options if I cant remove broken bolt from block?

#1

TECH Addict

Thread Starter

iTrader: (3)

Join Date: Feb 2006

Location: limbo

Posts: 2,124

Likes: 0

Received 0 Likes

on

0 Posts

ok so I've been putting off trying to remove the cam retainer bolt I broke off into my block last week, just been working around it putting everything else back together.. but the new bolts arrive today at the dealer so I'm going to TRY and get it out with an easy out. but its not going to be so easy, the bolt had red loctite on it and it didn't leave me with a flat surface to work with, it broke on an angle so if I can't get it out, what can I do? is there anything I can do other than dropping the k-member and wheeling the engine off to a machine shop? I was talking to my dad yesterday about it and he was saying it won't be so easy to drill the entire thing out and re-tap the hole if thats what needs to get done, especially if your not working with a flat surface..

so if I can't get it out, what can I do? is there anything I can do other than dropping the k-member and wheeling the engine off to a machine shop? I was talking to my dad yesterday about it and he was saying it won't be so easy to drill the entire thing out and re-tap the hole if thats what needs to get done, especially if your not working with a flat surface..

what do you guys think?

so if I can't get it out, what can I do? is there anything I can do other than dropping the k-member and wheeling the engine off to a machine shop? I was talking to my dad yesterday about it and he was saying it won't be so easy to drill the entire thing out and re-tap the hole if thats what needs to get done, especially if your not working with a flat surface..

so if I can't get it out, what can I do? is there anything I can do other than dropping the k-member and wheeling the engine off to a machine shop? I was talking to my dad yesterday about it and he was saying it won't be so easy to drill the entire thing out and re-tap the hole if thats what needs to get done, especially if your not working with a flat surface.. what do you guys think?

#2

TECH Addict

Join Date: Jun 2009

Location: Tulsa, OK

Posts: 2,012

Likes: 0

Received 0 Likes

on

0 Posts

Get a heavy duty soldering gun - at least 240 watts. Heat the busted bolt as much as you can with it. If you can get it hot enough, the Loctite will let go. You might even want to try one of the butane torch type soldering tools, although they are more limited in their heat capacity.

You may look at going into the hole with a Dremel tool to try and flatten the surface a bit if it's really extreme, but what I usually do is this:

Get a small center punch, and holding it at an angle equal to the angle of the broken bolt, make your mark. Then, do the same thing with the drill until you have an indentation in the end of the bolt, and bring the drill horizontal at that time. Start with a small bit, and use cutting oil. Once you have your hole, go to a little bit bigger drill bit, and so on. If you're really careful, and get your hole well centered, you can drill almost the entire bolt out without getting into the threads.

You may look at going into the hole with a Dremel tool to try and flatten the surface a bit if it's really extreme, but what I usually do is this:

Get a small center punch, and holding it at an angle equal to the angle of the broken bolt, make your mark. Then, do the same thing with the drill until you have an indentation in the end of the bolt, and bring the drill horizontal at that time. Start with a small bit, and use cutting oil. Once you have your hole, go to a little bit bigger drill bit, and so on. If you're really careful, and get your hole well centered, you can drill almost the entire bolt out without getting into the threads.

Last edited by fleetmgr; 08-14-2009 at 08:44 AM.

#3

Staging Lane

iTrader: (9)

I agree with fleetmgr,but I would get a propane torch like from lowes or home depot and heat the bolt and the surface around the bolt and then once it's hot you will need a good punch and a hammer. Hit the outer edge of the bolt with the punch and it should start tuning.You can also get an automatic center punch from a parts store or snap on,these work great on removing bolts in tight places.

#4

TECH Addict

Join Date: Jun 2009

Location: Tulsa, OK

Posts: 2,012

Likes: 0

Received 0 Likes

on

0 Posts

I agree with fleetmgr,but I would get a propane torch like from lowes or home depot and heat the bolt and the surface around the bolt and then once it's hot you will need a good punch and a hammer. Hit the outer edge of the bolt with the punch and it should start tuning.You can also get an automatic center punch from a parts store or snap on,these work great on removing bolts in tight places.

#5

12 Second Club

iTrader: (21)

Join Date: Jan 2007

Location: Dothan AL for now

Posts: 404

Likes: 0

Received 0 Likes

on

0 Posts

One thing we do to remove broken bolts is get a dremal and put a notch in the center of the bolt big enough to get a flat head screwdriver in there and get it out that way. Shouldnt be to hard if there is enough of the bolt sticking out.

Trending Topics

#9

TECH Enthusiast

Join Date: Feb 2003

Location: Longview, TX

Posts: 675

Likes: 0

Received 0 Likes

on

0 Posts

reverse style drill bits, now not only are you drilling and heating up, you are going the right way if it desides to come loose.

They were my best friend back when working at a dealership...

They were my best friend back when working at a dealership...

