DIY Powder Coating

#24

TECH Senior Member

iTrader: (34)

Only problem is that I live in a small town and only seem to find things in the bigger places. Then I have to drive 75 miles each way in my dads truck that gets ~10 mpg.....you get my drift haha

I found a couple locally for $25-$50 so I'll see when they give me a call back

DopeFedZ What kind of media are you using? I have always used silica sand and its hard on the original material. I thought about getting some glass, but wasn't sure how well it works, or maybe some soda. I heard that soda works really well for removing paint, but not so much for heavy rust

I found a couple locally for $25-$50 so I'll see when they give me a call back

DopeFedZ What kind of media are you using? I have always used silica sand and its hard on the original material. I thought about getting some glass, but wasn't sure how well it works, or maybe some soda. I heard that soda works really well for removing paint, but not so much for heavy rust

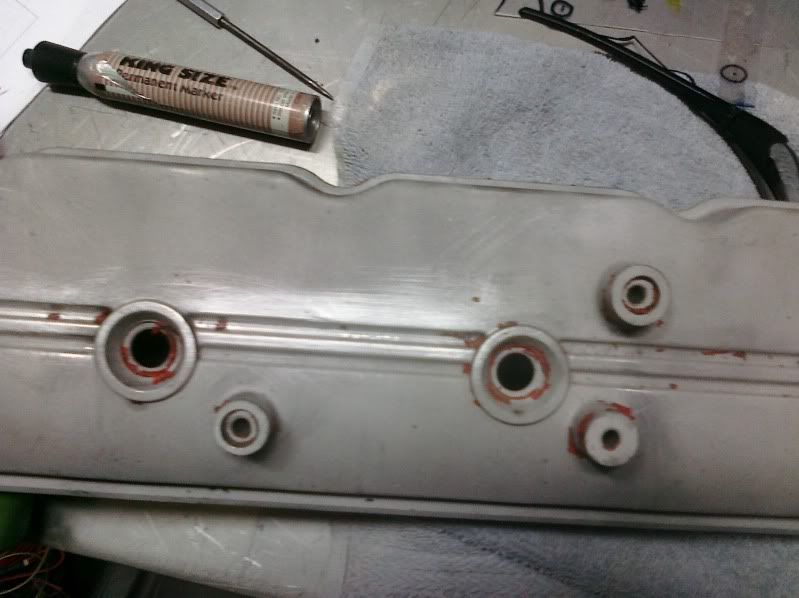

This is what the finish looks like. Disregard the shinier looking spots I was using a metal brush to try and remove whatever didn't come off after blasting.

Last edited by DopeFedZ; 03-10-2011 at 08:46 AM.

#25

Motorboater

iTrader: (53)

Coating small stuff in simple single coat colors like gloss black is pretty easy to do at home with a hobby gun and an old oven and blast cabinet.

Doing what I do is a different story. Just don't get carried away, its the biggest mistake I see local guys make. They start trying to make money at it, taking things on that are outside their skill range and equipment capacity and 2 days later the stuff is in my hands to get stripped and re done and they are embarassed about it. There's a HUGE difference between a $100 Eastwood hobby gun and my $5,000 Wagner.

Hanging anything bigger than a 6-8" part in a household size oven is not going to yeild correct durability unless you build heat shields in front of the elements. Huge rookie mistake with hobby equipment is forgetting about infared heat. You will set the oven at 400 deg lets say, but if the part is physically too close to the elements, it'll get hotter than that 400 and over cure the part, weakening the powder.

I could go on forever, but the infared heat thing I always point out so you don't have prolbems with your own parts you want to experiment with and put on your car. Have fun with it at home, just seriously don't get ahead of yourself. I just stripped and re-did a pile of very expensive aftermarket parts last week that a guy took to "his buddy that does powder coating on the side". He almost ruined his friends parts trying to do stuff that was way outside his skill and equipment range..owner of parts was NOT happy..

PS, pretty sure I recognize some of my work on DopeFedZ's motor there

Doing what I do is a different story. Just don't get carried away, its the biggest mistake I see local guys make. They start trying to make money at it, taking things on that are outside their skill range and equipment capacity and 2 days later the stuff is in my hands to get stripped and re done and they are embarassed about it. There's a HUGE difference between a $100 Eastwood hobby gun and my $5,000 Wagner.

