Has Anyone Converted to a Short Front Spindle?

#101

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

I'm still planning on replacing the frame rails like in post 96.

I'm considering running the C5 spindle instead of the C4. I like how it gives you a longer UCA. We'll see.

Fast, what are some things you like about the C5 spindle? Is it a better design geometry wise?

I'm considering running the C5 spindle instead of the C4. I like how it gives you a longer UCA. We'll see.

Fast, what are some things you like about the C5 spindle? Is it a better design geometry wise?

Last edited by JasonWW; 03-23-2009 at 09:10 AM.

#102

I think the C5 unit is a "better" casting...just made a little better. Geometry wise, they are very similar. The biggest difference in the two, is the upper ball joint pickup. The C4 has it extended much further away from the spindle body. The steering arm/tie rod pickup is a little different in the two also.

The C5 piece is used in quite a lot of street rod front end kits (lately, almost as much as the pinto). I know builders that have used them on several builds. Just seemed like the way to go when I first thought of doing this. I don't really have any hard science to back me up.

There is always a fabricated spindle. The Racecraft dropped spindles I have on my third gen look super nice. The car isn't done, so I haven't road tested them yet though. The 3" crack I just found in the block doesn't help either.

The C5 piece is used in quite a lot of street rod front end kits (lately, almost as much as the pinto). I know builders that have used them on several builds. Just seemed like the way to go when I first thought of doing this. I don't really have any hard science to back me up.

There is always a fabricated spindle. The Racecraft dropped spindles I have on my third gen look super nice. The car isn't done, so I haven't road tested them yet though. The 3" crack I just found in the block doesn't help either.

#103

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

Shouldn't the tie rod be parallel with the LCA? If you look at it straight ahead, you would measure the distance from the center of the LCA pivot bolt to the center of the inner tie rod joint. Then that distance should be the same from the center of the LCA balljoint to the tie rod ball joint. So that they make a perfect rectange. I think that's right.

The one factor I see messing it up is that under compression the top of the spindle tilts inward adding negative camber. The higher the tie rod is, the more toe-out you get when going through a dip.

#104

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

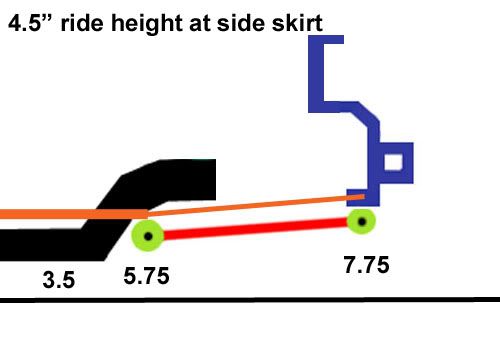

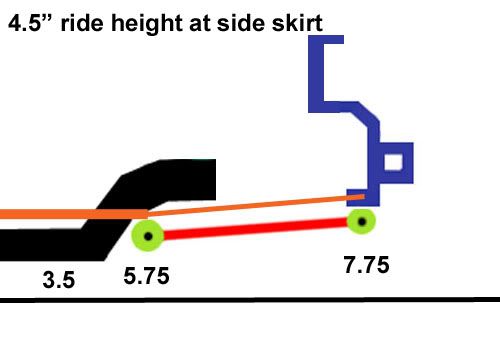

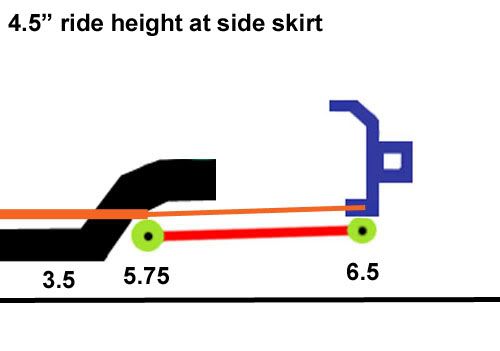

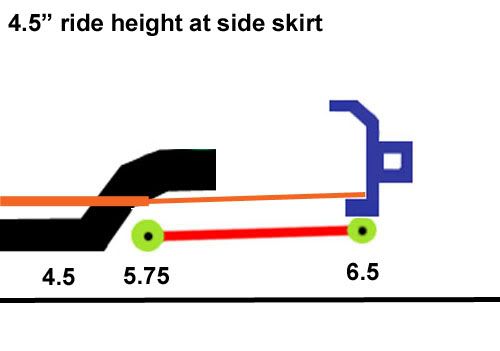

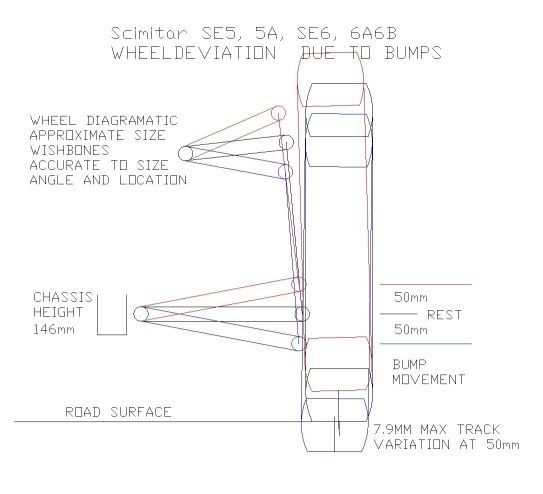

After looking at the whole suspension again, I don't think I'm ever going to get the LCA flat when at a ride height of say 4.5" at the side skirts.

