CAD Project Ideas

#1

So I'm a student and currently enrolled in a CAD project class. The project has to take the entire semester. I have to design/draw something in a CAD program and I can't think of anything to build. I was thinking a shortened rear end assembly with slicks for my truck. It would include axles, posi, ring/pinion, bearings, seals, housing, cover, ect. It would be a complete assembly.

I want to know if you guys have any good ideas for me other than the rear end. Maybe a redesigned supercharger system. Basically anything that you guys can throw at me would help. Is there anything that you know of that can be improved? Thanks

I want to know if you guys have any good ideas for me other than the rear end. Maybe a redesigned supercharger system. Basically anything that you guys can throw at me would help. Is there anything that you know of that can be improved? Thanks

#3

TECH Addict

iTrader: (4)

Join Date: Apr 2010

Location: Longview,TX & Tricitys,WA

Posts: 2,200

Likes: 0

Received 1 Like

on

1 Post

Does it have to be mechanical?

When i took the class we did a house and garage with complete layers for heating, electrical, plumbing, etc. The house was nice, but i've thought about it since and would do something different. But if you do something that you would want in the future it would save you some time.

When i took the class we did a house and garage with complete layers for heating, electrical, plumbing, etc. The house was nice, but i've thought about it since and would do something different. But if you do something that you would want in the future it would save you some time.

#5

A piston and rod would take me an hour and a half. This has to be something that will take me the entire semester. And also and assembly. I'm using Solidworks.

The twin turbo kit would be a great project. Maybe do a mirror image turbo kit for a car that doesn't have one specifically made for it yet.

The twin turbo kit would be a great project. Maybe do a mirror image turbo kit for a car that doesn't have one specifically made for it yet.

#6

TECH Addict

iTrader: (22)

Draw an engine then. You made it sound like you just started modeling and needed ideas to cut your teeth on. If your school has any SAE teams, talk to them. They always need stuff drawn up

Wires and tubing are nearly impossible to model accurately, atleast accurate enough for fabrication, so Id suggest against a TT design because all it will really be is a pretty picture

Wires and tubing are nearly impossible to model accurately, atleast accurate enough for fabrication, so Id suggest against a TT design because all it will really be is a pretty picture

Trending Topics

#8

On The Tree

Join Date: Sep 2010

Location: San Luis Obispo CA

Posts: 155

Likes: 0

Received 0 Likes

on

0 Posts

#11

do something engine based. How about pneumatic valve spring system for LS engines. Or how about a gear driven supercharger system. Not like the ones they currently have but think of it like a current 8 rib belt width. I wish i had access and the ability to use the programs you have. The current super charger gear drive setups obviousy work fine but they are so bulky and stick out in from of the engine so far. Just throwing ideas out. Plus if you have access to the machines at your school your probably could build these and test them.

#12

I went to school for CAD also. I like the rearend idea but make it more interesting... perhaps a 2 speed rearend for a road tractor or a planetary gear axle for offroad machinery??? be sure to post your work. what are you using solidworks?

#14

Hey man,

I wrote in here a year ago with the same question. I currently have a degree in drafting and certified by the ADDA including Mil specs....

