCUT

If you have worked on an engine before, this is doable but there are some do and donts and you best know which donts right up front. DON’T use a power tool for this project the first time you try it. The surface of the stock hypereutectic piston is at its thinnest section 220 thousandths. In most places its over .330” and some its .4”. The critical areas of the pistons are closest to the ring lands and it you cut through there, the piston would then become a Christams Tree ornament.

The engine is prepped for the flycutting. To do this operation, the ISKY fly-cut tool is used. Here is the head with the seat removed and the cutter is installed in one of the 4 positions:

The tool is basically a valve stem with a cutter head where a valve head would be and it goes in a cut up (destroyed) L92 head which had the seats removed from it. I have different heads for different fly-cut operations. A LS3/L92 head (you need the head you will use for the actual build because an LS6 head for example wont put the cuts where an LS3/L92 head needs them)would put the cuts where a L92 valve would touch the piston and a LS1/LS6 head would be used for a LS1,2,6 motor. The head is then clearanced for the size cutter you need to use. The ls3/l92 valves are 2.16” and you need the next bigger sized cutter which is 2.25”. You remove the seats in the head for the intake valves and using a aluminum cutter bit, you clearance the opening the valve seat was in for the bigger ISKY fly-cutter.

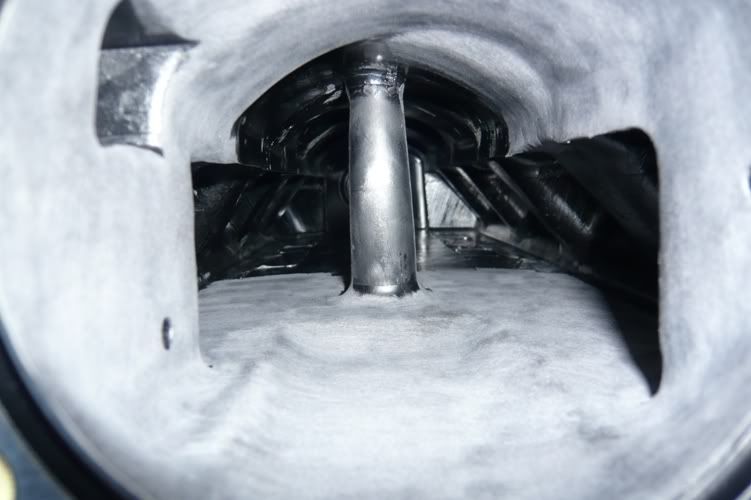

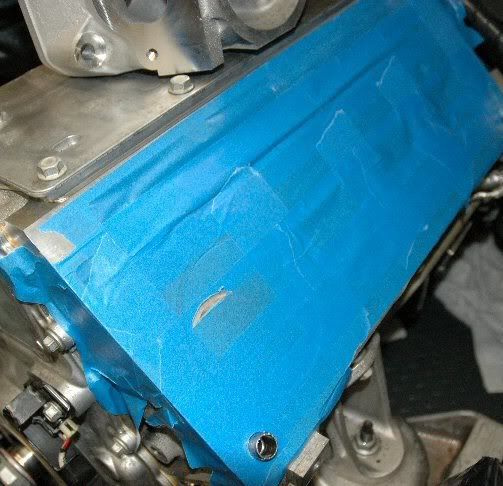

The engine is prepped for the cut by covering everything with garbage bags and using masking tape on the deck surfaces and anywhere else you can get the small amount of metal shavings like this:

A note to the OCD guy that thinks the amount of metal shavings will be astronomical and cover your entire garage: The amount of metal that comes off is small and the shavings are contained in the combustion chamber until you remove the head after the cut. You vacume it up and NOTHING gets into the engine.

This is the cutter-head on the engine and the cutter will turned by hand with the same handle you use from a tap and dye set. DO NOT USE A POWER TOOL IF THIS IS THE FIRST OR ONE OF THE FIRST TIMES YOU ARE DOING THIS. YOU WILL GO TOO FAR IF YOU DON’T USE CAUTION.

This is the second posting of this information. The first go-around there were some negative comments from a presumably threatened vendor. Moderators contacted me a wanted me to repost this information for the greater good as both a data point for a cam that worked and as a DIY thread for some people looking to do a package like this. This isnt state of the art nor am I saying there is anything here that cant be easily duplicated. I am retired and dont need a job selling car parts or installs.

I am well aware that many supporting tuners spec cams out for people but there is a big difference between specing a cam and installing one. I was informed this was to be a sticky for DIY info so at least someone thought it was of value. Haters can post away and the comments will be deleted. I hope it helps some on the fence with these heads. In the original post I listed the source for the ported manifold which made a big difference on 3 cars I tried it on and not checking to see if that vendor was a supporting vendor I listed his info which rightfully upset some apple carts when he turned out to not be a supporting vendor on this forum. While it was handled unprofessionaly by that vendor, I was wrong. There will be no parts sources listed for anything used in this build.

As I stated, I havent seen many results (not justspeced cams since I am aware everyone has an opinion) but actual specs and power results for a cam and these heads. I wanted to not use a ported set of heads since the 260cc runner while great for a stroker can have other undesirable results on a small dispalcement like a 6 liter. If anyone else has actual results for this displacement and they are willing to share cam specs, post away. Strokers will make TQ easily but the 3-4k rpm range seems to be troublesome on the 6 liter with these heads. To get past this I used a DCR of 8.7 for the 93 octane fuel available here. The heads were stock except for minor touching-up on the exhaust side. The goal here was that I never bought into the huge split theaory and some tuners using these heads have found that it doesnt do much for the results other than give you more overlap. If the exhausr runner is made to flow a little better, conventional cams can be used with small splits and thus less overlap. The results here with the ported manifold were striking through the midband and made me think the L76 manifold is a big reason for these heads not doing as well as they can. Now keep in mind that to make a decent size cam to fit with such compression and a good stainless set of valves, the P/V clearance was too close and required fly-cutting.