The LCA outer ball joint center is about 7.75" from the ground. That means for the LCA to be level at ride height, the center of the front LCA bolt needs to be the same 7.75" above the ground. The car will be riding much too high.

Here it is with the f-body spindle.

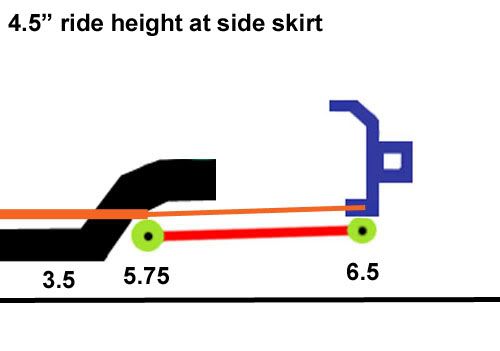

Here it is with the dropped Vette spindle.

Even with the vette spindle I'm about 1" from the ground. How can I get the side skirts to sit all the way on the ground?

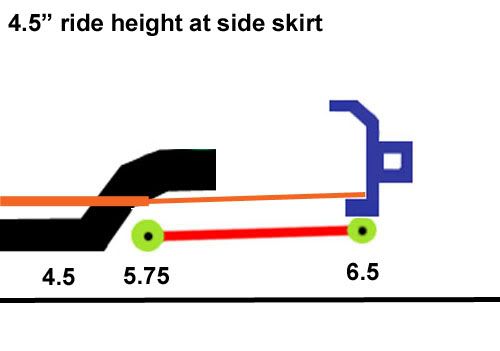

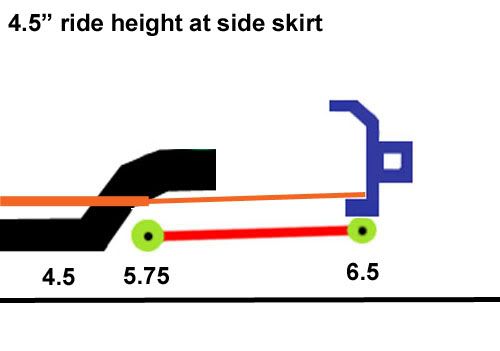

Can I lower the inner LCA mounts 1"?

I think that would work, plus it would require 1" less drop in the steering arm.

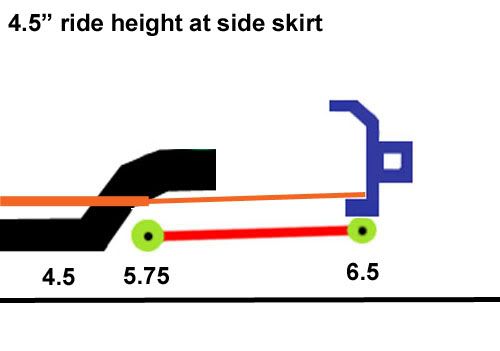

Something like this:

Do I need the front to go lower? Hmmm, I know I can raise the engine if I need to. At this point the LCA is still not flat, but it's pretty close.

Typically speaking, the stock front shocks give these cars 6" of travel. Using that, I would have 4.5" of compression travel and 1.5" of extension travel. I'm wondering if I should bump up the front travel to 7" so I'd have 2.5" of extension. I'm just thinking out loud.

The LCA outer ball joint center is about 7.75" from the ground. That means for the LCA to be level at ride height, the center of the front LCA bolt needs to be the same 7.75" above the ground. The car will be riding much too high.

Here it is with the f-body spindle.

Here it is with the dropped Vette spindle.

Even with the vette spindle I'm about 1" from the ground. How can I get the side skirts to sit all the way on the ground?

Can I lower the inner LCA mounts 1"?

I think that would work, plus it would require 1" less drop in the steering arm.

Something like this:

Do I need the front to go lower? Hmmm, I know I can raise the engine if I need to. At this point the LCA is still not flat, but it's pretty close.

Typically speaking, the stock front shocks give these cars 6" of travel. Using that, I would have 4.5" of compression travel and 1.5" of extension travel. I'm wondering if I should bump up the front travel to 7" so I'd have 2.5" of extension. I'm just thinking out loud.

Last edited by JasonWW; 03-23-2009 at 01:07 AM.

#105

Shouldn't the tie rod be parallel with the LCA? If you look at it straight ahead, you would measure the distance from the center of the LCA pivot bolt to the center of the inner tie rod joint. Then that distance should be the same from the center of the LCA balljoint to the tie rod ball joint. So that they make a perfect rectange. I think that's right.

