Space between torque converter and flywheel before bolts installed??

#24

TECH Regular

iTrader: (2)

Join Date: May 2005

Location: CHI,IL

Posts: 475

Likes: 0

Received 0 Likes

on

0 Posts

Your gap is a large .281 . These .187 shims would get you down to a perfect .096:

http://www.summitracing.com/parts/mez-fps437187

http://www.summitracing.com/parts/mez-fps437187

i have the Yank Flexplate and converter with a built 4l60e.

ya i thought it was 1/4 but tried the 9/32 and it was just flush with that.....

you think it was the flex plate that caused a huge gap?

#26

Moderator

You can use washers, but might need 3 for each bolt. You also need calipers to measure the washers so that each pack of 3 is the same width. Else you will twist the flexplate and/or get things out of balance.

I have done this - I wrap the outside of the three washers with masking tape and cutoff the extra; makes it easier to handle.

As you install the first two bolts (and washers) keep them loose so that you can fit the washers for the last bolt. Then start to tighten things up.

Sorry, I don't know why your gap is so big. I recall that my Yank SS3600 gap to a TCI flexplate was pretty big too.

I have done this - I wrap the outside of the three washers with masking tape and cutoff the extra; makes it easier to handle.

As you install the first two bolts (and washers) keep them loose so that you can fit the washers for the last bolt. Then start to tighten things up.

Sorry, I don't know why your gap is so big. I recall that my Yank SS3600 gap to a TCI flexplate was pretty big too.

#27

TECH Regular

iTrader: (2)

Join Date: May 2005

Location: CHI,IL

Posts: 475

Likes: 0

Received 0 Likes

on

0 Posts

And I will be ordering the shims to save that headache.

I have stock bolts,yanks supplied bolts(short) and set of bolts from the last guy who had the converter which the size is shorter then stock but longer than yanks bolts.

. I did the entire install in 5 hours. 1 hour of kicking it off the dowel pins. But all I have left is the shims and installing a trans cooler. Probably going to bypass the stock one.

How many quarts of fluid for bone dry trans. 10?

I have stock bolts,yanks supplied bolts(short) and set of bolts from the last guy who had the converter which the size is shorter then stock but longer than yanks bolts.

. I did the entire install in 5 hours. 1 hour of kicking it off the dowel pins. But all I have left is the shims and installing a trans cooler. Probably going to bypass the stock one.

How many quarts of fluid for bone dry trans. 10?

#28

Moderator

A bone dry 4L60E and converter will take about 12 -13 quarts.

Add fluid until the dipstick shows it about 1" above the full line. That will be about 10 quarts and enough to be safe when starting the engine. Then check it with the engine running and you will likely add another 2 quarts. After driving it a bit, you may find it down another 1/2 quart or so.

Actually my initial 10 quarts includes the amount you pour into the converter before installing it. A 1/2 quart should be enough and not so much that you spill it during installation.

Add fluid until the dipstick shows it about 1" above the full line. That will be about 10 quarts and enough to be safe when starting the engine. Then check it with the engine running and you will likely add another 2 quarts. After driving it a bit, you may find it down another 1/2 quart or so.

Actually my initial 10 quarts includes the amount you pour into the converter before installing it. A 1/2 quart should be enough and not so much that you spill it during installation.

#30

The torque converter for a 700r4 only works if I 1/8 thick washer. Will not get a reaction from transmission while bolted directly to fly wheel. Is it safe to run it with the spacers. I got about an inch from bell face to converter once its seated. Not sure if converter is deep enough

#31

FormerVendor

iTrader: (21)

The torque converter for a 700r4 only works if I 1/8 thick washer. Will not get a reaction from transmission while bolted directly to fly wheel. Is it safe to run it with the spacers. I got about an inch from bell face to converter once its seated. Not sure if converter is deep enough

Chris

#32

This is very bad advice... I did exactly that on my 4l80e transmission and the converter wobbled a lot. Luckily I didn't drive it like this. After reading the official gm instructions on installing the torque converter for a 4l80e, it clearly stated to push the converter all the way back to the transmission and measure the gap between the flexplate and torque converter pad. My gap was 0.250 in although if I pulled the converter towards the engine block I would fall within the spec of 1/16 - 3/16 in. So it really depends on the make and model of your transmission. Once I installed the proper spacers to bring the gap within spec the wobble went away. This saved me from damaging my tranny's pump and perhaps other things.

#33

TECH Junkie

This is very bad advice... I did exactly that on my 4l80e transmission and the converter wobbled a lot. Luckily I didn't drive it like this. After reading the official gm instructions on installing the torque converter for a 4l80e, it clearly stated to push the converter all the way back to the transmission and measure the gap between the flexplate and torque converter pad. My gap was 0.250 in although if I pulled the converter towards the engine block I would fall within the spec of 1/16 - 3/16 in. So it really depends on the make and model of your transmission. Once I installed the proper spacers to bring the gap within spec the wobble went away. This saved me from damaging my tranny's pump and perhaps other things.

fail

The following users liked this post:

FTICONVERTERS (12-30-2019)

#34

I posted that so that it may help someone else looking at this thread. You may not have realized, that even though this post is ten years old that people still read them; your post just proved it. If you Google "torque converter flexplate gap" this thread pops up -- which is how I found out it -- as the fourth item. Please don't allow feelings to be hurt, this is a place to share the truth and not so much about protecting someone's feelings.

