Maggie HD tensioner DIY

#21

TECH Addict

Thread Starter

iTrader: (14)

Join Date: Feb 2007

Location: Owasso, OK

Posts: 2,342

Likes: 0

Received 0 Likes

on

0 Posts

Yes to all of the above.

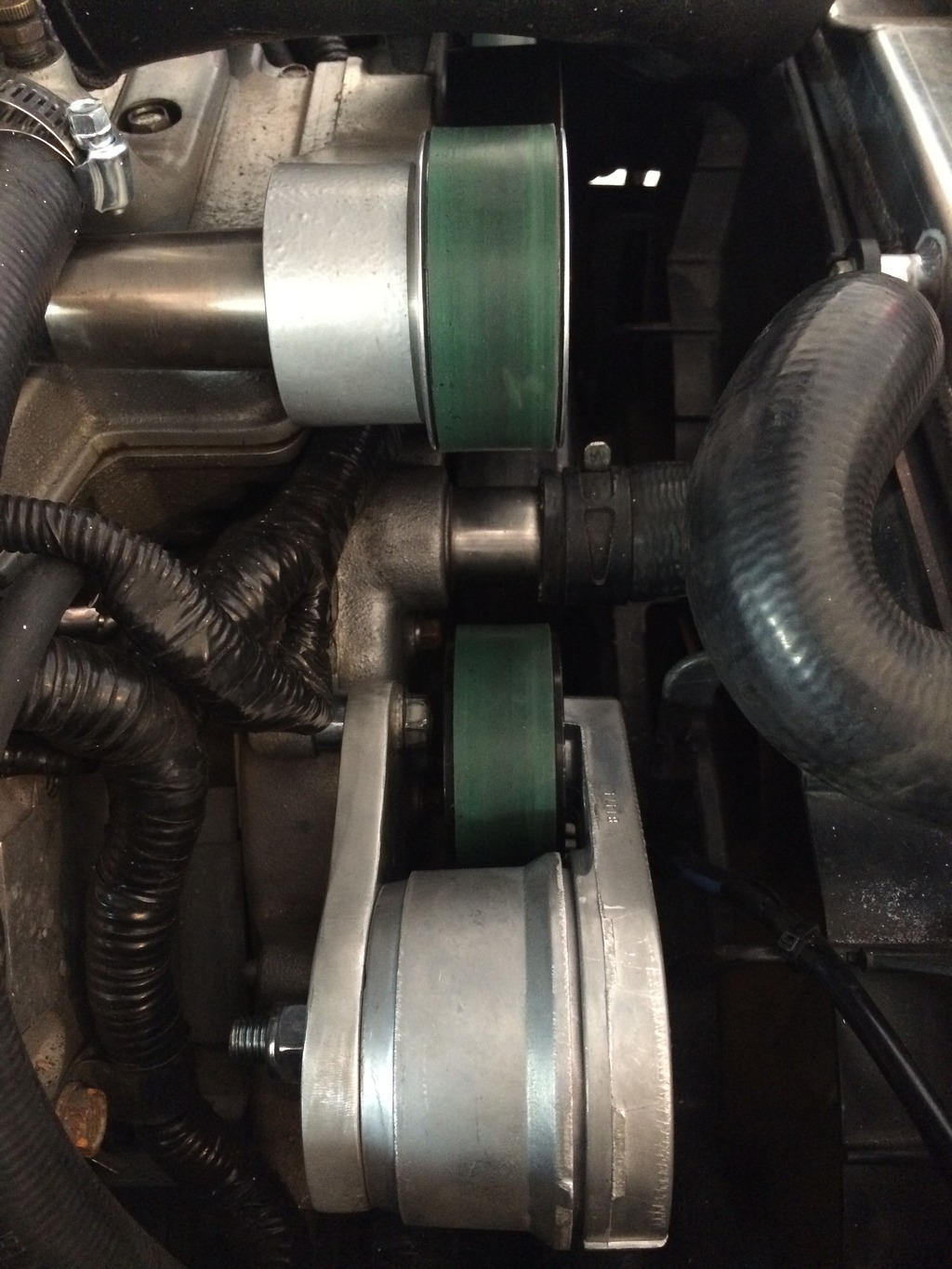

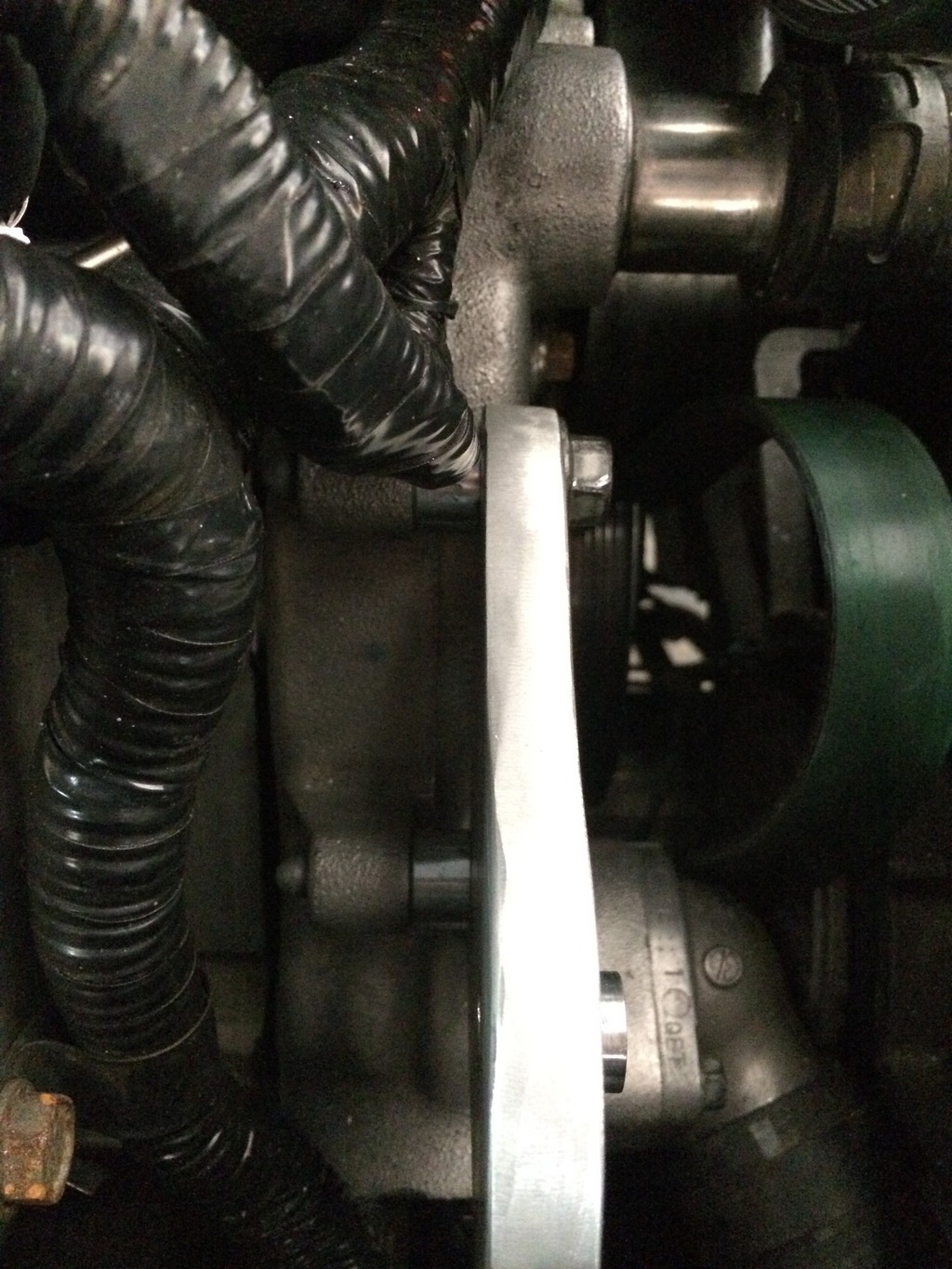

