4L60E's and Why I like 4L80E's

#21

11 Second Club

iTrader: (21)

At 400 HP I would use a 4L60E IF there are not going to be later power upgrades.

A 4L60E has it's place and it's benefits. While a 4L80E conversion isn't difficult there can always be roadblocks when doing a conversion and how easy they are to solve is highly dependent on the technical ability of the installer.

I am finishing up two installs at the shop now and discovered I had relays that didn't function normally (or as they were labeled) that had me doing some diagnostics today.

A 4L60E has it's place and it's benefits. While a 4L80E conversion isn't difficult there can always be roadblocks when doing a conversion and how easy they are to solve is highly dependent on the technical ability of the installer.

I am finishing up two installs at the shop now and discovered I had relays that didn't function normally (or as they were labeled) that had me doing some diagnostics today.

#22

that is my heartburn with the 4L60E.

It takes quite a bit of $$$ in parts to build one right and you still have some components that there just isn't an upgrade for. The planetaries, forward sprag, and 3-4 apply area are really the limitations on that unit at this point.

#23

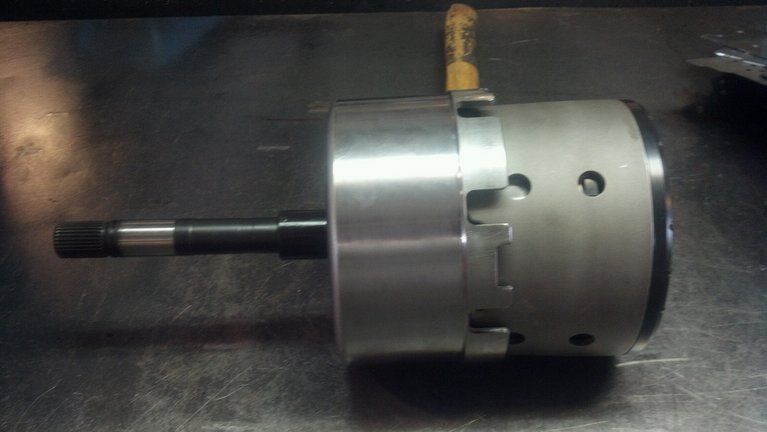

This particular trans is in a full size extended cab truck. Fairly heavy. It's tuned but otherwise a stock LQ9 and the owner takes it to the track often. We built the trans about 9 months ago. He twisted off the output shaft at the track, on street tires.

He elected to upgrade everything while it was apart. So it's getting a billet output shaft, 5 pinion planets, Sonnax input drum with billet input shaft.

#26

#27

Launching!

iTrader: (9)

Join Date: May 2011

Location: Carlisle, PA

Posts: 257

Likes: 0

Received 0 Likes

on

0 Posts

He was having problems with people buying parts and then needing help installing them. The guy BUILDS trans for a living so if you cant install them yourself then you should just be buying the tras from him.

#28

Our primary business is to build/sell performance transmissions.

One of our secondary operations has been selling parts to the public.

The parts sales are a somewhat considerable "gross sales" aspect of the business. The more I looked at trying to "smooth" my operation the more I saw that the biggest thorn in my side was selling parts.

By smoothing the operation, my goal is to make it more efficient, so it's easier to manage and we can deliver quicker and with more quality control.

I'm pretty sure if I took a poll of all my customers on this forum, the biggest complaint percentage wise would be delivery time. It is my biggest personal peeve.

Delivery time means more than just delivering quicker to the customer to keep them happy. That's the number one reason to try to reduce delivery times, because let's face it. It's the internet age and we ALL want it NOW.

The reality is, every unit we build is custom built and we don't shelf units ready for shipment. We've never been able to get that caught up. We're closer now than we've ever been. One reason is because I am not selling parts, another is that August is typically a slow month in this industry.

I have been considering not selling parts for most of the last year, and had intended to quit after Labor Day (now), but due to frustration I quit earlier this summer. So far, it's been a good decision.

Back to delivery time,

we're slow. Each unit is custom built. I try to start the builds in the order they were received in. Sometimes we begin a build knowing the parts are enroute. Then the parts show up, and they sent you the wrong type of billet shaft, or a billet shaft not completed into an assay as it is supposed to be, etc.

