A Little Dyno Time Today

#141

Banned

iTrader: (1)

Nowhere does it say what you are suggesting. I said you could bypass the turbine; I never that would improve economy. It was simply meant to show how a turbocharger can be controlled beyong spring settings, for whatever reason, i.e. diagnostic purposes. As an real world example, before I tune a fresh turbo setup I run the engine with the wastegate wired open, to get a baseline VE curve for the engine before real boost pressure is applied fully.

Sure, the engine in my vehicle right now will lose economy with the turbine disconnected, or with a traditional exhaust system. The turbo is helping improve economy. Do you wish to see comparisons of data-logs for both conditions?

Gibberish, if you convert temp to mechanical energy, you drop in temp. You can't convert it to mechanical energy AND make more heat, that doesn't make any sense. Furthermore, heat is energy, hotter air contains more energy, you make more power with the same mass of hotter air. I avoid the term heat, as it is involving enthalpy, entropy, physical chemistry, some things we do not need to introduce to fully understand the concepts we are discussing. I prefer to simply say "rise in temp".

You certainly can, for example I can lean out my air fuel ratio and to control detonation inject pure 100% distilled water. Doesn't matter if you are turbo or non-turbo or what, there are many ways to take the energy out of the air. If you need to. You can also put it back in if you need to, as many OEM intake designs incorporate such things as heating passages in throttle bodys or nearby the intake manifold/under/around those places to maintain and guarantee that air entering their engine will be brought up to at least some minimum temperature to guarantee smooth engine operation.

I am not ignoring anything. The engine's design is implemented based on what the designers expect. For example, the Japanese versions of many similar engines to ours have a whole point or more compression ratio, because Japan has a higher octane at the pump available, and perhaps because their local temps are usually lower than ours. The designers take into account the atmosphere, its temperature ranges, and fuel quality, that fit the model with a wide range of operating conditions.

Don't believe everything you read, until you test it for yourself. They are just random refs from journalists with no knowledge of combustion engines, taking snippits of information I suppose. That is why I grabbed a few of them from random searching. I can provide real world data that confirms connecting the turbine improves economy, if you want it so bad.

Care to provide an example of real world results that an engine has improved fuel economy in a vehicle with a Turbo, same engine? Every engine with boost does this. Simple math actually.

But you're ignoring where that push comes from. The Turbo converts heat into mechanical energy, it also generates heat. That heat generated is on the wrong side of the engine and must be combated.

Notice in that reference they (random people talking in a forum BTW, like this one....) say in THEORY and they reference Wikipedia? Umm not a very credible source. In reality, this doesn't happen. What this guy states is that if you COULD reduce the AFR to the same ratio (or leaner) as the NA engine it would be more efficient. The problem is that you can't.

This also ignores Expansion and Compression ratios. Both AFR and SCR/ER are things that change between NA and Forced Induction engines because they have to due to forced induction; both of which directly impact (greatly) thermal efficiency and therefore vehicle FE.

You'll also note how they say the engine MUST be downsized to increase FE.

Last edited by kingtal0n; 02-11-2016 at 01:13 AM.

#142

Banned

iTrader: (1)

Yall were going back and forth about engine VE and changes/mods to the PCM/ECU and I was just interjecting that from a tuning wide open throttle point of view, you are often looking at a very specific piece of the map, say one or two final rows for a max boost pressure or atmospheric pressure run, and regardless of what the computer "thinks" you can still run the engine the way you desire provided you can alter the map to produce the result you desire. The factory PCM has become full of "pot holes", safety inclusions which provide fuel or timing changes based on sensor feedback that traditional stand-alone ECU typically do not include, because they depend on the tuner also being a mechanic and diagnostician, being able to visibly/audibly verify the engine is running the way it should, not just relying on a complex series of pulleys/levels inside the programming to make it safe to drive (which usually results with sub-optimal performance). In other words, its for sheep to drive cars, not performance applications that demand higher percentages of output efficiency.