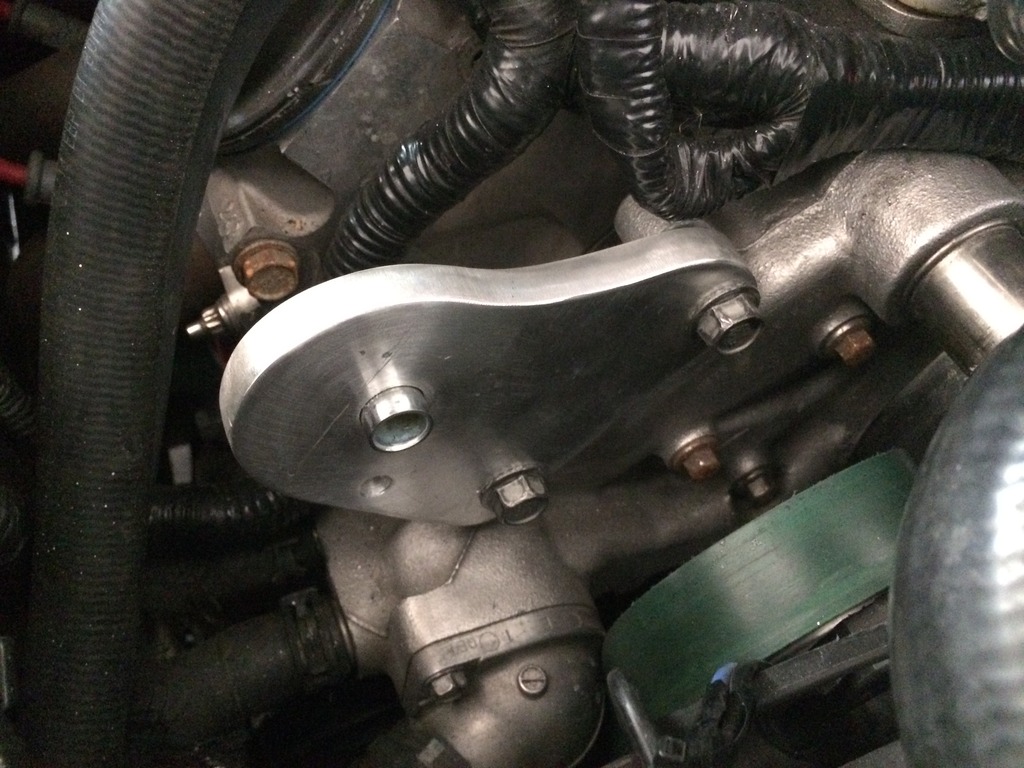

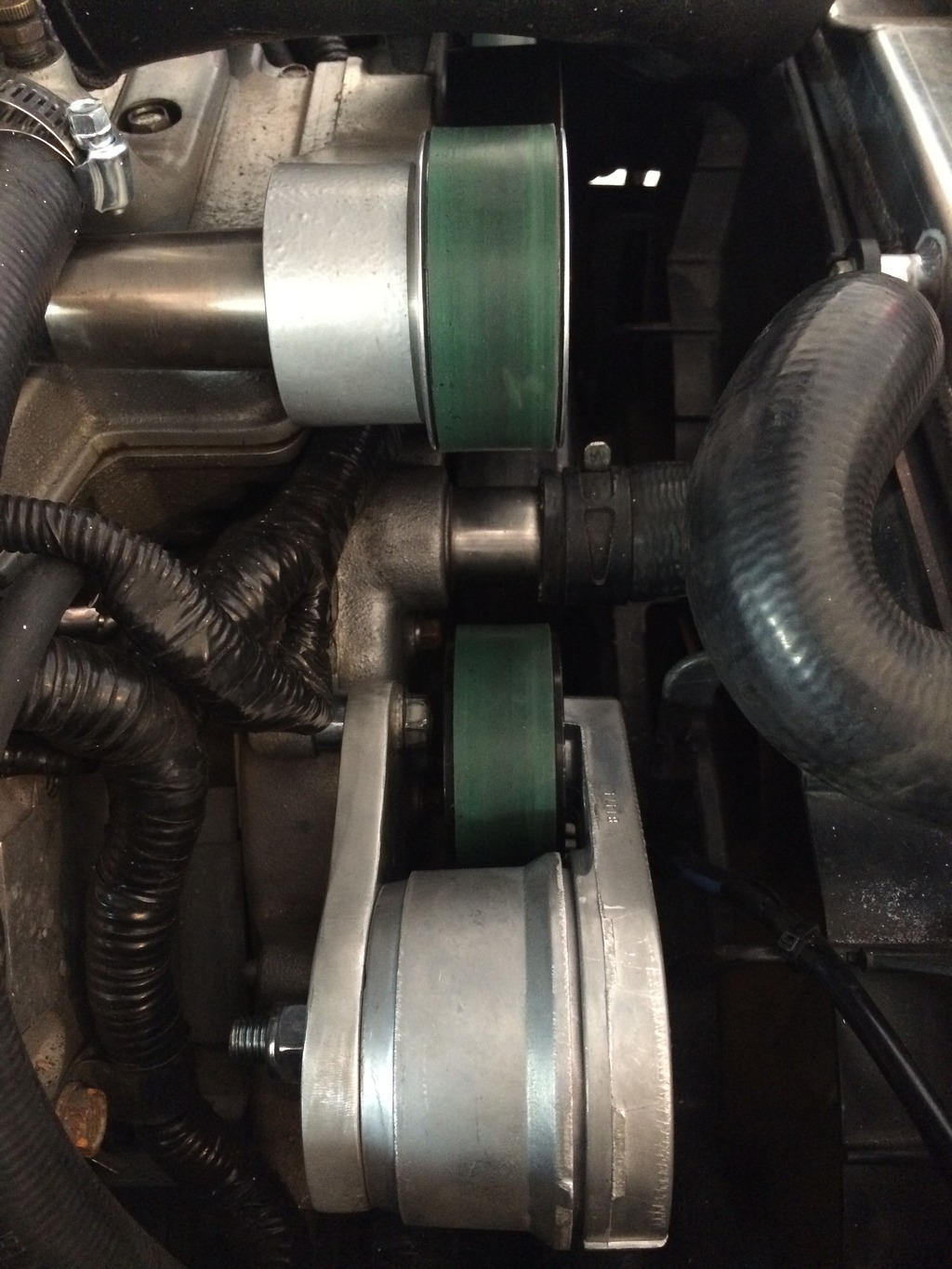

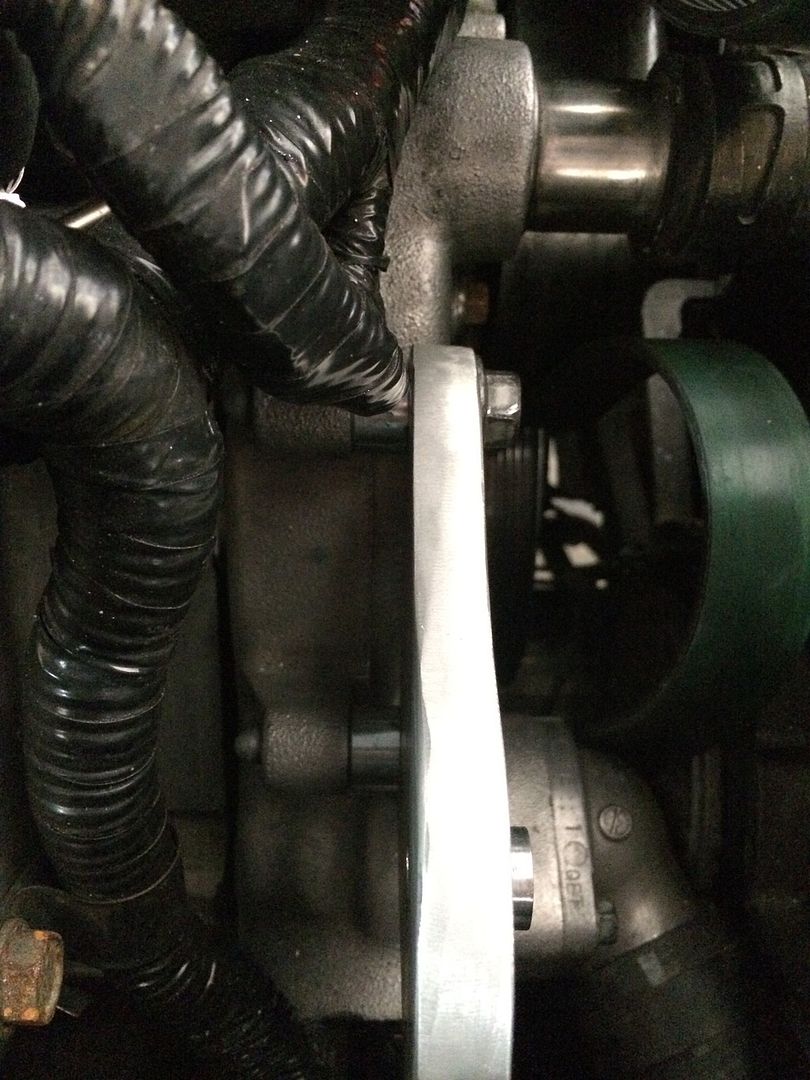

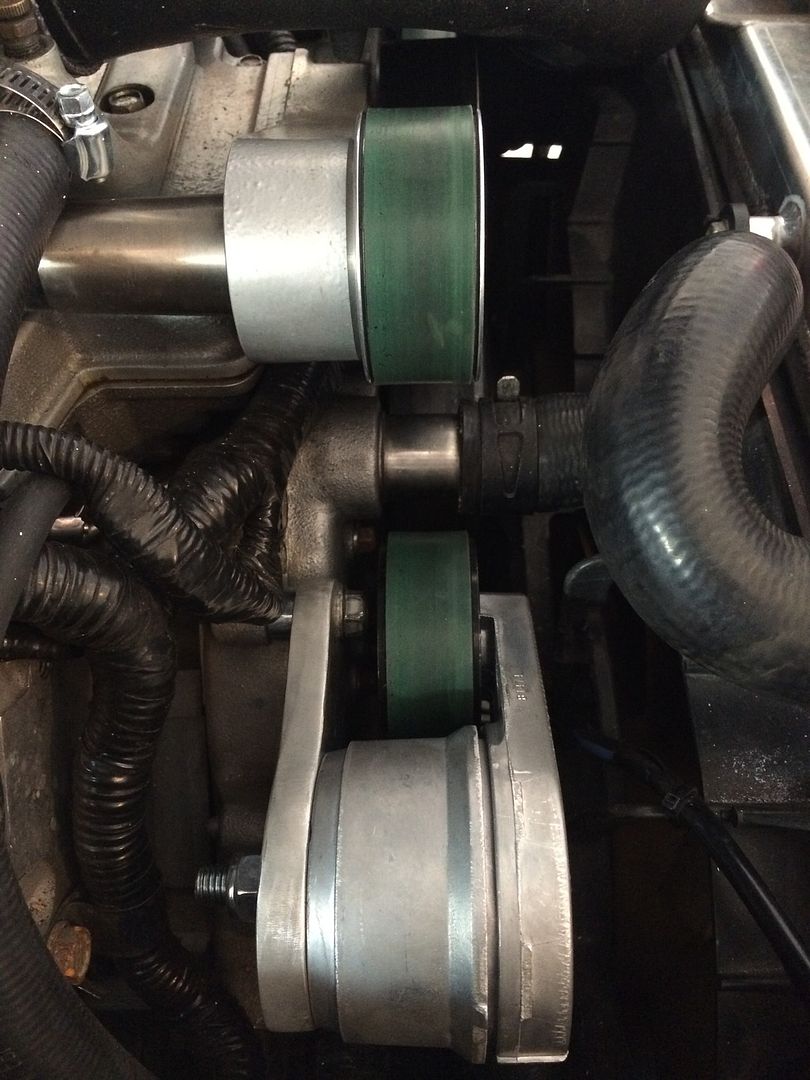