Even with the vette spindle I'm about 1" from the ground. How can I get the side skirts to sit all the way on the ground?

Can I lower the inner LCA mounts 1"?

I think that would work, plus it would require 1" less drop in the steering arm.

Do I need the front to go lower? Hmmm, I know I can raise the engine if I need to. At this point the LCA is still not flat, but it's pretty close.

Typically speaking, the stock front shocks give these cars 6" of travel. Using that, I would have 4.5" of compression travel and 1.5" of extension travel. I'm wondering if I should bump up the front travel to 7" so I'd have 2.5" of extension. I'm just thinking out loud.

Can I lower the inner LCA mounts 1"?

I think that would work, plus it would require 1" less drop in the steering arm.

Do I need the front to go lower? Hmmm, I know I can raise the engine if I need to. At this point the LCA is still not flat, but it's pretty close.

Typically speaking, the stock front shocks give these cars 6" of travel. Using that, I would have 4.5" of compression travel and 1.5" of extension travel. I'm wondering if I should bump up the front travel to 7" so I'd have 2.5" of extension. I'm just thinking out loud.

Your lca doesn't have to be level at ride height...it would be great if you could get it that way though. As long as your tie rod travels at the same rate as the lca, you should be fine...as far as bump steer is concerned.

As for changing lca mounting locations...I'll have to talk to one of my street rod gurus to make sure there isn't some important factor to consider.

#106

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

I'm actually very confident in this last picture I did. It keeps the roll center nice and low compared to the LCA being level. I'll show you in a minute.

And yes, I can do a body drop, but your limited to the front tires going through the hood. I'm not sure I actually need to body drop it. Just lowering the front suspension on the K-member is in a way a body drop. At this point the engine/k-member is pretty much maximized as far as vertical height goes. To go lower would require raising the engine/k-member and there is plenty of room for that. You can raise it 5" until it starts to approach the front windshield glass. (This requires custom wipers of course)

I have considered raising the front wheel arches slightly to get the car to sit a bit lower, but I'm not sure it would look good. I'm also going to be lowering the hood as much as I can to match a 6" shorter nose and create a more mid-engine look. I may have to add a bulge or scoop to keep the throttle body from sticking through.

And yes, I can do a body drop, but your limited to the front tires going through the hood. I'm not sure I actually need to body drop it. Just lowering the front suspension on the K-member is in a way a body drop. At this point the engine/k-member is pretty much maximized as far as vertical height goes. To go lower would require raising the engine/k-member and there is plenty of room for that. You can raise it 5" until it starts to approach the front windshield glass. (This requires custom wipers of course)

I have considered raising the front wheel arches slightly to get the car to sit a bit lower, but I'm not sure it would look good. I'm also going to be lowering the hood as much as I can to match a 6" shorter nose and create a more mid-engine look. I may have to add a bulge or scoop to keep the throttle body from sticking through.

Last edited by JasonWW; 03-24-2009 at 01:32 AM.

#107

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

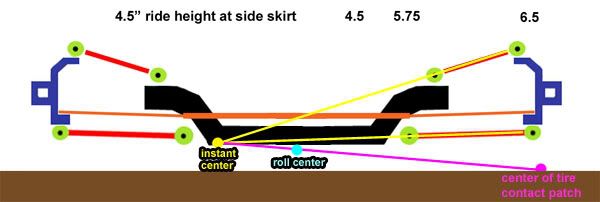

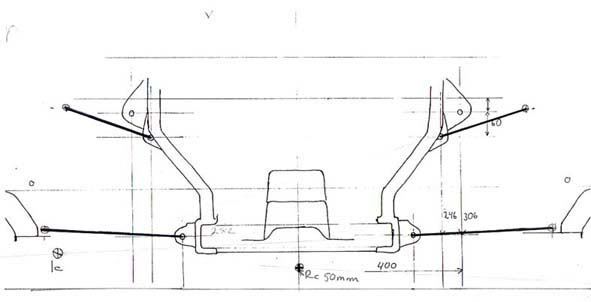

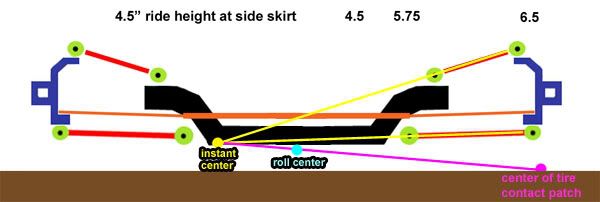

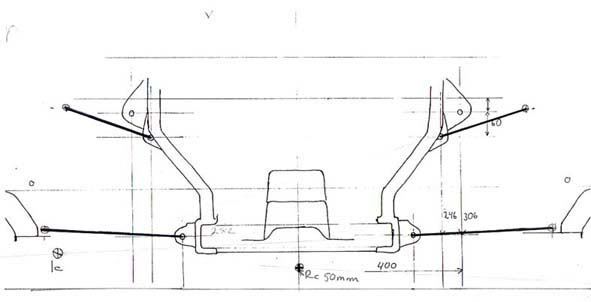

I've learned a bit more since yesterday. Here's what I can do with my car. Notice that the roll center is much lower than stock. It helps to keep the car level in turns.

