Pulling the engine - a little help here, please

#21

Launching!

iTrader: (2)

Join Date: Apr 2009

Location: Austin, TX

Posts: 218

Likes: 0

Received 0 Likes

on

0 Posts

I'm sorry we couldn't illustrate that point better but you now know why you have to pull the crossmember, or the tranny.

Crossmember bolts aren't that bad w/ a 3ft breaker bar.

I still think dropping it out of the bottom was pretty damn easy.

Crossmember bolts aren't that bad w/ a 3ft breaker bar.

I still think dropping it out of the bottom was pretty damn easy.

#22

Cadzila's Banned Troll Account

Join Date: Jan 2012

Location: Chicago NW Suburbs

Posts: 49

Likes: 0

Received 0 Likes

on

0 Posts

Made some progress last night, but in the end I think I found the answer to my "Why?" question. It appears to be a matter of oil pan vs. crossmember space. With the help of a 3" wide flat scaper/chisel thingy, I was able to get a gap started on the driver side, and then pryed a bit on each side and eventually got the bellhousing off the dowel pins. I've got about a 1.5" gap or thereabouts. However, I can't move the engine forward far enough to fully clear the transmission input shaft, because the sump of the oil pan hits the crossmember. I can't jack the engine up any farther because the bellhousing hits the top of the tranny tunnel at the firewall. The bellhousing isn't bolted to the engine anymore, but obviously everything needs to stay aligned until the input shaft is clear of the clutch.

(If one were to do this the "normal" way, the bellhousing would be tight to the back of the engine, and since the bellhousing slopes down a bit, as it comes forward with the engine you can jack the engine higher to get the oil pan over the crossmember. Hopefully that makes sense.)

So, I think I could drop the front crossmember just a bit - maybe an inch or so - and accomplish the mission. I'm guessing the crossmember bolts are torqued to 8 million ft-lb by the factory, though, so that may be easier said than done. Plus I'd have to rearrange my current jack stand and jack configuration, since the jack stands are under the crossmember as it sits now. If I have time to get at it tonight, I'll take a look at that route vs. the remove everything route and decide which path I want to take.

(If one were to do this the "normal" way, the bellhousing would be tight to the back of the engine, and since the bellhousing slopes down a bit, as it comes forward with the engine you can jack the engine higher to get the oil pan over the crossmember. Hopefully that makes sense.)

So, I think I could drop the front crossmember just a bit - maybe an inch or so - and accomplish the mission. I'm guessing the crossmember bolts are torqued to 8 million ft-lb by the factory, though, so that may be easier said than done. Plus I'd have to rearrange my current jack stand and jack configuration, since the jack stands are under the crossmember as it sits now. If I have time to get at it tonight, I'll take a look at that route vs. the remove everything route and decide which path I want to take.

sad, very sad

#23

TECH Addict

Thread Starter

iTrader: (19)

Join Date: Aug 2007

Location: Where the Navy tells me to go

Posts: 2,403

Received 106 Likes

on

88 Posts

I went ahead with the plan I mentioned a few nights ago. I loosened the 4 bolts that hold the front cross-member - as TexVette said, that was pretty easy with a jack handle / breaker bar. I unthreaded them to give about a 1" gap (cross-member was still on jack stands at that point). Then I removed the bolts that hold the steering shaft together (the cross-member doesn't need to be lowered enough that the shaft actually slides apart, just needed it loose so it could extend a bit). I popped the forward-most brake line clip out of the bottom of the passenger frame rail (since the ABS unit is mounted to the cross-member and the brake lines are all still connected I wanted to give the lines a bit more freedom to move). I then put two jack stands under the rocker sills (near the factory jack points), put a jack under the cross-member, jacked the front end up a little to move the jack stands out from under the cross-member, then lowered the jack under the cross-member. The car came to rest on the jack stands under the rocker sills, the cross-member dropped down, and the interference between the oil pan and cross-member was no more. Worked like a charm.

Obviously some clean up to do before the new engine goes in!

I've never done the method that others advocated, but I have to think dropping the cross-member like this is quicker/easier. The bolts for the cross-member are all easily accessible, as opposed to the tranny-to-bellhousing bolts, and there's no need to remove parts to access anything. Basically, it's just fewer things to mess with.

Last edited by AAIIIC; 04-10-2013 at 11:22 AM.

#28

TECH Addict

Thread Starter

iTrader: (19)

Join Date: Aug 2007

Location: Where the Navy tells me to go

Posts: 2,403

Received 106 Likes

on

88 Posts

Originally Posted by thebigjimsho

How's it going, Pat?

