View Poll Results: Which lines would be the easiest and last ??

Voters: 12. You may not vote on this poll

Looking for opinions on fuel line options

#1

Launching!

Thread Starter

Join Date: Jun 2005

Location: Chicago Area

Posts: 267

Likes: 0

Received 0 Likes

on

0 Posts

I'm trying to get a feel for what my best option here is for my 2nd LS swap.

I have a 1970 Olds 442 clone, and need new fuel lines for it.

My last swap I did all braided lines with Russell -6AN fittings front to back.

Afterwards I've read from various people that the rubber will deteriorate

and I'd have to replace it after a few years. Not sure how true that is.

So heres my options.....

#1. Stainless = Hard to bend, seems to be a real pain to flare as well.

#2. Steel lines = need a special flaring kit that costs $$$ ??

#3. Aluminum = Race only or street viable ?? What grades to look for ??

#4. EFI Braided hose line = I've been told this isn't reliable long term

I'm looking into something that's good enough up to 500hp, no drag racing.

Strictly a pro-touring cruiser for my little guy and the wife n me.

Any opinions on recommended fuel line options are welcome.

I saw GatTogaO's fuel setup in his GTO conversion with all solid lines and

compression fittings. Are compression's one time use deals or can you loosen

them and reuse them??

I have a 1970 Olds 442 clone, and need new fuel lines for it.

My last swap I did all braided lines with Russell -6AN fittings front to back.

Afterwards I've read from various people that the rubber will deteriorate

and I'd have to replace it after a few years. Not sure how true that is.

So heres my options.....

#1. Stainless = Hard to bend, seems to be a real pain to flare as well.

#2. Steel lines = need a special flaring kit that costs $$$ ??

#3. Aluminum = Race only or street viable ?? What grades to look for ??

#4. EFI Braided hose line = I've been told this isn't reliable long term

I'm looking into something that's good enough up to 500hp, no drag racing.

Strictly a pro-touring cruiser for my little guy and the wife n me.

Any opinions on recommended fuel line options are welcome.

I saw GatTogaO's fuel setup in his GTO conversion with all solid lines and

compression fittings. Are compression's one time use deals or can you loosen

them and reuse them??

#2

On The Tree

iTrader: (5)

Join Date: Jun 2008

Location: Loveland, Ohio

Posts: 145

Likes: 0

Received 0 Likes

on

0 Posts

I'll vote for braided stainless, but use the Teflon Lined kind with the appropriate fittings. This prevents to issues of wear that you are concerned about and also avoids the gas-smell problem.

It;s easy to assemble, but one of the more expensive routes to choose.

It;s easy to assemble, but one of the more expensive routes to choose.

#4

One other option is Copper-Nickel tubing

http://www.fedhillusa.com/

http://www.mamut.net/automec/shop/

Most places sell it as brake line but works just as well for gas lines. Pricey, but a dream to work with. Bends and flares with even cheapo tools and is suppose to be indestructible. I ordered mine from the England link above. Even with shipping it was actually cheaper than the USA link above. I got it two days after I ordered it.

I would echo what the other guys have said about teflon line vs. just rubber. If you ever plan on racing the car you might want to check into the class rules first. Some racing groups only allow so many inches of rubber fuel line.

From what buddies have told me Aluminum line can work harden and crack if it is allowed to move. If you go that route make sure you secure the line really well. Probably the most common fuel line used.

I hadn't thought about using the plastic fuel line that gary 68 linked to. Not sure what to make of that option.

http://www.fedhillusa.com/

http://www.mamut.net/automec/shop/

Most places sell it as brake line but works just as well for gas lines. Pricey, but a dream to work with. Bends and flares with even cheapo tools and is suppose to be indestructible. I ordered mine from the England link above. Even with shipping it was actually cheaper than the USA link above. I got it two days after I ordered it.

I would echo what the other guys have said about teflon line vs. just rubber. If you ever plan on racing the car you might want to check into the class rules first. Some racing groups only allow so many inches of rubber fuel line.

From what buddies have told me Aluminum line can work harden and crack if it is allowed to move. If you go that route make sure you secure the line really well. Probably the most common fuel line used.

I hadn't thought about using the plastic fuel line that gary 68 linked to. Not sure what to make of that option.

#5

Launching!

Thread Starter

Join Date: Jun 2005

Location: Chicago Area

Posts: 267

Likes: 0

Received 0 Likes

on

0 Posts

Another possibility, OEM nylon. Cheap, simple, reliable, on every car these days.

http://www.midwayautosupply.com/m-11...aspx?pagenum=3

http://www.midwayautosupply.com/m-11...aspx?pagenum=3

I had no clue where to look for the nylon stuff.