This package was installed on my car first and then two other cars with 3 different cam specs tried.

In this package the cam specs are:

XER Comp cams lobes 228/232 .588/.595 lift 114+2 LSA

The heads are box stock L92’s that were ported on the exhaust side slightly to get rid of the bump near the headers side and to narrow down the valve guide bosses.

Springs are: Patriot gold extreme duals

The intake manifold is ported.

Have a look at the work:

And the stage 2 ported TB:

Note the thinner center shaft that holds the TB blade:

The timing chain is an IWIS and is much stronger than a stock LS2. Held side by side with the stock LS2 it has so much less slack leading me to believe that the stock chain is retarding the cam its used with by 2-3 degrees. Out side of a double roller chain, this is the best there is.

The heads used Manley Race Flow intake and exhaust one piece stainless valves. I am opposed to welded stock valves. These valves eat up an additional .030" due to bigger margins. More on that later.

Powerbond under drive pulley.

Supporting mods were:

Vararam

LG headers-because the heads need the TQ

4.10 gears, remember this lowers the dyno reading.

THE INSTALL

This was done on my friend Craig's car.

Craig’s shop, was 120 degrees. The rip down was done by both of us.

The start:

Sliding the shaft out....thats the stock cam coming out.

FLY_CUTTING:

This is a how-to/DIY part from a different thread on another car I did this exact same install on. Pictures of the current motor's fly-cuts are further down the thread.

HOW TO FLYCUT

If you have worked on an engine before, this is doable but there are some do and donts and you best know which donts right up front. DON’T use a power tool for this project the first time you try it. The surface of the stock hypereutectic piston is at its thinnest section 220 thousandths. In most places its over .330” and some its .4”. The critical areas of the pistons are closest to the ring lands and it you cut through there, the piston would then become a Christams Tree ornament.

The engine is prepped for the flycutting. To do this operation, the ISKY fly-cut tool is used. Here is the head with the seat removed and the cutter is installed in one of the 4 positions:

The tool is basically a valve stem with a cutter head where a valve head would be and it goes in a cut up (destroyed) L92 head which had the seats removed from it. I have different heads for different fly-cut operations. A LS3/L92 head (you need the head you will use for the actual build because an LS6 head for example wont put the cuts where an LS3/L92 head needs them)would put the cuts where a L92 valve would touch the piston and a LS1/LS6 head would be used for a LS1,2,6 motor. The head is then clearanced for the size cutter you need to use. The ls3/l92 valves are 2.16” and you need the next bigger sized cutter which is 2.25”. You remove the seats in the head for the intake valves and using a aluminum cutter bit, you clearance the opening the valve seat was in for the bigger ISKY fly-cutter.

The engine is prepped for the cut by covering everything with garbage bags and using masking tape on the deck surfaces and anywhere else you can get the small amount of metal shavings like this:

A note to the OCD guy that thinks the amount of metal shavings will be astronomical and cover your entire garage: The amount of metal that comes off is small and the shavings are contained in the combustion chamber until you remove the head after the cut. You vacume it up and NOTHING gets into the engine.

This is the cutter-head on the engine and the cutter will turned by hand with the same handle you use from a tap and dye set. DO NOT USE A POWER TOOL IF THIS IS THE FIRST OR ONE OF THE FIRST TIMES YOU ARE DOING THIS. YOU WILL GO TOO FAR IF YOU DON’T USE CAUTION.

#2

TECH Enthusiast

Thread Starter

Once the head is actually on the engine there are some issues you need to be aware of as to where the cutter actually makes the cut.

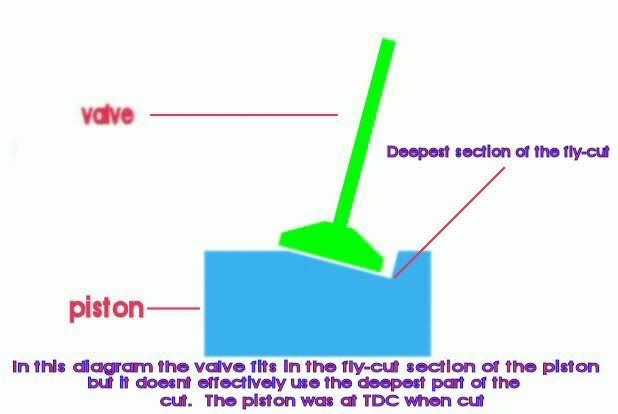

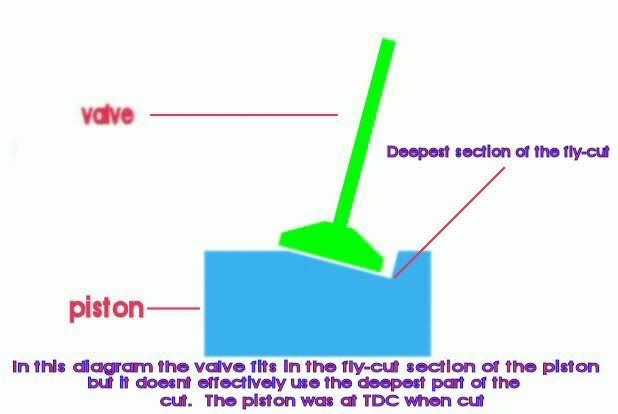

P/V interference is never when the piston is at top dead center. Why is this an issue? The piston is on its way down the cylinder when the intake valve is off the seat during the overlap period. The crank position for intake valve interference is after TDC until about 15 degrees past. The exhaust is in danger of hitting when the piston is approaching TDC from about 15 degrees before until TDC. Now, the fact that the piston isn’t at the top is the issue. The valve isn’t at a right angle to the top of the piston and therefore the place the valve would touch changes cam to cam depending on the height of the piston. This is a trangle formed by the valve, piston head, and an imaginary perpendicular that we drop from the valve stem to the piston. The further down the piston is the lower the valve contact would be. I made this picture to inllustrate:

The red line is if the piston was at TDC and the Blue line is where the valve may touch if the piston was some arbitrary amount of distance down the cylinder. As the piston is farther down the valve would touch further down in the direction of the black arrow. If you actually spin the crank +/- 15 degrees from TDC you will see that the distance is actually only a few thousandths of an inch different and of no concern if you use the size cutter we use here which is 2.25 minus 2.16 = .09/2 or .0045” wider than we need. There is also no gasket here so the cut will be high enough on the piston to not worry about missing the spot where the valve would touch. The wider cut does actually waste some of the precious cutter depth we need. For those that can picture it, the valve may actually touch at the spot where the cut is only .04 deep if you cut .06 at the edge.

