Making an intake, could use your input.

#1

Staging Lane

Thread Starter

Join Date: Sep 2010

Location: Santa Cruz

Posts: 83

Likes: 0

Received 0 Likes

on

0 Posts

The idea has morphed from a sheet metal carb manifold into to a carbon fiber efi manifold. Since I'm working off my cathedral ported motor that will be the first design tested. If all goes well other applications will follow.

at first I thought the runners could be short like a drag intake, then I realized for my needs the runners would have to extend into the plenum

after calculating the displacement of the runners I realized the plenum is too small.

I just about gave up after spending too much on crap for the plug/molds and a few days shaping for nothing, starting over didn't sound like much fun.

but I guess thats part of developing an idea...

after designing the runners long enough for a stock engine to appreciate, I realized they could be cut down to dial-in most setups.

well then I got all fired up again.

so I designed the plenum around the new runners in a way to maximize airflow thruout the plenum and promote continued circulation.

Here's the new skeleton and runner template to give you guys an idea of what I'm working toward

the new runners are 10" long and open up to 1.5" plus 1/2" radius bell-flange

at first I thought the runners could be short like a drag intake, then I realized for my needs the runners would have to extend into the plenum

after calculating the displacement of the runners I realized the plenum is too small.

I just about gave up after spending too much on crap for the plug/molds and a few days shaping for nothing, starting over didn't sound like much fun.

but I guess thats part of developing an idea...

after designing the runners long enough for a stock engine to appreciate, I realized they could be cut down to dial-in most setups.

well then I got all fired up again.

so I designed the plenum around the new runners in a way to maximize airflow thruout the plenum and promote continued circulation.

Here's the new skeleton and runner template to give you guys an idea of what I'm working toward

the new runners are 10" long and open up to 1.5" plus 1/2" radius bell-flange

Last edited by inde-fab; 05-14-2011 at 11:10 PM.

#2

Staging Lane

Thread Starter

Join Date: Sep 2010

Location: Santa Cruz

Posts: 83

Likes: 0

Received 0 Likes

on

0 Posts

since its for an ls1/ls2 I think factory injectors and fuel rail should probobly be used so it's a bolt-on kinda deal. How about the knock sensor? I'm thinking it should be an option as well for the same reason. what else?

I know, nos ports. likely addition after the n/a setup is dialed in decent.

let me know what else I can do to make it a user friendly and versatile design. thanks!

I will be offering board members a half price promo once the design is proven production-worthy.

thanks in advance for any and all input, I really appreciate the help I get here.

I know, nos ports. likely addition after the n/a setup is dialed in decent.

let me know what else I can do to make it a user friendly and versatile design. thanks!

I will be offering board members a half price promo once the design is proven production-worthy.

thanks in advance for any and all input, I really appreciate the help I get here.

Last edited by inde-fab; 05-14-2011 at 11:02 PM.

#3

Staging Lane

Thread Starter

Join Date: Sep 2010

Location: Santa Cruz

Posts: 83

Likes: 0

Received 0 Likes

on

0 Posts

everything is figured out finally, now just a couple/few more days of moldmaking and I will be ready to make a prototype in fiberglass.

I'm really happy with how the runner layout is coming along. hopefully that part of the mold will be nearly assembled tomorrow. some more details on the plenum to address before its ready to go but it's getting close.

Here's the fun question:

what would be the ultimate combo? throttle body, injectors, fuel rails, etc?

and another...

what would be the preferred nitrous system to pre-plumb for???

and the last one.

what type of gasket material would you guys recommend for the top/bottom plenum joint?

was just thinking maybe something like you would see on a 2-piece intake manifold, grey fel-pro stuff with hi-temp rtv? I'm not a proper mechanic so maybe one of u guys can chime in. Thanks!

I'm really happy with how the runner layout is coming along. hopefully that part of the mold will be nearly assembled tomorrow. some more details on the plenum to address before its ready to go but it's getting close.

Here's the fun question:

what would be the ultimate combo? throttle body, injectors, fuel rails, etc?

and another...

what would be the preferred nitrous system to pre-plumb for???

and the last one.

what type of gasket material would you guys recommend for the top/bottom plenum joint?

was just thinking maybe something like you would see on a 2-piece intake manifold, grey fel-pro stuff with hi-temp rtv? I'm not a proper mechanic so maybe one of u guys can chime in. Thanks!