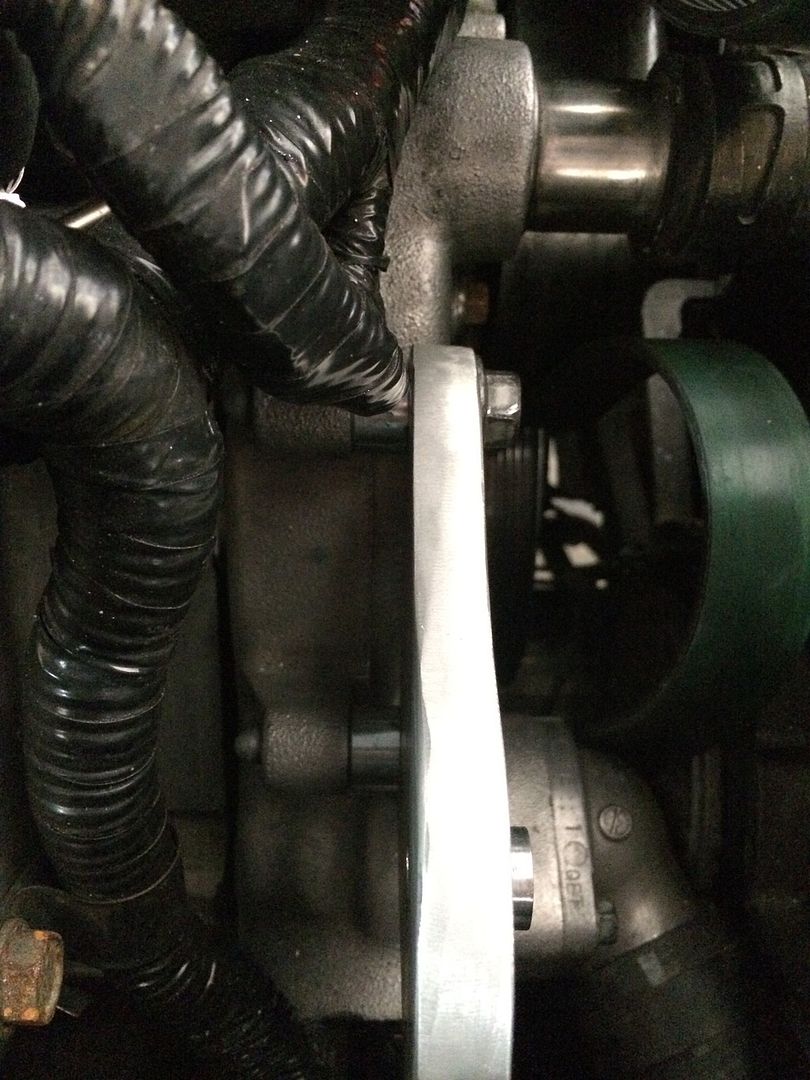

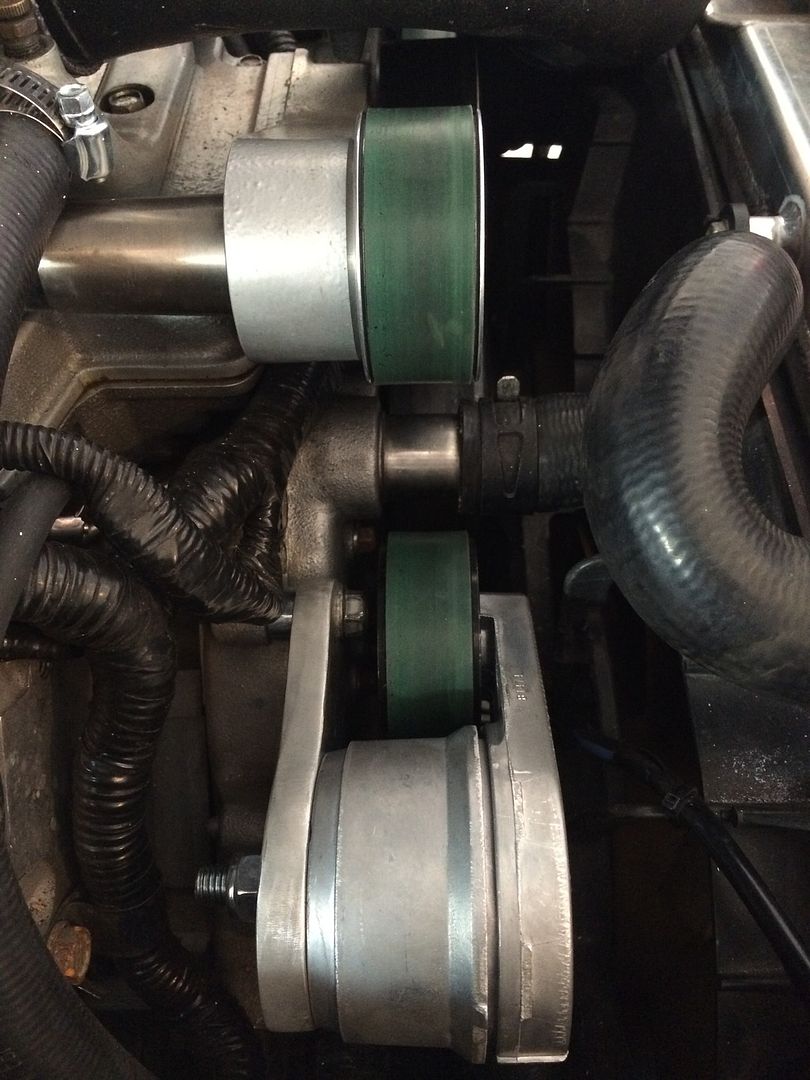

When installing the belt, it's easier to route the belt around the tensioner with the belt off the blower pulley. Then push the tensioner down and route around the blower and under the blower idler last.

