How to fix your already cracked door panels

#42

TECH Fanatic

iTrader: (5)

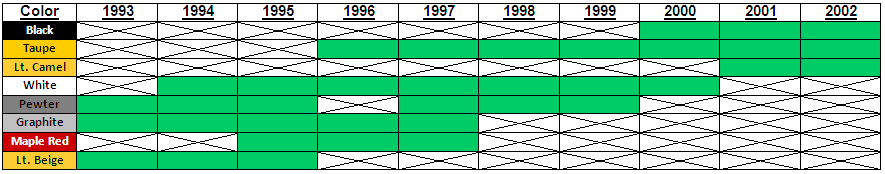

You're pretty much correct for the guys with Taupe (Tan) interior, they used the same color from 1996-2002. For the Ebony owners, if you want one that is not cracked yet and cannot find one from a car being parted out then your best bet is probably to get one from an LT1 car and have it dyed at an upholstery shop, or just dye it yourself with any of the off-the-shelf dyes that you can pick up at the auto parts store (SEM, Dupli-Color, etc).

My driver side panel was cracked, but the previous owner did the fix and it looks fine now. My passenger side one is just starting to crack now (it's maybe a half an inch long tear), I'm probably going to pull it off sometime during the holidays and do the fix before it gets any worse.

#46

TECH Fanatic

iTrader: (96)

Well guys went out to the other garage today pulled the cover off the bird and pulled it around the other driveway to wash it and got in and what do ya know I got a crack on my pass and drivers doors on a garage queen car at that go figure, but now I'm fixing these blasted things this week! ...

97ramsst

97ramsst  --- thanks for the write up, this is why I luv this site great people that help each other out posting stuff like this....

--- thanks for the write up, this is why I luv this site great people that help each other out posting stuff like this....

97ramsst

97ramsst  --- thanks for the write up, this is why I luv this site great people that help each other out posting stuff like this....

--- thanks for the write up, this is why I luv this site great people that help each other out posting stuff like this.... The following users liked this post:

guessohw (11-13-2020)

#51

TECH Regular

I've had my first 4th gen since June, still learning.

Do the door panels always crack in the same spot, like 6-8" from the end of the panel, or other places too on the top of the panel?

Can anyone recommend a specific epoxy? In similar situations in the past I used fiberglass resin and mesh with good results, but it's a messy PITA...

Do the door panels always crack in the same spot, like 6-8" from the end of the panel, or other places too on the top of the panel?

Can anyone recommend a specific epoxy? In similar situations in the past I used fiberglass resin and mesh with good results, but it's a messy PITA...

#52

TECH Resident

iTrader: (7)

I used Bondo 806 / 280 + mesh and excellent surface prep. Same epoxy in both kits. I suspect that is sufficient with good prep, but I would not use it again. Good door panels are too rare to try to save some money on adhesive. I believe the panels are polypropylene, which is a low energy plastic. If I were doing any similar, significant repairs or preventive maintenance on polypropylene panels again, I would probably spend the money on 3M™ Scotch-Weld™ Structural Plastic Adhesive DP8005 and the applicator + tips, or a Lord Fusor equivalent.

In addition, I direct people to more info in my last post in this thread.

Firebird Door Panel Crack – What Years?

In addition, I direct people to more info in my last post in this thread.

Firebird Door Panel Crack – What Years?

The following 2 users liked this post by bsf:

k3000 (08-15-2019), ramairjohn2000 (12-10-2020)

The following users liked this post:

k3000 (08-15-2019)

#54

TECH Regular

This forum is SO awesome, thanks so much guys!

bsf you are so right, these door panels on older GM cars are SO hard to find, and expensive.

I don't think I want to wrap these either, I would prefer to repair them.

I'm glad I saw this information before mine were cracked all the way through. Right now they're about 1/4" on one, and 1/2" on the other one.

Is the 3M™ Scotch-Weld™ Structural Plastic Adhesive DP8005 and the 3M panel bond the same thing?

Anyone else have any thoughts on the best adhesives to use? I'm thinking some kind of mesh reinforcement and pre-sanding the panel for adhesion would be a very good idea whatever adhesive / bonding agent I end up using.