#36

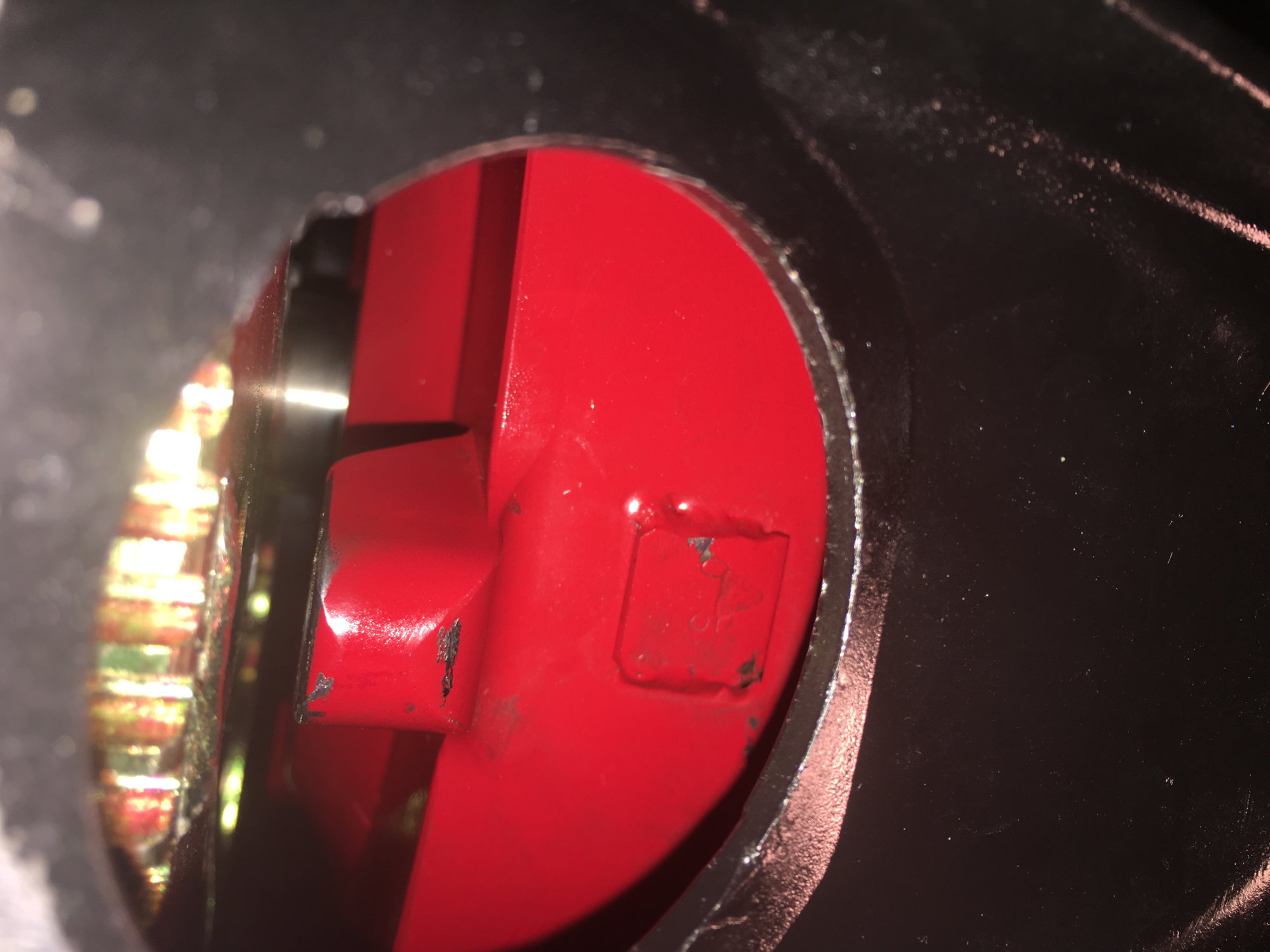

First use feeler gauges to know how far off you are. When measuring it is important to push the torque converter all the way back against the transmission. Then measure the distance from the torque converter pad and the flex plate pad. If the distance is not within 1/16 to 3/16" then you need shims/washers. Place the washer(s) between the torque converter pad and the flex-plate pad then screw in the torque converter bolt. I would strongly recommend to NOT torque down the torque converter bolts until you have placed in all the bolts. I went with class 10.9 washers from AutoZone, part number 002740. I simply picked washers that brought me within spec, fortunately I didn't need more than one washer for each pad. I hope this helps.

Last edited by Daniel De La Torre; 02-08-2020 at 12:40 PM.

#38

TECH Junkie