Delivery time not only affects customer satisfaction but it affects the flow of work through our shop. I have 6 build benches. 2 benches per builder. I have 3 teardown tables, 2 converter benches that we have been using as overflow but are now dedicated to the converter area.

If a builder has a build going on each bench, then begins another one while awaiting parts, or has to pull one back from the dyne to the build bench, things start getting cluttered. THAT is when you make mistakes like the one brought up earlier in this thread.

The more efficient we are at getting the transmissions built, dyno'd, packaged for shipment, shipped, etc, the quicker we can get then to the customer, and begin another build.

Everytime we get held up by an unanticipated event, it creates a ripple effect that slows down everything behind it on the work list.

A few weeks ago I did some major work to the dyno. It was not operable for 2 days. That was a kink that took a week to get caught up on.

Parts sales takes a HUGE amount of time.

I also felt that they were taking away our focus on our primary business of building the best transmission on the market at a reasonable cost.

Larger companies have a sales staff. These are dedicated people who may not know how to rebuild a transmission but are taught standard answers and are capable of "selling" parts.

One of the aspects of my business is that I want to keep it technician oriented. I want the customer to be able to talk to a technician. By that I mean a fellow enthusiast who is an expert in his field. The guy who builds transmissions during the week, and races on weekends. That is me or one of my builders.

You MIGHT get that at some other shops, but usually not. The guy on the phone at your favorite speed shop may be very well versed in their fuel pump selection but he isn't going to tell you how to rebuild your transmission over the phone.

Nor would most here expect him/her to.

However when someone orders parts from my shop, I become the technical expert who has to help them through every aspect of their build/install/tuning.

It is expected by the consumer. When I don't do it, I get called every name in the book. There are some posts on this thread that hint at it. I'm the ******* because I won't sell the parts now.

I have taught people to build transmissions over the phone/email/forums for years. I get calls because people know I am willing to help due to the fact I post here and on other forums.

I have answered questions for customers ranging from basic diagnostic and assembly, to converter selection, to chassis setup, and many other aspects of setting up a car, that aren't even applicable to what I sold to the customer, if I sold them anything at all.

I do actually enjoy helping people be successful with their transmissions/cars but I cannot answer every question that goes along with a transmission rebuild even if I did nothing but sold parts.

The profit margin on the parts I sell isn't great. I make more off the labor of the transmission build, and I'm not getting rich by any means in either case. Prices will actually be increasing later this month on everything.

At some point in time I can't continue to give away tech advice for free or a small profit on parts, especially when while I am doing so, I am taking away from paying customers who deserve their product and our full effort to that.

I have also had another aspect of the business up my sleeve that I've mentioned here some time ago but there were some hiccups in the plan.

As of this week, we are now building converters in house. I anticipate this will take a large amount of time as well for the sales/selection aspect.

Many enthusiasts want to build their own transmissions. I do not discourage that, but I am unwilling to be the technical resource for everyone who decides to do so. I learned much of what I know the hard way, before the internet, and most guys now won't do any research except to find a phone number of who they can call to ask.

An added difficulty to this, is that today's hotrodders aren't dealing with a simple TH400 or Powerglide that is entirely mechanical/hydraulic, they are dealing with late model electronically controlled transmissions that require at least a fundamental understanding of electronics, electrical diagnosis, and tools to do so. Many enthusiasts don't have the tools or capability to diagnose even basic electrical function.

A 4L60E or 4L80E doesn't function when a fuse is blown or an ignition switch has gone bad. If I sell a valve body, kit, or transmission to a customer, when they install it and it doesn't function, I'm the first person they call.

I didn't install it. I didn't take on the responsibility of installing it. I sold the component. I don't mind assisting when there is an issue, but when I start having to explain electrical circuits by relating to a light switch in a house to a customer, that customer needs to find a qualified technician to work on their car.

These modern cars aren't enthusiast friendly. It takes quite an investment in tools, software, and experience to really be good at working on them.