Last edited by inde-fab; 05-14-2011 at 11:13 PM.

#4

TECH Fanatic

iTrader: (63)

To make a product to sell (i'm guessing you are,) a 78mm throttle body won't cut it, even if it's made of gold, with all of the 92mm and bigger intakes out there. Mock something up with a 102+mm throttle body. Also, there isn't much room in front of your runners to pick up air from the plenum.

#5

Staging Lane

Thread Starter

Join Date: Sep 2010

Location: Santa Cruz

Posts: 83

Likes: 0

Received 0 Likes

on

0 Posts

this was supposed to be a project for my own race program. only way I can justify continuing to dump days into it is if I sell a few.

appreciate the comment on the runners. I backed them off about 3/4" on the final design

remember they will be cut down for each application.

runners are still close to 10" long, they now open up to 1.75" and I will do a quarter inch-1/2" flare on the end depending on how much space there is to work with in there.

I can make interchangeable flange/ mouths for different sized throttle bodies. the 102 would be bad-a. what injectors would go well with it?

I would love to see some intakes dialed in at the strip but they are really designed for offroad endurance racing so the focus is more on torquey midrange to top end, so thats why I'm excited about the tuneability factor on the design.

Knock sensor provision yay or nay?

I know it seems like alot of talk but the moldmaking and research process has been alittle more drawn out than anticipated. hopefully finishing molds this week.

thanks for the help.

appreciate the comment on the runners. I backed them off about 3/4" on the final design

remember they will be cut down for each application.

runners are still close to 10" long, they now open up to 1.75" and I will do a quarter inch-1/2" flare on the end depending on how much space there is to work with in there.

I can make interchangeable flange/ mouths for different sized throttle bodies. the 102 would be bad-a. what injectors would go well with it?

I would love to see some intakes dialed in at the strip but they are really designed for offroad endurance racing so the focus is more on torquey midrange to top end, so thats why I'm excited about the tuneability factor on the design.

Knock sensor provision yay or nay?

I know it seems like alot of talk but the moldmaking and research process has been alittle more drawn out than anticipated. hopefully finishing molds this week.

thanks for the help.

Last edited by inde-fab; 05-16-2011 at 12:13 PM.

#6

Staging Lane

Thread Starter

Join Date: Sep 2010

Location: Santa Cruz

Posts: 83

Likes: 0

Received 0 Likes

on

0 Posts

got a good enough cast of the knock sensor hole to make work

runners coming together nicely, I realized they're not that far off stock. still need to get some injector bungs or make some. Thinking about getting ahold of the machinist I work with on that. I could have them made out of nylatron for alot less then alum. (just gotta check the heat range on that stuff first)

plenum inner molds ready to be trued up at the cabinet shop next door tomorrow, then minor bondo fillwork and those are ready to mold off!

once I make the plenum I can mock it in place to find exactly where the runners will intersect. That point will become the separation plane for the mold so inner runners of various shapes/lengths can be made later

I may try to lower the plenum height again tomorrow so it will work for more ppl. It's my last chance to modify the runner shape before molding

If some of you want to throw out a measurement from valve cover high side to hood and vehicle it would be cool to know what cars it could work on.

I want to drop it down but this angle seems like it would stuff the air right at the in. valve better then the stocker.

someone recommended I make the throttle body assembly on an attatchment flange so that larger T.B.'s can be used later (102mm)

yes thank u, good call. Thats exactly why I'm posting this, I'm over worrying if someone will copy it.

I just want to make something that truly performs and can benefit as many setups as possible.

being carbon fiber in the end I know its gonna look sweet.

runners coming together nicely, I realized they're not that far off stock. still need to get some injector bungs or make some. Thinking about getting ahold of the machinist I work with on that. I could have them made out of nylatron for alot less then alum. (just gotta check the heat range on that stuff first)

plenum inner molds ready to be trued up at the cabinet shop next door tomorrow, then minor bondo fillwork and those are ready to mold off!

once I make the plenum I can mock it in place to find exactly where the runners will intersect. That point will become the separation plane for the mold so inner runners of various shapes/lengths can be made later

I may try to lower the plenum height again tomorrow so it will work for more ppl. It's my last chance to modify the runner shape before molding

If some of you want to throw out a measurement from valve cover high side to hood and vehicle it would be cool to know what cars it could work on.

