The Ultimate 4L60E 3/4 Clutch ?

#22

Moderator

Thread Starter

As Ron stated, when you have a Vette, you pretty much have to use the 4L60e; also, lots of F-body people here don't want to bang out their tunnel and make other mods for a 4L80e. And they won't consider the smaller TH400 because of lack of overdrive.

Several trans builders are now experimenting with this Sonnax drum on cars/trucks with 750 whp. Don't think anyone is selling it yet other than PATC in their $6000 trans. As Jake says, the 3/4 piston doesn't have enough surface area to really solve the problem, but I and others are hoping that it will help.

All these expensive/custom parts make such a 4L60e much more expensive than a build 4L80e, but if you don't have a choice, we want to try the latest improvements.

Personally, if/when I put a turbo/super charger on by car, I too will go 4L80e as I can fit it.

Several trans builders are now experimenting with this Sonnax drum on cars/trucks with 750 whp. Don't think anyone is selling it yet other than PATC in their $6000 trans. As Jake says, the 3/4 piston doesn't have enough surface area to really solve the problem, but I and others are hoping that it will help.

All these expensive/custom parts make such a 4L60e much more expensive than a build 4L80e, but if you don't have a choice, we want to try the latest improvements.

Personally, if/when I put a turbo/super charger on by car, I too will go 4L80e as I can fit it.

#24

As Ron stated, when you have a Vette, you pretty much have to use the 4L60e; also, lots of F-body people here don't want to bang out their tunnel and make other mods for a 4L80e. And they won't consider the smaller TH400 because of lack of overdrive.

Several trans builders are now experimenting with this Sonnax drum on cars/trucks with 750 whp. Don't think anyone is selling it yet other than PATC in their $6000 trans. As Jake says, the 3/4 piston doesn't have enough surface area to really solve the problem, but I and others are hoping that it will help.

All these expensive/custom parts make such a 4L60e much more expensive than a build 4L80e, but if you don't have a choice, we want to try the latest improvements.

Personally, if/when I put a turbo/super charger on by car, I too will go 4L80e as I can fit it.

Several trans builders are now experimenting with this Sonnax drum on cars/trucks with 750 whp. Don't think anyone is selling it yet other than PATC in their $6000 trans. As Jake says, the 3/4 piston doesn't have enough surface area to really solve the problem, but I and others are hoping that it will help.

All these expensive/custom parts make such a 4L60e much more expensive than a build 4L80e, but if you don't have a choice, we want to try the latest improvements.

Personally, if/when I put a turbo/super charger on by car, I too will go 4L80e as I can fit it.

A couple of things I'll mention and try to keep it short.

First,

I spoke with Gregg Nader from Sonnax at length yesterday at the PRI show about this drum setup.

There are some further advantages besides just clutch count.

The drum is treated to help fatigue areas from cracking.

The bolt on top plate gives the obvious advantage of more frictions and no snap ring blowout, but is also stiffer to prevent coning.

The apply plate is as well.

It's well known I'm not a huge proponent of the 4L60 series trans. My lack of interest in this unit is WHY I have spent so much time on the development of 4L80E parts.

I've been very successful using the 4L60's at and slightly above 600HP/TQ but it has some inherent issues (all units do) with powerflow. Many of these are circumvented in the valve body calibration. Simply keep them from beating themselves to death on shifts.

Anybody interested in the Sonnax drum, I will be stocking them and will try to pass them along at good pricing as well as 300M billet input shafts.

#25

Moderator

Thread Starter

Thank you for the additional info Jake.

I have five different friction/steel combos for this drum now, have made some preliminary measurements and will post details with part numbers and pictures soon.

In the mean time, I have PM'ed and emailed several builders with questions related to using the Transgo Clutch Spring kit (included in the HD2) with this drum, although I suspect it applies to stock drums too. Transgo says this spring kit is designed for operation over 5500 rpm. I shift close to 7000 rpm for best ET times, but this is mostly a street car.

Q1 - Should I replace the Sonnax drum's 3-4 checkball with the Transgo simple bleed hole?

Q2 - I like to use the 3-4 release springs on the side, which Sonnax recommends and provides for their drum. (It seems logical that they would reduce friction in 1st/2nd gear by keeping the apply and backing plates separated.)

How many of the stiffer Transgo springs should I then use in the 3-4 spring cage? I'm inclined to use 11 of the stock ones and 11 of the Transgo stiff ones. Does anyone have experience and/or recommendations?