Here's a proper race setup.

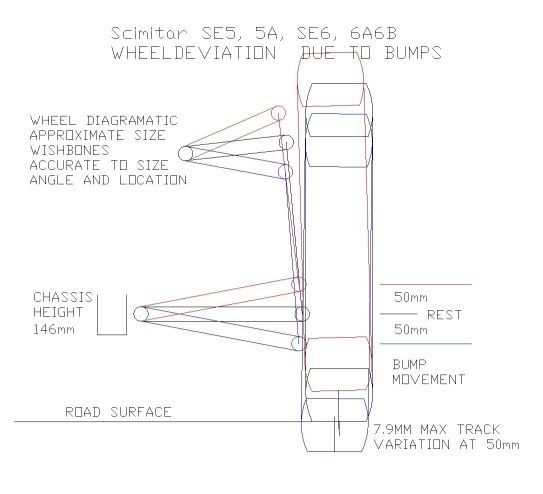

One of the benefits of this type of control arm angling is that you'll gain negative camber in compression, but it sort of nuetralizes positive camber gain in extension.

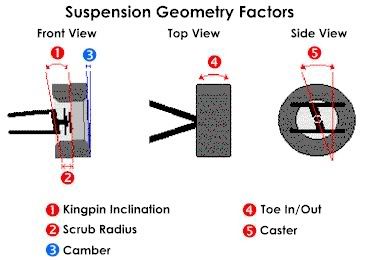

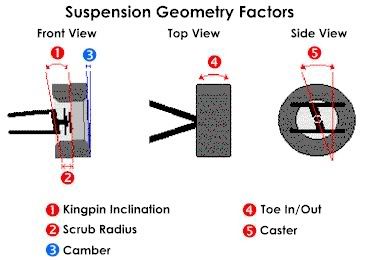

The vertical difference in balljoint location on the spindles is known as the kingpin inclination as seen in the pic below.

Kingpin Inclination determines steering feel to a great extent. In the front view above, the red line on the right represents the center line of the tire/wheel. The kingpin inclination is several degrees, the angle between the center line and the line running through the upright or knuckle. The kingpin inclination determines steering effort, and feedback.

Scrub radius is the distance from the centerline of the tire/wheel to where the kingpin line intersects with the road surface. The larger the distance, the more effort is required to turn the wheel, as the wheel has to "scrub" slightly to turn around the kingpin axis.

Knowing this, I think I'm going to stick with the early C4 spindles and not worry so much about the C5's. They are a nice forged aluminum peice and I believe I can even make them work with the ABS and TCS (assuming I were to run those).

I think at this point I just need to figure out the anti dive geometry for the upper arms and I'm golden. I'll save Ackerman and the steering arms for later since they are related.

Here's a proper race setup.

One of the benefits of this type of control arm angling is that you'll gain negative camber in compression, but it sort of nuetralizes positive camber gain in extension.

The vertical difference in balljoint location on the spindles is known as the kingpin inclination as seen in the pic below.

Kingpin Inclination determines steering feel to a great extent. In the front view above, the red line on the right represents the center line of the tire/wheel. The kingpin inclination is several degrees, the angle between the center line and the line running through the upright or knuckle. The kingpin inclination determines steering effort, and feedback.

Scrub radius is the distance from the centerline of the tire/wheel to where the kingpin line intersects with the road surface. The larger the distance, the more effort is required to turn the wheel, as the wheel has to "scrub" slightly to turn around the kingpin axis.

Knowing this, I think I'm going to stick with the early C4 spindles and not worry so much about the C5's. They are a nice forged aluminum peice and I believe I can even make them work with the ABS and TCS (assuming I were to run those).

I think at this point I just need to figure out the anti dive geometry for the upper arms and I'm golden. I'll save Ackerman and the steering arms for later since they are related.

Last edited by JasonWW; 03-24-2009 at 01:53 AM.

#108

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

Let me edit this post.

I know I'm going to have to use a U shaped upper arm in order for it to fit around the airbag.