HOW DO YOU ADJUST THE DEPTH OF THE CUT?

The cutter stem has a bearing that is adjusted with the head on the car and the cutter is actually lowered to be in contact with the piston. The bearing is tightened down with an allen key. careful not to strip it but make it tight. If it comes loose the cut will go too deep especially for those not watching and using a power toll to spin it. It is best to bolt the head down lightly to compress the tape and get a good measurement. The bearing on the stem is loose and is moved onto the velve stem. The bearing will be spaced away from the valve stem guide using a feeler guage as in this next picture:

The feeler gauge is positioned here only to show you how it is placed for the measurement. This must be done with the head on the car and the cutter in contact with the piston. I used .06” and spaced the bearing that far from the valve stem. This bearing will not allow the cutter to go lower than that distance. Using a mirror and constantly checking that the bearing is tight and correctly placed, you turn the cutter by hand clockwise as in this picture:

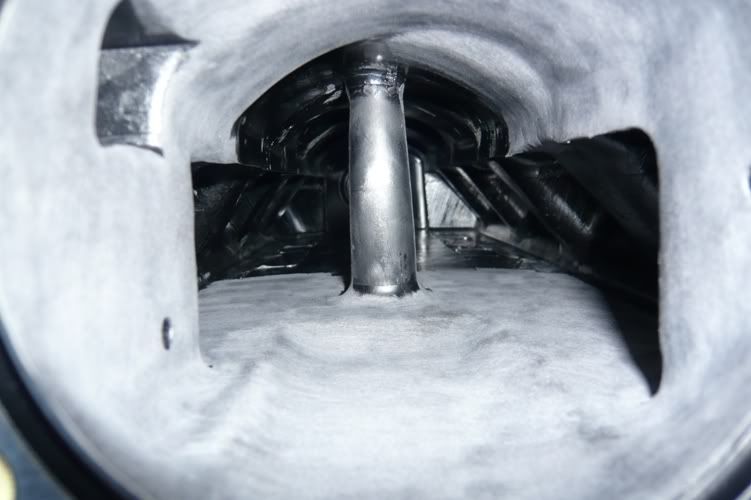

The cutter being sharp, makes the cut in about 40-50 turns by hand. Take your time and check a few times. The head cant get closer to the piston because the head deck surface touches the piston. The relief is oversized so it will fit the valve a various heights in case of interference. Check frequently on your first few turns to see the progress you are making. If it takes 2 hours for all 8, fine, if it takes 2 days, fine. Its not a race. The finished cut looks like this and the head gets a cleaning with a vacuumed as does the engine block deck surface every time the cutter head is lifted off. This is what you see (note there is no way the metal can get in the cylinders):

Once you complete the cut, you cover that relief and move to the next up position piston on the other side of the motor. There is no chance of metal shavings getting in the motor if you are meticulous about the clean up. Every opening is guarded as you can see in the picture.

Here is the finished product:

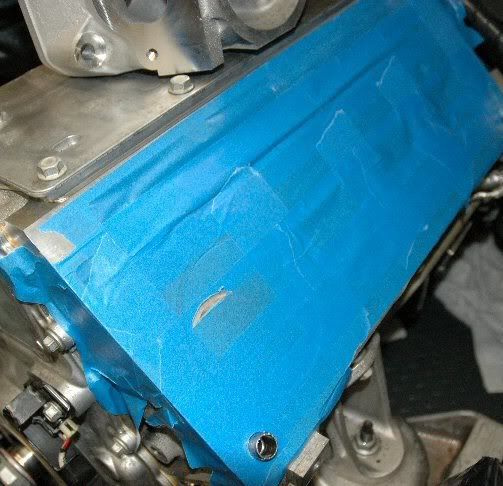

And this is a JE forged piston with 2cc reliefs cut in. Note the intake valve position:

The depth is verified with the feeler gauge in the relief at an angle of course. If its not deep enough put it back on and give it a few more turns.

FLY-CUTTING 101-back in session

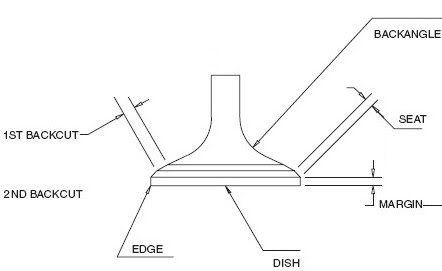

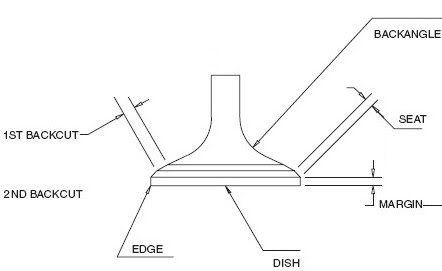

In most L92 set-ups like this one, the pistons would have to be cut. Each car is different and every cam, even the same grind, will vary. The Manley race flow valve has a thicker margin than the stock valve by .030”. Yes I measured them. In the picture below the various parts of a valve are labeled.

