Has Anyone Converted to a Short Front Spindle?

#143

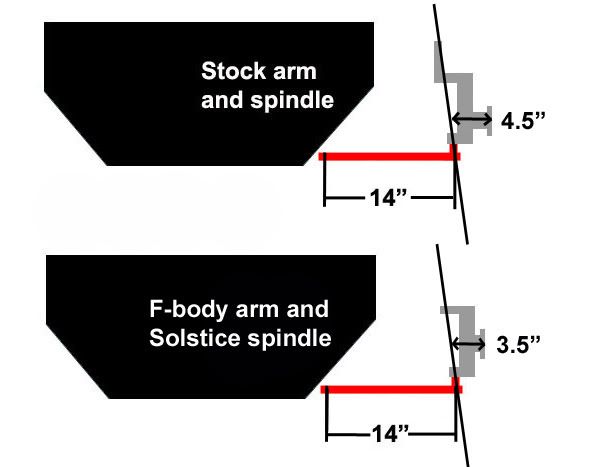

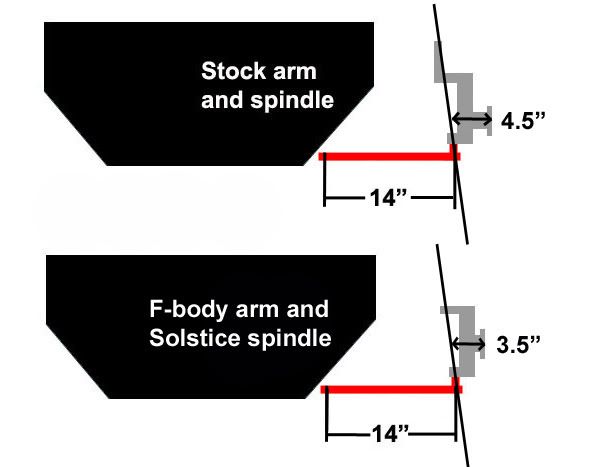

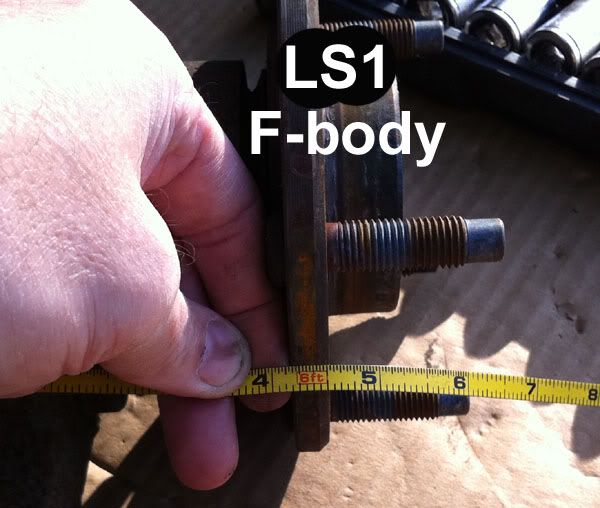

When you measure the wheel mounting flange to kingpin axis, the F-body spindle and hub is 4.5" and the Solstice hub is 3.5". So just swapping spindles and hubs means that the front tires would be tucked in 1" more.

The solution? Have 1" hub adapters made that will change the bolt pattern and give me the correct center bore (70mm) for my existing wheels.

Photos so I don't forget.

The solution? Have 1" hub adapters made that will change the bolt pattern and give me the correct center bore (70mm) for my existing wheels.

Photos so I don't forget.

Last edited by JasonWW; 04-16-2011 at 12:18 AM.