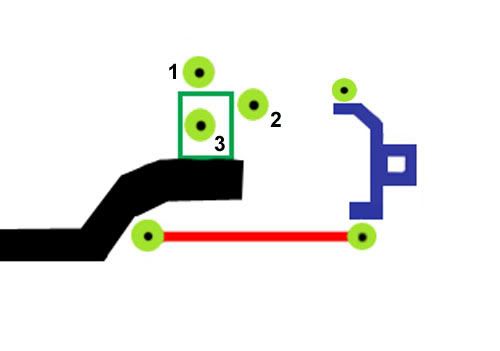

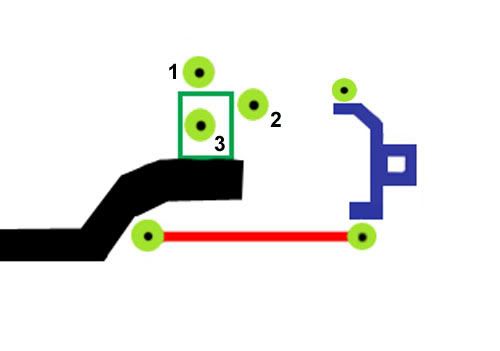

I may do this on my black car. It would be easiest to build a 5 sided box I can weld inside the stock frame rail. Then have each UCA mount fit into it's own box and bolt onto place. That way I can have the UCA mounts as close to the engine as possible. Just like position 3 in this pic:

I know I'm going to have to use a U shaped upper arm in order for it to fit around the airbag.

I may do this on my black car. It would be easiest to build a 5 sided box I can weld inside the stock frame rail. Then have each UCA mount fit into it's own box and bolt onto place. That way I can have the UCA mounts as close to the engine as possible. Just like position 3 in this pic:

Last edited by JasonWW; 07-07-2009 at 04:31 AM.

#110

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

I'm still kicking the idea around. At this point in time my upper controls arms are almost touching the shock towers and I don't want to notch the arms to fit around the brake cylinder like Kenny did. Pic below.

I'd rather swap to a vette spindle, with it's built in extra 1.25" drop, and do away with the shock towers altogether.

I'd rather swap to a vette spindle, with it's built in extra 1.25" drop, and do away with the shock towers altogether.