The margin takes away from P/V clearance therefore by about that amount. The heads being milled, and thinner gaskets are other factors. This install also advanced the cam 2 degrees from the original. Before everyone gets confused, my cam is a 230/234 XER on a 114LSA. The last cam I had was a 228/232 and it was stronger in the mid-band. These are very small differences but a man knows his ‘tool’. Duration takes away from P/V clearance too as it grows. I wouldnt be a bit surprised if a 226/230 or a 226/232 would do as good or better than this cam did. Data from various sources suggests that smaller works better on this head.

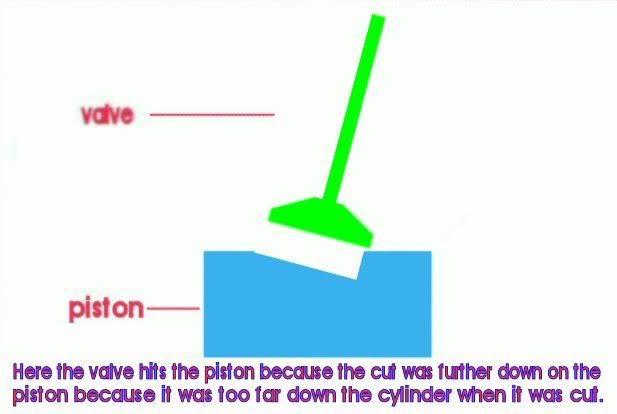

When you determine what clearance you need and decide to fly-cut a certain amount you have to realize that there is a difference between the fly-cut cut depth and the usable depth. Just because you cut a certain amount doesn’t mean the depth is the needed depth where the valve actually touches.

Taped up prior to fly-cutting:

Completed fly-cuts:

Pistons were cleaned by Craig before reassembly.

P/V interference is never when the piston is at top dead center. Why is this an issue? The piston is on its way down the cylinder when the intake valve is off the seat during the overlap period. The crank position for intake valve interference is after TDC until about 15 degrees past. The exhaust is in danger of hitting when the piston is approaching TDC from about 15 degrees before until TDC. Now, the fact that the piston isn’t at the top is the issue. The valve isn’t at a right angle to the top of the piston and therefore the place the valve would touch changes cam to cam depending on the height of the piston. This is a trangle formed by the valve, piston head, and an imaginary perpendicular that we drop from the valve stem to the piston. The further down the piston is the lower the valve contact would be. I made this picture to inllustrate:

The red line is if the piston was at TDC and the Blue line is where the valve may touch if the piston was some arbitrary amount of distance down the cylinder. As the piston is farther down the valve would touch further down in the direction of the black arrow. If you actually spin the crank +/- 15 degrees from TDC you will see that the distance is actually only a few thousandths of an inch different and of no concern if you use the size cutter we use here which is 2.25 minus 2.16 = .09/2 or .0045” wider than we need. There is also no gasket here so the cut will be high enough on the piston to not worry about missing the spot where the valve would touch. The wider cut does actually waste some of the precious cutter depth we need. For those that can picture it, the valve may actually touch at the spot where the cut is only .04 deep if you cut .06 at the edge.

HOW DO YOU ADJUST THE DEPTH OF THE CUT?

The cutter stem has a bearing that is adjusted with the head on the car and the cutter is actually lowered to be in contact with the piston. The bearing is tightened down with an allen key. careful not to strip it but make it tight. If it comes loose the cut will go too deep especially for those not watching and using a power toll to spin it. It is best to bolt the head down lightly to compress the tape and get a good measurement. The bearing on the stem is loose and is moved onto the velve stem. The bearing will be spaced away from the valve stem guide using a feeler guage as in this next picture:

The feeler gauge is positioned here only to show you how it is placed for the measurement. This must be done with the head on the car and the cutter in contact with the piston. I used .06” and spaced the bearing that far from the valve stem. This bearing will not allow the cutter to go lower than that distance. Using a mirror and constantly checking that the bearing is tight and correctly placed, you turn the cutter by hand clockwise as in this picture:

The cutter being sharp, makes the cut in about 40-50 turns by hand. Take your time and check a few times. The head cant get closer to the piston because the head deck surface touches the piston. The relief is oversized so it will fit the valve a various heights in case of interference. Check frequently on your first few turns to see the progress you are making. If it takes 2 hours for all 8, fine, if it takes 2 days, fine. Its not a race. The finished cut looks like this and the head gets a cleaning with a vacuumed as does the engine block deck surface every time the cutter head is lifted off. This is what you see (note there is no way the metal can get in the cylinders):

Once you complete the cut, you cover that relief and move to the next up position piston on the other side of the motor. There is no chance of metal shavings getting in the motor if you are meticulous about the clean up. Every opening is guarded as you can see in the picture.

Here is the finished product:

And this is a JE forged piston with 2cc reliefs cut in. Note the intake valve position:

The depth is verified with the feeler gauge in the relief at an angle of course. If its not deep enough put it back on and give it a few more turns.

FLY-CUTTING 101-back in session

In most L92 set-ups like this one, the pistons would have to be cut. Each car is different and every cam, even the same grind, will vary. The Manley race flow valve has a thicker margin than the stock valve by .030”. Yes I measured them. In the picture below the various parts of a valve are labeled.

The margin takes away from P/V clearance therefore by about that amount. The heads being milled, and thinner gaskets are other factors. This install also advanced the cam 2 degrees from the original. Before everyone gets confused, my cam is a 230/234 XER on a 114LSA. The last cam I had was a 228/232 and it was stronger in the mid-band. These are very small differences but a man knows his ‘tool’. Duration takes away from P/V clearance too as it grows. I wouldnt be a bit surprised if a 226/230 or a 226/232 would do as good or better than this cam did. Data from various sources suggests that smaller works better on this head.