I want to drop it down but this angle seems like it would stuff the air right at the in. valve better then the stocker.

someone recommended I make the throttle body assembly on an attatchment flange so that larger T.B.'s can be used later (102mm)

yes thank u, good call. Thats exactly why I'm posting this, I'm over worrying if someone will copy it.

I just want to make something that truly performs and can benefit as many setups as possible.

being carbon fiber in the end I know its gonna look sweet.

Last edited by inde-fab; 05-17-2011 at 12:00 AM.

#7

TECH Fanatic

iTrader: (63)

this was supposed to be a project for my own race program. only way I can justify continuing to dump days into it is if I sell a few.

appreciate the comment on the runners. I backed them off about 3/4" on the final design

remember they will be cut down for each application.

runners are still close to 10" long, they now open up to 1.75" and I will do a quarter inch-1/2" flare on the end depending on how much space there is to work with in there.

I can make interchangeable flange/ mouths for different sized throttle bodies. the 102 would be bad-a. what injectors would go well with it?

I would love to see some intakes dialed in at the strip but they are really designed for offroad endurance racing so the focus is more on torquey midrange to top end, so thats why I'm excited about the tuneability factor on the design.

Knock sensor provision yay or nay?

I know it seems like alot of talk but the moldmaking and research process has been alittle more drawn out than anticipated. hopefully finishing molds this week.

thanks for the help.

appreciate the comment on the runners. I backed them off about 3/4" on the final design

remember they will be cut down for each application.

runners are still close to 10" long, they now open up to 1.75" and I will do a quarter inch-1/2" flare on the end depending on how much space there is to work with in there.

I can make interchangeable flange/ mouths for different sized throttle bodies. the 102 would be bad-a. what injectors would go well with it?

I would love to see some intakes dialed in at the strip but they are really designed for offroad endurance racing so the focus is more on torquey midrange to top end, so thats why I'm excited about the tuneability factor on the design.

Knock sensor provision yay or nay?

I know it seems like alot of talk but the moldmaking and research process has been alittle more drawn out than anticipated. hopefully finishing molds this week.

thanks for the help.

