Pinion adjustment for TQ-arm?

#1

Just wondering what everybody thinks is a good setting for pinion angle on the street. I would like to have a decent compromise to take advantage of the suspension that is on the car, but I don't want it to be to aggressive. The pinion angle is currently set at -1 for the street. Let me know what you think

#6

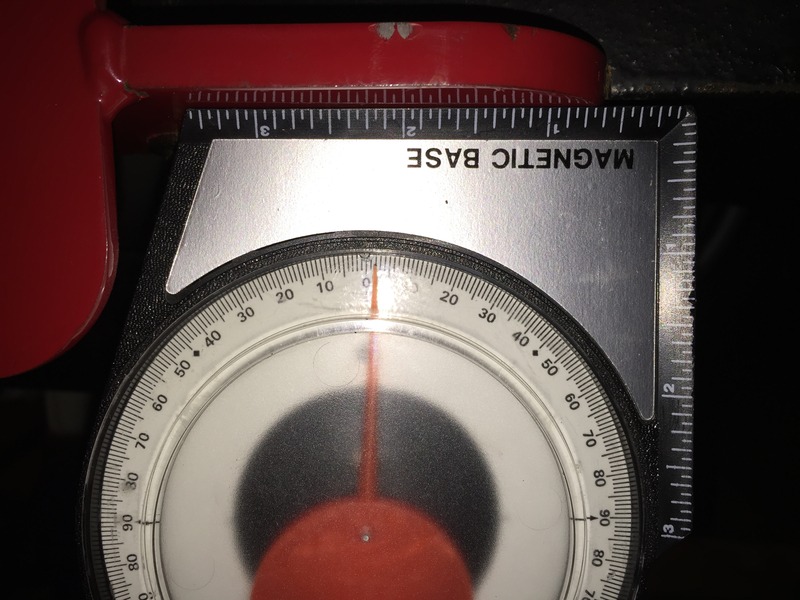

Ok, so I checked the angle on my drive-shaft (0), and the bottom of the BMR tq-arm rear mount plate @ pinion (-2) (rear-end is slightly pointing towards the ground (down). drive-shaft (0 - 2) rear end. If I did this correctly I believe it is set at (-2) now. Let me know what you think?

Trending Topics

#12

LS1Tech Premium Sponsor

iTrader: (5)

Just want to clarify a few things here:

First off, pinion angle does not affect traction or performance, nor is it affected by driving application

The only thing that factors into where pinion angle should be set is if you run a rubber/poly bushing lower control arm or a rod end. Poly/rubber will be -2* and rod ends will be -1 or 0.

The simplest and most effective way to measure the correct working angle of your driveline is to measure a good point that is an accurate reference to the centerline of the crankshaft. I like to use the crank pulley/balancer personally. But any machined surface on the engine or trans will work. You want the difference to measure between the engine and pinion. Driveshaft angle is irrelevant.

For example if your engine measures 5* (down towards the rear of the car) you will want the pinion to be pointed up 3*. They should be running on the same plane. The difference in angle is to allow for the slack in the drivetrain under load so that ideally you will have 0* under acceleration which means your engine and pinion centerlines are perfectly parallel and the u-joint working angles are identical.

Hope this helps a little

First off, pinion angle does not affect traction or performance, nor is it affected by driving application

The only thing that factors into where pinion angle should be set is if you run a rubber/poly bushing lower control arm or a rod end. Poly/rubber will be -2* and rod ends will be -1 or 0.

The simplest and most effective way to measure the correct working angle of your driveline is to measure a good point that is an accurate reference to the centerline of the crankshaft. I like to use the crank pulley/balancer personally. But any machined surface on the engine or trans will work. You want the difference to measure between the engine and pinion. Driveshaft angle is irrelevant.

For example if your engine measures 5* (down towards the rear of the car) you will want the pinion to be pointed up 3*. They should be running on the same plane. The difference in angle is to allow for the slack in the drivetrain under load so that ideally you will have 0* under acceleration which means your engine and pinion centerlines are perfectly parallel and the u-joint working angles are identical.

Hope this helps a little

#14

TECH Addict

iTrader: (1)

I've got to ask, how much of an improvement are one of these aftermarket torque arms over stock for a car that rarely sees the track?  I've got a nearly full aftermarket suspension (control arms, relocation brackets, panhard bar, subframe connectors, 25mm solid sway bar) and the stock torque arm is the only part yet to be replaced. My car is built more for handling than a drag setup like most on here...how much benefit is there in that regard for road course/street/auto x type setup? Also, mine's lowered 1.5"...does that require the adjustable version to compensate I would assume?