#144

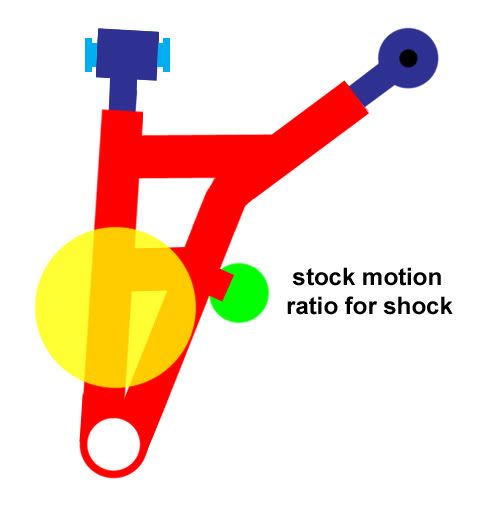

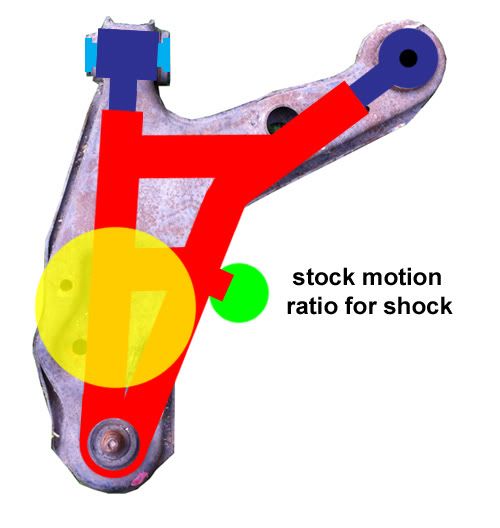

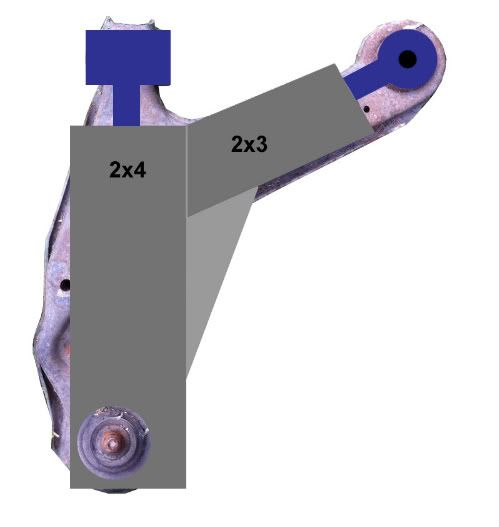

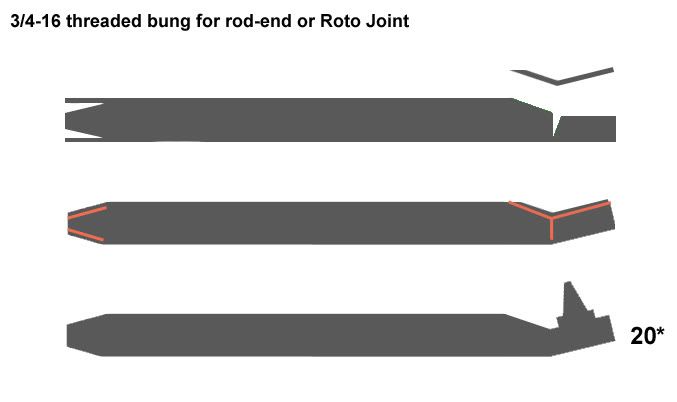

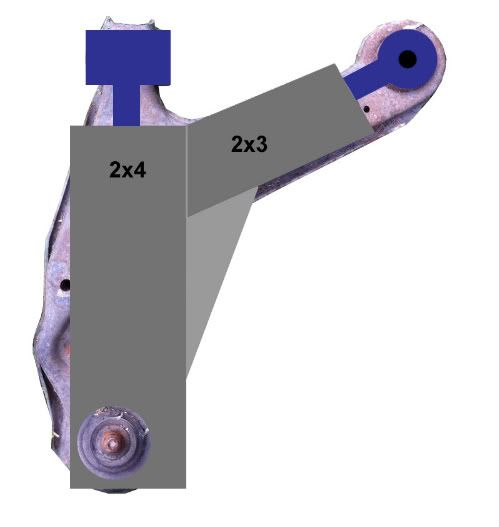

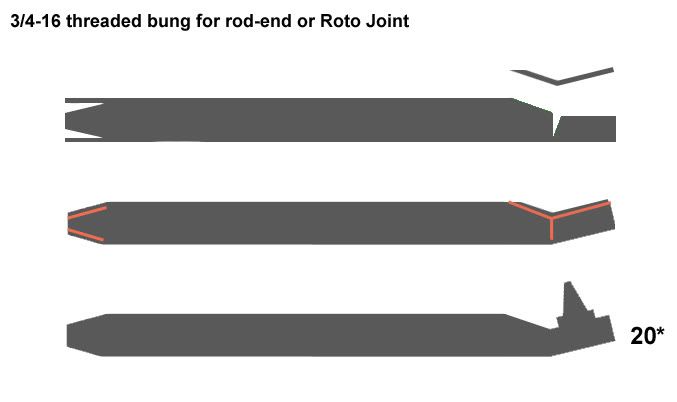

I'm going make me some new lower control arms. I don't know a lot about them, but here is my idea based on 2x3 and 2x4 1/4" wall rectangular tubing and using 3/4"-16 bungs for either rod-ends or Roto Joints/Del Sphere bushings.

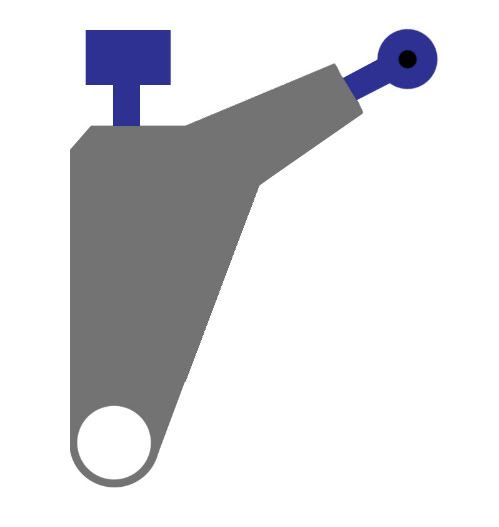

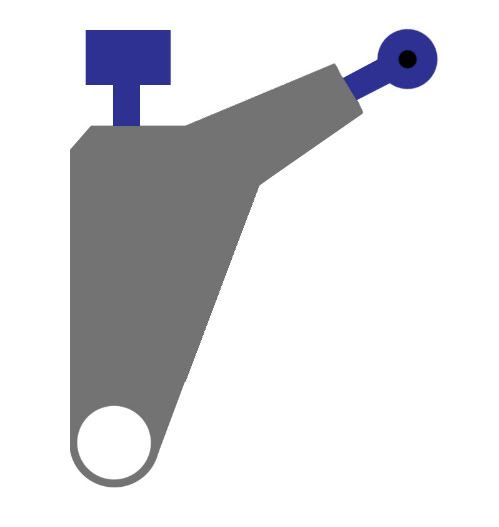

Tweaked a little to make it look nicer.

Tweaked a little to make it look nicer.

Last edited by JasonWW; 04-18-2011 at 11:16 PM.

#145

I'm thinking I'll go with this upper control arm. Length has yet to be determined.

It uses the Moog K772 threaded style upper ball joint that is very common in race circles. I need to get some specifics on this joint to make sure it will fit the spindle. It has 7* taper. I'll probably just take the spindle down to the auto parts store and see if it fits.

On the lower ball joint I need to use the Moog K6537. This is the Solstice and C5/C6 vette ball joint. I believe it has a 7* taper. I can't find any locally, all special order. It would be nice if I could find a screw in ball joint, but due to the spindle being aluminum, the tapered part is 1/2" longer than steel spindles which makes them hard to find. Roughly speaking, the big end of the taper is 0.8125 and the little end is 0.5625. Tapered length is 1.5".

It uses the Moog K772 threaded style upper ball joint that is very common in race circles. I need to get some specifics on this joint to make sure it will fit the spindle. It has 7* taper. I'll probably just take the spindle down to the auto parts store and see if it fits.

