Camaro 6L80 switch to a slip yoke

#21

Staging Lane

Thread Starter

Join Date: Nov 2008

Location: Mile High City

Posts: 82

Likes: 0

Received 0 Likes

on

0 Posts

I do still have the yoke, I'm just not sure where though. For that matter, I still have the un-used Camaro driveshaft too.

What do you need the yoke for?

What do you need the yoke for?

#22

Any luck on this???

I have the same problem. Mines going into a 1981 C10. I got the 2-piece shaft from the donor vehicle (2010 Camaro), but I'm second-guessing going this route on a truck. I called Street & Performance (www.hotrodlane.cc) and they make a 6L80E tail housing conversion kit for $329.95. I'm sure its just a tail housing from a truck's 6L80, but they insured everything would be there for the conversion.

Justin

#23

Staging Lane

Thread Starter

Join Date: Nov 2008

Location: Mile High City

Posts: 82

Likes: 0

Received 0 Likes

on

0 Posts

Hey Justin, I ended up going with the T400 bolt-on yoke 68SSTT suggested earlier in this tread. I think I bought a brand new one for 50 bucks off from ebay and paid a CNC shop 50 bucks to make the recess work with the 6L80.

I finally decided against the Camaro driveshaft when I bought one and took it into a driveshaft shop and they said if you don’t get that center bearing mount almost perfectly square to the trans tail shaft it will **** out that rubber donut in a hurry. They also weren’t happy to see that it was spun-welded together making it much harder to rework it to mate it to the rear-end. So I went with the T400 yoke and had a truck driveshaft made up with the slip in the shaft. Much much cheaper and less headaches in the long run.

I finally decided against the Camaro driveshaft when I bought one and took it into a driveshaft shop and they said if you don’t get that center bearing mount almost perfectly square to the trans tail shaft it will **** out that rubber donut in a hurry. They also weren’t happy to see that it was spun-welded together making it much harder to rework it to mate it to the rear-end. So I went with the T400 yoke and had a truck driveshaft made up with the slip in the shaft. Much much cheaper and less headaches in the long run.

#24

The 6L80 has the same 32 spline pattern as any turbo400 or 4L80. So almost any 3/4 ton or bigger GM truck should have the slip yoke that you need. As long as the Ujoints are the same size. But make sure you don't get one from a truck with the 6L90. That's a 34 spline. I don't know if you do your own work or buy used parts, but this would most likely be the best way to go. Hope it helps.

The following users liked this post:

Pro-Tour Heavy Chevy (05-14-2024)

#26

#27

Firstly i got a t400 bolt on truck yoke

http://www.dennysdriveshaft.com/p230...32_spline.html

then i had to machine the yoke to replicate the 3 bolt yoke, it required some length machined off and a step machined from the inside at the trans end.

Then i got a slip joint installed in a tailshaft that i had made a per these 4x4 shafts.

http://www.dennysdriveshaft.com/c4_4x4_driveshafts.html

The only thing that has to be done is the alignment spigot on the end of the output shaft on the trans needs to be machined back to allow the u joint to fit. I'll try take some photos of my shaft and post.

http://www.dennysdriveshaft.com/p230...32_spline.html

then i had to machine the yoke to replicate the 3 bolt yoke, it required some length machined off and a step machined from the inside at the trans end.

Then i got a slip joint installed in a tailshaft that i had made a per these 4x4 shafts.

http://www.dennysdriveshaft.com/c4_4x4_driveshafts.html

The only thing that has to be done is the alignment spigot on the end of the output shaft on the trans needs to be machined back to allow the u joint to fit. I'll try take some photos of my shaft and post.

#28

Staging Lane

Thread Starter

Join Date: Nov 2008

Location: Mile High City

Posts: 82

Likes: 0

Received 0 Likes

on

0 Posts

Unfortunetly I don't. I just picked a 32 spline one off Ebay and it worked just fine. Since I knew it was going to be headed for a CNC mill anyways, all I cared about was the splines.

#29

GM 2wd HD2500 Silverado pickups:

6L90e Slip Yoke -36 spline

New GM Part # 15897994 http://www.gmpartsdirect.com/results.cfm

Schematic:

http://parts.nalleygmc.com/showAssem...rimLevel=14295

6L90e Slip Yoke -36 spline

New GM Part # 15897994 http://www.gmpartsdirect.com/results.cfm

Schematic:

http://parts.nalleygmc.com/showAssem...rimLevel=14295

#30

TECH Regular

iTrader: (3)

Has anyone used the kit that changes out the ouptut shaft of the 6L80E? This is the kit I was thinking about buying:

http://www.transmissioncenter.net/6l...arts_6l90e.htm

Are there any specialized tools required?

http://www.transmissioncenter.net/6l...arts_6l90e.htm

Are there any specialized tools required?