By my measurements, using all 22 Transgo stiff springs triples the spring cage pressure from 30 lbs to 100 lbs, resulting in 70lbs less apply pressure on the clutch. (And using 22 Transgo spring and the 3-4 release springs would be too much.)

I understand that the overrun clutch return cage also needs stiffer springs to ensure the forward housing stays in place when the 3-4 spring cage is stiffened.

Or just share with us your recommended mods for 7000 rpm shifts at the track and good longevity on the street.

Thank you.

Ted.

I have five different friction/steel combos for this drum now, have made some preliminary measurements and will post details with part numbers and pictures soon.

In the mean time, I have PM'ed and emailed several builders with questions related to using the Transgo Clutch Spring kit (included in the HD2) with this drum, although I suspect it applies to stock drums too. Transgo says this spring kit is designed for operation over 5500 rpm. I shift close to 7000 rpm for best ET times, but this is mostly a street car.

Q1 - Should I replace the Sonnax drum's 3-4 checkball with the Transgo simple bleed hole?

Q2 - I like to use the 3-4 release springs on the side, which Sonnax recommends and provides for their drum. (It seems logical that they would reduce friction in 1st/2nd gear by keeping the apply and backing plates separated.)

How many of the stiffer Transgo springs should I then use in the 3-4 spring cage? I'm inclined to use 11 of the stock ones and 11 of the Transgo stiff ones. Does anyone have experience and/or recommendations?

By my measurements, using all 22 Transgo stiff springs triples the spring cage pressure from 30 lbs to 100 lbs, resulting in 70lbs less apply pressure on the clutch. (And using 22 Transgo spring and the 3-4 release springs would be too much.)

I understand that the overrun clutch return cage also needs stiffer springs to ensure the forward housing stays in place when the 3-4 spring cage is stiffened.

Or just share with us your recommended mods for 7000 rpm shifts at the track and good longevity on the street.

Thank you.

Ted.

#26

8 Second Club

iTrader: (3)

One thing to remember is that the TH400 was designed for big block engines back in the mid 60's when 500ft lbs of torque was common. They are pretty dang stout stock. Add an HD 2nd gear sprag and they are very strong.

The 700R4 and later 4L60 were designed for whimpy small blocks where fuel economy was the primary concern. Not to mention GM was pinching pennies. They didn't need to be real strong.

Ron

The 700R4 and later 4L60 were designed for whimpy small blocks where fuel economy was the primary concern. Not to mention GM was pinching pennies. They didn't need to be real strong.

Ron

#27

TECH Fanatic

iTrader: (18)

3/4 clutch pack. then when you buy a transmission your out for over a month while they try to figure out why it failed. Then after that they want to see your tune file to see if you have done anything that would cause it to die. That's their way out. In my case they never found anything and it failed again after some beatings on the street. I gave up

#28

TECH Fanatic

iTrader: (20)

3/4 clutch pack. then when you buy a transmission your out for over a month while they try to figure out why it failed. Then after that they want to see your tune file to see if you have done anything that would cause it to die. That's their way out. In my case they never found anything and it failed again after some beatings on the street. I gave up

