CFM in the Real World

#1

TECH Resident

Thread Starter

iTrader: (10)

Join Date: May 2005

Location: Long Island, NY

Posts: 835

Likes: 0

Received 0 Likes

on

0 Posts

this is jsut a theory...

heads all ahve flow ratings and everyone ports their heads to improve it so on and so forth....

would there be a formula for flow requirements based on engine size (305vs 350vs 383) and cam spec (230/236 will need more fuel/air than 224/224)

wouldnt there be a point where the cylinder is full and 230CFM will have the same result as a 310CFM head? (considering the intake isnt restricting the heads)

trying to figure out CFM ratings on the tech side, not the business side... if your car only needs 280CFM, why pay extra to make it flow 300CFM

heads all ahve flow ratings and everyone ports their heads to improve it so on and so forth....

would there be a formula for flow requirements based on engine size (305vs 350vs 383) and cam spec (230/236 will need more fuel/air than 224/224)

wouldnt there be a point where the cylinder is full and 230CFM will have the same result as a 310CFM head? (considering the intake isnt restricting the heads)

trying to figure out CFM ratings on the tech side, not the business side... if your car only needs 280CFM, why pay extra to make it flow 300CFM

#4

TECH Fanatic

iTrader: (10)

Join Date: Aug 2004

Location: Rochester,Ny

Posts: 1,433

Likes: 0

Received 0 Likes

on

0 Posts

thats only half of the story,you are forgetting that port volume and cross section is equally as important as the flow numbers.If you have a 250cc intake port that flows 300cfm at .600,and you put that head up against lets say an AFR 205,which with a 205cc port flows about the same,the 205 will make much more power and torque on a 346 ls.Every engine will make the most hp/tq with a certain port volume/cross section intake and exhaust port.The hard part is getting the maximum cfm out of that port while staying in that range of volume and cross section..So if you could design a 205cc intake port that flows 600cfm,it will definitly mean a lot more power,as the air speed and velocity required to flow 600cfm would be rediculous,and would fill the cylinder much better.You are also forgetting that its possible to fill a cylinder with Higher than ambient air pressure,without using a power adder.

#5

wouldnt there be a point where the cylinder is full and 230CFM will have the same result as a 310CFM head? (considering the intake isnt restricting the heads)

trying to figure out CFM ratings on the tech side, not the business side... if your car only needs 280CFM, why pay extra to make it flow 300CFM

The real need for the additional airflow comes in at higher RPM's when the engine has less time to fill the cylinders. If for some reason you were never going to spin your performance engine past say 4000 RPM, you would in fact be wasting money purchasing more head than you need to some extent, but why would you cut off your performance potential by shifting so early? (you wouldn't is the logical answer).

