Flat Crank LS1?

#21

TECH Apprentice

iTrader: (3)

Join Date: May 2004

Location: Ambridge PA

Posts: 311

Likes: 0

Received 0 Likes

on

0 Posts

WJ used it in a big inch big block. Ferrari's are hardly big engines. The benefits are realized with a short stroke big bore combo at higher rpm's. For an LSx street engine the cost vs. power gained wouldn't make sense.

Bill

Bill

#22

TECH Senior Member

Originally Posted by 99 Black Bird T/A

Seems like an individual intake runner with it's own throttle body would be a nice for this.

Something like

Something like

#23

Banned

iTrader: (10)

Originally Posted by Monza355

WJ used it in a big inch big block. Ferrari's are hardly big engines. The benefits are realized with a short stroke big bore combo at higher rpm's. For an LSx street engine the cost vs. power gained wouldn't make sense.

Bill

Bill

People with the financial means have done the R&D and havent made much head way with them.

As you stated, the cost vs gain doesnt make sense.

#24

Originally Posted by edcmat-l1

They (180 deg cranks) have their place. 90 degree V8s dont seem to be one of them.

#25

Originally Posted by Monza355

WJ used it in a big inch big block. Ferrari's are hardly big engines. The benefits are realized with a short stroke big bore combo at higher rpm's. For an LSx street engine the cost vs. power gained wouldn't make sense.

Bill

Bill

It was a real crowd pleaser,(sound wise).

WJ did some plug tests and pulled the engine out of the car,

(burnt pistons, I think)

With the carb intake systems they have to run in prostock,

no real advantage,as fuel distribution is a problem with this new 180' firing order.

If prostock could run real fuel injection,

a real power possibility could be had, proper fuel distribution.

But that engine did sound cool, 500 inches at big rpm.

LHP

Haywardperformance.com

#26

14 Second Truck Club

iTrader: (36)

Join Date: Oct 2004

Location: Chicago, Il

Posts: 2,633

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by engineermike

I think you have 2 at TDC at the same time, but that's not different from a 90 deg crank. One is on TDC compression, while the other is on TDC exhaust.

Mike

Mike

#28

The exhaust pulse part might help spool a turbo. A lot of T4 turbo apps on I-4s come with divided housings specificly to separate the pulses out evenly to improve boost threshold and response. But frankly with the curent turbo tech and the displacement we have to work with, its a minor point.

Other than that, the hard fact is that the valve train is the real limiter for the vast majority of us. If you want serious high RPM fun, solid rollers tend to be the way to go. Not so good for a street car. In the grand scheme of things, OHC is far better for high RPM street cars. So essentially its a mis-match of technology. Heads perfect for large displacement normal rpm, block great for low displacement high rpm.

I want to make an 8000RPM al bore 380ish CI street LSX in the worst way and drop it into a BMW E36. But it simply is not practical to run that kind of RPM on an OHV engine on a street app.

Other than that, the hard fact is that the valve train is the real limiter for the vast majority of us. If you want serious high RPM fun, solid rollers tend to be the way to go. Not so good for a street car. In the grand scheme of things, OHC is far better for high RPM street cars. So essentially its a mis-match of technology. Heads perfect for large displacement normal rpm, block great for low displacement high rpm.

I want to make an 8000RPM al bore 380ish CI street LSX in the worst way and drop it into a BMW E36. But it simply is not practical to run that kind of RPM on an OHV engine on a street app.

#29

Depends on how wild you are planning to go. Honestly I think the valvetrain would be your primary limitation on RPMs. De-stroked, bored and with the valvetrain sorted 10,000rpm is not unobtainable.

And just think what that would sound like, NA or otherwise. It could make just 300hp and be worth it.

I'm thinking dead between 8 second muscle car and a Ferrari Testarosa. (Might even have performance like it!)

And just think what that would sound like, NA or otherwise. It could make just 300hp and be worth it.

I'm thinking dead between 8 second muscle car and a Ferrari Testarosa. (Might even have performance like it!)

#30

OWN3D BY MY PROF!

iTrader: (176)

I didn't know too much about flat crank engines so I looked it up and here's what I found.

The V8-Engine

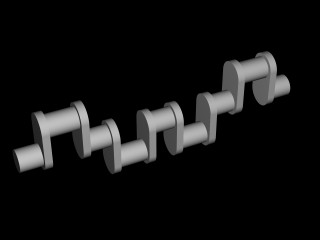

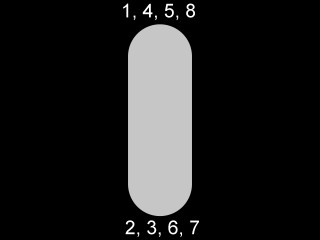

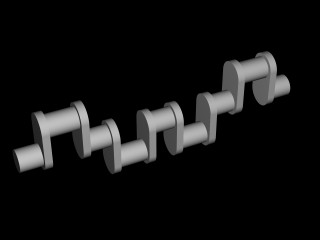

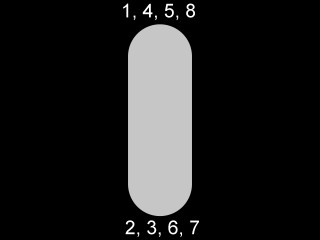

There are two types of V8s which differ by crankshaft. The V-angle is always 90°. The two types are called cross-plane (crank pins at a 90° angle) and flat-plane (crank pins at 180°). V8 engines have the advantage of not being in need of split crank pins in order to avoid vibrations between cylinder banks.