Last edited by Hart_Rod; 01-18-2013 at 10:49 AM.

#31

So is there not a slip yoke from another transmission that will work (without modification) on the 6L80?

I'm in the same boat - I have a 6l80 from a G8 going into a 67 Camaro and a 10 bolt 8.5 rearend.

I though about 2 other options if I do not replace the yoke.

1. Use the 2 piece drive shaft from the G8, shorten it and put a 10 bolt joint on the end of it. To do this, I would have to find a way to mount the center bearing on the 2 piece driveshaft.

2. Use a truck slip joint like Altitude with a 10 bolt rear end joint and use the G8 transmission end joint (the one that bolts to the G8 rubber disc) at the transmission

Number one option would be the cheapest but I have to fab up something to mount the center bearing too. I have priced it yet , but should only cost about $150 to shorten the driveshaft and put a 10 bolt joint on.

Any thoughts?

number two option is going cost me about $450 from my local drive shaft shop.

I'm in the same boat - I have a 6l80 from a G8 going into a 67 Camaro and a 10 bolt 8.5 rearend.

I though about 2 other options if I do not replace the yoke.

1. Use the 2 piece drive shaft from the G8, shorten it and put a 10 bolt joint on the end of it. To do this, I would have to find a way to mount the center bearing on the 2 piece driveshaft.

2. Use a truck slip joint like Altitude with a 10 bolt rear end joint and use the G8 transmission end joint (the one that bolts to the G8 rubber disc) at the transmission

Number one option would be the cheapest but I have to fab up something to mount the center bearing too. I have priced it yet , but should only cost about $150 to shorten the driveshaft and put a 10 bolt joint on.

Any thoughts?

number two option is going cost me about $450 from my local drive shaft shop.

#32

Staging Lane

Thread Starter

Join Date: Nov 2008

Location: Mile High City

Posts: 82

Likes: 0

Received 0 Likes

on

0 Posts

There are a few reasons I abandoned option 1. Most importantly was when I was told that the bearing and the rubber donut at the trans had to be exact or in a very big hurry I was going to **** out that donut. That in addition to the fact that the 2010 Camaro driveshaft, I was trying to use, was a couple inches shorter than what was required for my Chevelle. Meaning one of the two pieces would have had to have been completely remade. Which would have had to be done anyways, since the Camaro shaft works backwards from what I needed since the slip yoke at the bearing points towards the engine instead of the rearend. Because with the Camaroís independent rear suspension the pumpkin is solidly mounted and doesnít move. Not sure how your G8 shaft is set up, but I'd check that.

So in the end, it was only about a 100 bucks more in my case and that 100 bucks bought me a lot of peace of mind with zero fab time on my part.

So in the end, it was only about a 100 bucks more in my case and that 100 bucks bought me a lot of peace of mind with zero fab time on my part.

#33

TECH Regular

iTrader: (3)

There are a few reasons I abandoned option 1. Most importantly was when I was told that the bearing and the rubber donut at the trans had to be exact or in a very big hurry I was going to **** out that donut. That in addition to the fact that the 2010 Camaro driveshaft, I was trying to use, was a couple inches shorter than what was required for my Chevelle. Meaning one of the two pieces would have had to have been completely remade. Which would have had to be done anyways, since the Camaro shaft works backwards from what I needed since the slip yoke at the bearing points towards the engine instead of the rearend. Because with the Camaroís independent rear suspension the pumpkin is solidly mounted and doesnít move. Not sure how your G8 shaft is set up, but I'd check that.

So in the end, it was only about a 100 bucks more in my case and that 100 bucks bought me a lot of peace of mind with zero fab time on my part.

So in the end, it was only about a 100 bucks more in my case and that 100 bucks bought me a lot of peace of mind with zero fab time on my part.

#35

TECH Regular

iTrader: (3)

http://www.driveshaftshop.com/domest...ece-driveshaft

I talked to them and they said they would build it to my desired length for around $700-750. Thoughts?

The following users liked this post:

67_ls1 (02-22-2024)

#36

Staging Lane

Thread Starter

Join Date: Nov 2008

Location: Mile High City

Posts: 82

Likes: 0

Received 0 Likes

on

0 Posts

Thatís a pretty interesting solution! Wonder why itís taken someone till now to figure that out.