Trending Topics

#8

Teching In

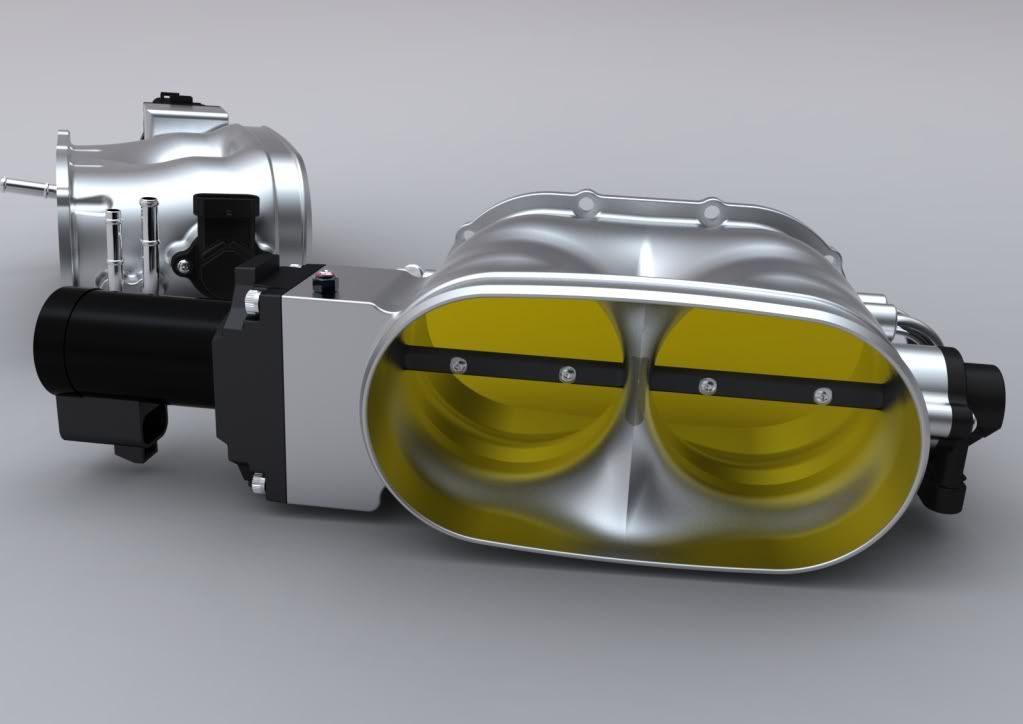

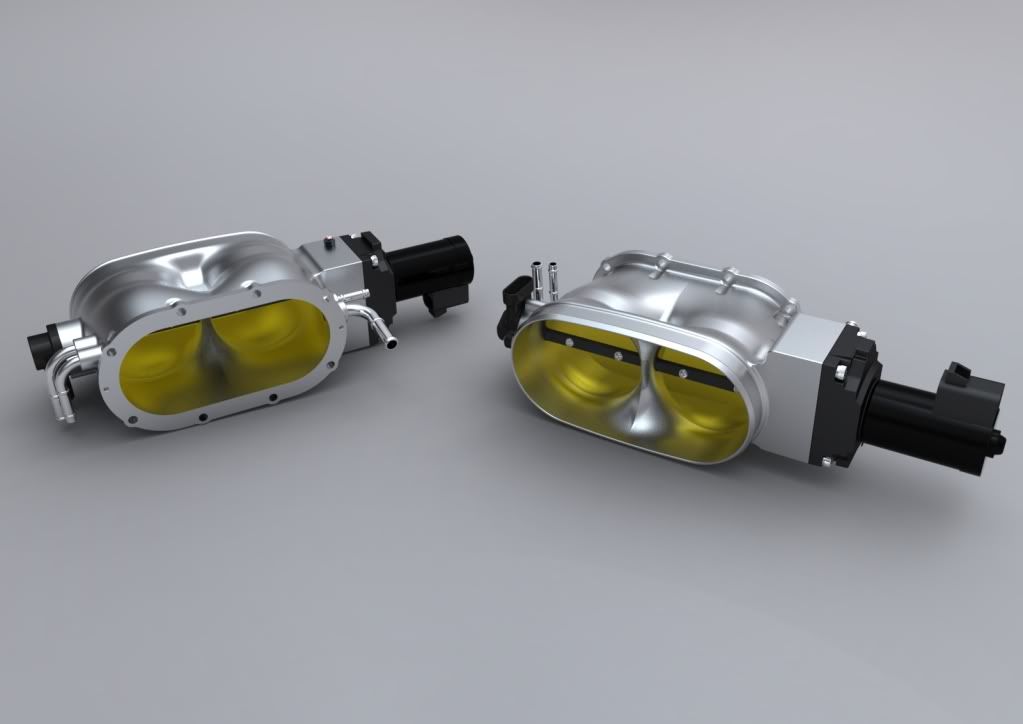

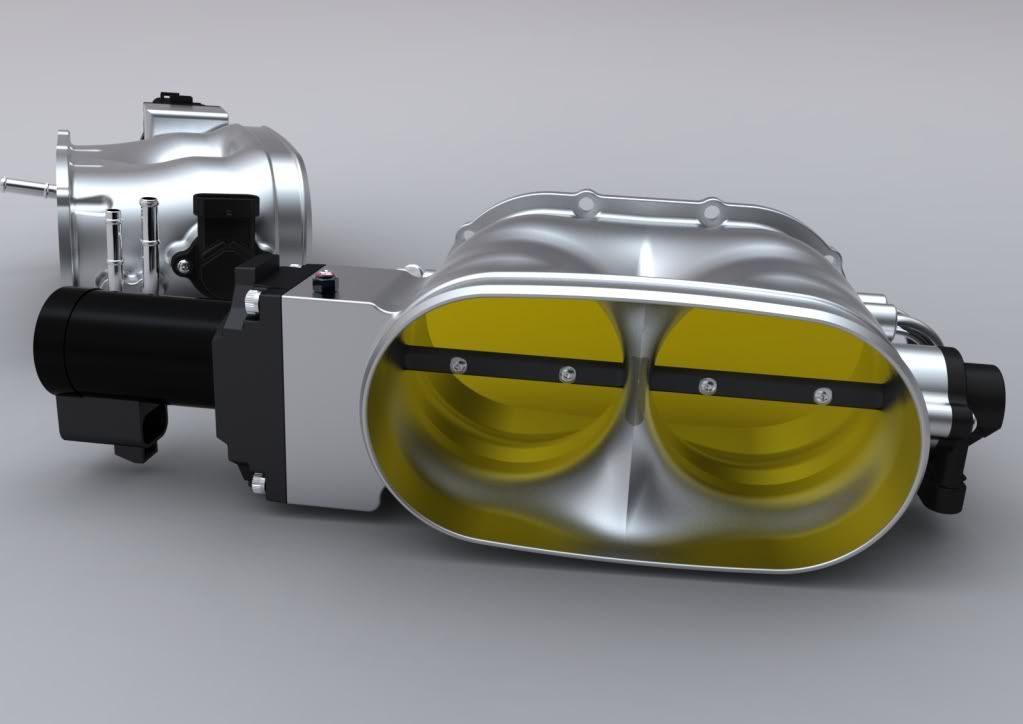

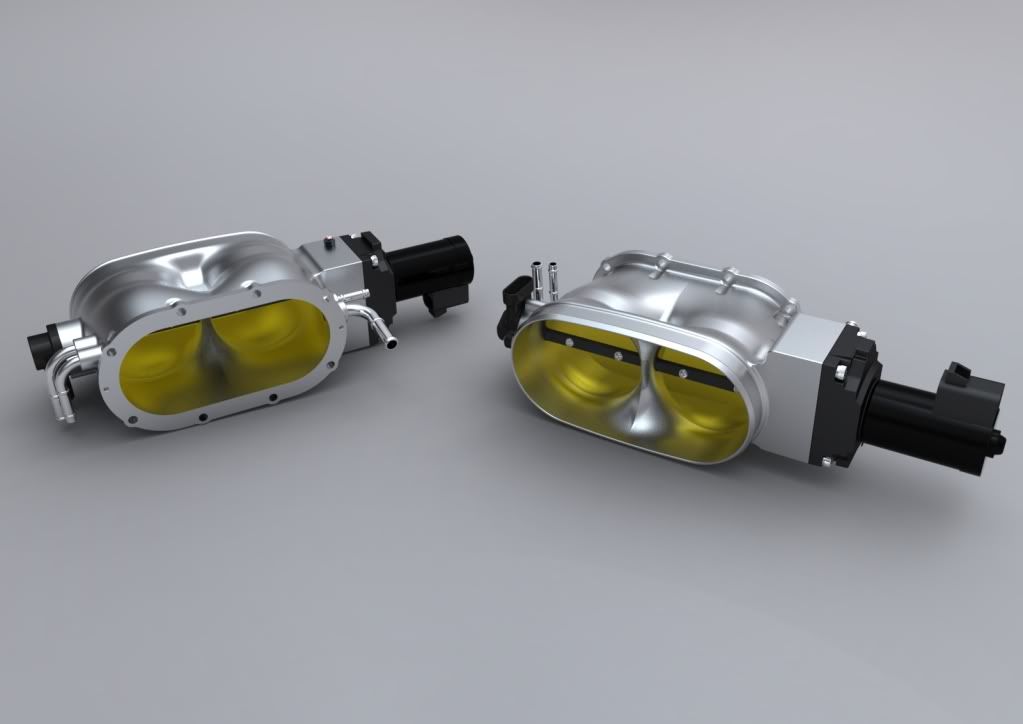

For big engines the 102mm throttle body does not flow unrestricted enough - we have measured many that still exhibit a significant pressure drop at WOT.

I make the 108mm as shown below, albeit only in an electronic version at the moment (still working on the cable version). It retains nice progression & driveability like the OE unit. I can send you the mounting bolt-pattern if you want to incorporate a suitable flange.

I make the 108mm as shown below, albeit only in an electronic version at the moment (still working on the cable version). It retains nice progression & driveability like the OE unit. I can send you the mounting bolt-pattern if you want to incorporate a suitable flange.

#9

Staging Lane

Thread Starter

Join Date: Sep 2010

Location: Santa Cruz

Posts: 83

Likes: 0

Received 0 Likes

on

0 Posts

those are tasty bits right there.