I've got a nearly full aftermarket suspension (control arms, relocation brackets, panhard bar, subframe connectors, 25mm solid sway bar) and the stock torque arm is the only part yet to be replaced. My car is built more for handling than a drag setup like most on here...how much benefit is there in that regard for road course/street/auto x type setup? Also, mine's lowered 1.5"...does that require the adjustable version to compensate I would assume?

To those that have one, was it an immediate noticeable difference on the street? Or something I would only notice launching on a drag strip?

To those that have one, was it an immediate noticeable difference on the street? Or something I would only notice launching on a drag strip?

#15

11 Second Club

iTrader: (4)

Join Date: Jan 2005

Location: Rowletts,KY

Posts: 1,004

Likes: 0

Received 0 Likes

on

0 Posts

Just want to clarify a few things here:

First off, pinion angle does not affect traction or performance, nor is it affected by driving application

The only thing that factors into where pinion angle should be set is if you run a rubber/poly bushing lower control arm or a rod end. Poly/rubber will be -2* and rod ends will be -1 or 0.

The simplest and most effective way to measure the correct working angle of your driveline is to measure a good point that is an accurate reference to the centerline of the crankshaft. I like to use the crank pulley/balancer personally. But any machined surface on the engine or trans will work. You want the difference to measure between the engine and pinion. Driveshaft angle is irrelevant.

For example if your engine measures 5* (down towards the rear of the car) you will want the pinion to be pointed up 3*. They should be running on the same plane. The difference in angle is to allow for the slack in the drivetrain under load so that ideally you will have 0* under acceleration which means your engine and pinion centerlines are perfectly parallel and the u-joint working angles are identical.

Hope this helps a little

First off, pinion angle does not affect traction or performance, nor is it affected by driving application

The only thing that factors into where pinion angle should be set is if you run a rubber/poly bushing lower control arm or a rod end. Poly/rubber will be -2* and rod ends will be -1 or 0.

The simplest and most effective way to measure the correct working angle of your driveline is to measure a good point that is an accurate reference to the centerline of the crankshaft. I like to use the crank pulley/balancer personally. But any machined surface on the engine or trans will work. You want the difference to measure between the engine and pinion. Driveshaft angle is irrelevant.

For example if your engine measures 5* (down towards the rear of the car) you will want the pinion to be pointed up 3*. They should be running on the same plane. The difference in angle is to allow for the slack in the drivetrain under load so that ideally you will have 0* under acceleration which means your engine and pinion centerlines are perfectly parallel and the u-joint working angles are identical.

Hope this helps a little

#16

Village Troll

iTrader: (2)

Maybe I am missing what is being said here, but at this point in the video:

https://www.youtube.com/watch?featur...75ZQvpws#t=107

Where he says two equal angles cancel out accel/decel you can clearly hear there is accel/decel at the end point, or what would be the differential as well as in the middle of the driveline.

https://www.youtube.com/watch?featur...75ZQvpws#t=107

Where he says two equal angles cancel out accel/decel you can clearly hear there is accel/decel at the end point, or what would be the differential as well as in the middle of the driveline.

#17

I've got to ask, how much of an improvement are one of these aftermarket torque arms over stock for a car that rarely sees the track?  I've got a nearly full aftermarket suspension (control arms, relocation brackets, panhard bar, subframe connectors, 25mm solid sway bar) and the stock torque arm is the only part yet to be replaced. My car is built more for handling than a drag setup like most on here...how much benefit is there in that regard for road course/street/auto x type setup? Also, mine's lowered 1.5"...does that require the adjustable version to compensate I would assume?

I've got a nearly full aftermarket suspension (control arms, relocation brackets, panhard bar, subframe connectors, 25mm solid sway bar) and the stock torque arm is the only part yet to be replaced. My car is built more for handling than a drag setup like most on here...how much benefit is there in that regard for road course/street/auto x type setup? Also, mine's lowered 1.5"...does that require the adjustable version to compensate I would assume?

To those that have one, was it an immediate noticeable difference on the street? Or something I would only notice launching on a drag strip?

To those that have one, was it an immediate noticeable difference on the street? Or something I would only notice launching on a drag strip?

When I removed my stocker it was bent from mostly street duty with only 2-3 track trips. That was only with bolt-ons too, car was slow and ran high 12s.

#18

LS1Tech Premium Sponsor

iTrader: (5)

If pinion angle has no effect on traction, Then is this what we are trying to achive like in this video?

Driveshaft Angle Trainer - YouTube

Driveshaft Angle Trainer - YouTube