On the lower ball joint I need to use the Moog K6537. This is the Solstice and C5/C6 vette ball joint. I believe it has a 7* taper. I can't find any locally, all special order. It would be nice if I could find a screw in ball joint, but due to the spindle being aluminum, the tapered part is 1/2" longer than steel spindles which makes them hard to find. Roughly speaking, the big end of the taper is 0.8125 and the little end is 0.5625. Tapered length is 1.5".

Last edited by JasonWW; 04-18-2011 at 06:35 AM.

#146

I have 3 basic bushing material choices: Rod-end, rubber and delrin. Polyurethane is doable, but it's not to my liking.

They can all be used with a 3/4"-16 weld-in bung. $6-$13

Rubber $28

Spohn Delrin $37

Rod-ends $15-$35

They can all be used with a 3/4"-16 weld-in bung. $6-$13

Rubber $28

Spohn Delrin $37

Rod-ends $15-$35

Last edited by JasonWW; 04-19-2011 at 03:59 AM.

#147

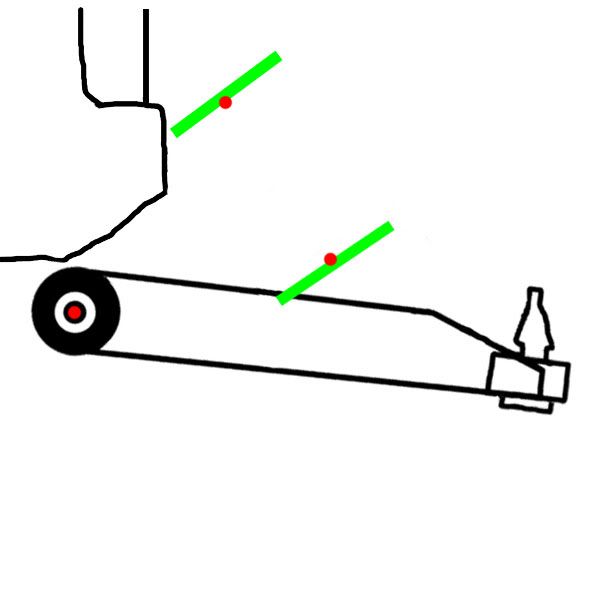

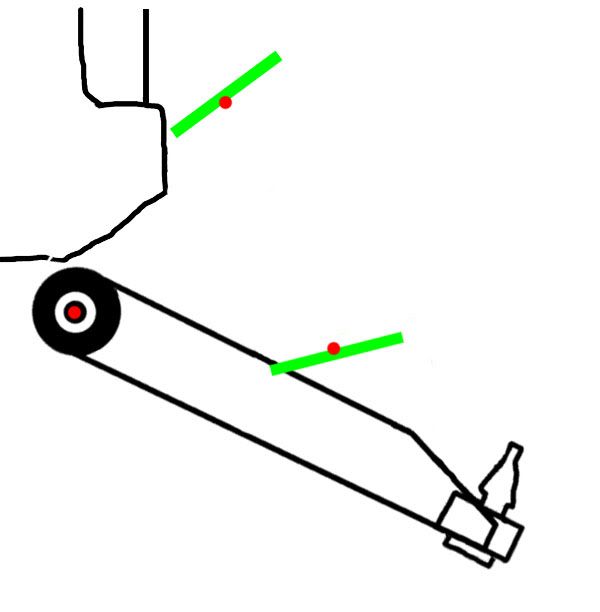

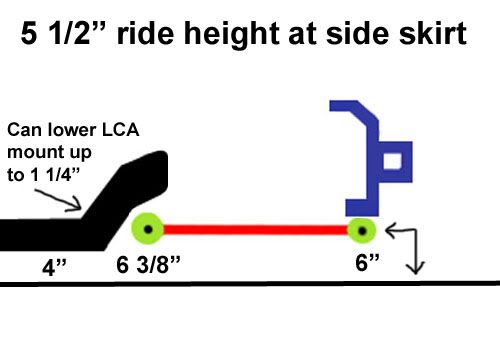

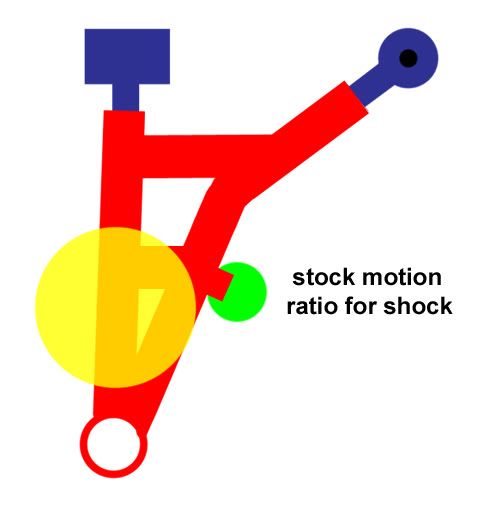

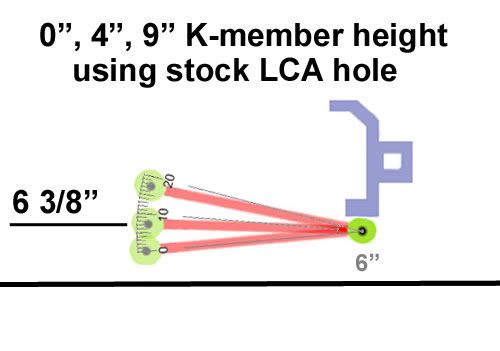

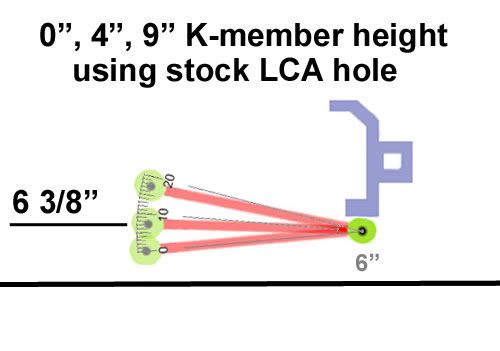

Based on my rim/tire and the Solstice spindle, I know my lower ball joint is going to be right at 6" above the ground. In order to keep my LCA as flat as possible at ride height, I can either use the stock K-member mount holes or lower them slightly. Here are the arm angles based on me raising the K-member/engine 1" and the ride height set at the skirts at 4.5" (4" at K-member).

Note that there is less than 20* of movement for the entire 9" of travel. That means I can use a roto joint in the stock caster bushing location as it has 28* of movement.