#29

Moderator

Thread Starter

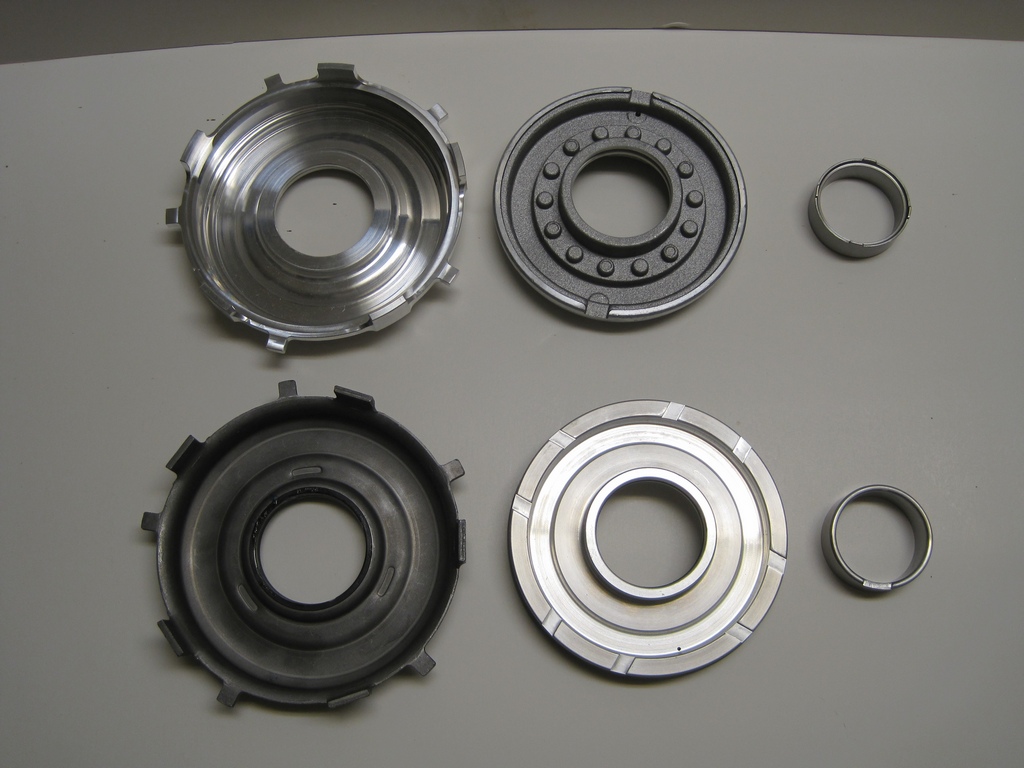

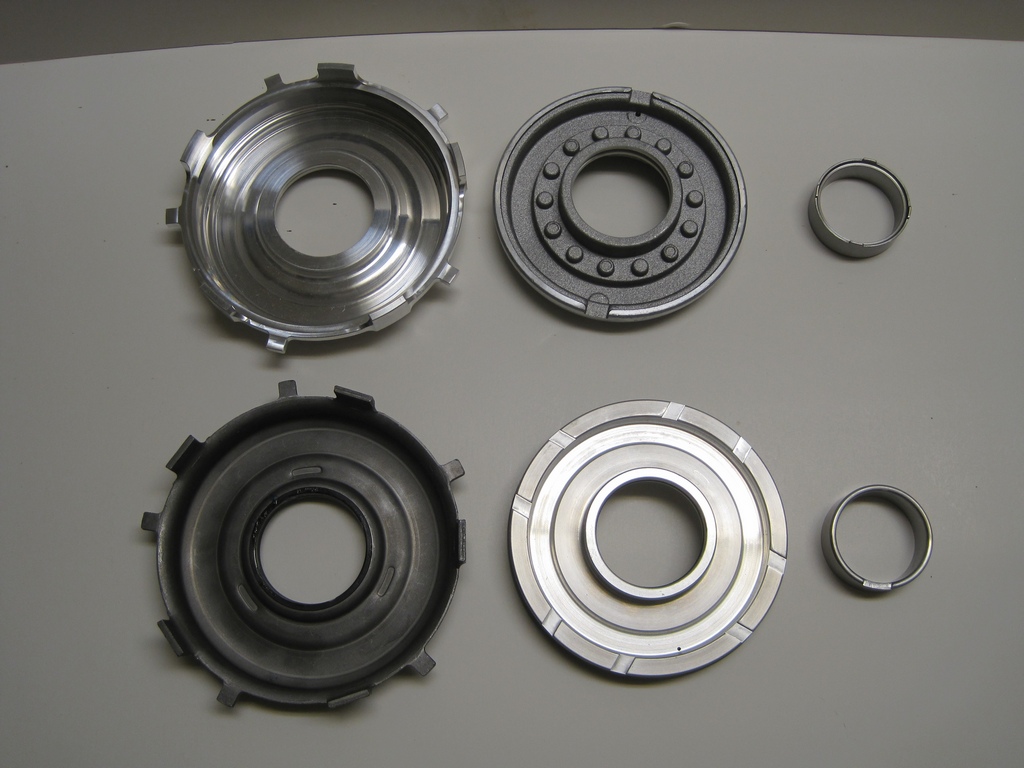

Here is a picture of what comes with the Sonnax Input Drum kit. Notice that it does not include the input shaft.

The primary difference is the top where it supports a screw-in plate and not the snap ring.