Looking at this the prices are the same as the Russell Aluminum stuff.

What did you use for yours??

Last edited by Aceshigh; 07-20-2011 at 07:11 PM.

#6

Aces...I first bought the stainless fuel line and bent it up all pretty with 37 degree flares, etc. Looked great! I had to make it in three sections so thats what...6 b-nuts. When it came time to check for leaks...yep...you guessed it. Every one of my hard line connections leaked. I bought some conical seals and used those on the hardline on the firewall but the rest of it I yanked out and ran one piece of teflon lined braided stainless. Man! I wish I had done that to start with! Way easier and looks just as good. But use teflon lined!

Do you have a build thread on your 442?

Do you have a build thread on your 442?

#7

TECH Addict

iTrader: (10)

Use regular steel or stainless steel hard line. I have used 3/8" steel brake line with good results. Advance sells line with a green coating on the outside that seems to be pretty tough, so I usually use that. If you want something with an OEM look, you can get 3/8" brake line with a zinc finish at other parts stores.

Also, consider making up your lines and having someone else flare them. Any time I need a critical flare done, I go to my local Parker store. They have some nice tools and make perfect flares every time. I think I get charged a little over $1 per flare, which is cheap. I have never had a leak on a connection where the Parker store made the flare!

I think there's a rule of thumb that compression fittings should not be used on fuel lines, but people still do it. I have been using a stainless Swagelok union on my system (which is a 2-ferrule compression fitting) and so far it's been fine.

Overall, I feel like steel is the best choice. It's tough, reasonably easy to work with and flare, readily available, and inexpensive. If you garage your car and keep it out of the weather, stainless probably isn't necessary.

Also, consider making up your lines and having someone else flare them. Any time I need a critical flare done, I go to my local Parker store. They have some nice tools and make perfect flares every time. I think I get charged a little over $1 per flare, which is cheap. I have never had a leak on a connection where the Parker store made the flare!

I think there's a rule of thumb that compression fittings should not be used on fuel lines, but people still do it. I have been using a stainless Swagelok union on my system (which is a 2-ferrule compression fitting) and so far it's been fine.

Overall, I feel like steel is the best choice. It's tough, reasonably easy to work with and flare, readily available, and inexpensive. If you garage your car and keep it out of the weather, stainless probably isn't necessary.

Trending Topics

#8

TECH Addict

iTrader: (3)

Another possibility, OEM nylon. Cheap, simple, reliable, on every car these days.

http://www.midwayautosupply.com/m-11...aspx?pagenum=3

http://www.midwayautosupply.com/m-11...aspx?pagenum=3

#9

Launching!

Thread Starter

Join Date: Jun 2005

Location: Chicago Area

Posts: 267

Likes: 0

Received 0 Likes

on

0 Posts

Aces...I first bought the stainless fuel line and bent it up all pretty with 37 degree flares, etc. Looked great! I had to make it in three sections so thats what...6 b-nuts. When it came time to check for leaks...yep...you guessed it. Every one of my hard line connections leaked. I bought some conical seals and used those on the hardline on the firewall but the rest of it I yanked out and ran one piece of teflon lined braided stainless. Man! I wish I had done that to start with! Way easier and looks just as good. But use teflon lined!

So here's the next questions.

How did you lay it out ?? Was it pre-bent ?? Excuse this question I'm a friggin tard with a billion options to choose from. I'm trying to figure out what's the best , and most IN-expensive way to get new fuel lines. I'm not sure what the purpose of braiding is on a stainless or regular steel line. Scuff prevention??

I was thinking hard lines with russell connections from the Regulator to the front only. Then braided rubber for the flexible last 2 feet up to the frame rail. Then for the regulators 2 lines BACK to the tank, I wasn't sure yet.

Do you have a build thread on your 442?

Here ya go. https://ls1tech.com/forums/conversio...l#post15176720

Harley, Harley, Hayabusa. LOL.....they get priority.

I need to move to a bigger house but we're trapped by the market at the moment.

My 42 year old OEM Steel fuel lines have lasted this long, so I'm thinking Stainless isn't necessary but obviously it would be nice.

BTW What is a "Parker Store" ? Hydraulic supply or something ??

Last edited by Aceshigh; 07-20-2011 at 10:36 PM.

#10

TECH Addict

iTrader: (10)

How did you lay it out ?? Was it pre-bent ?? Excuse this question I'm a friggin tard with a billion options to choose from. I'm trying to figure out what's the best , and most IN-expensive way to get new fuel lines. I'm not sure what the purpose of braiding is on a stainless or regular steel line. Scuff prevention??