When you determine what clearance you need and decide to fly-cut a certain amount you have to realize that there is a difference between the fly-cut cut depth and the usable depth. Just because you cut a certain amount doesn’t mean the depth is the needed depth where the valve actually touches.

Taped up prior to fly-cutting:

Completed fly-cuts:

Pistons were cleaned by Craig before reassembly.

#3

TECH Enthusiast

Thread Starter

TECH POINT

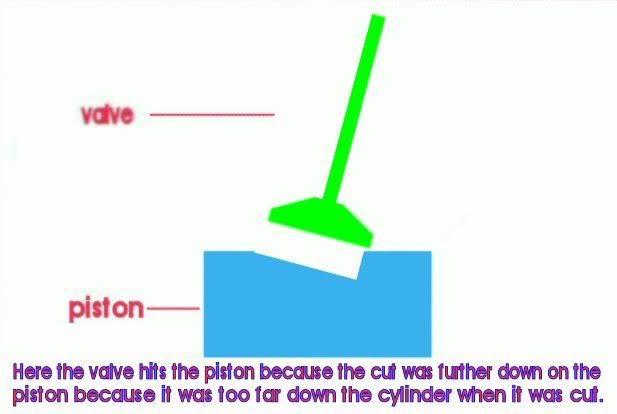

The following hand drawn diagram shows the place where a valve actually touches a piston and where the cut is actually made. First thing to note is that when a piston is close to a valve that’s off the seat, the piston is not at top dead center (TDC). The intake valve’s contact (or near contact) occurs between 0 and 15 degrees after TDC when the piston is heading down. On the top diagram, the cut made is at TDC which is made with a 2.25” cutter. Since the valve is 2.165”, the cut has a wasted space of about .0425” that isn’t where the valve would touch. The deepest part of the cut is actually too high for the valve because of two reasons: The cutter is bigger than the valve and the piston has to be cut higher in the cylinder bore than where the piston would be if it would contact the valve at 0-15 degrees past TDC. Diagram 2 shows the piston further down the bore during contact IF YOU HAD THE PISTON TOO LOW FOR THE FLY-CUT and the edge of the valve touches the edge of the cut. Unfortunately you cant take a chance of putting the cut too far down the piston. What this amounts too is that the cut is unlikely to be deepest where the valve would touch and so the real cut depth is deeper than your actual gained clearance distance. Since the piston is limited in how deep you can cut, the distance must be discriminated. If you get an .080” cut, the usable depth is less. How much? You guess. While compression is your friend, the ring lands get close to the cut at the edges.

Craig was cut .075” at the deepest but at TDC so the effective depth is more like .055". The depth wasnt really needed but if things work out on a future grind, it may benefit from the added available space.

TIMING CHAIN SECURITY

I sit here late night or actually early morning as I see the sun is about to rise with a friend's car on my mind. Last night his timing chain broke. He had a 228 cam too and wouldnt have thought his cam-only car would have needed more but... While the LS2 chain is reported to be much stronger than the previous LS1/6 chain, its still an item that stretches. When I removed Craig’s timing chain and held it next to the new IWIS chain, the difference in length was big. The added stretch allows the gears to lead each other which changes the actual cam timing setting. The IWIS chain is much stronger and is a new minimum for me on cam installs.

HEAD PREP/PORTING

The intake runner is a whopping 260cc’s and is already too big for this application. Since it already flows 320-330cfm out of the box, it makes no sense to increase this side of the head’s performance. Yes ported it will make 350cfm but ported casting have more times than not, cost low end TQ for the added cost. The heads are $380 for the pair and 100 bucks or so for the milling to get the compression up. The exhaust side is the weaker.

SPINNING the die grinder...

While a high velocity port runner will perform better than a slower velocity bigger runner, many believe that the cams needed to work with these heads must be huge splits. Texas speed has gottem 460rwhp with a single pattern 228/228 cam, I have gotten these repeated great results with a 228/232 and 230/234, and I have even seen a reverse split make the same power on these heads as a 243 ported casting. So the next time someone tells you that you need a 228/238 or a 228/242, tell them to post the results of the cam in use or if ts a guess to keep the overlap grind for their car.

Once you do this minor clean-up that I did, the heads will work with exactly the same cams as a cathedral port head. Even box stock, my car pulled similar power to Craig’s with the same cam grind. I dyno’ed 471rwhp through 4.10’s with the 228 cam. I have some mods he doesn’t have, namely an aluminum flywheel, and much lighter rear wheels which lessen driveline losses.

Yes we dyno’ed the car. We went to an independent shop to do the dyno’s so there wasn’t a conflict of interest. The owner is an honest [to be truthful in communication; free of knowingly false information] guy that works with you and wanted to see true results. I didn’t have to worry about getting a set of manually entered false weather data designed to make you think you picked the wrong shop for the install. Since I am allowed to operate the dyno if I wanted to, I know there isn’t anything shady going on. The weather data is at the top of this power vs rpm listing

NOTE: The shop's wideband was giving all sorts of weird readings and simply needed to be recalibrated or something. The part throttle steady a/f reading was reading 17-18:1 for stoic so something was off so we used an LM-1 mounted before the cats to do the tune. The narrow bands were also reading way rich so ignore the a/f column:

This is the dyno sheet on the 4th pull after optimizing the tune on the dyno. I came pretty close with a street tune and was also close on the HP prediction within 1.4HP.

Keep in mind that the car has 4.10’s and that makes the reading 10-12HP lower at this level so the final numbers are 472-474rwhp and 425-430rwtq. These are corrected SAE numbers. Uncorrected was 1hp lower. Pulls were made on a 97 degree day.

The midband TQ is free of dips in the troublesome 3k-4k rpms and output at 4krpms is 380rwtq and hits 400rwtq at 4300rpm. Keep in mind that this sheet reflects the power through 4.10 gears and as such the 3.42's would likely have been a bit better 385-390 or so. In any event the car pulls great for a 228 cam. Another fact is that the TQ stays over this level all the way out to 6300rpm's.