#143

TECH Addict

Nowhere does it say what you are suggesting. I said you could bypass the turbine; I never that would improve economy. It was simply meant to show how a turbocharger can be controlled beyong spring settings, for whatever reason, i.e. diagnostic purposes. As an real world example, before I tune a fresh turbo setup I run the engine with the wastegate wired open, to get a baseline VE curve for the engine before real boost pressure is applied fully.

Sure, the engine in my vehicle right now will lose economy with the turbine disconnected, or with a traditional exhaust system. The turbo is helping improve economy. Do you wish to see comparisons of data-logs for both conditions?

Gibberish, if you convert temp to mechanical energy, you drop in temp. You can't convert it to mechanical energy AND make more heat, that doesn't make any sense. Furthermore, heat is energy, hotter air contains more energy, you make more power with the same mass of hotter air. I avoid the term heat, as it is involving enthalpy, entropy, physical chemistry, some things we do not need to introduce to fully understand the concepts we are discussing. I prefer to simply say "rise in temp".

Also, you don't make more power with the same mass of hotter air, you can extract more power from the same mass of hotter air because it will have more volume or more pressure. But that only applies to the Turbine side. It doesn't apply to the compressor/intake side. Hotter air will not result in more power. It'll result in a blown engine. But, even if it didn't, the hotter air cannot expand as much given the limitations of an internal combustion engine and how hot it can get the gases before everything melts. This means less air per cycle can be forced in, which means less fuel, which means less power. This is why intercoolers increase performance so much.

Here we see that you're ignoring the other half of the turbo.... again.

You certainly can, for example I can lean out my air fuel ratio and to control detonation inject pure 100% distilled water. Doesn't matter if you are turbo or non-turbo or what, there are many ways to take the energy out of the air. If you need to. You can also put it back in if you need to, as many OEM intake designs incorporate such things as heating passages in throttle bodys or nearby the intake manifold/under/around those places to maintain and guarantee that air entering their engine will be brought up to at least some minimum temperature to guarantee smooth engine operation.

You're spewing non-sense.

I am not ignoring anything. The engine's design is implemented based on what the designers expect. For example, the Japanese versions of many similar engines to ours have a whole point or more compression ratio, because Japan has a higher octane at the pump available, and perhaps because their local temps are usually lower than ours. The designers take into account the atmosphere, its temperature ranges, and fuel quality, that fit the model with a wide range of operating conditions.

Don't believe everything you read, until you test it for yourself. They are just random refs from journalists with no knowledge of combustion engines, taking snippits of information I suppose. That is why I grabbed a few of them from random searching. I can provide real world data that confirms connecting the turbine improves economy, if you want it so bad.

Last edited by hrcslam; 02-11-2016 at 01:46 AM.

#144

TECH Addict

Yall were going back and forth about engine VE and changes/mods to the PCM/ECU and I was just interjecting that from a tuning wide open throttle point of view, you are often looking at a very specific piece of the map, say one or two final rows for a max boost pressure or atmospheric pressure run, and regardless of what the computer "thinks" you can still run the engine the way you desire provided you can alter the map to produce the result you desire. The factory PCM has become full of "pot holes", safety inclusions which provide fuel or timing changes based on sensor feedback that traditional stand-alone ECU typically do not include, because they depend on the tuner also being a mechanic and diagnostician, being able to visibly/audibly verify the engine is running the way it should, not just relying on a complex series of pulleys/levels inside the programming to make it safe to drive (which usually results with sub-optimal performance). In other words, its for sheep to drive cars, not performance applications that demand higher percentages of output efficiency.

Ace and I both understand how to deal with tuning on a scale...... It doesn't require as many words as you're using either.

#145

Banned

iTrader: (1)

Yes, with the exact same drive cycle too. I would also like to see the tune changed to represent boost and NA, as in AFR ratio's lowered, timing advanced, etc. Of course it would be unreasonable for me to request you also increase SCR for NA too wouldn't it? Wouldn't want to compare the NA optimized for NA to a Turbo optimized for the Turbo would we?......