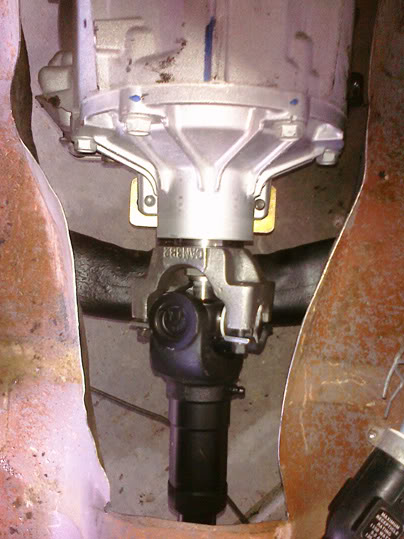

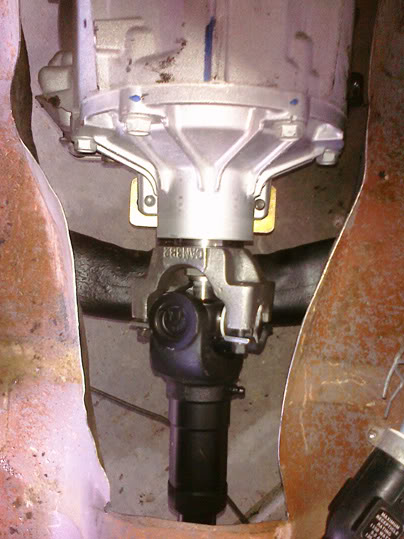

I unbolted the triangle piece from the trans and sent that to a CNC shop along with a turbo 400 bolt on yoke, that has the same spline count. They milled it to match the seat length of the triangle one. You can see below that the T400 is a little bit longer. Plus there is small bit of the splines that need to be removed from the bottom. Then I just simply bolted the T400 yoke to the 6L80. The yoke cost me 50 bucks and so did the machining. The driveshaft was pretty cheap since it was just a standard universal joint at each end, under 400 if I remember right.

Sorry, I thought these pictures were earlier in this thread, but they were in my build thread.

I unbolted the triangle piece from the trans and sent that to a CNC shop along with a turbo 400 bolt on yoke, that has the same spline count. They milled it to match the seat length of the triangle one. You can see below that the T400 is a little bit longer. Plus there is small bit of the splines that need to be removed from the bottom. Then I just simply bolted the T400 yoke to the 6L80. The yoke cost me 50 bucks and so did the machining. The driveshaft was pretty cheap since it was just a standard universal joint at each end, under 400 if I remember right.

Sorry, I thought these pictures were earlier in this thread, but they were in my build thread.

#37

TECH Regular

iTrader: (3)

Thatís a pretty interesting solution! Wonder why itís taken someone till now to figure that out.

I unbolted the triangle piece from the trans and sent that to a CNC shop along with a turbo 400 bolt on yoke, that has the same spline count. They milled it to match the seat length of the triangle one. You can see below that the T400 is a little bit longer. Plus there is small bit of the splines that need to be removed from the bottom. Then I just simply bolted the T400 yoke to the 6L80. The yoke cost me 50 bucks and so did the machining. The driveshaft was pretty cheap since it was just a standard universal joint at each end, under 400 if I remember right.

Sorry, I thought these pictures were earlier in this thread, but they were in my build thread.

I unbolted the triangle piece from the trans and sent that to a CNC shop along with a turbo 400 bolt on yoke, that has the same spline count. They milled it to match the seat length of the triangle one. You can see below that the T400 is a little bit longer. Plus there is small bit of the splines that need to be removed from the bottom. Then I just simply bolted the T400 yoke to the 6L80. The yoke cost me 50 bucks and so did the machining. The driveshaft was pretty cheap since it was just a standard universal joint at each end, under 400 if I remember right.

Sorry, I thought these pictures were earlier in this thread, but they were in my build thread.

.

.

#38

Staging Lane

Thread Starter

Join Date: Nov 2008

Location: Mile High City

Posts: 82

Likes: 0

Received 0 Likes

on

0 Posts

Couldn't be happier! Like I said earlier, the peace of mind outweighed everything else.

I'm considering turning that Camaro driveshaft into some chairs, for a conversation starter, in my garage.

I'm considering turning that Camaro driveshaft into some chairs, for a conversation starter, in my garage.