SO can they be set up to run on an LS1 cable t.b. harness? or

what do I have to do to make that baby work is the real question.

I would happily make a flange for those, thats exactly what I want for my race engine

having the gasket or part number would be handy for molding.

Feel free to send a cable prototype my way =) thats gonna be a really nice piece.

SO can they be set up to run on an LS1 cable t.b. harness? or

what do I have to do to make that baby work is the real question.

I would happily make a flange for those, thats exactly what I want for my race engine

having the gasket or part number would be handy for molding.

Feel free to send a cable prototype my way =) thats gonna be a really nice piece.

Last edited by inde-fab; 05-18-2011 at 01:41 AM.

#10

Staging Lane

Thread Starter

Join Date: Sep 2010

Location: Santa Cruz

Posts: 83

Likes: 0

Received 0 Likes

on

0 Posts

thanks, I'm sure this kinda simple stuff seems like nothing to you guys in the know but this is huge to design. (esp for an LS newb) I had planned on making the mount "posts" out of aluminum and could score them for specific rail heights.

#11

Teching In

I figure it will be July before I have the LS1-style cable version available, but then it will be a direct plug-n-play to the OEM harness/loom.

During testing of the electronic version, we swapped the OEM manifold & TB on my mates wife's car with this 108mm and didn't tell her so that we could get a truely unbiased opinion. She never noticed any difference driving to and from home (including taking the kids to school) because the low-speed modulation is just like the factory unit.

It is only at ~>22% throttle that any difference is noticed - but then it comes on strong!

Summary - driveability is great.

FYI ...