Are you dense? What happens to gas when you compress it? Just as the Turbo uses high pressure gas (that is hot, from compression and ignition.....) to spin a turbine that results in lower pressure gas (and therefore lower temps), when you compress gas, with a compressor directly connected to the turbine, that gas heats up (and this is ignoring heat transfer from the turbine to the compressor!). Why the hell else would we be fighting detonation on a low compression engine?! Second, yes enthalpy IS involved, along with everything else. Again you can't pick and choose. Physics doesn't work that way.

Also, you don't make more power with the same mass of hotter air, you can extract more power from the same mass of hotter air because it will have more volume or more pressure. But that only applies to the Turbine side. It doesn't apply to the compressor/intake side. Hotter air will not result in more power.

Hot air does have more energy. But not much. Lets say we have a 6.0 engine at 6k RPM.

6L x 6000RPM / 60 seconds / 2 revs per cycle = 300 L / second = 0.3 m^3 /s

Ok, so how much energy is required to heat 300L of air by 100F/56C?

1.1389 kg/m^3 x 0.3 m^3 x 1005 J/(kgK) x (93C-37C) = 19.2kJ

19.2kJ/s = 25.7 HP.

6L x 6000RPM / 60 seconds / 2 revs per cycle = 300 L / second = 0.3 m^3 /s

Ok, so how much energy is required to heat 300L of air by 100F/56C?

1.1389 kg/m^3 x 0.3 m^3 x 1005 J/(kgK) x (93C-37C) = 19.2kJ

19.2kJ/s = 25.7 HP.

It'll result in a blown engine. But, even if it didn't, the hotter air cannot expand as much given the limitations of an internal combustion engine and how hot it can get the gases before everything melts. This means less air per cycle can be forced in, which means less fuel, which means less power. This is why intercoolers increase performance so much.

Hahahahahhahahahaha, so I quoted YOUR sources and you tell me not to believe everything I read.... from your sources? The guy referencing Wikipedia, like its a valid argument, is telling me NOT to believe the sources HE provided?! OMG, this is priceless!

Hahahahahhahahahaha, so I quoted YOUR sources and you tell me not to believe everything I read.... from your sources? The guy referencing Wikipedia, like its a valid argument, is telling me NOT to believe the sources HE provided?! OMG, this is priceless!

Last edited by kingtal0n; 02-11-2016 at 03:14 AM.

#148

TECH Addict

iTrader: (13)

I could show that a head/cam combo has a higher IAT than a turbo setup, by simply providing the turbo setup with appropriate cooling equipment/conditions. The same way I can show that a head/cam combo on an LT1 at a very low IAT is just as dangerous to the engine as a high IAT (too many air molecules = death). If I can kill the OEM engine with a super low temp, or a super high temp, then clearly the high temp by itself is not a direct cause for engine failure, it only makes a certain special case for itself, and doesn't make boosted air "special" with respect to ruining an engine.

#149

TECH Addict

iTrader: (3)

Originally Posted by kingtal0n View Post

I could show that a head/cam combo has a higher IAT than a turbo setup, by simply providing the turbo setup with appropriate cooling equipment/conditions.

I just dont understand your logic, Listen to what you are saying here, A H/C setup will have a higher temp than a turbo because by providing the turbo with cooling equipment, you can lower the temps, well you could say that with a H/C also, I can lower the temps by use of engineering controls such as adding additional airflow, fluid injection, heck spray the radiator with nitrous, It doesn't make any sense. I see that you dont agree with anyone's theory which all have good points. Anyway each to their own, everyone can believe their choice......

I could show that a head/cam combo has a higher IAT than a turbo setup, by simply providing the turbo setup with appropriate cooling equipment/conditions.

I just dont understand your logic, Listen to what you are saying here, A H/C setup will have a higher temp than a turbo because by providing the turbo with cooling equipment, you can lower the temps, well you could say that with a H/C also, I can lower the temps by use of engineering controls such as adding additional airflow, fluid injection, heck spray the radiator with nitrous, It doesn't make any sense. I see that you dont agree with anyone's theory which all have good points. Anyway each to their own, everyone can believe their choice......