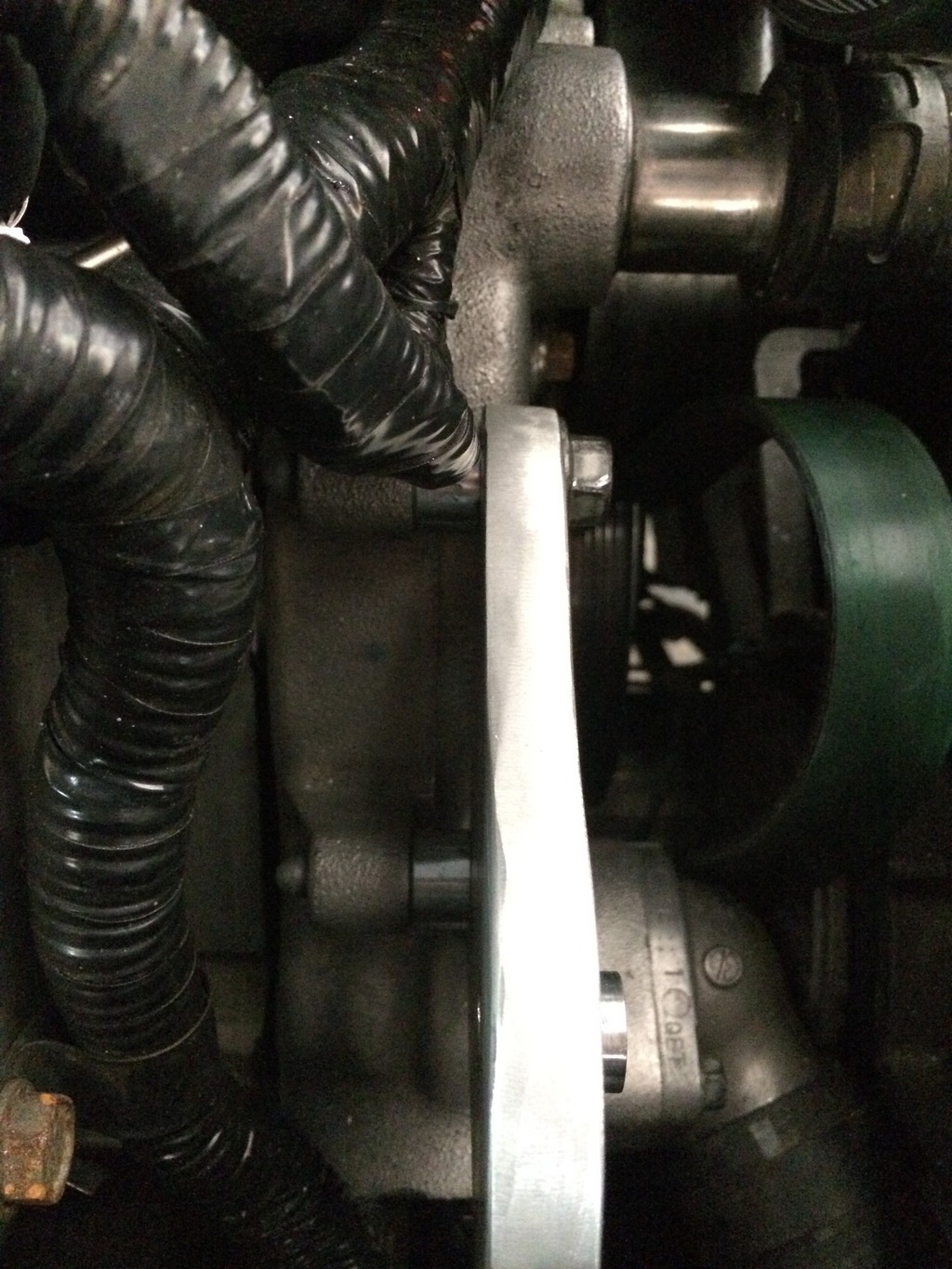

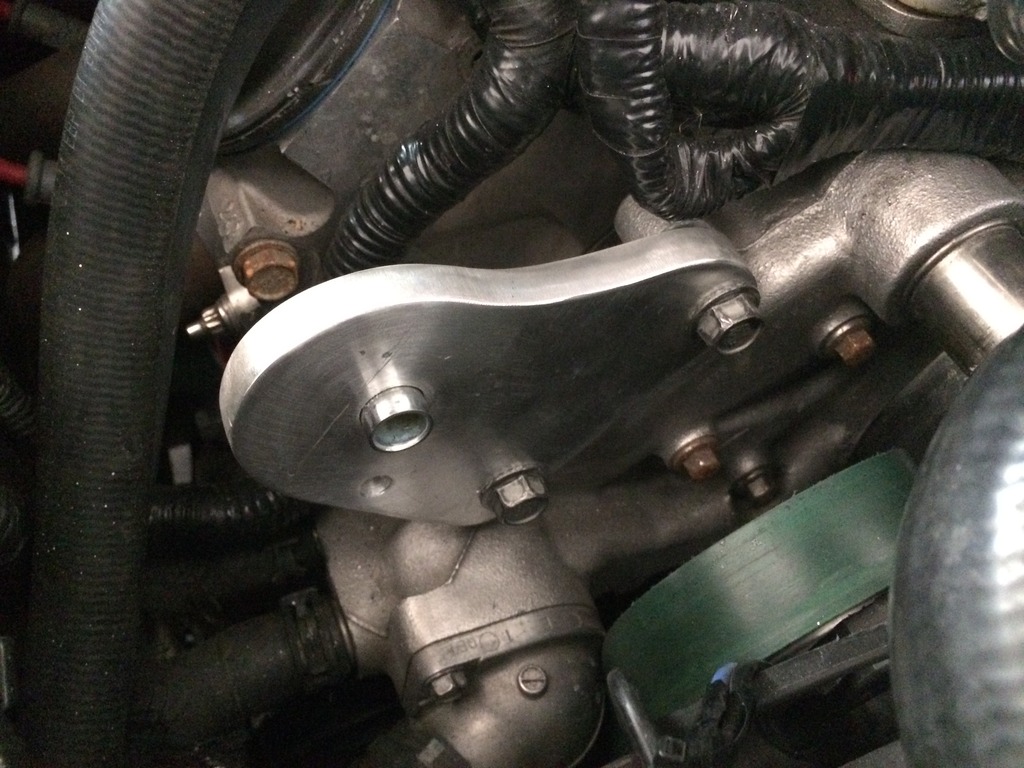

I actually made the bracket he is using. Here are some pics of it mocked up on my car. You may or may not need change belt length based on where you drill the tensioner locator hole. I set it up for my car because that's all I had to use, and the belt he was using is now too long. I run a 102.5 belt on mine. He had a 103.7. Since I have on overdriven crank and undersriven accessories, that 102.5 may or may not work with his.

When installing the belt, it's easier to route the belt around the tensioner with the belt off the blower pulley. Then push the tensioner down and route around the blower and under the blower idler last.

I actually made the bracket he is using. Here are some pics of it mocked up on my car. You may or may not need change belt length based on where you drill the tensioner locator hole. I set it up for my car because that's all I had to use, and the belt he was using is now too long. I run a 102.5 belt on mine. He had a 103.7. Since I have on overdriven crank and undersriven accessories, that 102.5 may or may not work with his.

Last edited by raven154; 05-25-2015 at 12:27 PM.

#22

TECH Fanatic

Yes to all of the above.

When installing the belt, it's easier to route the belt around the tensioner with the belt off the blower pulley. Then push the tensioner down and route around the blower and under the blower idler last.