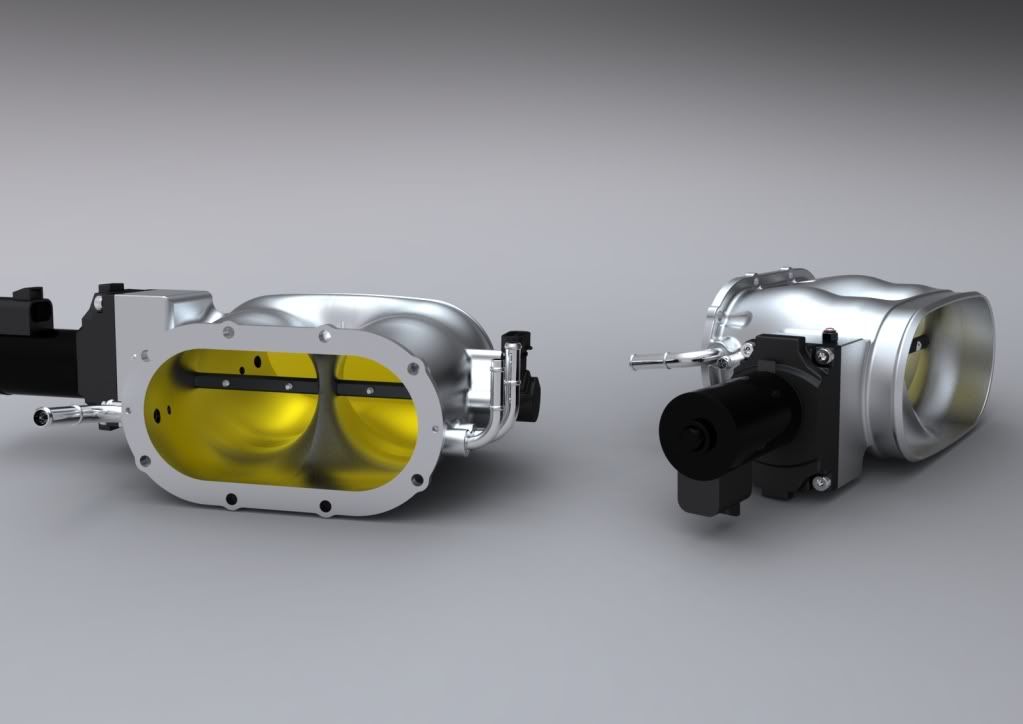

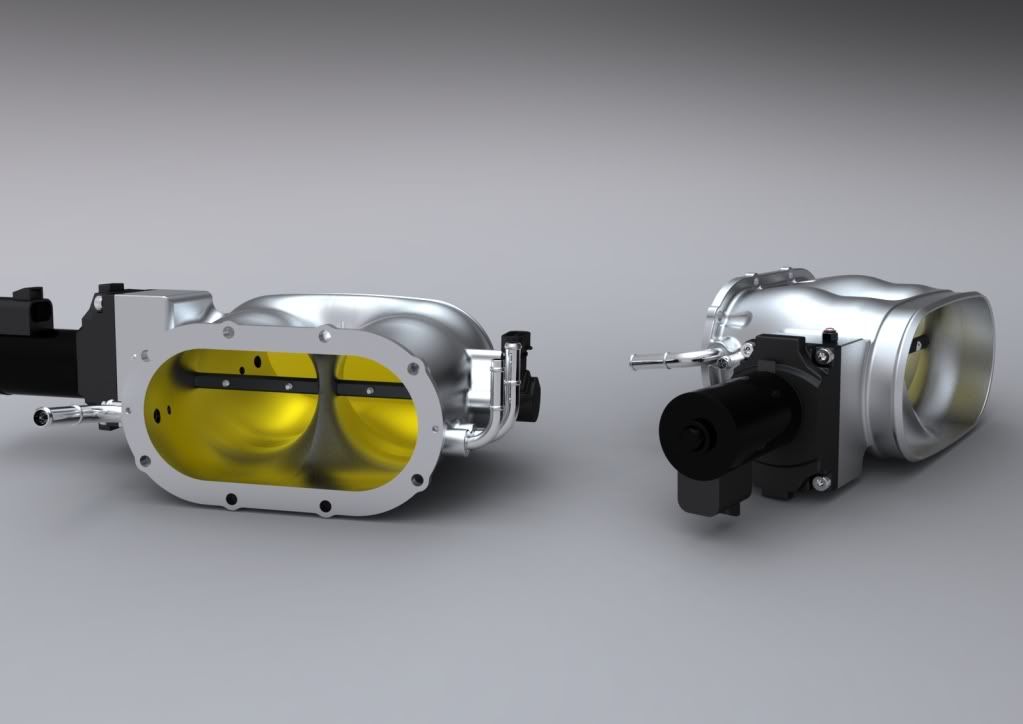

There is also this style which I make for upgrading the Harrop superchargers. It may be better suited for installations that are limited in height. These do not have such an OE modulation - they are lots more aggressive at low air speeds.

During testing of the electronic version, we swapped the OEM manifold & TB on my mates wife's car with this 108mm and didn't tell her so that we could get a truely unbiased opinion. She never noticed any difference driving to and from home (including taking the kids to school) because the low-speed modulation is just like the factory unit.

It is only at ~>22% throttle that any difference is noticed - but then it comes on strong!

Summary - driveability is great.

FYI ...

There is also this style which I make for upgrading the Harrop superchargers. It may be better suited for installations that are limited in height. These do not have such an OE modulation - they are lots more aggressive at low air speeds.

Last edited by PerformanceDefined; 05-18-2011 at 02:33 AM.

#12

Staging Lane

Thread Starter

Join Date: Sep 2010

Location: Santa Cruz

Posts: 83

Likes: 0

Received 0 Likes

on

0 Posts

all I can say is wow.

That design looks amazing for a lower profile design, I would love flange dimensions and rough outside dim. on that item too if ya don't mind =)

I would love to build an intake using that one on a vette.

most ppl would prob. think it's a blower at first glance.

beautiful work your doin' down under.

Thanks for the pics/info.

That design looks amazing for a lower profile design, I would love flange dimensions and rough outside dim. on that item too if ya don't mind =)

I would love to build an intake using that one on a vette.

most ppl would prob. think it's a blower at first glance.

beautiful work your doin' down under.

Thanks for the pics/info.

#13

Teching In

Drop me an email via ken@southways.com.au & I will send some PDF's. Can you also make use of any digital data? (dxf, iges, etc).