#150

Village Troll

iTrader: (2)

He'll be back in a few once he bookworms his way into producing more sloppily-put-together responses as well as consulting with those employed at the shop he hung around...

Here's my personal car. We built a thousand of them. Made one million dollars:

Here's my personal car. We built a thousand of them. Made one million dollars:

#151

TECH Addict

There is not much adjusting for cruise situation from N/A to turbo applications. The ignition timing during highway cruise in a 3000lb vehicle, whether it has a turbo or not, is roughly the same all else being equal. You need to hold SCR still if you want to observe the changes another variable is responsible for. I can't add a turbo AND drop SCR because changes to output or economy could be attributed to either. So we can just examine both separately instead, or not at all, since SCR is not a reason to blame the additional turbocharger, since the real culprit is the fuel quality. In other words, we look at maximum power in an application and THEN determine the fuel quality necessary. The way you are approaching it is from the point of view that fuel quality is limited to $1.80/gal, which limits SCR, which doesn't make any sense since i will use whatever fuel I need to in order to win.

I am not really sure what this says, but maybe this will help. Tires stay inflated because of collisions of air molecules. Air molecules present in an exhaust system are bouncing from the surfaces of their containers. Temperature increases speed them up, more collisions per unit time, faster speeds. They still must bounce from the walls of their containers, no matter how low the temperature we might achieve, they still speed through the air and bounce, applying a force to whatever they bounce from, just as light does. The walls of their container in an exhaust system are made of metal. The air molecules have no choice but to bounce from the metal of the container. The turbine blade is also made of metal, and represents another wall of the container. The air molecules are going to bounce off the walls of the pipe, and bounce off the turbine, the difference is, the turbine can be moved. If we hold the turbine still, and wire open a large enough "wastegate" (drill a hole somewhere), we have a naturally aspirated engine, minus the weight advantage and reduction to plumbings. If I let the turbine go, not close the wastegate but simply let the turbine move freely as opposed to holding it exactly still, now it will begin to move, and that will drive the compressor. So now air molecules are being forced towards the engine, and yet, my exhaust gas pressure has not gone up a single unit, not even 0.00000001psi, because the conditions are all exactly the same except that now the turbine can actually move when the air molecules are exerting their force on it, instead of simply treating it as another "wall", bouncing away just the same. The air temp should then decrease, since now the turbine is able to absorb some of the gas molecules energy, slowing it down.

I didn't realize tire's had a 4 stroke cycle.

Conversion and conversation of energy doesn't agree with your assessment. If the turbine is spinning, it is taking power to do it. If it is spinning the compressor fast enough to push the piston, it is also putting that resistance on something else. Yes, SOME of that comes from heat, but not all of it. I've never seen a properly sized NA exhaust reach 30+psi, but that would be common in Turbo's. 30PSI of exhaust pressure on a stock LT1 is approx 117ft/lbs of force the piston has to drive against. In contrast, let's say that 30psi the turbine is getting is giving the compressor 15psi, that would mean the Compressor is giving the piston 58.5Ft/lbs of force on the intake side. The net result is a LOSS of 58.5ft/lbs. Even if it only took 15 PSI on the turbine to drive the compressor to 15 PSI, you'd have a ZERO effect on the system and it's total effect on pumping losses would be NILL compared to NA. To get the gain you speak of you'd have to get more PSI from the Compressor than the Turbine is receiving, I've never heard of it. Last I heard it takes a feat of engineering to approach 1:1......

In other words, a boosted motor may reduce pumping losses on the intake stroke, but the turbo also increases pumping losses on the exhaust stroke; and the increased pumping losses on the exhaust stroke are higher than the decreased losses on the intake stroke. A turbo may be more efficient than a supercharger, but due to PHYSICS it is not more efficient than NA. An engine has NEVER gain FE with a Turbo than without one. Think about it. Why?