#111

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

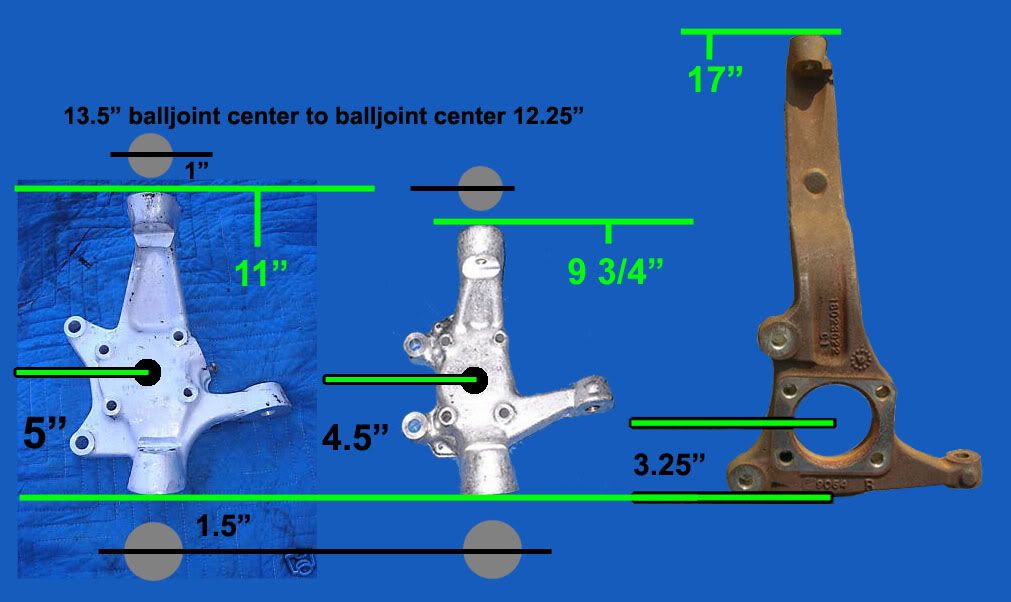

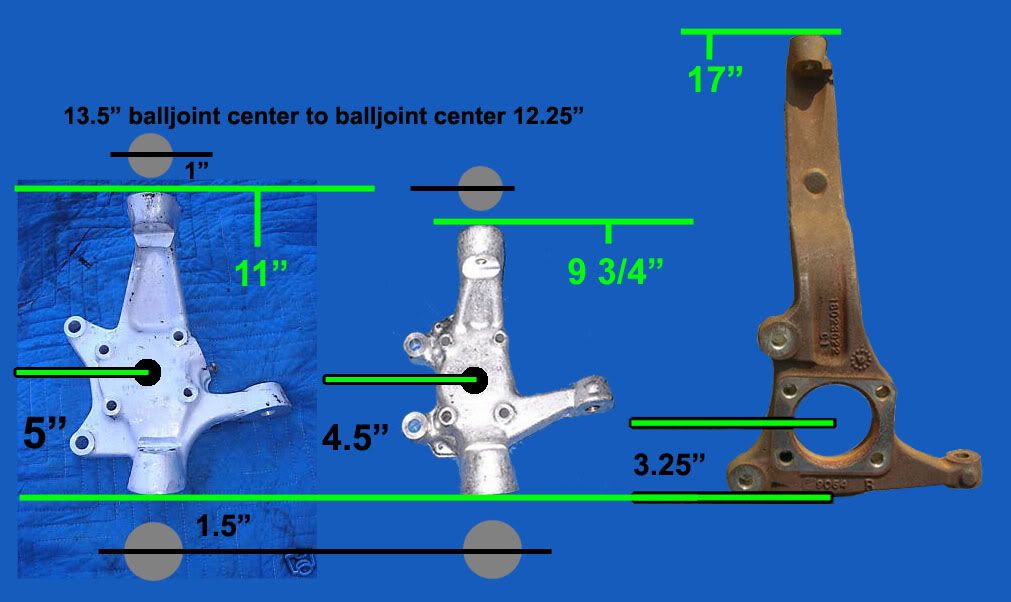

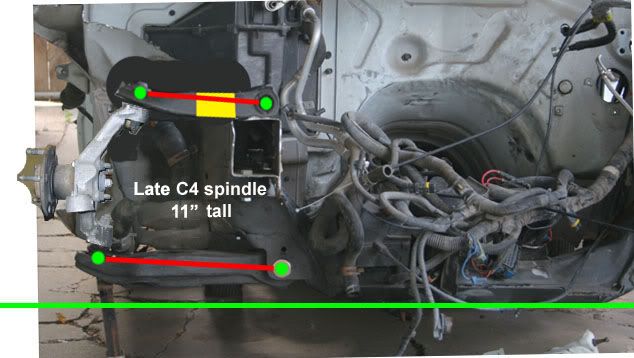

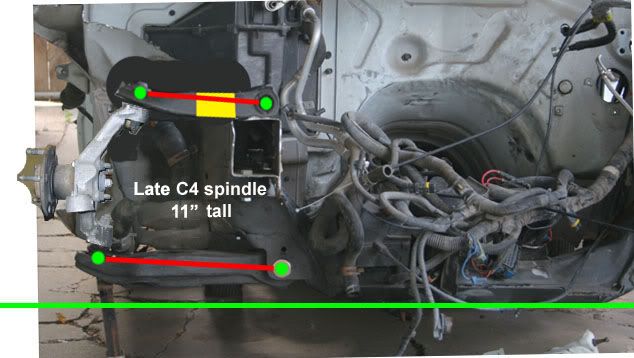

Here's my latest spindle comparison.

I think going with the taller "late C4" or even the C5 spindle is going to be the ticket. I'm looking every where for C5 spindle specs and haven't found any. So if anyone out there has one or can measure one for me, I'd sure appreciate it.

Note that the later C4 unit will give you a 1.75" drop over the stock unit. That's sweet right there. I'm guessing the C5 will be about the same since both spindles were made to fit 17"+ only rims.

I'm guessing the C5 will be about the same since both spindles were made to fit 17"+ only rims.

I think going with the taller "late C4" or even the C5 spindle is going to be the ticket. I'm looking every where for C5 spindle specs and haven't found any. So if anyone out there has one or can measure one for me, I'd sure appreciate it.

Note that the later C4 unit will give you a 1.75" drop over the stock unit. That's sweet right there.

I'm guessing the C5 will be about the same since both spindles were made to fit 17"+ only rims.

I'm guessing the C5 will be about the same since both spindles were made to fit 17"+ only rims.

#112

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

A quick photoshop with a taller spindle. The geometry is just no good, but I have a way to put the upper control arm pivots inside the frame rails if need be.

I've also got some good ideas on strengthening the stock frame rails by tying them into the stock K-member, but still allowing them to be seperated. I'll do up a pic here shortly.

I've also got some good ideas on strengthening the stock frame rails by tying them into the stock K-member, but still allowing them to be seperated. I'll do up a pic here shortly.

Last edited by JasonWW; 03-04-2011 at 09:36 PM.