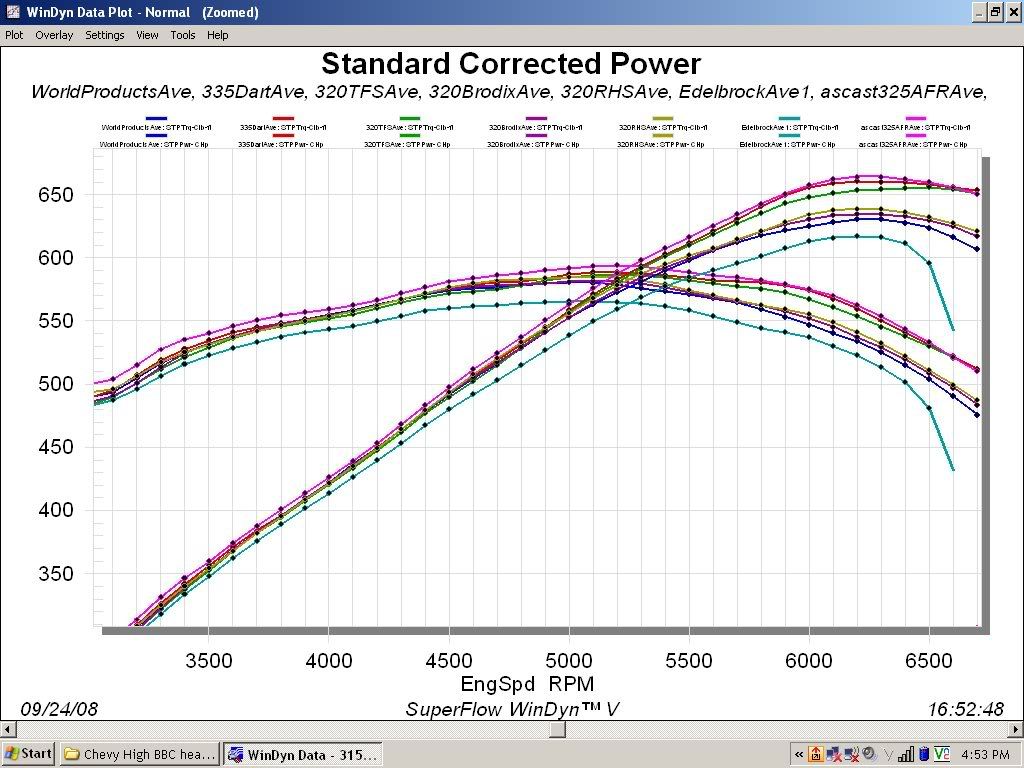

Here is a comparison of the same 502 CID engine (only 8.5 to 1 CR) with the same camshaft and the same compression with the only difference being seven different cylinder heads. Note there is one head that even on the bottom shows a little better than the others and of course shows a little better upstairs overall, but the thing that's interesting with this comparison is that it shows the trend your speculating and Im further clarifying....in the lower RPM ranges where airflow isnt at a premium yet, the difference in power output was less with all seven heads (tighhter spread between best to worst). Higher in the curve however its a completely different story showing much larger differences in peak torque/power output which not by any coincidence is directly correlated to the strength of each cylinder head's usable flow curve in this test (up to .650 lift given the cam in question), especially considering that curve relative to volume (and ultimately airspeed).

Check it out...I wish I hadnt cropped the lower RPM data where the pulls were started (between 2500 and 3000 RPM's) because there was an even tighter field there (I did so at the time to better show the resolution/differences higher up by shrinking the total window some making the gaps between the heads upstairs easier to view). Even down low you can still see the more efficient higher flowing heads still helping out, but the gains widen alot more with RPM (and air demand) really showing the better players from the weaker ones.

Whats also interesting is that six of the seven heads tested here were "as cast" heads in the $2000 - $2500 price range and the only fully ported (and most expensive) head in this test was the Dart 335's (which were also the largest heads in this test). While that head actually had the highest peak flow past .700 lift on the flowbench, with a gross .670 lift solid roller used in this test (lifting the valve only to .650 net and spending alot of time in the .600 range), the larger port and additional airflow wasn't capitolized on in this particular test.....showing once again that the proper combination is key (and more important than how much money you spend).

Hope this info helps...

-Tony

Last edited by Tony Mamo @ AFR; 01-25-2009 at 03:15 PM.

#6

TECH Resident

Thread Starter

iTrader: (10)

Join Date: May 2005

Location: Long Island, NY

Posts: 835

Likes: 0

Received 0 Likes

on

0 Posts

thats exactly what iw as looking for thank you... and thanks for the 205 vs 250 port info too... looks like i got some more studying to do

do you happen to have the flow ratings on those heads by chance? to futher aid in the comparison

Last edited by greatskiiiier; 01-25-2009 at 04:27 PM.

#7

OWN3D BY MY PROF!

iTrader: (176)

Tony, I have that article in an older magazine. What you say peaks my interest more in working towards further educating myself in this subject.

With the variances in cam design now how would the ever changing lobe technology affect this sort of selection? With super aggresive LSK lobes we are seeing much faster ramp rates than lesser lobes. Are we still trying to effectively maximize velocity through the port or slightly opening up the ports to flow more air? With velocity I see the advantages of ramming air into the cylinder, but with a static flow rate would decreasing the pressure and increasing the flow make more of a difference? How would that change with having a super aggresive LSK lobe versus a relatively lazy XE lobe?

With the ideas of maximum performance in mind getting the most air in the cylinders is the goal. I remember with Patrick Gs heads that you worked over for him your whole goal was maximimizing the airflow in the lower CFM range where you'll spend the most time. The results were great and with the super efficient ports of the AFR 205s, tight quench, and small combustion chambers resulting in an effective burn it put out great numbers.

Now, on the other side of the equation where do you draw the boundary between optimal velocity and flow? Do you just work a port with the ideas of maintaining a maximum velocity with flow as the added advantage or the other way around?

With the variances in cam design now how would the ever changing lobe technology affect this sort of selection? With super aggresive LSK lobes we are seeing much faster ramp rates than lesser lobes. Are we still trying to effectively maximize velocity through the port or slightly opening up the ports to flow more air? With velocity I see the advantages of ramming air into the cylinder, but with a static flow rate would decreasing the pressure and increasing the flow make more of a difference? How would that change with having a super aggresive LSK lobe versus a relatively lazy XE lobe?