With a cross-plane V8, however, the last cylinder is not in the same position as the first, so there is end-to-end vibration again. That can be solved by adding counterweights to the crankshaft which cancel the forced created by the pistons. That is possible only in a V-engine with a V-angle of 90° and without splitted crank pins. These counterweights, fitted to an inline engine, would move to the side when the piston moves up or down and therefore generate additional vibration. But in a 90° V-engine there are pistons on the same crank pin which move exactly into the opposite directions of the counterweights (because of the bank angle) and their forces can be cancelled. Cross-plane V8s are therefore running quite smooth but because of the heavier crankshaft they are not as revvy.

Flat-plane V8 engines do not have those problems. They are also more responsive because of less rotational inertia. That increases maximum rpm and top-end power. In addition the crank case can be smaller which lowers the center of gravity.

But why are the flat-plane engines used in sports cars only if there are so many advantages? That's because of the crankshaft itself, the disadvantage of the flat-plane type. As you can see, the arrangement of crank pins is identical to a four cylinder engine which means there are also vibrations, only stronger, as basically two inline-four engines are running simultaneously. In sports cars those vibrations are reduced by using very lightweight pistons and connecting rods. That is of course expensive and because ride quality isn't too important either, the rough characteristics (compared to a cross-plane) are tolerated. Because of the crankshaft, the sound of such an engine is the one of two four cylinder engines. A (typical american) cross-plane burbling cannot be achieved.

frontal crankshaft view:

The V8-Engine

There are two types of V8s which differ by crankshaft. The V-angle is always 90°. The two types are called cross-plane (crank pins at a 90° angle) and flat-plane (crank pins at 180°). V8 engines have the advantage of not being in need of split crank pins in order to avoid vibrations between cylinder banks.

With a cross-plane V8, however, the last cylinder is not in the same position as the first, so there is end-to-end vibration again. That can be solved by adding counterweights to the crankshaft which cancel the forced created by the pistons. That is possible only in a V-engine with a V-angle of 90° and without splitted crank pins. These counterweights, fitted to an inline engine, would move to the side when the piston moves up or down and therefore generate additional vibration. But in a 90° V-engine there are pistons on the same crank pin which move exactly into the opposite directions of the counterweights (because of the bank angle) and their forces can be cancelled. Cross-plane V8s are therefore running quite smooth but because of the heavier crankshaft they are not as revvy.

Flat-plane V8 engines do not have those problems. They are also more responsive because of less rotational inertia. That increases maximum rpm and top-end power. In addition the crank case can be smaller which lowers the center of gravity.

But why are the flat-plane engines used in sports cars only if there are so many advantages? That's because of the crankshaft itself, the disadvantage of the flat-plane type. As you can see, the arrangement of crank pins is identical to a four cylinder engine which means there are also vibrations, only stronger, as basically two inline-four engines are running simultaneously. In sports cars those vibrations are reduced by using very lightweight pistons and connecting rods. That is of course expensive and because ride quality isn't too important either, the rough characteristics (compared to a cross-plane) are tolerated. Because of the crankshaft, the sound of such an engine is the one of two four cylinder engines. A (typical american) cross-plane burbling cannot be achieved.

frontal crankshaft view:

#31

180 cranks have been around since the days of the flat head ford V-8 and vibration is still the problem. indy car engine are "flat crank" but very short stroke. they changed the "olds" indy car engine from 90 degree to flat crank to get away from the NASCAR engine sound they had in the beginning and there was not more power but the engines spooled up faster because of the lighter rotating assy. they have tried flat crank SBC for short track racing but the driver hands would fall asleep from all the vibration of the solid mounted engine and it also cracked the welds in the oil pan.

#32

Originally Posted by CirclesCenter

Depends on how wild you are planning to go. Honestly I think the valvetrain would be your primary limitation on RPMs. De-stroked, bored and with the valvetrain sorted 10,000rpm is not unobtainable.

And just think what that would sound like, NA or otherwise. It could make just 300hp and be worth it.

I'm thinking dead between 8 second muscle car and a Ferrari Testarosa. (Might even have performance like it!)

And just think what that would sound like, NA or otherwise. It could make just 300hp and be worth it.

I'm thinking dead between 8 second muscle car and a Ferrari Testarosa. (Might even have performance like it!)

I dunno. I would think so, at least with some tuning before the sniffer test LOL. But again, the valve train is the key. A basic LSX short block well built and balanced with even a 4 inch stroke can take over 8K. Its the springs and rockers and rods that are the weak point.