#113

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

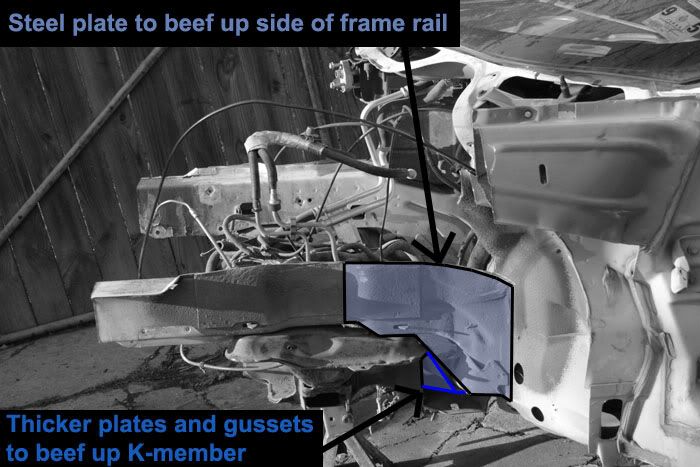

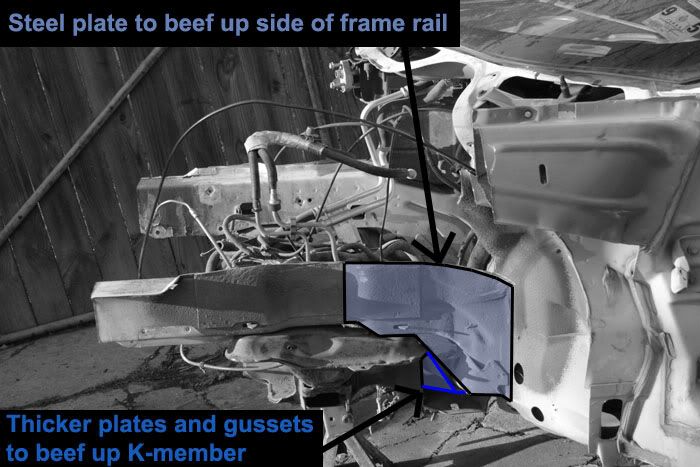

Okay, here is the first of my frame bracing ideas. I'm not too concerned about the frame rails moving left and right becuase the K-member will be acting as an X brace in those directions.

Plate size is yet to be determined, but it needs to be strong to support the weight of the frontend with no help from the removed shock towers. I'm thinking 3/16" or 1/4". I can also have holes cut out in unnecessary areas to save weight without reducing any strength.

That should handle the front frame rails, but I'm wondering how front the firewall is. I may beef up the rail to firewall mounts as well as run extra plate from the rails to under the floor.

Plate size is yet to be determined, but it needs to be strong to support the weight of the frontend with no help from the removed shock towers. I'm thinking 3/16" or 1/4". I can also have holes cut out in unnecessary areas to save weight without reducing any strength.

That should handle the front frame rails, but I'm wondering how front the firewall is. I may beef up the rail to firewall mounts as well as run extra plate from the rails to under the floor.

Last edited by JasonWW; 03-05-2011 at 02:11 AM.

#114

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

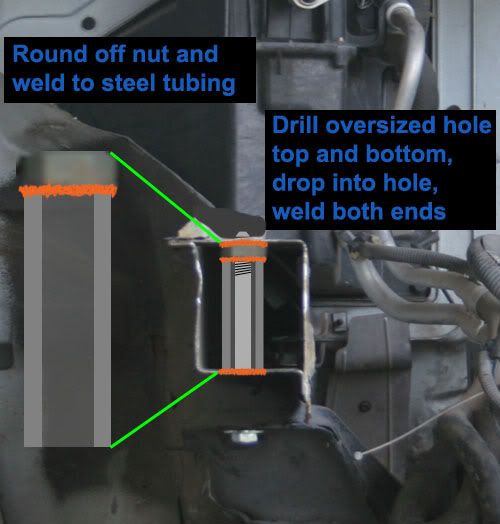

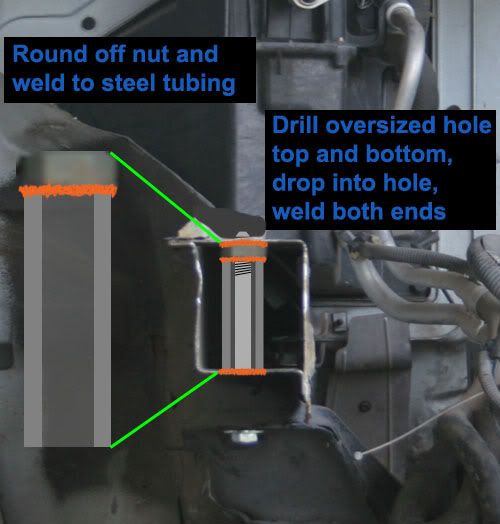

I'll rework the 4 front K-member bolt holes for increased strenth as well. This is sort of a flush mount, crush sleeve design. I know I'm not the first to make this, so it must have a name. If you know the name, let me know.

Here's the stock bolt design.

Here's my upgraded design.

2 or 4 extra bolts from the K-member to frame is also an option to increase strength.

Here's the stock bolt design.

Here's my upgraded design.

2 or 4 extra bolts from the K-member to frame is also an option to increase strength.

Last edited by JasonWW; 03-05-2011 at 02:09 AM.