With the ideas of maximum performance in mind getting the most air in the cylinders is the goal. I remember with Patrick Gs heads that you worked over for him your whole goal was maximimizing the airflow in the lower CFM range where you'll spend the most time. The results were great and with the super efficient ports of the AFR 205s, tight quench, and small combustion chambers resulting in an effective burn it put out great numbers.

Now, on the other side of the equation where do you draw the boundary between optimal velocity and flow? Do you just work a port with the ideas of maintaining a maximum velocity with flow as the added advantage or the other way around?

Trending Topics

#8

2 reasons:

1) The valve is going to spend more time (in crankshaft degrees of rotation) near peak lift than at low lift once the valve is lifted off the seat. (get the valve to max lift as fast as possible, hold it there as long as needed, close the valve as fast as possible)

2) At low lift, the piston is mostly either moving in the wrong direction or at a low piston speed, so it's not really drawing a lot pressure in the cylinder anyway.

#9

With the variances in cam design now how would the ever changing lobe technology affect this sort of selection? With super aggresive LSK lobes we are seeing much faster ramp rates than lesser lobes. Are we still trying to effectively maximize velocity through the port or slightly opening up the ports to flow more air? With velocity I see the advantages of ramming air into the cylinder, but with a static flow rate would decreasing the pressure and increasing the flow make more of a difference? How would that change with having a super aggresive LSK lobe versus a relatively lazy XE lobe?

With the ideas of maximum performance in mind getting the most air in the cylinders is the goal. I remember with Patrick Gs heads that you worked over for him your whole goal was maximimizing the airflow in the lower CFM range where you'll spend the most time. The results were great and with the super efficient ports of the AFR 205s, tight quench, and small combustion chambers resulting in an effective burn it put out great numbers.

Now, on the other side of the equation where do you draw the boundary between optimal velocity and flow? Do you just work a port with the ideas of maintaining a maximum velocity with flow as the added advantage or the other way around?

With the ideas of maximum performance in mind getting the most air in the cylinders is the goal. I remember with Patrick Gs heads that you worked over for him your whole goal was maximimizing the airflow in the lower CFM range where you'll spend the most time. The results were great and with the super efficient ports of the AFR 205s, tight quench, and small combustion chambers resulting in an effective burn it put out great numbers.

Now, on the other side of the equation where do you draw the boundary between optimal velocity and flow? Do you just work a port with the ideas of maintaining a maximum velocity with flow as the added advantage or the other way around?

#10

FormerVendor

iTrader: (38)

Join Date: Nov 2008

Location: Pearland, TX

Posts: 2,309

Likes: 0

Received 0 Likes

on

0 Posts

Very useful info, and one that hopefully alot will read and learn from. So many people get hung up on peak Flow #'s and such, especially @ .700. How many of the cars on this site have .700+ lift cams? I do know it is more popular with the LS generation heads to look at flow #'s at .600 and .650 (people are learning )

)

And yes, (as it has been pointed out) your theory for the most part is correct. Huge flow #'s do not always account for huge power #'s. It is the whole package that works as a unit. I mean, you put a set of 400 CFM @ .800 heads on a 346" 10:1 motor with a 220* cam, what kind of power do you think that motor will make? Not nearly as good as if it had a set of 300 CFM @ .600 heads on it. And of course you need to pay attention to mid lift flow #'s as well (some will argue more importanly) It jsut really depends on what YOU are trying to do, and what PACKAGE you are putting together. I know it has been said on this site along the lines of: Good cam, crappy heads equal crappy power, But crappy cam, good heads makes good power, or something like that. I like to think that crappy cam regardless of heads makes crappy power and crappy heads regardless of cam, makes crappy power...you need BOTH to make good power

)

)And yes, (as it has been pointed out) your theory for the most part is correct. Huge flow #'s do not always account for huge power #'s. It is the whole package that works as a unit. I mean, you put a set of 400 CFM @ .800 heads on a 346" 10:1 motor with a 220* cam, what kind of power do you think that motor will make? Not nearly as good as if it had a set of 300 CFM @ .600 heads on it. And of course you need to pay attention to mid lift flow #'s as well (some will argue more importanly) It jsut really depends on what YOU are trying to do, and what PACKAGE you are putting together. I know it has been said on this site along the lines of: Good cam, crappy heads equal crappy power, But crappy cam, good heads makes good power, or something like that. I like to think that crappy cam regardless of heads makes crappy power and crappy heads regardless of cam, makes crappy power...you need BOTH to make good power