I want to run a mechanical water gauge on my LS1. HOW?

#42

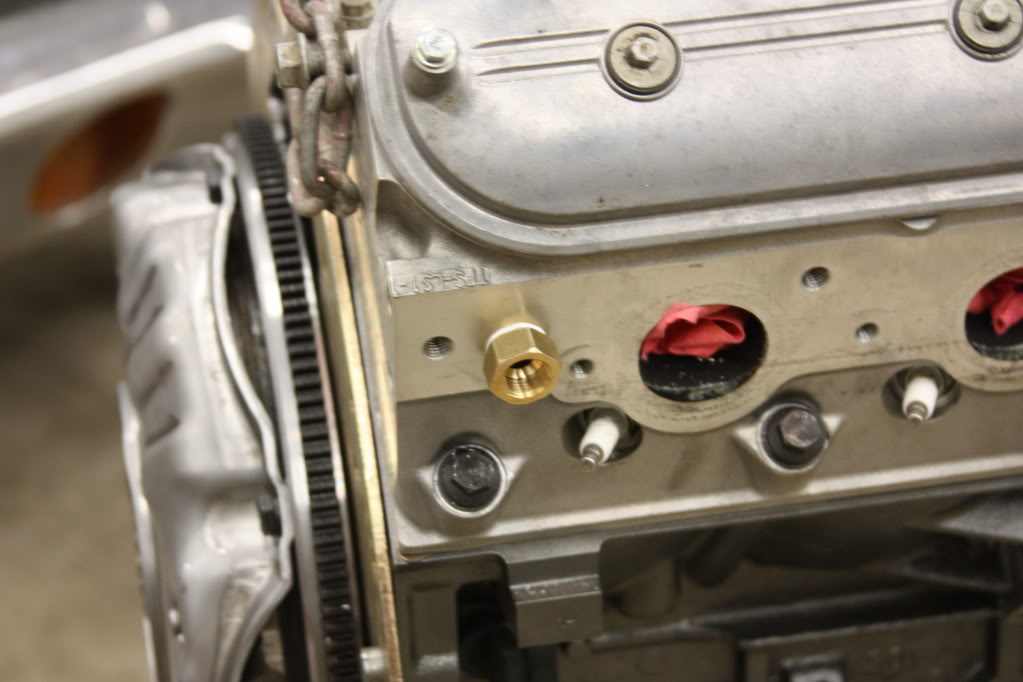

I used my oil pressure sensor that came on my engine (the salvage yard broke it). I then cleaned the rest of the plastic stuff off and drilled and tapped it for 1/8" npt. (which usually come with your gauge) I'll take a pic here in a few and post it up.

#43

I am pretty sure if you get the one that 71ANTICARB is talking about it is for a electrical sending unit and it will not allow that bulbous sending unit from the mechanical gauge fit, the 2 fittings on the left is a 1/2 and 3/8 adaptor either one of those will fit into the S&P adaptor that I am talking about. I would go with the 1/2 as I said it is not the cleanest installation as it is big due to the mechanical sending unit, I eventually spent a little more and got the more expensive electrical water temp gauge as it is a cleaner installation and works with the adaptor that 71ANTICARB is talking about and it is alot easier to hide the sending unit wire versus that ugly mechanical sending unit cable thing.

#45

I don't think so the mechanical sending unit probe is at least 1.5-2.0 inches long it is not going to fit into that adaptor you are looking at, that one will work fine for a electrical gauge sending unit. The mechanical one is much bigger and will not let the probe fit through, I'm done good luck to the op on whatever he chooses.

#51

On The Tree

iTrader: (4)

My sending unit that I pictured is 5/8 - 18. The two adapters I pictured are 3/8 and 1/2 npt. So i'll wait till the adapters I ordered come in and see how it works. Worst comes to worst i'll splice my upper radiator hose with the 5/8 - 18 thread. Although I really would rather read the temp from the head.

#57

On The Tree

iTrader: (4)

Nope didn't order it. But they advertise its longer to accommodate the huge sensor. Although I can't see much benefit if the sensor doesn't fit through the 12mm adapter.

Ive been doing some wiring harness research and I'm going to try electric gauges for now. I'll tap the head when I rebuild the motor in a few years.

Ive been doing some wiring harness research and I'm going to try electric gauges for now. I'll tap the head when I rebuild the motor in a few years.

#58

I am pretty sure if you get the one that 71ANTICARB is talking about it is for a electrical sending unit and it will not allow that bulbous sending unit from the mechanical gauge fit, the 2 fittings on the left is a 1/2 and 3/8 adaptor either one of those will fit into the S&P adaptor that I am talking about. I would go with the 1/2 as I said it is not the cleanest installation as it is big due to the mechanical sending unit, I eventually spent a little more and got the more expensive electrical water temp gauge as it is a cleaner installation and works with the adaptor that 71ANTICARB is talking about and it is alot easier to hide the sending unit wire versus that ugly mechanical sending unit cable thing.

#59

Ok I'll give ya that one. I still don't see how the S&P one would be any different. Do you have a pic of it.

Here I just made this thread:

https://ls1tech.com/forums/conversio...l#post14906867

Here I just made this thread:

https://ls1tech.com/forums/conversio...l#post14906867

#60

Ok I'll give ya that one. I still don't see how the S&P one would be any different. Do you have a pic of it.

Here I just made this thread:

https://ls1tech.com/forums/conversio...l#post14906867

Here I just made this thread:

https://ls1tech.com/forums/conversio...l#post14906867