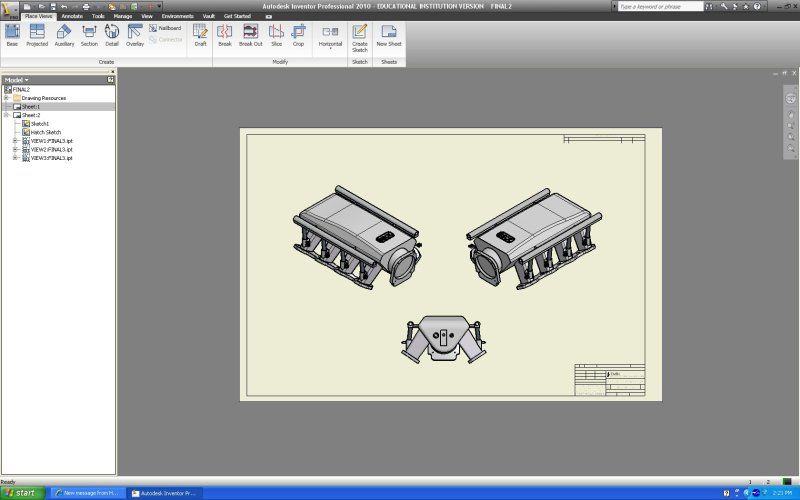

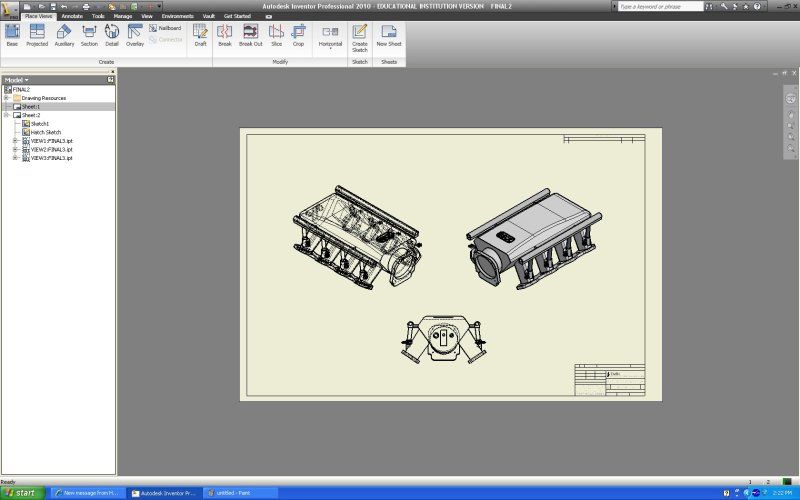

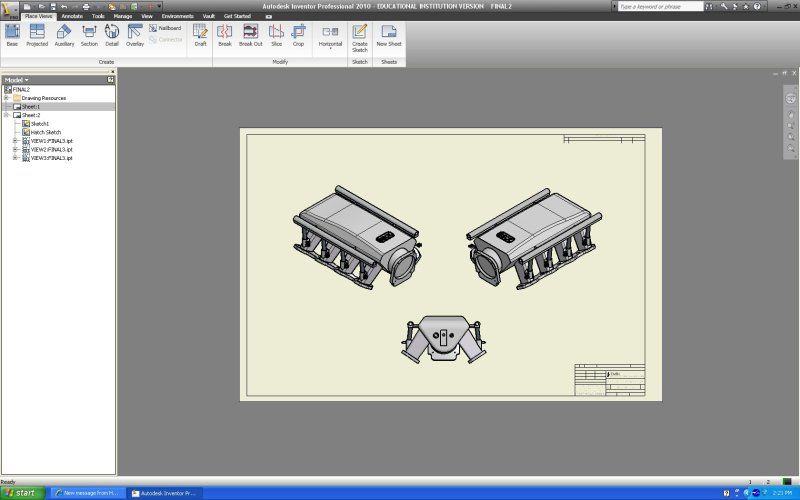

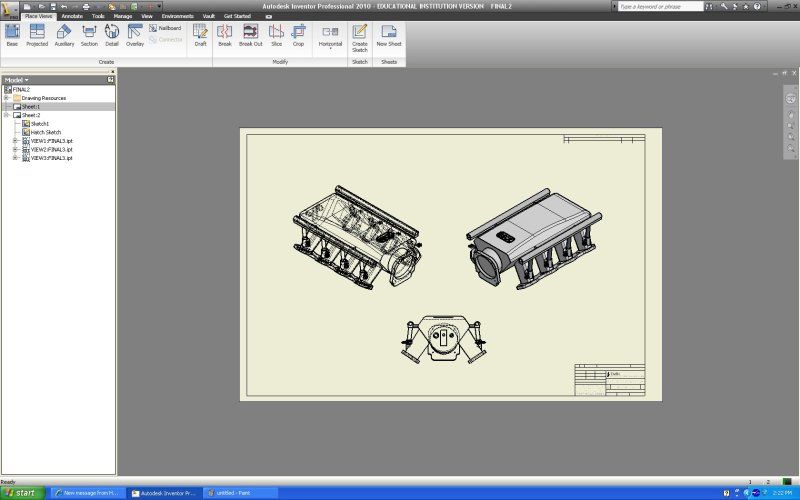

This was my final project for class:

It's the sheet metal intake i'm running my my T/A, wish I have more photos of the file but that computer is home and i'm at college getting my ME...

I wrote in here a year ago with the same question. I currently have a degree in drafting and certified by the ADDA including Mil specs....

This was my final project for class:

It's the sheet metal intake i'm running my my T/A, wish I have more photos of the file but that computer is home and i'm at college getting my ME...

#15

Ok, now I envy you guys....I wish I had a butt load of money, a good computer, a great cad program or two, and the tooling to build what I come up with. Keep on going guys and build our future!

#20

A piston and rod would take me an hour and a half. This has to be something that will take me the entire semester. And also and assembly. I'm using Solidworks.

The twin turbo kit would be a great project. Maybe do a mirror image turbo kit for a car that doesn't have one specifically made for it yet.

The twin turbo kit would be a great project. Maybe do a mirror image turbo kit for a car that doesn't have one specifically made for it yet.

Anyways, I'd say to build your "dream differential." Incorporate some of your personal thoughts on how to make a differential better.