The kit includes the Sonnax input drum reinforcement ring which gets pressed on AFTER pressing in the input shaft. To work with the reinforcement ring, a modified aluminum overrun piston is provided. This aluminum overrun piston must be used with an old-style aluminum forward piston (not provided). Since the old-style GM aluminum forward piston had a reputation for cracking, it is suggested to use the Sonnax billet aluminum forward piston. (Another $95).

As an alternative, I found an early-production billet overrun piston which works with the new-style OEM steel forward piston; it includes a slightly different reinforcement ring.

Comparing them, on the top are the Sonnax Billet Forward piston (extra $95), and the supplied custom-modified Overrun piston and input drum reinforcement sleeve.

On the bottom are a stock GM steel Forward piston, and the billet overrun piston with matching input drum reinforcement ring.

The Sonnax supplied apply plate is only .120 thick, compared to the stock .220; however it is uniquely reinforced on the inside and .340 thick there as can be seen in this picture.

Since the clearance cannot be adjusted with different thickness backing plates, the only way to change the clearance is with different thickness frictions or steels. For example, Hi-Energy frictions come in .067, .062 and .080 advertised thicknesses. I noticed that different batches had slightly different thicknesses; for example some of the .062 I ordered came in at .065. The Raybestos Blue are advertised at .062, but measured .065. The same was true with steels; I bought two sets of .076 steels from two vendors (TranStar and transmissionpartsusa.com); the first were actually .080 and the other .078. When you multiply these small .002 differences over 8 or 9 units, it is .016 to nearly .020. Here is a picture with specs of the different thickness frictions and steels I experimented with.

After getting suggestions from several trans builders, I am aiming for .005 dry clearance PER Hi-Energy friction and .007 clearance PER Blue friction. (In other word, .045 and .063 dry clutch clearance.) Wet, each clutch will be about .001 thicker, so would be aiming for .036 clearance with Hi-Energy and .054 with Blue clutches.

9x BW .067 with 8x .080 steels = .031 (dry) ==> Too tight

9x BW .067 with 8x .078 steels = .047 (dry) ==> Perfect for 9 Hi-Energy clutches

9x Raybestos Blue .062 (.065) with 8x .078 steels = .062 (dry) ==> Perfect for 8 Blue clutches

For those who prefer thicker steels with 8 clutches, I made this measurement:

8x BW .067 with 7x .095 steels = .060 (dry) ==> A bit loose

Real .097 steels should give an excellent .046 clearance, but I only had the GM 4L65E steels, which aren't a good choice anyway because they can only be bought as a kit of 7 frictions and 6 steels. I had a few TranStar 74120D steels which measured a true .097.

Therefore, to build the Sonnax Input drum with 9 BorgWarner Hi-Energy clutches, I would recommend buying the following parts from TranStar or equivalent vendor:

9x 74100D 3-4 Clutch .067 Hi-Energy (Request Borg Warner)

4x 74100CA 3-4 Clutch .062 Hi-Energy (Request Borg Warner)

8x 74120AK 3-4 Clutch .076 Kolene Steel

Depending upon the actual thickness of the steels, you might have to use a few of the .062 frictions to get the desired clearance.

The steels I measured at .078 were from Transmissionpartsusa.com:

8x 35553K 3-4 Clutch .077 Kolene Steel

Again, different vendors and different batches seem to have slightly different thicknesses for the "same" part; therefore you may need an assortment to reach the desired clearance. These frictions and steels are only about $3 a piece.

I will be using the Blue frictions for my actual build. I will report whether the 2-3 shift feels different compared to my current setup with a stock drum and 8x GPX105 frictions.

The primary difference is the top where it supports a screw-in plate and not the snap ring.

The kit includes the Sonnax input drum reinforcement ring which gets pressed on AFTER pressing in the input shaft. To work with the reinforcement ring, a modified aluminum overrun piston is provided. This aluminum overrun piston must be used with an old-style aluminum forward piston (not provided). Since the old-style GM aluminum forward piston had a reputation for cracking, it is suggested to use the Sonnax billet aluminum forward piston. (Another $95).

As an alternative, I found an early-production billet overrun piston which works with the new-style OEM steel forward piston; it includes a slightly different reinforcement ring.

Comparing them, on the top are the Sonnax Billet Forward piston (extra $95), and the supplied custom-modified Overrun piston and input drum reinforcement sleeve.

On the bottom are a stock GM steel Forward piston, and the billet overrun piston with matching input drum reinforcement ring.

The Sonnax supplied apply plate is only .120 thick, compared to the stock .220; however it is uniquely reinforced on the inside and .340 thick there as can be seen in this picture.