I can make WAY more money working on people's daily driver's as a general repair shop or regular transmission shop, than I do as a performance transmission shop. We do it because it's what we like doing (some days anyway...)

#30

That said,

due to demand I've considered revamping the parts sales and scaling it back to just a couple of kits, our transbrakes, the Griner TH400 transbrakes, and that is all with the caveat that sales are to professional installers only and there will be ZERO tech support provided beyond the instruction sheets.

One of the issues with parts sales is instructions. Some of the instructions I don't want to post online due to proprietary info or pictures. Some of my instructions need to be updated and improved. However no matter how good they are, someone will try to overthink them. They will want to add to or take away when it is not written in the instructions.

Mix and match other companies instructions.

If I were to write what really needed to be written to cover every installer, it would be a book. Most of our professional customers have no issues with the instructions. Some learn new tricks from them. We have other big name companies that use our parts and they rarely need tech help, when they do, it's most often their end user having electrical/tuning issues because they don't understand that aspect of it.

There are also interchange concerns with various year models. The 4L80E is an example. If a customer tells us they are using an early 91-96 core, the kit has different components than a 97-up kit. We often have customers give us bad info on the order and then want us to correct it later.

I had a customer recently order the wrong transmission. They ordered a 4L80E and then wondered why it wouldn't fit in place of a 4L60E, even after I specifically asked, "ARE YOU SURE, THAT DOESN'T SOUND RIGHT".

I spend about 6-7 hrs a day on the phone already, and parts sales don't justify the time they require.

So it's something I will continue to evaluate but at this time I think it was a good decision. It's better for our transmission customers AND my sanity.

due to demand I've considered revamping the parts sales and scaling it back to just a couple of kits, our transbrakes, the Griner TH400 transbrakes, and that is all with the caveat that sales are to professional installers only and there will be ZERO tech support provided beyond the instruction sheets.

One of the issues with parts sales is instructions. Some of the instructions I don't want to post online due to proprietary info or pictures. Some of my instructions need to be updated and improved. However no matter how good they are, someone will try to overthink them. They will want to add to or take away when it is not written in the instructions.

Mix and match other companies instructions.

If I were to write what really needed to be written to cover every installer, it would be a book. Most of our professional customers have no issues with the instructions. Some learn new tricks from them. We have other big name companies that use our parts and they rarely need tech help, when they do, it's most often their end user having electrical/tuning issues because they don't understand that aspect of it.

There are also interchange concerns with various year models. The 4L80E is an example. If a customer tells us they are using an early 91-96 core, the kit has different components than a 97-up kit. We often have customers give us bad info on the order and then want us to correct it later.

I had a customer recently order the wrong transmission. They ordered a 4L80E and then wondered why it wouldn't fit in place of a 4L60E, even after I specifically asked, "ARE YOU SURE, THAT DOESN'T SOUND RIGHT".

I spend about 6-7 hrs a day on the phone already, and parts sales don't justify the time they require.

So it's something I will continue to evaluate but at this time I think it was a good decision. It's better for our transmission customers AND my sanity.

#31

Man-Crush Warning

iTrader: (1)

While the wait for the trans was kinda a bummer, I think its worth it.

There are not many places these days where you can call the business and talk to the owner. And then for them to actually want to inform you of what you are asking in detail versus run you off the phone? Always impressive to me.

Top it off with a ton of helpful posts across the internet and I am sold.

There are not many places these days where you can call the business and talk to the owner. And then for them to actually want to inform you of what you are asking in detail versus run you off the phone? Always impressive to me.

Top it off with a ton of helpful posts across the internet and I am sold.

#32

#33

TECH Enthusiast

Good, honest replies Jake!

We do have a couple of 4l60e Vettes running hard, (low 9s@148 ish) at 3600lb race weight... But you are right, you'll spend a fortune to make one live, and even then, its probably on borrowed time.

Not a lot of options tho for the C5/C6 crowd.

We do have a couple of 4l60e Vettes running hard, (low 9s@148 ish) at 3600lb race weight... But you are right, you'll spend a fortune to make one live, and even then, its probably on borrowed time.

Not a lot of options tho for the C5/C6 crowd.