What is important is that they mention several times that turbochargers also help engines breath and that results with better economy also, besides just downsizing displacement. Realizing that the journalist posting the advertisement must have picked that up from somewhere, somebody higher up is passing these details on, they can't come up with that on their own, even you are having trouble with it, so there are the two major "efforts" underway, that is, implementing turbochargers and using engines with less friction. Lets read between the lines and use this info responsibly. It doesn't necessarily need to lose displacement to lose friction. And also notice how they are still implicating that turbochargers being added isn't in any way detrimental whatsoever to the economy of these vehicles, that the weight and existence of them is justifiable for what must be a fairly impressive cost.

As stated earlier, Boost reduces pumping losses on the intake stroke, but Turbo's increase resistance on the exhaust stroke (this was stated by that guy from the link you provided that you told me to ignore, I actually quoted that part of his statement).

On to smaller engines. Smaller engines usually increase FE in vehicles because they operate in a range with a better BSFC under the same load as a larger one. In other words, the smaller engine will be using less fuel per horsepower per hour to make the SAME power as a larger one in the same vehicle. It has little to do with internal friction. In fact, a quick look into geometry shows that a larger engine will have less friction per CID than a smaller one. You know, since the area quadruples in relation to it's diameter. In other words, If I went from a 2" bore with a 6.28" circumference and an area of 3.14"^2 and doubled the bore, my circumference would be 12.56" (so double the frictional area) and an area of 12.56"^2 (quadruple the area). Apply that to volume and you see the jist of it (it quadruples the volume by doubling the area). 3.14" of area at 100PSI can only generate 314Lbs of force, but 12.56 at 100 PSI generates 1256lbs of force. Put that on the same stroke (3.48") and you'd get 91ft/lbs vs 364ft/lbs. So a larger engine with double the frictional area produces 596% more torque than the smaller one at the same mean expansion pressure. The end result is a situation that favors the larger engine in frictional losses per unit of displacement. But, I'm sure you'll ignore that too.

Last edited by hrcslam; 02-11-2016 at 09:30 PM.

#152

Banned

iTrader: (1)

Originally Posted by kingtal0n View Post

I could show that a head/cam combo has a higher IAT than a turbo setup, by simply providing the turbo setup with appropriate cooling equipment/conditions.

I just dont understand your logic, Listen to what you are saying here, A H/C setup will have a higher temp than a turbo because by providing the turbo with cooling equipment, you can lower the temps, well you could say that with a H/C also, I can lower the temps by use of engineering controls such as adding additional airflow, fluid injection, heck spray the radiator with nitrous, It doesn't make any sense. I see that you dont agree with anyone's theory which all have good points. Anyway each to their own, everyone can believe their choice......

I could show that a head/cam combo has a higher IAT than a turbo setup, by simply providing the turbo setup with appropriate cooling equipment/conditions.

I just dont understand your logic, Listen to what you are saying here, A H/C setup will have a higher temp than a turbo because by providing the turbo with cooling equipment, you can lower the temps, well you could say that with a H/C also, I can lower the temps by use of engineering controls such as adding additional airflow, fluid injection, heck spray the radiator with nitrous, It doesn't make any sense. I see that you dont agree with anyone's theory which all have good points. Anyway each to their own, everyone can believe their choice......

Temperature is a choice. Auto makers decide what temp the coolant should be, what temp the air should be, and implement their decision with hardware such as cooling passages (which are sometimes heating passages).

As temp drops in the IAT, engine power should be increasing. We have all agreed that at some power level the stock piston will fail. So if you continue to reduce temperature eventually the engine will make enough power to ruin the stock piston.

#153

Banned

iTrader: (1)

Alignment and suspension is also a tricky mistress, I have very little experience setting up a vehicle for much more than daily driving.

The same goes for wiring, and welding; Sure I've wired a few cars, and welded up my own aluminum intercooler plumbing with various tig welders over the years; but I cannot be trusted with a mig welder to save my life.

The same goes for a machine shop. I do not own a machine shop. Don't you send your engine off to somebody else to have it worked on? Arn't "they" welding up your head and fixing stuff in your engine?