Since the clearance cannot be adjusted with different thickness backing plates, the only way to change the clearance is with different thickness frictions or steels. For example, Hi-Energy frictions come in .067, .062 and .080 advertised thicknesses. I noticed that different batches had slightly different thicknesses; for example some of the .062 I ordered came in at .065. The Raybestos Blue are advertised at .062, but measured .065. The same was true with steels; I bought two sets of .076 steels from two vendors (TranStar and transmissionpartsusa.com); the first were actually .080 and the other .078. When you multiply these small .002 differences over 8 or 9 units, it is .016 to nearly .020. Here is a picture with specs of the different thickness frictions and steels I experimented with.

After getting suggestions from several trans builders, I am aiming for .005 dry clearance PER Hi-Energy friction and .007 clearance PER Blue friction. (In other word, .045 and .063 dry clutch clearance.) Wet, each clutch will be about .001 thicker, so would be aiming for .036 clearance with Hi-Energy and .054 with Blue clutches.

9x BW .067 with 8x .080 steels = .031 (dry) ==> Too tight

9x BW .067 with 8x .078 steels = .047 (dry) ==> Perfect for 9 Hi-Energy clutches

9x Raybestos Blue .062 (.065) with 8x .078 steels = .062 (dry) ==> Perfect for 8 Blue clutches

For those who prefer thicker steels with 8 clutches, I made this measurement:

8x BW .067 with 7x .095 steels = .060 (dry) ==> A bit loose

Real .097 steels should give an excellent .046 clearance, but I only had the GM 4L65E steels, which aren't a good choice anyway because they can only be bought as a kit of 7 frictions and 6 steels. I had a few TranStar 74120D steels which measured a true .097.

Therefore, to build the Sonnax Input drum with 9 BorgWarner Hi-Energy clutches, I would recommend buying the following parts from TranStar or equivalent vendor:

9x 74100D 3-4 Clutch .067 Hi-Energy (Request Borg Warner)

4x 74100CA 3-4 Clutch .062 Hi-Energy (Request Borg Warner)

8x 74120AK 3-4 Clutch .076 Kolene Steel

Depending upon the actual thickness of the steels, you might have to use a few of the .062 frictions to get the desired clearance.

The steels I measured at .078 were from Transmissionpartsusa.com:

8x 35553K 3-4 Clutch .077 Kolene Steel

Again, different vendors and different batches seem to have slightly different thicknesses for the "same" part; therefore you may need an assortment to reach the desired clearance. These frictions and steels are only about $3 a piece.

I will be using the Blue frictions for my actual build. I will report whether the 2-3 shift feels different compared to my current setup with a stock drum and 8x GPX105 frictions.

The following users liked this post:

n2xlr8n66 (06-26-2021)

#30

Moderator

Thread Starter

Update:

As of 2/1/13, FLT is now using the Sonnax Input Drum in the top-of-the-line Level 7 4L65E:

http://www.finishlinetrans.com/trans...rmance4L65.htm

I know that other builders are successfully testing that input drum in even 700HP trucks. I don't have enough power (only 500HP) to really stress it, but I am hearing only good things about it.

As of 2/1/13, FLT is now using the Sonnax Input Drum in the top-of-the-line Level 7 4L65E:

http://www.finishlinetrans.com/trans...rmance4L65.htm

I know that other builders are successfully testing that input drum in even 700HP trucks. I don't have enough power (only 500HP) to really stress it, but I am hearing only good things about it.

#31

I have one holding up behind a boosted 6.0 in a 4x4 truck that in current form is holding up. I have no idea what the horsepower is and I am not going to throw random horsepower "guesses" out there but at about 20lbs of boost on ethanol it lived... If you do the math its a decent amount of HP... It did take a few times of learning the hard way what doesn't work so good at that power level but it has 500+ hard miles on it without issue. I will say friction material and line pressure are key to making it live......

#32

9 Second Club

iTrader: (13)

How is this holding up mrvedit? About to order some parts for my 4L65e rebuild, and I'm thinking of purchasing this from Jake with the input shaft if he is still selling them for a good price.

I will also be purchasing the Sonnax 6 pinion planetary with the 2.84 first as shown here>>> http://www.trutechtrans.com/Sonnax-77284-K-Basket.html <<< to get me a better SLR and gear spread with my rear 4.10 gears.