Hanging anything bigger than a 6-8" part in a household size oven is not going to yeild correct durability unless you build heat shields in front of the elements. Huge rookie mistake with hobby equipment is forgetting about infared heat. You will set the oven at 400 deg lets say, but if the part is physically too close to the elements, it'll get hotter than that 400 and over cure the part, weakening the powder.

I could go on forever, but the infared heat thing I always point out so you don't have prolbems with your own parts you want to experiment with and put on your car. Have fun with it at home, just seriously don't get ahead of yourself. I just stripped and re-did a pile of very expensive aftermarket parts last week that a guy took to "his buddy that does powder coating on the side". He almost ruined his friends parts trying to do stuff that was way outside his skill and equipment range..owner of parts was NOT happy..

PS, pretty sure I recognize some of my work on DopeFedZ's motor there

#27

TECH Addict

Thread Starter

iTrader: (12)

Join Date: Mar 2007

Posts: 2,467

Likes: 0

Received 0 Likes

on

0 Posts

Coating small stuff in simple single coat colors like gloss black is pretty easy to do at home with a hobby gun and an old oven and blast cabinet.

Doing what I do is a different story. Just don't get carried away, its the biggest mistake I see local guys make. They start trying to make money at it, taking things on that are outside their skill range and equipment capacity and 2 days later the stuff is in my hands to get stripped and re done and they are embarassed about it. There's a HUGE difference between a $100 Eastwood hobby gun and my $5,000 Wagner.

Hanging anything bigger than a 6-8" part in a household size oven is not going to yeild correct durability unless you build heat shields in front of the elements. Huge rookie mistake with hobby equipment is forgetting about infared heat. You will set the oven at 400 deg lets say, but if the part is physically too close to the elements, it'll get hotter than that 400 and over cure the part, weakening the powder.

I could go on forever, but the infared heat thing I always point out so you don't have prolbems with your own parts you want to experiment with and put on your car. Have fun with it at home, just seriously don't get ahead of yourself. I just stripped and re-did a pile of very expensive aftermarket parts last week that a guy took to "his buddy that does powder coating on the side". He almost ruined his friends parts trying to do stuff that was way outside his skill and equipment range..owner of parts was NOT happy..

PS, pretty sure I recognize some of my work on DopeFedZ's motor there

Doing what I do is a different story. Just don't get carried away, its the biggest mistake I see local guys make. They start trying to make money at it, taking things on that are outside their skill range and equipment capacity and 2 days later the stuff is in my hands to get stripped and re done and they are embarassed about it. There's a HUGE difference between a $100 Eastwood hobby gun and my $5,000 Wagner.

Hanging anything bigger than a 6-8" part in a household size oven is not going to yeild correct durability unless you build heat shields in front of the elements. Huge rookie mistake with hobby equipment is forgetting about infared heat. You will set the oven at 400 deg lets say, but if the part is physically too close to the elements, it'll get hotter than that 400 and over cure the part, weakening the powder.

I could go on forever, but the infared heat thing I always point out so you don't have prolbems with your own parts you want to experiment with and put on your car. Have fun with it at home, just seriously don't get ahead of yourself. I just stripped and re-did a pile of very expensive aftermarket parts last week that a guy took to "his buddy that does powder coating on the side". He almost ruined his friends parts trying to do stuff that was way outside his skill and equipment range..owner of parts was NOT happy..

PS, pretty sure I recognize some of my work on DopeFedZ's motor there

Thanks for the reply

#28

Motorboater

iTrader: (53)

If the suspension parts are steel,since they are under the car and more likely to see some projectile based abuse, you will want to either:

1) phosphate treat after a very complete blasting job(go for white level blasting, google that if you need to know what I mean)

2)Primer with a ZINC RICH primer after white blasting

3) Both if you want to get crazy

I don't phosphate, I like to use zinc primer. Adds significant durability and rust protection in case the topcoat gets chipped.

1) phosphate treat after a very complete blasting job(go for white level blasting, google that if you need to know what I mean)

2)Primer with a ZINC RICH primer after white blasting

3) Both if you want to get crazy

I don't phosphate, I like to use zinc primer. Adds significant durability and rust protection in case the topcoat gets chipped.