Note that there is less than 20* of movement for the entire 9" of travel. That means I can use a roto joint in the stock caster bushing location as it has 28* of movement.

Last edited by JasonWW; 04-19-2011 at 07:18 AM.

#148

Fricken ball joints are kicking me in the nuts.

The lower one is the same as a C5 and C6 vette and runs $100. $25 bucks for a cheapie which I'm not feeling too good about. I don't want the thing breaking on me.

The upper appears to be built into the Solstice control arm and is not removable. Yep, looks like a new upper arm is only $64. Doesn't help me, though.

Locally I found a screw-in Moog K772 upper ball joint which is what that race adjustable control arm uses and it's too large to fit in the spindle. So I can enlarge the spindle hole at least 1/8", but it's going to weaken the spindle.

So I'm kind screwed.

This is a budget build, so I may go to my local salvage yard and pick up a complete lower A-arm with used ball joint for $65. I can either try and use the complete arm or just pull the ball joint out to use in a custom lower arm.

I don't know what to do about the upper joint yet.

The lower one is the same as a C5 and C6 vette and runs $100. $25 bucks for a cheapie which I'm not feeling too good about. I don't want the thing breaking on me.

The upper appears to be built into the Solstice control arm and is not removable. Yep, looks like a new upper arm is only $64. Doesn't help me, though.

Locally I found a screw-in Moog K772 upper ball joint which is what that race adjustable control arm uses and it's too large to fit in the spindle. So I can enlarge the spindle hole at least 1/8", but it's going to weaken the spindle.