Any input or updates you can give from running this for the last couple years would be great.

I will also be purchasing the Sonnax 6 pinion planetary with the 2.84 first as shown here>>> http://www.trutechtrans.com/Sonnax-77284-K-Basket.html <<< to get me a better SLR and gear spread with my rear 4.10 gears.

Any input or updates you can give from running this for the last couple years would be great.

#33

Moderator

Thread Starter

Everything is holding up perfectly. I have about 100 track runs with 525HP (flywheel) on the combo and shifts are as good as the first day.

I plan to open and inspect the trans this winter just as soon as FLT can supply me with a billet output shaft to upgrade. (There is a shortage of them now.)

Interesting that TruTech has a 6-pinion 2.84 planetary at "only" $690; not sure if it is billet, but low volume parts often are. I have a billet 6-pinion 2.84 from another, more expensive, source. I was unable to document any ET improvement at the track, but I often make multiple changes at once. The lower 2.84 1st gear ratio did help with my traction problems.

I plan to open and inspect the trans this winter just as soon as FLT can supply me with a billet output shaft to upgrade. (There is a shortage of them now.)

Interesting that TruTech has a 6-pinion 2.84 planetary at "only" $690; not sure if it is billet, but low volume parts often are. I have a billet 6-pinion 2.84 from another, more expensive, source. I was unable to document any ET improvement at the track, but I often make multiple changes at once. The lower 2.84 1st gear ratio did help with my traction problems.

#34

9 Second Club

iTrader: (13)

Good to hear. I'm not sure if the Sonnax planet is billet or not, but if I can combat traction issues using it, I'm going to give it a shot. Surely has to be better than a 3.06 first and 4.10 gears.

The only other part I'm inclined to purchase, is a billet pump rotor since my shift rpm is rather high.

The only other part I'm inclined to purchase, is a billet pump rotor since my shift rpm is rather high.

#35

Go with a 7 or 10 vane setup as they will give more volume as the rpm goes past 5,000 rpm. Make sure you use the Transgo hi-rpm steel rings and spring with this. The steel rings keep from breaking the 7 vane rotor setup. If you go over 7,800 rpm add the inner spring to this setup. This will keep the pressure from dropping at higher than 7,800 rpm's. With a 3.06 first gear if you have traction problems, then yes, the 2.84 gear set will help. With these gear sets being out here for over 4 years now, I am still waiting for a "true" comparison, as I think in a car (10.50's or quicker) that is already dialed in, and you make the "gear change only", you will see very little gain. Maybe .05" of a second. Not worth the money.

#36

Thanks for a great write-up. This is just what I was looking for. I am going through my 1994 Camaro 4L60E, which I built-up 10 years ago. It has served me well, 400 RWHP, 11.8 sec and on the NOS, 600 RWHP, 10.6 @130mph. Probably only 200 1/4 passes over these 10 years. For the build, I used a kit form "the real" Art Carr, in CA. It had a 7 friction Red Alto pack, set at 0.030" clearance. During the teardown, the pack measures 0.078" clearance. It was still shifting ok, maybe a little sluggish (not crisp). So thus the teardown, and am curious what it looks like after 10 years. For reference this is what is has:

1) stock input shaft

2) stock output shaft

3) stock 4 planet gear sets, front and rear

4) re-enforcing ring on input drum

5) Red-alto 2-4 band, narrow (it was burnt on tear-down)

The 3-4 red alto pack were pretty much blackened. I did not have the spring returns installed, per Superior Shift Kit recommendation. I'm somewhat surprised it was working as good as it was. Maybe because I was running pretty high line pressures, around 260-280 at WOT. I have line pressure data logged. This was accomplished by aftermarket boost valve and tweaking the pressure control solenoid torx screw, per Superior Shift Kit instructions. I too talked to Gregg Nader, Sonnex engineer at the this year's PRI show. He pretty much sold me on their input drum. But, as expected, wanted me to revert valve-body mods back to stock and use their Performance Pack, which I'll probably do. Also will be converting to the 5-planet gear sets.

I also noticed some slippage (burn marks) on the forward clutches, which was surprising, considering my high line pressure. From what I've read, it seems like the Blues would be a good choice for the Forward and Overrun frictions also.