I actually made the bracket he is using. Here are some pics of it mocked up on my car. You may or may not need change belt length based on where you drill the tensioner locator hole. I set it up for my car because that's all I had to use, and the belt he was using is now too long. I run a 102.5 belt on mine. He had a 103.7. Since I have on overdriven crank and undersriven accessories, that 102.5 may or may not work with his.

When installing the belt, it's easier to route the belt around the tensioner with the belt off the blower pulley. Then push the tensioner down and route around the blower and under the blower idler last.

I actually made the bracket he is using. Here are some pics of it mocked up on my car. You may or may not need change belt length based on where you drill the tensioner locator hole. I set it up for my car because that's all I had to use, and the belt he was using is now too long. I run a 102.5 belt on mine. He had a 103.7. Since I have on overdriven crank and undersriven accessories, that 102.5 may or may not work with his.

(Wish I had a darn Bridgeport.)

#23

TECH Addict

Thread Starter

iTrader: (14)

Join Date: Feb 2007

Location: Owasso, OK

Posts: 2,342

Likes: 0

Received 0 Likes

on

0 Posts

5x5 would be perfect and it's .5" thick. I'm pretty sure my spacers where around .460 but I don't remember now. I'll pull on out and measure. And me too on the Bridgeport lol I cut it out with a band saw and shaped it with a flap wheel on my 4" grinder. All the drilling was by hand.

#24

TECH Fanatic

5x5 would be perfect and it's .5" thick. I'm pretty sure my spacers where around .460 but I don't remember now. I'll pull on out and measure. And me too on the Bridgeport lol I cut it out with a band saw and shaped it with a flap wheel on my 4" grinder. All the drilling was by hand.