I need to rearrange the garage so I can better work on things. Should be able to get that done tonight, then perhaps move on to pulling out the stock cam.

Originally Posted by thebigjimsho

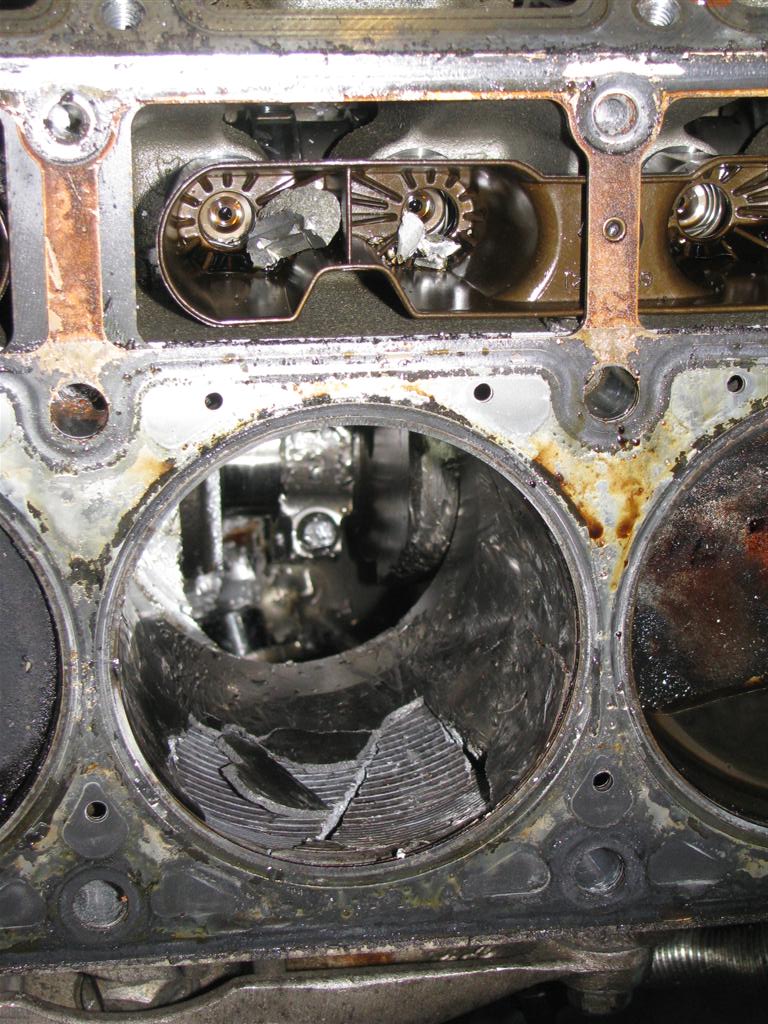

awful big hole in the side of the block....

Not only did it blow out the driver side of the block, but it nearly got the passenger side, too:

Where all the fun began:

(I didn't remove anything. The #5 piston was in pieces in the bottom of the pan, along with the #5 rod.)

#29

Launching!

I think since your car is down you should see if you could talk to bmr or someone about fabbing up a tubular k member for us, and send yours to them for mock up.........assumeing theyll pay shipping...lol

good luck on the car hope everything goes back in smoothly...

good luck on the car hope everything goes back in smoothly...

#30

TECH Addict

Thread Starter

iTrader: (19)

Join Date: Aug 2007

Location: Where the Navy tells me to go

Posts: 2,403

Received 106 Likes

on

88 Posts

After a few more months of procrastinating, long work hours, working on the other two cars, and waiting on parts, I finally got the new engine put together and just wanted to close the loop on this.

Yes.

The exhaust, driveshaft and transmission were never removed from the car, the bellhousing was never removed from the transmission, and the slave cylinder was never touched. I stabbed the input shaft into the clutch the same way I've done it on my Subaru - angle the rear of the engine down as you lower it into the engine bay, jack the front of the transmission up so the input shaft is at the proper angle, slide things together. It wasn't a cake walk, but if I managed to do it this way by myself, having never pulled an engine from one of these cars before, I'd say it can't be all that hard.

The exhaust, driveshaft and transmission were never removed from the car, the bellhousing was never removed from the transmission, and the slave cylinder was never touched. I stabbed the input shaft into the clutch the same way I've done it on my Subaru - angle the rear of the engine down as you lower it into the engine bay, jack the front of the transmission up so the input shaft is at the proper angle, slide things together. It wasn't a cake walk, but if I managed to do it this way by myself, having never pulled an engine from one of these cars before, I'd say it can't be all that hard.