1) stock input shaft

2) stock output shaft

3) stock 4 planet gear sets, front and rear

4) re-enforcing ring on input drum

5) Red-alto 2-4 band, narrow (it was burnt on tear-down)

The 3-4 red alto pack were pretty much blackened. I did not have the spring returns installed, per Superior Shift Kit recommendation. I'm somewhat surprised it was working as good as it was. Maybe because I was running pretty high line pressures, around 260-280 at WOT. I have line pressure data logged. This was accomplished by aftermarket boost valve and tweaking the pressure control solenoid torx screw, per Superior Shift Kit instructions. I too talked to Gregg Nader, Sonnex engineer at the this year's PRI show. He pretty much sold me on their input drum. But, as expected, wanted me to revert valve-body mods back to stock and use their Performance Pack, which I'll probably do. Also will be converting to the 5-planet gear sets.

I also noticed some slippage (burn marks) on the forward clutches, which was surprising, considering my high line pressure. From what I've read, it seems like the Blues would be a good choice for the Forward and Overrun frictions also.

Last edited by iedvk; 12-28-2014 at 08:40 PM.

#37

What did you decide on this? I noticed on PATC website that Superior has a spring loaded check-valve for bleeding the 3-4 piston.

From PATC website:

#41CB. This patent-pending 4L60 / 4L60-E / 4L65-E, 3-4 Rapid Relief Valve replaces the ball capsule in the input drum with a spring-loaded ball valve to help eliminate clutch drag on the release, according to the company. It also greatly reduces centrifugal apply in high-performance applications. Cost $29.00

I wonder if this would be worth while? I am planning to put back in the 3-4 return springs that comes with the Sonnax kit.

#38

Moderator

Thread Starter

What did you decide on this? I noticed on PATC website that Superior has a spring loaded check-valve for bleeding the 3-4 piston.

From PATC website:

#41CB. This patent-pending 4L60 / 4L60-E / 4L65-E, 3-4 Rapid Relief Valve replaces the ball capsule in the input drum with a spring-loaded ball valve to help eliminate clutch drag on the release, according to the company. It also greatly reduces centrifugal apply in high-performance applications. Cost $29.00

I wonder if this would be worth while? I am planning to put back in the 3-4 return springs that comes with the Sonnax kit.

From PATC website:

#41CB. This patent-pending 4L60 / 4L60-E / 4L65-E, 3-4 Rapid Relief Valve replaces the ball capsule in the input drum with a spring-loaded ball valve to help eliminate clutch drag on the release, according to the company. It also greatly reduces centrifugal apply in high-performance applications. Cost $29.00

I wonder if this would be worth while? I am planning to put back in the 3-4 return springs that comes with the Sonnax kit.

I tried the Superior spring-loaded check valve several years ago on a stock input drum. During mock-up it dragged on the reverse drum! I called Superior and they said this sometimes happens with Chinese reverse drums, but mine was GM stock from a 2009 trans. They also said they were going to engineer a shorter valve, but I don't think it happened. My advise is to stay away from it.

Other builders block the stock checkball and drill their own bleed holes on the side where centripetal force will pool the fluid. Since I don't know that detail, I just use the HD bleed cartridge.

Note that FLT, RPM and Performabuilt all use the Sonnax input drum in their high end builds now.

#39

TECH Junkie

mrvedit as you know I did my first rebuild this past spring and to date has been flawless. I was looking to add the sonnax input drum before next season and came across your excellent info posted in this thread.

Couple questions for ya now.....

First, this thread is a few years old now so do you have any new thoughts on this input drum? Has it been holding up well for you? Seems to be a necessary upgrade.

Second, the 6 pinion 2.84 carrier 77284-K , do you now think this is a worth while upgrade?

Couple questions for ya now.....

First, this thread is a few years old now so do you have any new thoughts on this input drum? Has it been holding up well for you? Seems to be a necessary upgrade.

Second, the 6 pinion 2.84 carrier 77284-K , do you now think this is a worth while upgrade?

Last edited by 98CayenneT/A; 10-05-2016 at 06:56 PM.

#40

Moderator

Thread Starter

The Sonnax input drum has been working well for me, and as far as I know, the sponsors who include it with their higher-level builds are happy with it too.

I have an earlier 2.84 6-pinion carrier which was crazy expensive. While I like the closer ratios, I saw no advantage at the drag strip, and would therefore would say it is hard to justify the $600 (?) price.

I have an earlier 2.84 6-pinion carrier which was crazy expensive. While I like the closer ratios, I saw no advantage at the drag strip, and would therefore would say it is hard to justify the $600 (?) price.