If I tried to take credit for anything "I built" I would be a pompous, arrogant ***. I am not here to take credit for anything; I am here to provide new ways to see the same objective, alternative pathways for budget minded enthusiasts. I am a problem solver. You give me a dollar cap, a budget, and I provide a system of reliable parts with maximum output and longevity vs cost/economy. And I get it done fast, most installs within one week, with a complete paint job is possible. Nothing I hate more than standing around, waiting for some machine shop or other guy to finish something. I am NOT good at waiting. My goal is to bypass all of the waiting for us; one week for most 500bhp setups, and complete car ready to drive for 10 years with minimal maintenance is ready for daily service using mostly stock parts. Also I dont take a cent till its finished if I am doing the work. One car at a time. No such thing as a "long term project" you pull up somewhere and see 15 cars pushed to the side and 4 employees and they want your car as the 16th.... GTFO of there, he wants the deposit for the 16th car to finish the 1st one.

I came to LS tech to pick up on tips and tricks for late model V8 platforms, so that when I create my initial build sheet (for cookie cutting a few setups) I have a list of things to be aware of, such as steam ports or weak oil pump drive collars that need attention before anything reliable can be assumed. And while I am here, I share anything I have free. If I see you broke down on the road, I stop and help. I am not a rich or big shot.

Last edited by kingtal0n; 02-11-2016 at 08:14 PM.

#156

Banned

iTrader: (1)

From a physics discussion, a better reference,

Reference https://www.physicsforums.com/thread...essors.809831/

another

Reference https://www.physicsforums.com/thread...ciency.780484/

Originally Posted by jackaction

The real advantage of turbocharger would be a better power-to-weight ratio (whether you want more power with the same engine weight or a lighter engine that produces the same power) due to the compressor and a better fuel efficiency due to the turbine recovering some energy. It is not cleaner: The environmental impact is if you use a lighter version to replace a bigger naturally aspirated engine, the weight reduction should affect the fuel consumption. It is not cheaper, more reliable or simpler; It is usually considered more complex which usually leads to more expensive and/or less reliable and/or more maintenance.

another

1. Some of the energy from the exhaust drives the turbo and the attached compressor, which means that you are extracting usable work from the exhaust which would otherwise go out the tailpipe and be lost. It also means you don't have to use some of the engine's power output to turn a belt to drive the compressor. 2. The compressor driven by the turbo is able to force more air into the engine to be burned with the fuel, avoiding the intake losses which occur in a NA engine. The air comes out of the compressor at a higher pressure than ambient, so the engine does not have to work as hard to compress the air/fuel mixture in a SI engine (or just the air for a CI engine).

Last edited by kingtal0n; 02-11-2016 at 09:23 PM.

#157

Banned

iTrader: (1)

Actually, it only takes 2 days. First day pull the engine, prep for paint, and shoot the bay that night. overnight the bay dries, re-install engine, car goes back for remaining bodywork, glass comes out, gets shot that or the next day. This is cookie cutter potential, the same body guy has dismantled the same chassis 35 or 55 times already, so there is very little hunting around for clips or plugs, very little fighting with wiring or trying to figure out where what goes.

In for pics? I record all projects for reference, I can show this 2 day paint/prep with engine installed if you wish. And if it further pleases, I can show one of my own (owner) vehicle as the subject, that I daily'd till sold. What takes a full week is if the car needs engine mounts fabbed, a driveshaft cut, wiring, plumbing, etc... But paint by itself is quick when the car is already in good shape to start.

In for pics? I record all projects for reference, I can show this 2 day paint/prep with engine installed if you wish. And if it further pleases, I can show one of my own (owner) vehicle as the subject, that I daily'd till sold. What takes a full week is if the car needs engine mounts fabbed, a driveshaft cut, wiring, plumbing, etc... But paint by itself is quick when the car is already in good shape to start.

Last edited by kingtal0n; 02-11-2016 at 09:26 PM.

#158

TECH Addict

From a physics discussion, a better reference,

Reference https://www.physicsforums.com/thread...essors.809831/

another

Reference https://www.physicsforums.com/thread...ciency.780484/

Reference https://www.physicsforums.com/thread...essors.809831/

another

Reference https://www.physicsforums.com/thread...ciency.780484/

#159

Banned

iTrader: (1)

All of this ignores the rest of the 4 cycle. It only speaks to the positives, it ignores the negatives and how the system as a whole is actually less efficient. You are still ignoring the parts you don't like. And you are still referencing a forum, not something accredited.