So I'm kind screwed.

This is a budget build, so I may go to my local salvage yard and pick up a complete lower A-arm with used ball joint for $65. I can either try and use the complete arm or just pull the ball joint out to use in a custom lower arm.

I don't know what to do about the upper joint yet.

Last edited by JasonWW; 04-19-2011 at 11:08 PM.

#150

What do you guys think about hubcentric wheel adapters?

I'm having second thoughts about them due to their price and extra weight.

I'm seriously considering swapping over to C5 hubs. I know the rears can be used in the front, you just have that big splined hole doing nothing.

Now I'm thinking, I know that the F-body front hubs have 47 teeth on the ABS rings and my car is 4 channel and the rear rings on the axles are also 47 teeth. I have no idea about the Solstice hubs. I was thinking of making my own rear independant suspension anyway, since it's much simplier in comparison to the front.

So why not run Solstice spindles at all 4 corners all converted to C5 hubs? Maybe even use rear hubs all around. My ABS and TCS would remain functional and those hubs are probably beefier than the Solstice ones. If they are designed to handle the 295 tire on the back of the vette then they should handle my setup no problem.

Make sense?

I'm having second thoughts about them due to their price and extra weight.

I'm seriously considering swapping over to C5 hubs. I know the rears can be used in the front, you just have that big splined hole doing nothing.

Now I'm thinking, I know that the F-body front hubs have 47 teeth on the ABS rings and my car is 4 channel and the rear rings on the axles are also 47 teeth. I have no idea about the Solstice hubs. I was thinking of making my own rear independant suspension anyway, since it's much simplier in comparison to the front.

So why not run Solstice spindles at all 4 corners all converted to C5 hubs? Maybe even use rear hubs all around. My ABS and TCS would remain functional and those hubs are probably beefier than the Solstice ones. If they are designed to handle the 295 tire on the back of the vette then they should handle my setup no problem.

Make sense?

#151

A quick update. The Solstice spindles are the same except for the brake mounting lugs. Fronts are spaced wide, rears are spaced narrower.

I don't know how I missed that.

Also, it appears the 13" and 14" front Vette rotors are going to bolt right on. The hat height is within 2mm. So they will sit further in by 2mm, but I think it will clear everything. If need be, a thin spacer can be made.

Since the stock Solstice rotors are only 11.6" I think there will be room for a simple adapter plate to space the caliper out further. I'm wondering if I should buy the bigger rotors and CTS-V calipers now or save some money and slap some 13" rotors on with my stock calipers.

I don't know how I missed that.

Also, it appears the 13" and 14" front Vette rotors are going to bolt right on. The hat height is within 2mm. So they will sit further in by 2mm, but I think it will clear everything. If need be, a thin spacer can be made.

Since the stock Solstice rotors are only 11.6" I think there will be room for a simple adapter plate to space the caliper out further. I'm wondering if I should buy the bigger rotors and CTS-V calipers now or save some money and slap some 13" rotors on with my stock calipers.

Last edited by JasonWW; 04-26-2011 at 04:10 PM.

#152

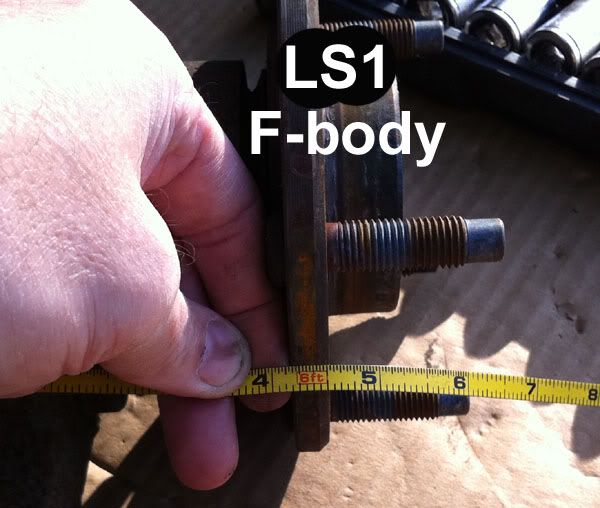

I got the vette lower ball joints today and it looks like they are the same mounting diameter as the stock ones. That's great, it gives me the option of buying premade sleeves from Spohn.