If you make your own hard lines, try to make them follow the original location of the factory fuel lines. Looking at your build thread, you're capable of bending your own lines. Get a tubing bender (can be bought cheap off Summit, eBay, etc) and make them one bend at a time. Remember that saying "measure twice, cut once?" Well I measure about 10 times and then bend. With a little practice, you'll get comfortable with the bender. If you mess up, steel tube is pretty cheap. You can also make it in segments and put the segments together with a union. Above all, take your time. Before you make a bend, figure out what the tube will look like after the bend, and make sure that's what you want!

I have never seen stainless braiding over a hard steel fuel line - but that doesn't mean it's not out there! Maybe for heat protection? I doubt it's abrasion resistance, as any motion would also cut through the steel line.

Parker is a company that makes a wide variety of fittings, tube, hose, etc, mostly for industrial use. They're similar to the Eaton/Aeroquip/Weatherhead family of products. Parker has their own stores (maybe franchised?) all over the US that sell all Parker products. I have used their stores in several states and every one was excellent with knowledgeable staff, etc.

#11

sawzall wielding director

iTrader: (4)

I haven`t made up my mind yet.

On my el camino swap I used regular steel hardline and some pieces of the OEM nylon line for the flex sections. I double flared the ends and used small sections of steel line cut off junkyard cars that had the correct quick connect flares. This setup was dirt cheap but I was always a little worried about rust cause my brake lines are steel and I end up replacing at least one of them every couple years. I haven`t had any problems yet though. Only thing I really didn`t like is some of the plastic lines I picked up had bends molded in and theres no way to get rid of that.

My brother did his 78 buick from front to back with OEM nylon lines. Best setup yet. The only issue is that he had a very easy time. The gas tank and fuel lines from a 94-96 LT1 B-Body are the exact length needed and the bends are perfect. So his looks and functions like the OEM designed it to be there. If you were doing a B-Body swap thats the way to go.

Stainless is a great option but its a PITA to work with. On my next swap I`m torn between doing stainless or plastic. Neither one bends easily (but I have heard you can bend the plastic pretty tight if you use a heatgun and patience.

I would avoid aluminum as I have not yet found an aluminum fuel line that was rated for 60psi. Most are only rated to 35psi.

Braided line seems pretty expensive to me and then I would worry about the rubber degrading.

On my el camino swap I used regular steel hardline and some pieces of the OEM nylon line for the flex sections. I double flared the ends and used small sections of steel line cut off junkyard cars that had the correct quick connect flares. This setup was dirt cheap but I was always a little worried about rust cause my brake lines are steel and I end up replacing at least one of them every couple years. I haven`t had any problems yet though. Only thing I really didn`t like is some of the plastic lines I picked up had bends molded in and theres no way to get rid of that.

My brother did his 78 buick from front to back with OEM nylon lines. Best setup yet. The only issue is that he had a very easy time. The gas tank and fuel lines from a 94-96 LT1 B-Body are the exact length needed and the bends are perfect. So his looks and functions like the OEM designed it to be there. If you were doing a B-Body swap thats the way to go.

Stainless is a great option but its a PITA to work with. On my next swap I`m torn between doing stainless or plastic. Neither one bends easily (but I have heard you can bend the plastic pretty tight if you use a heatgun and patience.

I would avoid aluminum as I have not yet found an aluminum fuel line that was rated for 60psi. Most are only rated to 35psi.

Braided line seems pretty expensive to me and then I would worry about the rubber degrading.

#12

Launching!

Thread Starter

Join Date: Jun 2005

Location: Chicago Area

Posts: 267

Likes: 0

Received 0 Likes

on

0 Posts

Okay, I spoke with Camcojb (Jody) and got MOST of this worked out.

I was confused, when people said "Teflon coated , stainless steel lines"

I thought they were Stainless lines with an inner lining of Teflon/PTFE.

Now I understand that Teflon is a DUPONT owned name for PTFE lines.

Samething, and I also now understand that these are PTFE lines with a stainless

steel braiding OVER them. I was confused on that part, and now I get it.

I also read a post by Lonnies Performance where he said only black PTFE

is designed for fuels. Not sure how true that is but I asked him for a quote.

So I'm going to do hard lines the length of the car.

Three feet from the tank I'll mount the regulator, and put hard lines from there

going up to the firewall. Then I'll do a PTFE stainless line from there up to the

fuel rail. Also on the tank to regulator I'll do PTFE Stainless lines. Thanks for

the help guys.