#11

On The Tree

iTrader: (3)

Join Date: Oct 2006

Location: Clovis, CA

Posts: 123

Likes: 0

Received 0 Likes

on

0 Posts

If you're that worried about it and not so confident in being able to do it I'd call around the local machine shops or a well known repair shop. There's a local guy around here that will do on-site thread and broken bolt repair. It'd be worth the $50 to have it done cleanly and not butcher the hole and cause a bigger headache, just my .02

#12

TECH Addict

Thread Starter

iTrader: (3)

Join Date: Feb 2006

Location: limbo

Posts: 2,124

Likes: 0

Received 0 Likes

on

0 Posts

thanks for the responses! I've been too busy today getting ready for a wedding so I haven't touched it yet and prolly wont get a chance to till after this weekend. but I did just take some pics to show what I'm working with>

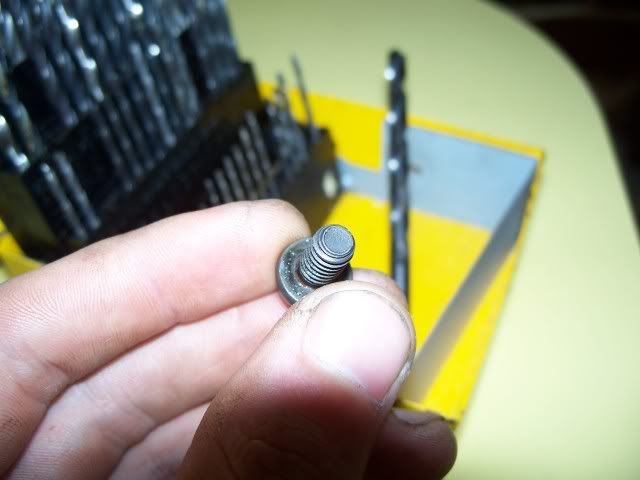

^thats the smallest easy out I have and as you can see nothing is sticking out its a lil recessed.

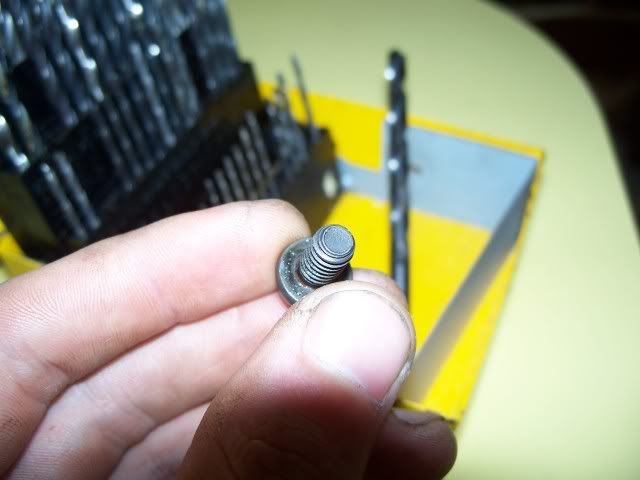

^and thats the size of an intact one

outsourcing this would def be ideal, I'm scared as hell about messing up my block...how ever the nearest machine shop is an hour away.. he drags a mustang tho so I MIGHT be able to talk the guy into commin down and helping me out tho, I'll hafta see about that.

other than that theres some good ideas in here, keep em coming! I'll prolly end up trying to get something to work monday..

^thats the smallest easy out I have and as you can see nothing is sticking out its a lil recessed.

^and thats the size of an intact one

outsourcing this would def be ideal, I'm scared as hell about messing up my block...how ever the nearest machine shop is an hour away.. he drags a mustang tho so I MIGHT be able to talk the guy into commin down and helping me out tho, I'll hafta see about that.

other than that theres some good ideas in here, keep em coming! I'll prolly end up trying to get something to work monday..

#17

TECH Apprentice

iTrader: (10)

No rod, it's wire. Just get a nut with a slightly smaller diameter I.D. than the bolt. Hold the nut in place with some vise-grips (or better yet, get someone else to hold it), and get a tack weld in the hole. Once you've got it tacked in place, weld the hole shut. Doesn't have to be perfectly centered, you just need something to get a wrench on.

#18

TECH Senior Member

iTrader: (8)

The welding a nut is the best suggestion so far if a left-hand drill bit wont work.

I seel both left hand bits and a stud extractor welding alloy at my work. The welding rod is designed so that the slag protects the threads even if the bolt is broken off down in the hole.

Make a small puddle of weld on top of the bolt, weld a flat washer on, then a nut, and turn it out. The heat from the welding process will benefit you as well

I seel both left hand bits and a stud extractor welding alloy at my work. The welding rod is designed so that the slag protects the threads even if the bolt is broken off down in the hole.

Make a small puddle of weld on top of the bolt, weld a flat washer on, then a nut, and turn it out. The heat from the welding process will benefit you as well

#19

TECH Addict

Thread Starter

iTrader: (3)

Join Date: Feb 2006

Location: limbo

Posts: 2,124

Likes: 0

Received 0 Likes

on

0 Posts

The welding a nut is the best suggestion so far if a left-hand drill bit wont work.

I seel both left hand bits and a stud extractor welding alloy at my work. The welding rod is designed so that the slag protects the threads even if the bolt is broken off down in the hole.

Make a small puddle of weld on top of the bolt, weld a flat washer on, then a nut, and turn it out. The heat from the welding process will benefit you as well

I seel both left hand bits and a stud extractor welding alloy at my work. The welding rod is designed so that the slag protects the threads even if the bolt is broken off down in the hole.

Make a small puddle of weld on top of the bolt, weld a flat washer on, then a nut, and turn it out. The heat from the welding process will benefit you as well

No rod, it's wire. Just get a nut with a slightly smaller diameter I.D. than the bolt. Hold the nut in place with some vise-grips (or better yet, get someone else to hold it), and get a tack weld in the hole. Once you've got it tacked in place, weld the hole shut. Doesn't have to be perfectly centered, you just need something to get a wrench on.