CNC machined from 2.75" o.d. x .375" (3/8") wall seamless mechanical tubing

SKU# SYZ-BJC-1

$15.00 each

CNC machined from 2.75" o.d. x .375" (3/8") wall seamless mechanical tubing

SKU# SYZ-BJC-1

$15.00 each

Last edited by JasonWW; 04-26-2011 at 04:08 PM.

#153

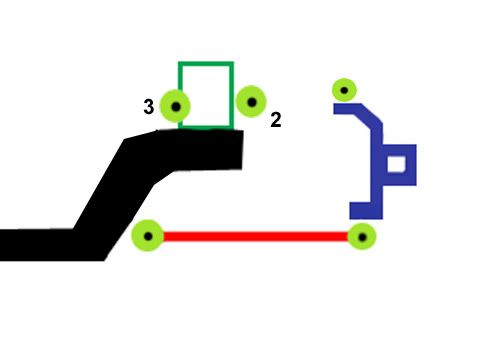

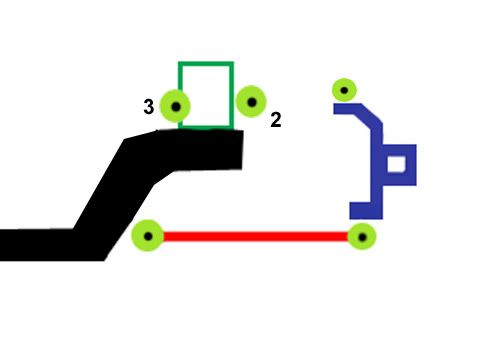

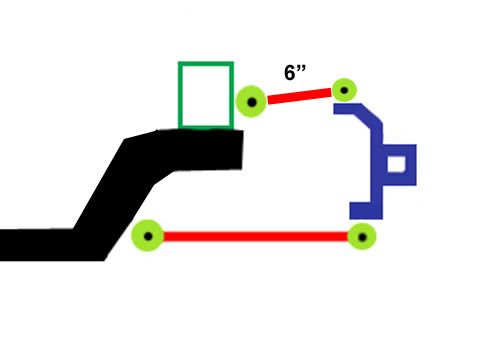

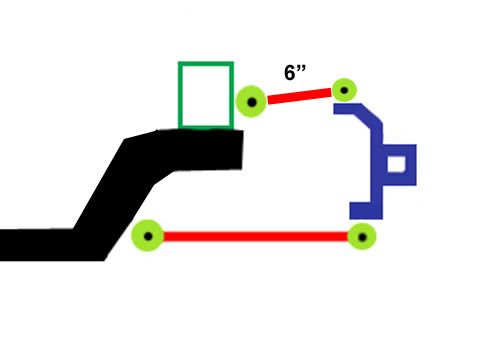

The question on my mind right now is whether to go the easy way and run a 6" upper control arm like Randy:

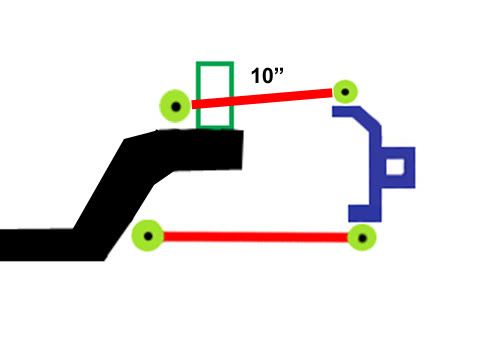

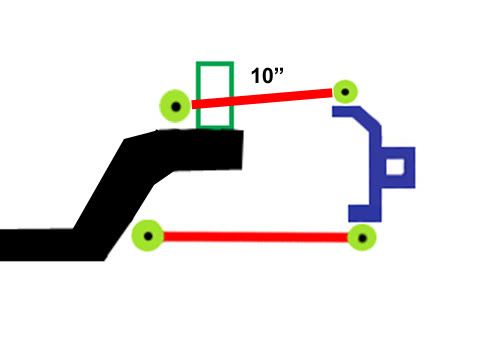

Or if I should modify the frame and run a much longer 10" upper arm.