BTW I found a Parker hydraulic supply not too far from me.= in Elk Grove.

Never knew what they were. Thanks.

I was confused, when people said "Teflon coated , stainless steel lines"

I thought they were Stainless lines with an inner lining of Teflon/PTFE.

Now I understand that Teflon is a DUPONT owned name for PTFE lines.

Samething, and I also now understand that these are PTFE lines with a stainless

steel braiding OVER them. I was confused on that part, and now I get it.

I also read a post by Lonnies Performance where he said only black PTFE

is designed for fuels. Not sure how true that is but I asked him for a quote.

So I'm going to do hard lines the length of the car.

Three feet from the tank I'll mount the regulator, and put hard lines from there

going up to the firewall. Then I'll do a PTFE stainless line from there up to the

fuel rail. Also on the tank to regulator I'll do PTFE Stainless lines. Thanks for

the help guys.

BTW I found a Parker hydraulic supply not too far from me.= in Elk Grove.

Never knew what they were. Thanks.

Last edited by Aceshigh; 07-21-2011 at 05:36 AM.

#13

TECH Junkie

iTrader: (1)

If you look at the price of the line itself, the nylon is a lot cheaper.

If you add up the adapters, connectors, etc for the AN fittings, you'll find the nylon fittings end up cheaper too.

I used stainless braided short lines at the tank and the fuel rail. I used 3/8" hardline with 37 degree flairs through the car.

If I had to do it again, I would just go with all nylon line/fittings.

If you add up the adapters, connectors, etc for the AN fittings, you'll find the nylon fittings end up cheaper too.

I used stainless braided short lines at the tank and the fuel rail. I used 3/8" hardline with 37 degree flairs through the car.

If I had to do it again, I would just go with all nylon line/fittings.

#14

Launching!

Thread Starter

Join Date: Jun 2005

Location: Chicago Area

Posts: 267

Likes: 0

Received 0 Likes

on

0 Posts

If you look at the price of the line itself, the nylon is a lot cheaper.

If you add up the adapters, connectors, etc for the AN fittings, you'll find the nylon fittings end up cheaper too.

I used stainless braided short lines at the tank and the fuel rail. I used 3/8" hardline with 37 degree flairs through the car.

If I had to do it again, I would just go with all nylon line/fittings.

If you add up the adapters, connectors, etc for the AN fittings, you'll find the nylon fittings end up cheaper too.

I used stainless braided short lines at the tank and the fuel rail. I used 3/8" hardline with 37 degree flairs through the car.

If I had to do it again, I would just go with all nylon line/fittings.

Gary,

You were 100% right.

The initial link you posted I thought that was the price PER fitting.

Turns out the Nylon fittings come in packs of 5 for $12.99 or 2 for $6.99 @ Autozone and Advanced Auto Parts.

So I bought the entire kit (Dorman 800-300) for $140 with free shipping off Advanced with the compression tool,

and I'm running all Nylon lines and connectors. I used a $50 off coupon code (VISA)

Never again am I buying an AN fitting for $15-$20 each. Not when the OEM Nylon fuel connectors are ~$2 a piece.

This is all OEM Ford, GM, Chrysler use and it's been in cars for well over a decade as far as I can tell and it's safe

and totally inexpensive to use.

Last edited by Aceshigh; 08-09-2011 at 11:08 PM.

#16

Be a little careful. Those hard 90° turns in that Dorman kit will not flow as well as the smooth radius of the full flow AN fittings. Also know that the nylon stuff doesn't go any bigger than 3/8. Not a problem for 90% of the swaps, but will be an issue for the serious HP machine.

Can't argue with the price, but sometimes cheaper is not always better.

Can't argue with the price, but sometimes cheaper is not always better.

#19

TECH Enthusiast

iTrader: (9)

If you look at the price of the line itself, the nylon is a lot cheaper.

If you add up the adapters, connectors, etc for the AN fittings, you'll find the nylon fittings end up cheaper too.

I used stainless braided short lines at the tank and the fuel rail. I used 3/8" hardline with 37 degree flairs through the car.

If I had to do it again, I would just go with all nylon line/fittings.

If you add up the adapters, connectors, etc for the AN fittings, you'll find the nylon fittings end up cheaper too.

I used stainless braided short lines at the tank and the fuel rail. I used 3/8" hardline with 37 degree flairs through the car.

If I had to do it again, I would just go with all nylon line/fittings.

I bought one of the kits too, haven't used it yet, but will be shortly.