#115

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

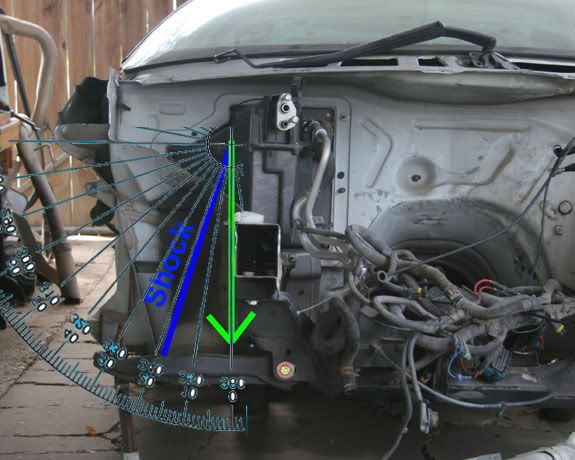

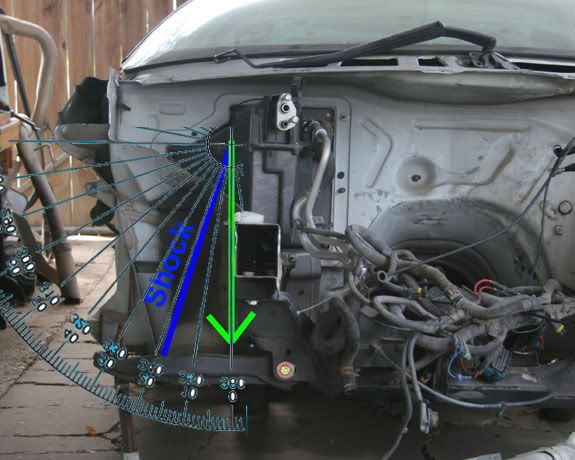

Next on the list is figuring out where to put the top shock/spring mount and how to fabricate it. These need to be strong, as each side supports 2,000lbs. Then you add driving down the road and hitting a bump or pothole or getting the car airborn on a crest. You know, the usual stuff.  The weight will multiply quickly.

The weight will multiply quickly.

If you level your car, cut a hole out right above the shock top (the tip of the stud) and drop a plumbbob, you'll see it falls right next to the outer frame rail. This is interesting because I was thinking it was at least a few inches further out. Anyway, here's a pic.

I'm going to say it's roughly 18*. It's not exact, but then again, this isn't rocket science. I'll probably move the upper mount location 1/2" out and 1" forward just to give me some more room for my airbags.

As you can see, the angle will get narrower as the suspension extends and wider as the suspension compresses. So the upper shock mount needs to be able to pivot slightly to avoid binding.

The weight will multiply quickly.

The weight will multiply quickly.If you level your car, cut a hole out right above the shock top (the tip of the stud) and drop a plumbbob, you'll see it falls right next to the outer frame rail. This is interesting because I was thinking it was at least a few inches further out. Anyway, here's a pic.

I'm going to say it's roughly 18*. It's not exact, but then again, this isn't rocket science. I'll probably move the upper mount location 1/2" out and 1" forward just to give me some more room for my airbags.

As you can see, the angle will get narrower as the suspension extends and wider as the suspension compresses. So the upper shock mount needs to be able to pivot slightly to avoid binding.

Last edited by JasonWW; 03-05-2011 at 03:01 AM.

#116

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

I could build a basic hoop out of round tubing and add a brace behind it. Things get tricky here because the brake master cylinder is going to be close on the drivers side. So do that side first, then duplicate on passenger side.

Or

Side view. Exact height and spacing of tubes will depend on master cylinder and upper control arm mounts, but this is the general idea.

Or

Side view. Exact height and spacing of tubes will depend on master cylinder and upper control arm mounts, but this is the general idea.

Last edited by JasonWW; 03-05-2011 at 03:57 AM.

#117

How about something like this? That is an fbody it's mocked up on...

Thread here: http://www.frrax.com/rrforum/index.php?showtopic=14781

Thread here: http://www.frrax.com/rrforum/index.php?showtopic=14781

#118

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

How about something like this? That is an fbody it's mocked up on...

Thread here: http://www.frrax.com/rrforum/index.php?showtopic=14781

Thread here: http://www.frrax.com/rrforum/index.php?showtopic=14781

Just kidding

#120

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

I see that's Randy doing it to his race car.

A lot of the guys over at FRRAX laughed at me for trying to remove the shock towers saying it was a dumb idea and it was too dangerous, etc... A lot of those guys are very narrow minded so I stopped going over there. Randy is pretty cool though. I'll talk to him about what I'm doing.

It looks like he's having a shop build up his stuff and he's spending a small fortune to do it as well ($3,000 pr. spindles ). I can't do that. I have to do it myself and for a meager sum. Stock vette spindles (except steering arms), stock vette hubs, stock 13" rotors and calipers (14" rotors and calipers eventually). It won't be the lightest, but it will be lighter for sure.

). I can't do that. I have to do it myself and for a meager sum. Stock vette spindles (except steering arms), stock vette hubs, stock 13" rotors and calipers (14" rotors and calipers eventually). It won't be the lightest, but it will be lighter for sure.

It looks like he's going with a shorter length upper arm. That's fine for him as he doesn't need a lot of suspension travel like I do.

A lot of the guys over at FRRAX laughed at me for trying to remove the shock towers saying it was a dumb idea and it was too dangerous, etc... A lot of those guys are very narrow minded so I stopped going over there. Randy is pretty cool though. I'll talk to him about what I'm doing.

It looks like he's having a shop build up his stuff and he's spending a small fortune to do it as well ($3,000 pr. spindles

It looks like he's going with a shorter length upper arm. That's fine for him as he doesn't need a lot of suspension travel like I do.

Last edited by JasonWW; 03-08-2011 at 02:26 PM.

.

.