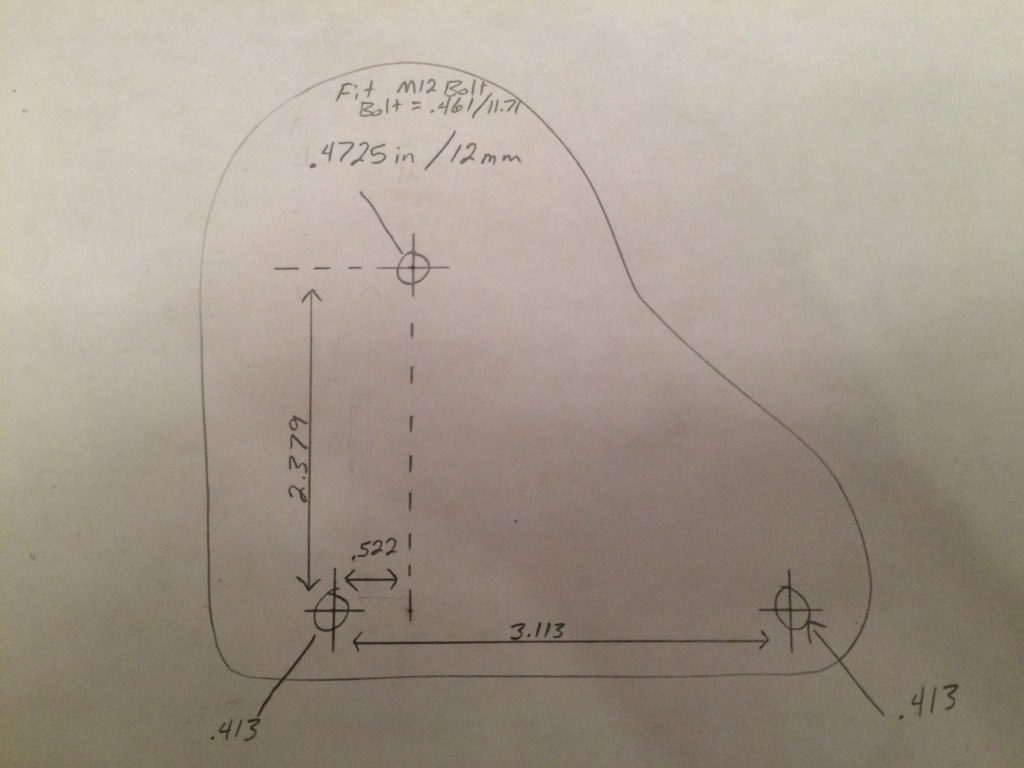

Do you have center-to-center dimension of the two mounting holes? Dia? And maybe a triangulation of the hole to keep the tensioner from rotating? (I realize that last hole location affects the amount of belt tension applied as the tensioner is loaded and isn't quantified here.)

#25

TECH Addict

Thread Starter

iTrader: (14)

Join Date: Feb 2007

Location: Owasso, OK

Posts: 2,342

Likes: 0

Received 0 Likes

on

0 Posts

Cool. I've got a drill press, but no band saw. I'll figure something out.

Do you have center-to-center dimension of the two mounting holes? Dia? And maybe a triangulation of the hole to keep the tensioner from rotating? (I realize that last hole location affects the amount of belt tension applied as the tensioner is loaded and isn't quantified here.)

Do you have center-to-center dimension of the two mounting holes? Dia? And maybe a triangulation of the hole to keep the tensioner from rotating? (I realize that last hole location affects the amount of belt tension applied as the tensioner is loaded and isn't quantified here.)

#26

TECH Fanatic

#27

TECH Addict

Thread Starter

iTrader: (14)

Join Date: Feb 2007

Location: Owasso, OK

Posts: 2,342

Likes: 0

Received 0 Likes

on

0 Posts

No, that is a hardware store spacer I pressed in to engage the back of the tensioner. It isn't needed, just something extra I did to make fit and finish a little better. The one on my car doesn't have this.

#28

I have to give credit where its due.

The OP (Bobby) is a pretty smart car guy, and was great to deal with re-tensioner. He comes from a good family, and was very helpful and I'd like to say thanks again Bobby.

I had a 103.7 belt prior to this, but I think I might have to go down to a 101.5. I think my belt was long prior or it stretched but regardless the 103.5 is too long.

The new tensioner at idle and a quick stab of the throttle is much more secure, and doesn't walk like the crap one from the kit.

And I must say the tensioner is made in CANADA. Do I need to say anymore?

The OP (Bobby) is a pretty smart car guy, and was great to deal with re-tensioner. He comes from a good family, and was very helpful and I'd like to say thanks again Bobby.

I had a 103.7 belt prior to this, but I think I might have to go down to a 101.5. I think my belt was long prior or it stretched but regardless the 103.5 is too long.

The new tensioner at idle and a quick stab of the throttle is much more secure, and doesn't walk like the crap one from the kit.

And I must say the tensioner is made in CANADA. Do I need to say anymore?

#29

TECH Fanatic

EDIT: Okay. Just ordered the tensioner and a piece of aluminum for the bracket. Gotta wait to see what belt's gonna work.

Last edited by rand49er; 05-27-2015 at 12:10 PM. Reason: add a line

#30

What size belt are you running now?

#34

TECH Fanatic

I can't start this tensioner conversion yet. My car goes into the dealer tomorrow am to get the fuel pump recall done.

#35

TECH Addict

Thread Starter

iTrader: (14)

Join Date: Feb 2007

Location: Owasso, OK

Posts: 2,342

Likes: 0

Received 0 Likes

on

0 Posts

Sorry haven't been able to get the measurements yet. My shop flooded with all this rain we have been having. I had to pull everything out. While everything was out I power washed the floor. Then while I was moving some stuff around trying to get it ready to go back in the shop, my backhoe broke and now I don't have any steering. Made moving stuff back in a real pain.

#36

TECH Fanatic

Bought a little, used, 9" band saw today.

The more I think about this, depending on the belt size, is it possible to pin the tensioner to such a degree that too much load is put on the accessories and cause bearing failure in one or more of them?

I suppose I could provide for multiple pinning location holes so as to "adjust" the belt tension for a given belt size.

Anybody else play with this a bit?

The more I think about this, depending on the belt size, is it possible to pin the tensioner to such a degree that too much load is put on the accessories and cause bearing failure in one or more of them?

I suppose I could provide for multiple pinning location holes so as to "adjust" the belt tension for a given belt size.

Anybody else play with this a bit?

#37

TECH Addict

Thread Starter

iTrader: (14)

Join Date: Feb 2007

Location: Owasso, OK

Posts: 2,342

Likes: 0

Received 0 Likes

on

0 Posts

I don't think you could over load the bearings with an automatic tensioner like this. To do something like that you would need a manual tensioner and to really crank it down.

#38

#40

TECH Fanatic