I can use position 2 or 3 or anywhere in between.

Or if I should modify the frame and run a much longer 10" upper arm.

I can use position 2 or 3 or anywhere in between.

Last edited by JasonWW; 05-05-2011 at 11:06 PM.

#154

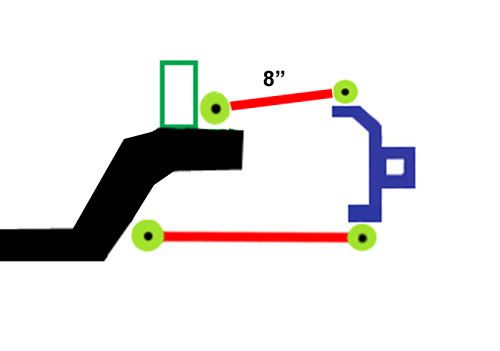

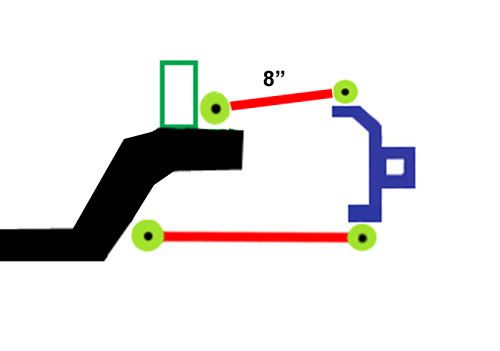

With the stock frame rails, I can run a 6" arm like this:

If I replace the front frame rails with 2x4 tubing, I can run an 8" arm like this:

Or a 10" arm like this:

It just depends on how long I want the upper arm.

.

If I replace the front frame rails with 2x4 tubing, I can run an 8" arm like this:

Or a 10" arm like this:

It just depends on how long I want the upper arm.

.

Last edited by JasonWW; 05-06-2011 at 12:13 AM.

#155

TECH Apprentice

#156

Ah, Found it. Some one else started a thread about his big crash.

http://www.frrax.com/rrforum/index.p...opic=14913&hl=

Last edited by JasonWW; 05-06-2011 at 01:22 AM.

#158

I'm really having a rough time deciding on what tubing to use. Most all the aftermarket tubular arms are made from 1.25" 0.120 wall DOM. I want mine stronger so I was thinking 1.5" 0.188 wall DOM, but I can't find any locally. What I can find is 1.5" 0.120 wall DOM for $108 for a 20 foot length. The larger diameter is automatically going to make it stronger than the 1.25" stuff and that's important since the weight pushes down right in the middle of the arm.

Does anyone have any doubts about the 1.5" 0.120 wall DOM not being strong enough?

The ID would be 1.25" and there are 2 places selling 3/4"-16 RH bungs that fit it. McMaster Carr $6 and Ballistic Fabrication $12. I just ordered from MMC.

My balljoint cup is coming in from Spohn here in the next couple of days ($12 shipping!) as well as a rear C5 hub. I think I'm going to run rear C5 hubs on all 4 corners. C5 spindles in rear as well.

Does anyone have any doubts about the 1.5" 0.120 wall DOM not being strong enough?

The ID would be 1.25" and there are 2 places selling 3/4"-16 RH bungs that fit it. McMaster Carr $6 and Ballistic Fabrication $12. I just ordered from MMC.

My balljoint cup is coming in from Spohn here in the next couple of days ($12 shipping!) as well as a rear C5 hub. I think I'm going to run rear C5 hubs on all 4 corners. C5 spindles in rear as well.

Last edited by JasonWW; 05-10-2011 at 05:42 PM.