I hate these GM plastics issues! But it's part of owning any older GM car.

bsf not sure how you know what kind of plastic these are, but good for you. And your logic is quite sound these are getting so hard to find might as well use the best possible methods for repairs...

bsf you are so right, these door panels on older GM cars are SO hard to find, and expensive.

I don't think I want to wrap these either, I would prefer to repair them.

I'm glad I saw this information before mine were cracked all the way through. Right now they're about 1/4" on one, and 1/2" on the other one.

Is the 3M™ Scotch-Weld™ Structural Plastic Adhesive DP8005 and the 3M panel bond the same thing?

Anyone else have any thoughts on the best adhesives to use? I'm thinking some kind of mesh reinforcement and pre-sanding the panel for adhesion would be a very good idea whatever adhesive / bonding agent I end up using.

I hate these GM plastics issues! But it's part of owning any older GM car.

bsf not sure how you know what kind of plastic these are, but good for you. And your logic is quite sound these are getting so hard to find might as well use the best possible methods for repairs...

#55

TECH Resident

iTrader: (7)

bsf not sure how you know what kind of plastic these are....

The following users liked this post:

k3000 (08-15-2019)

The following users liked this post:

k3000 (08-15-2019)

#57

TECH Regular

Thank you sjsingle1, much appreciated.

If I was going to be fixing them all the time I guess I would shop for price, but since the goal is the best possible repair, 3M's high prices don't deter me!

If I was going to be fixing them all the time I guess I would shop for price, but since the goal is the best possible repair, 3M's high prices don't deter me!

#58

TECH Regular

A well known and reputable vendor says this. I'm not sure if he's a sponsor here or not. Thoughts on this?

"FIREBIRD DOOR PANEL CRACKING: Contrary to what you might read elsewhere on the internet (but similarly related). The common door panel cracking is not due to "the staple" that the upper window sweep seal is mounted with. The supplier for GM changed the composition of the plastic (PPO) used in door panels produced somewhere in the early to middle of 1998. What happens is that when the panels are exposed to enough thermal cycles (cold-hot-cold), and particularly in colder climates, the PPO expands and contracts. This causes the PPO to become brittle. The most vulnerable point is where the panel has the most stress, which is at the 90 degree corner where the upper window sweep mounts. The cracking will a lot of times find it's way to the staple puncture. This is usually after the crack started at the 90 degree bend. From many years of experience we've seen the cracks form going TO the staples rather than originating AT the staple and cracking away from it.

It's not a matter of mileage or use (I'm sure plenty of you reading have low mileage cars with cracked panels), it's the environmental conditions they are subject to.

Panels that can identified by dates earlier (about where we have calculated, but not a certainty) than Feb '98 have the older PPO material and do not have the cracking issue the later panels have. So realize that wherever you source door panels from, anything that was produced after that date (again the date is not carved in stone, but you can include all late '98 and newer) are eventually going to crack if exposed to enough thermal cycles."

I'm thinking of going two different ways. One is to reinforce the entire top of my 2000 ebony panel with fiberglass mesh. The other way I want to look in to is if some of the parts from the 2000 ebony panel could be swapped on to a panel made from 93-97, and dye the older panel to match the ebony color.

Thoughts?

"FIREBIRD DOOR PANEL CRACKING: Contrary to what you might read elsewhere on the internet (but similarly related). The common door panel cracking is not due to "the staple" that the upper window sweep seal is mounted with. The supplier for GM changed the composition of the plastic (PPO) used in door panels produced somewhere in the early to middle of 1998. What happens is that when the panels are exposed to enough thermal cycles (cold-hot-cold), and particularly in colder climates, the PPO expands and contracts. This causes the PPO to become brittle. The most vulnerable point is where the panel has the most stress, which is at the 90 degree corner where the upper window sweep mounts. The cracking will a lot of times find it's way to the staple puncture. This is usually after the crack started at the 90 degree bend. From many years of experience we've seen the cracks form going TO the staples rather than originating AT the staple and cracking away from it.

It's not a matter of mileage or use (I'm sure plenty of you reading have low mileage cars with cracked panels), it's the environmental conditions they are subject to.