I was happy with the numbers but felt it should have bettered my car’s last dyno. The factors of the aluminum flywheel and lightened rear wheels (16lbs less) are the items I have to thank.

My car mae 471rwhp and 434rwtq through 4.10's and hit 410rwtq at 4k when I had this same cam....minus the 2 degree advance but with more compression. I havent dyno'ed with the current 230 but I think its worse actually.

The results are great for a 228 cam. There are zero driveabiltiy issues. With the exhaust cutouts closed the car sounds as quiet as a caddy on the hiway. The car has posted video footage of its performance including 30mpg gallon not only verified on the DIC but on actual miles traveled vs gallons filled.

TO PORT OR NOT TO PORT the intake side

One area that I didn’t explore is to do a professional competition valve job. Supporting tuners on this board have done this and realized notable gains. One tuner noted only a loss of 10rwtq and a gain of 6rwhp at peak with a well known porter’s 2000 dollar version of these heads. Stay box stock and enjoy the savings or just do a valve job. A valve job also moves the valve into the direction of the runner gaining some precious clearance back.

In summing up, I have to say that the results of tuners such as RPM motors, LG motorsports, Cartek, and DTE powertrain have had some great results. None publicised cam specs and its frustrating but I understand R&D is an expensive thing.

All back together:

I like the clean install look. Not that I dont like the FAST but this looks stock and appeals to a lot of guys that want it to look that way. The stock fuel rail covers fit if you use the shorter injectors as the LS2 injecotrs are taller and make the covers look 'off'.

TUNING

These heads are the same casting as those that appear on the LS3 motor. The casting number while 823 and the corvettes castings being 821, not withstanding, porters report there is no difference. The new LS3 tune on the 2008 has a change to the timing curve. There is a notable increase in the timing values between 3k and 4k from the factory so it made sense that I try this increase on my L92 headed car. I went to my curve and found that it had already started to take on that curve as I kept adding timing. Timing is higher in places because of inefficiencies. When a cylinder head is inefficient it allows more timing to be run.

The car gained plenty on the dyno with about 6hp gained and 12rwtq in some places. Charlie from RPM has a point when he states that dyno tuning always has more found in the power curve than a street only tune. Its difficult to safely duplicate it on the street. Street tunes are definitely second best. You live and learn Spin.:yesnod: I had limited time and pulls since I was falling asleep and the tune has som much left in it.

Thanks for taking the time to read my long winded report here. I hope some people benefit. Craig is happy that the entire project cost him about 450 bucks after selling his FAST and stock heads. The install was free on labor. He is a good friend.

The following hand drawn diagram shows the place where a valve actually touches a piston and where the cut is actually made. First thing to note is that when a piston is close to a valve that’s off the seat, the piston is not at top dead center (TDC). The intake valve’s contact (or near contact) occurs between 0 and 15 degrees after TDC when the piston is heading down. On the top diagram, the cut made is at TDC which is made with a 2.25” cutter. Since the valve is 2.165”, the cut has a wasted space of about .0425” that isn’t where the valve would touch. The deepest part of the cut is actually too high for the valve because of two reasons: The cutter is bigger than the valve and the piston has to be cut higher in the cylinder bore than where the piston would be if it would contact the valve at 0-15 degrees past TDC. Diagram 2 shows the piston further down the bore during contact IF YOU HAD THE PISTON TOO LOW FOR THE FLY-CUT and the edge of the valve touches the edge of the cut. Unfortunately you cant take a chance of putting the cut too far down the piston. What this amounts too is that the cut is unlikely to be deepest where the valve would touch and so the real cut depth is deeper than your actual gained clearance distance. Since the piston is limited in how deep you can cut, the distance must be discriminated. If you get an .080” cut, the usable depth is less. How much? You guess. While compression is your friend, the ring lands get close to the cut at the edges.

Craig was cut .075” at the deepest but at TDC so the effective depth is more like .055". The depth wasnt really needed but if things work out on a future grind, it may benefit from the added available space.

TIMING CHAIN SECURITY

I sit here late night or actually early morning as I see the sun is about to rise with a friend's car on my mind. Last night his timing chain broke. He had a 228 cam too and wouldnt have thought his cam-only car would have needed more but... While the LS2 chain is reported to be much stronger than the previous LS1/6 chain, its still an item that stretches. When I removed Craig’s timing chain and held it next to the new IWIS chain, the difference in length was big. The added stretch allows the gears to lead each other which changes the actual cam timing setting. The IWIS chain is much stronger and is a new minimum for me on cam installs.

HEAD PREP/PORTING

The intake runner is a whopping 260cc’s and is already too big for this application. Since it already flows 320-330cfm out of the box, it makes no sense to increase this side of the head’s performance. Yes ported it will make 350cfm but ported casting have more times than not, cost low end TQ for the added cost. The heads are $380 for the pair and 100 bucks or so for the milling to get the compression up. The exhaust side is the weaker.

SPINNING the die grinder...

While a high velocity port runner will perform better than a slower velocity bigger runner, many believe that the cams needed to work with these heads must be huge splits. Texas speed has gottem 460rwhp with a single pattern 228/228 cam, I have gotten these repeated great results with a 228/232 and 230/234, and I have even seen a reverse split make the same power on these heads as a 243 ported casting. So the next time someone tells you that you need a 228/238 or a 228/242, tell them to post the results of the cam in use or if ts a guess to keep the overlap grind for their car.

Once you do this minor clean-up that I did, the heads will work with exactly the same cams as a cathedral port head. Even box stock, my car pulled similar power to Craig’s with the same cam grind. I dyno’ed 471rwhp through 4.10’s with the 228 cam. I have some mods he doesn’t have, namely an aluminum flywheel, and much lighter rear wheels which lessen driveline losses.