It is usually admitted that exhaust gas turbocharging (EGT) is a useful technology to improve engine power and fuel economy.

The study results of the two improved turbocharging systems show that using the engine exhaust gas energy to improve turbocharging system transient performances has very good application prospects and energy-saving potentials on gasoline engine.

The study results of the two improved turbocharging systems show that using the engine exhaust gas energy to improve turbocharging system transient performances has very good application prospects and energy-saving potentials on gasoline engine.

Another article with test engines and output graphs for proof:

A turbocharged engine is more thermally efficient than a naturally aspirated engine. This is easy to understand when you remember that the turbo uses energy normally wasted out of the exhaust.

...

In the Australian government test cycle, the naturally aspirated Skoda 2.0 FSI has a fuel consumption of 8.5 litres/100km while the turbo 2.0 FSI has a tested economy of 8.1 litres/100km! That’s right, the car with more power is also more economical!

...

In the Australian government test cycle, the naturally aspirated Skoda 2.0 FSI has a fuel consumption of 8.5 litres/100km while the turbo 2.0 FSI has a tested economy of 8.1 litres/100km! That’s right, the car with more power is also more economical!

I grow tired of this. Everywhere you look, you find that turbochargers may improve economy, and they are working on advances to it i.e. steam turbocharging and direct injection techs to go along with it. I don't find a single paper saying otherwise, just you.

#160

Banned

iTrader: (1)

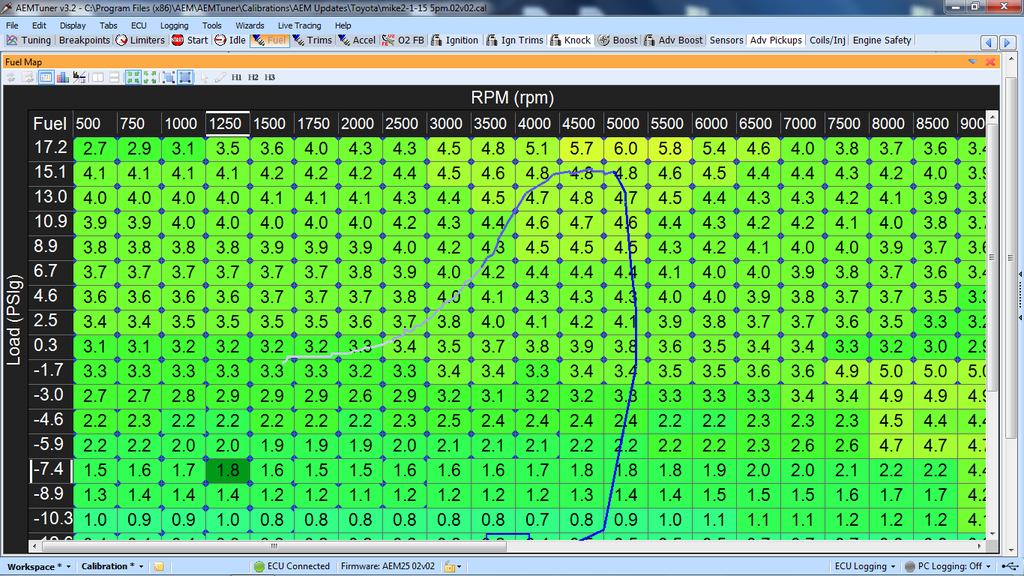

Each box contains an injector pulsewidth. For this engine I disabled the boost compensation map (for the most part, it might still be adding 2% up top) This is from a 2jz-gte I tuned. It shows what you want, a 1-bar of boost pressure without a 100% VE increase to injector on-time due to an OEM camshaft restricting VE primarily. VE does not always correlate torque (you cannot always say peak VE = peak torque), since ignition timing can ruin torque output even when VE is good or getting better.