Panels that can identified by dates earlier (about where we have calculated, but not a certainty) than Feb '98 have the older PPO material and do not have the cracking issue the later panels have. So realize that wherever you source door panels from, anything that was produced after that date (again the date is not carved in stone, but you can include all late '98 and newer) are eventually going to crack if exposed to enough thermal cycles."

I'm thinking of going two different ways. One is to reinforce the entire top of my 2000 ebony panel with fiberglass mesh. The other way I want to look in to is if some of the parts from the 2000 ebony panel could be swapped on to a panel made from 93-97, and dye the older panel to match the ebony color.

Thoughts?

#59

TECH Resident

iTrader: (7)

A well known and reputable vendor says this. I'm not sure if he's a sponsor here or not. Thoughts on this?

"FIREBIRD DOOR PANEL CRACKING: Contrary to what you might read elsewhere on the internet (but similarly related). The common door panel cracking is not due to "the staple" that the upper window sweep seal is mounted with. The supplier for GM changed the composition of the plastic (PPO) used in door panels produced somewhere in the early to middle of 1998. What happens is that when the panels are exposed to enough thermal cycles (cold-hot-cold), and particularly in colder climates, the PPO expands and contracts. This causes the PPO to become brittle. The most vulnerable point is where the panel has the most stress, which is at the 90 degree corner where the upper window sweep mounts. The cracking will a lot of times find it's way to the staple puncture. This is usually after the crack started at the 90 degree bend. From many years of experience we've seen the cracks form going TO the staples rather than originating AT the staple and cracking away from it.

It's not a matter of mileage or use (I'm sure plenty of you reading have low mileage cars with cracked panels), it's the environmental conditions they are subject to.

Panels that can identified by dates earlier (about where we have calculated, but not a certainty) than Feb '98 have the older PPO material and do not have the cracking issue the later panels have. So realize that wherever you source door panels from, anything that was produced after that date (again the date is not carved in stone, but you can include all late '98 and newer) are eventually going to crack if exposed to enough thermal cycles."

I'm thinking of going two different ways. One is to reinforce the entire top of my 2000 ebony panel with fiberglass mesh. The other way I want to look in to is if some of the parts from the 2000 ebony panel could be swapped on to a panel made from 93-97, and dye the older panel to match the ebony color.

Thoughts?

"FIREBIRD DOOR PANEL CRACKING: Contrary to what you might read elsewhere on the internet (but similarly related). The common door panel cracking is not due to "the staple" that the upper window sweep seal is mounted with. The supplier for GM changed the composition of the plastic (PPO) used in door panels produced somewhere in the early to middle of 1998. What happens is that when the panels are exposed to enough thermal cycles (cold-hot-cold), and particularly in colder climates, the PPO expands and contracts. This causes the PPO to become brittle. The most vulnerable point is where the panel has the most stress, which is at the 90 degree corner where the upper window sweep mounts. The cracking will a lot of times find it's way to the staple puncture. This is usually after the crack started at the 90 degree bend. From many years of experience we've seen the cracks form going TO the staples rather than originating AT the staple and cracking away from it.

It's not a matter of mileage or use (I'm sure plenty of you reading have low mileage cars with cracked panels), it's the environmental conditions they are subject to.

Panels that can identified by dates earlier (about where we have calculated, but not a certainty) than Feb '98 have the older PPO material and do not have the cracking issue the later panels have. So realize that wherever you source door panels from, anything that was produced after that date (again the date is not carved in stone, but you can include all late '98 and newer) are eventually going to crack if exposed to enough thermal cycles."

I'm thinking of going two different ways. One is to reinforce the entire top of my 2000 ebony panel with fiberglass mesh. The other way I want to look in to is if some of the parts from the 2000 ebony panel could be swapped on to a panel made from 93-97, and dye the older panel to match the ebony color.

Thoughts?

#60

TECH Regular

I'm thinking about using regular fiberglass resin with mesh on my door panels, I've had good luck with it in the past.

You're so right about the professionals that know what to choose to work with and how to use it!

I run in to this issue a LOT. I'm still trying to figure out what adhesives they use to bond rubber to plastic on laptops!

You're so right about the professionals that know what to choose to work with and how to use it!

I run in to this issue a LOT. I'm still trying to figure out what adhesives they use to bond rubber to plastic on laptops!