Yes we dyno’ed the car. We went to an independent shop to do the dyno’s so there wasn’t a conflict of interest. The owner is an honest [to be truthful in communication; free of knowingly false information] guy that works with you and wanted to see true results. I didn’t have to worry about getting a set of manually entered false weather data designed to make you think you picked the wrong shop for the install. Since I am allowed to operate the dyno if I wanted to, I know there isn’t anything shady going on. The weather data is at the top of this power vs rpm listing

NOTE: The shop's wideband was giving all sorts of weird readings and simply needed to be recalibrated or something. The part throttle steady a/f reading was reading 17-18:1 for stoic so something was off so we used an LM-1 mounted before the cats to do the tune. The narrow bands were also reading way rich so ignore the a/f column:

This is the dyno sheet on the 4th pull after optimizing the tune on the dyno. I came pretty close with a street tune and was also close on the HP prediction within 1.4HP.

Keep in mind that the car has 4.10’s and that makes the reading 10-12HP lower at this level so the final numbers are 472-474rwhp and 425-430rwtq. These are corrected SAE numbers. Uncorrected was 1hp lower. Pulls were made on a 97 degree day.

The midband TQ is free of dips in the troublesome 3k-4k rpms and output at 4krpms is 380rwtq and hits 400rwtq at 4300rpm. Keep in mind that this sheet reflects the power through 4.10 gears and as such the 3.42's would likely have been a bit better 385-390 or so. In any event the car pulls great for a 228 cam. Another fact is that the TQ stays over this level all the way out to 6300rpm's.

I was happy with the numbers but felt it should have bettered my car’s last dyno. The factors of the aluminum flywheel and lightened rear wheels (16lbs less) are the items I have to thank.

My car mae 471rwhp and 434rwtq through 4.10's and hit 410rwtq at 4k when I had this same cam....minus the 2 degree advance but with more compression. I havent dyno'ed with the current 230 but I think its worse actually.

The results are great for a 228 cam. There are zero driveabiltiy issues. With the exhaust cutouts closed the car sounds as quiet as a caddy on the hiway. The car has posted video footage of its performance including 30mpg gallon not only verified on the DIC but on actual miles traveled vs gallons filled.

TO PORT OR NOT TO PORT the intake side

One area that I didn’t explore is to do a professional competition valve job. Supporting tuners on this board have done this and realized notable gains. One tuner noted only a loss of 10rwtq and a gain of 6rwhp at peak with a well known porter’s 2000 dollar version of these heads. Stay box stock and enjoy the savings or just do a valve job. A valve job also moves the valve into the direction of the runner gaining some precious clearance back.

In summing up, I have to say that the results of tuners such as RPM motors, LG motorsports, Cartek, and DTE powertrain have had some great results. None publicised cam specs and its frustrating but I understand R&D is an expensive thing.

All back together:

I like the clean install look. Not that I dont like the FAST but this looks stock and appeals to a lot of guys that want it to look that way. The stock fuel rail covers fit if you use the shorter injectors as the LS2 injecotrs are taller and make the covers look 'off'.

TUNING

These heads are the same casting as those that appear on the LS3 motor. The casting number while 823 and the corvettes castings being 821, not withstanding, porters report there is no difference. The new LS3 tune on the 2008 has a change to the timing curve. There is a notable increase in the timing values between 3k and 4k from the factory so it made sense that I try this increase on my L92 headed car. I went to my curve and found that it had already started to take on that curve as I kept adding timing. Timing is higher in places because of inefficiencies. When a cylinder head is inefficient it allows more timing to be run.

The car gained plenty on the dyno with about 6hp gained and 12rwtq in some places. Charlie from RPM has a point when he states that dyno tuning always has more found in the power curve than a street only tune. Its difficult to safely duplicate it on the street. Street tunes are definitely second best. You live and learn Spin.:yesnod: I had limited time and pulls since I was falling asleep and the tune has som much left in it.

Thanks for taking the time to read my long winded report here. I hope some people benefit. Craig is happy that the entire project cost him about 450 bucks after selling his FAST and stock heads. The install was free on labor. He is a good friend.

Last edited by Spinmonster; 07-18-2008 at 05:04 AM.

#4

8 Second Club

iTrader: (40)

Join Date: Aug 2005

Location: Raleigh,North Carolina

Posts: 1,861

Likes: 0

Received 0 Likes

on

0 Posts

You must be referring to stock flat top pistons regarding using less than 230* on the intake?

And obviously what LSA you use, impacts the PTV clearance as well.

Good writeup, I was wondering what happened to it. Good to see it back.

And obviously what LSA you use, impacts the PTV clearance as well.

Good writeup, I was wondering what happened to it. Good to see it back.

#5

TECH Enthusiast

Thread Starter

6 liters are a lot tougher to get the compression up so you run out of clearance fast after milling and gaskets to counter the big combustion chamber. A 230 cam and a 114 LSA would need north of 11.5:1 comp to get near a 8.7 DCR. Not having the compression wasnt helping things. Timing isnt needed as much for complete combustion with the higher cylinder pressures from the higher compression. The low end benefits on the cars I used this set-up on varying from 10.9 to 11.7:1 compression. It often nets 30rwtq at 3500rpm and more than 15rwtq at peak ...4800rpm.

Your motor doesnt need the compression and being the WCCH version has to be a great combo with forced induction. Rich stays on the phone to help you a lot too. Highly recomended.

Last edited by Spinmonster; 07-18-2008 at 07:32 AM.

#6

Banned

iTrader: (10)

No one felt threatened Spin. Just a couple people who are familiar with you were pointing out how ironic it was that you were "paving the way" 2 years after the fact while for soooo long you were an L92 nay-sayer. Thats all.

I, for the most part GIVE AWAY information. With the exception of cam specs. I will however, give people reasonable limits to operate within.