#16

12 Second Club

iTrader: (21)

Join Date: Jun 2007

Location: Muskegon, MI

Posts: 1,102

Likes: 0

Received 0 Likes

on

0 Posts

got a good enough cast of the knock sensor hole to make work

runners coming together nicely, I realized they're not that far off stock. still need to get some injector bungs or make some. Thinking about getting ahold of the machinist I work with on that. I could have them made out of nylatron for alot less then alum. (just gotta check the heat range on that stuff first)

plenum inner molds ready to be trued up at the cabinet shop next door tomorrow, then minor bondo fillwork and those are ready to mold off!

once I make the plenum I can mock it in place to find exactly where the runners will intersect. That point will become the separation plane for the mold so inner runners of various shapes/lengths can be made later

I may try to lower the plenum height again tomorrow so it will work for more ppl. It's my last chance to modify the runner shape before molding

If some of you want to throw out a measurement from valve cover high side to hood and vehicle it would be cool to know what cars it could work on.

I want to drop it down but this angle seems like it would stuff the air right at the in. valve better then the stocker.

someone recommended I make the throttle body assembly on an attatchment flange so that larger T.B.'s can be used later (102mm)

yes thank u, good call. Thats exactly why I'm posting this, I'm over worrying if someone will copy it.

I just want to make something that truly performs and can benefit as many setups as possible.

being carbon fiber in the end I know its gonna look sweet.

runners coming together nicely, I realized they're not that far off stock. still need to get some injector bungs or make some. Thinking about getting ahold of the machinist I work with on that. I could have them made out of nylatron for alot less then alum. (just gotta check the heat range on that stuff first)

plenum inner molds ready to be trued up at the cabinet shop next door tomorrow, then minor bondo fillwork and those are ready to mold off!

once I make the plenum I can mock it in place to find exactly where the runners will intersect. That point will become the separation plane for the mold so inner runners of various shapes/lengths can be made later

I may try to lower the plenum height again tomorrow so it will work for more ppl. It's my last chance to modify the runner shape before molding

If some of you want to throw out a measurement from valve cover high side to hood and vehicle it would be cool to know what cars it could work on.

I want to drop it down but this angle seems like it would stuff the air right at the in. valve better then the stocker.

someone recommended I make the throttle body assembly on an attatchment flange so that larger T.B.'s can be used later (102mm)

yes thank u, good call. Thats exactly why I'm posting this, I'm over worrying if someone will copy it.

I just want to make something that truly performs and can benefit as many setups as possible.

being carbon fiber in the end I know its gonna look sweet.

Last edited by ShortChevy; 05-19-2011 at 12:42 PM.

#17

Staging Lane

Thread Starter

Join Date: Sep 2010

Location: Santa Cruz

Posts: 83

Likes: 0

Received 0 Likes

on

0 Posts

yes I was mistaken, knocks are under the valley cover right?

okay well that simplifies the TB flange assembly alot

I was noticing that none of the other intakes had it so I was starting to wonder if that was something else. like I said, LS1 newb here.

okay well that simplifies the TB flange assembly alot

I was noticing that none of the other intakes had it so I was starting to wonder if that was something else. like I said, LS1 newb here.

#18

12 Second Club

iTrader: (21)

Join Date: Jun 2007

Location: Muskegon, MI

Posts: 1,102

Likes: 0

Received 0 Likes

on

0 Posts

Gen III LS engines the KS's are located in in the valley cover yes. Gen IV are in the skirt. EGR was used on the F-body LS1 intakes but not the Y-body. Also when the LS6 intake went in the F-body there was no EGR provision. SLP did sell a LS6 intake with a EGR provision. LS engines don't really need EGR, they are efficient enough. A lot of people, myself included, pulled the EGR system for less weight and bay clutter. Sorry for the drawn out post, just figured I'd fill ya in a bit.

#19

Staging Lane

Thread Starter

Join Date: Sep 2010

Location: Santa Cruz

Posts: 83

Likes: 0

Received 0 Likes

on

0 Posts

thank you for that, great info. I really appreciate the help u guys offer here.

plenum molds done, runner molds getting painfully close.

Depending on weather (need it warm) I will hopefully be molding early next week. I have some other jobs coming thru so I gotta get this thing wrapping up pretty soon. I wish I could play with prototypes everyday...

plenum molds done, runner molds getting painfully close.

Depending on weather (need it warm) I will hopefully be molding early next week. I have some other jobs coming thru so I gotta get this thing wrapping up pretty soon. I wish I could play with prototypes everyday...