While this is a good, thorough write up, it is far from ground breaking. It is at this stage of the game, old news.

Absolutely no one is/was being a hater.

I, for the most part GIVE AWAY information. With the exception of cam specs. I will however, give people reasonable limits to operate within.

While this is a good, thorough write up, it is far from ground breaking. It is at this stage of the game, old news.

Absolutely no one is/was being a hater.

Trending Topics

#8

8 Second Club

iTrader: (40)

Join Date: Aug 2005

Location: Raleigh,North Carolina

Posts: 1,861

Likes: 0

Received 0 Likes

on

0 Posts

My mahle off the shelf pistons for L92's. 4.030" bore, 3.622" stroke 6.125" rod with -4cc valve reliefs. I had a ton of PTV clearance with a 238-242 .605/.610 115 lsa. I rely on the large 75cc chambers to get my cr down.

Now valve shrouding definitely is an issue with the 6.0L bore.

Now valve shrouding definitely is an issue with the 6.0L bore.

#9

TECH Enthusiast

Thread Starter

Please, you're making it out to be so much more than it is. I am humbled this coming from a guy that used 2000 dollar ported L92 heads to get 510 rwhp on a 403 with a tiny 234 cam. Thats way more impressive. You should be the one taking the credit for the best in show here. Ground breaking and earth shattering!!!

#10

TECH Enthusiast

Thread Starter

No one felt threatened Spin. Just a couple people who are familiar with you were pointing out how ironic it was that you were "paving the way" 2 years after the fact while for soooo long you were an L92 nay-sayer. Thats all.

I, for the most part GIVE AWAY information. With the exception of cam specs. I will however, give people reasonable limits to operate within.

While this is a good, thorough write up, it is far from ground breaking. It is at this stage of the game, old news.

Absolutely no one is/was being a hater.

I, for the most part GIVE AWAY information. With the exception of cam specs. I will however, give people reasonable limits to operate within.

While this is a good, thorough write up, it is far from ground breaking. It is at this stage of the game, old news.

Absolutely no one is/was being a hater.

I guess a 470+rwhp package with a basically stock set of L92's must have bothered some more than others. Sorry you werent more supportive.

#11

LS1 Tech Administrator

iTrader: (14)

This is an outstanding thread with lots of detail (including photos). If we can get some good tech to continue in this thread, I will consider making this a sticky.

__________________

2013 Corvette Grand Sport A6 LME forged 416, Greg Good ported TFS 255 LS3 heads, 222/242 .629"/.604" 121LSA Pat G blower cam, ARH 1 7/8" headers, ESC Novi 1500 Supercharger w/8 rib direct drive conversion, 747rwhp/709rwtq on 93 octane, 801rwhp/735rwtq on race fuel, 10.1 @ 147.25mph 1/4 mile, 174.7mph Half Mile.

2016 Corvette Z51 M7 Magnuson Heartbeat 2300 supercharger, TSP LT headers, Pat G tuned, 667rwhp, 662rwtq, 191mph TX Mile.

2009.5 Pontiac G8 GT 6.0L, A6, AFR 230v2 heads. 506rwhp/442rwtq. 11.413 @ 121.29mph 1/4 mile, 168.7mph TX Mile

2000 Pewter Ram Air Trans Am M6 heads/cam 508 rwhp/445 rwtq SAE, 183.092 TX Mile

2022 Cadillac Escalade 6.2L A10 S&B CAI, Corsa catback.

2023 Corvette 3LT Z51 soon to be modified.

Custom LSX tuning in person or via email press here.

2013 Corvette Grand Sport A6 LME forged 416, Greg Good ported TFS 255 LS3 heads, 222/242 .629"/.604" 121LSA Pat G blower cam, ARH 1 7/8" headers, ESC Novi 1500 Supercharger w/8 rib direct drive conversion, 747rwhp/709rwtq on 93 octane, 801rwhp/735rwtq on race fuel, 10.1 @ 147.25mph 1/4 mile, 174.7mph Half Mile.

2016 Corvette Z51 M7 Magnuson Heartbeat 2300 supercharger, TSP LT headers, Pat G tuned, 667rwhp, 662rwtq, 191mph TX Mile.

2009.5 Pontiac G8 GT 6.0L, A6, AFR 230v2 heads. 506rwhp/442rwtq. 11.413 @ 121.29mph 1/4 mile, 168.7mph TX Mile

2000 Pewter Ram Air Trans Am M6 heads/cam 508 rwhp/445 rwtq SAE, 183.092 TX Mile

2022 Cadillac Escalade 6.2L A10 S&B CAI, Corsa catback.

2023 Corvette 3LT Z51 soon to be modified.

Custom LSX tuning in person or via email press here.

#12

Restricted User

Join Date: May 2006

Location: virginia

Posts: 132

Likes: 0

Received 0 Likes

on

0 Posts

Dam don't take your post and run again after all the flack.... sometimes I wonder who is more sensitive females or males.

After all these years the same cam is what you ended up with??? Guess it works for everything?

https://ls1tech.com/forums/showthrea...t=#post5263035

After looking thru your posts I seriously wonder how much you actually know when you throw out 8.7DCR on EVERYTHING without any account for some idea of how it relates to octane and Vol Eff. I found that and a lot of deleted threads where you talked smack about L92 setups..... especially one LG deal that made more power on the same cubes as yours did here.

Jes

After all these years the same cam is what you ended up with??? Guess it works for everything?

https://ls1tech.com/forums/showthrea...t=#post5263035

After looking thru your posts I seriously wonder how much you actually know when you throw out 8.7DCR on EVERYTHING without any account for some idea of how it relates to octane and Vol Eff. I found that and a lot of deleted threads where you talked smack about L92 setups..... especially one LG deal that made more power on the same cubes as yours did here.

Jes

Last edited by Jessica; 07-18-2008 at 09:57 PM.