I can't vouch for the durability of it, but I don't think it would be so heavily used in OE applications if it wasn't safe.

Nylon gets my vote too, as I've done a combination of hard lines and braided PFTE in the past, it gets expensive fast, paying $9+ for each individual fitting.

#20

TECH Addict

iTrader: (1)

I have bent up and flared plain steel tube hydraulic lines in the past and plan to use the same tools to make hardlines for my LSx swap.

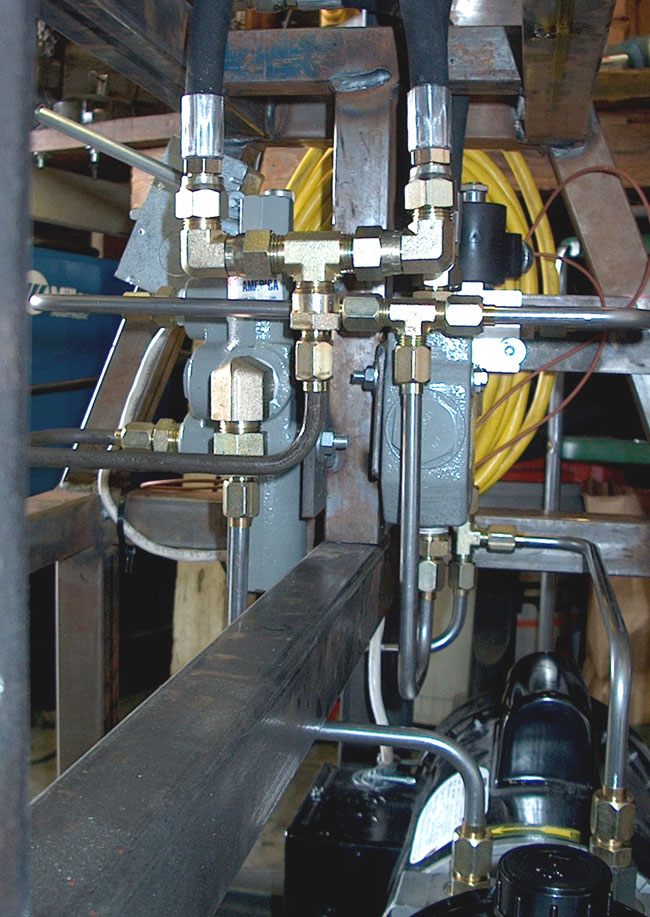

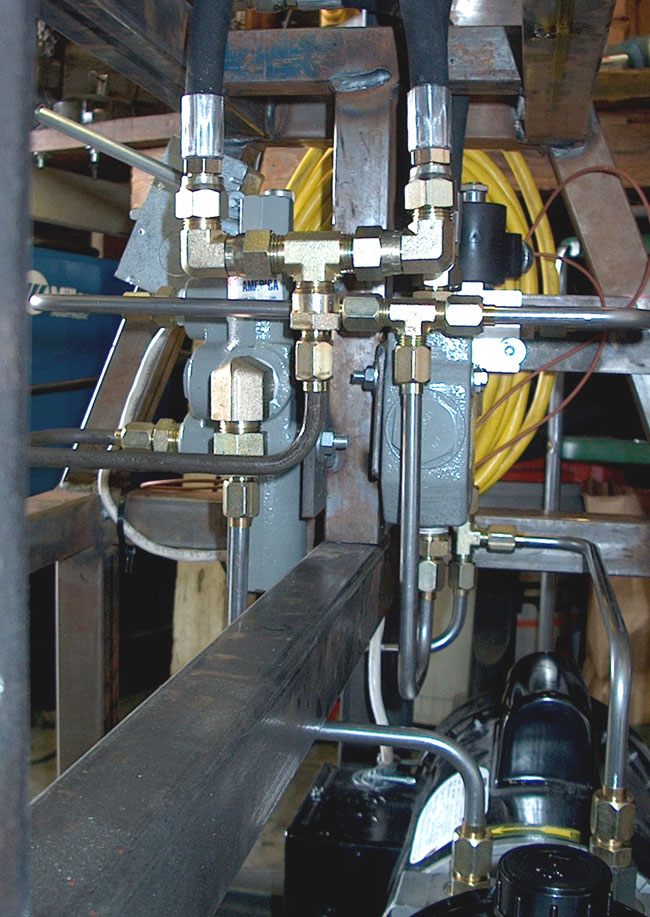

Here is an example of some hydraulic lines I made from 3/8". There are a lot of flare connections here, but no leaks at over 2000psi. This system uses JIC fittings which are very similar to AN (same flare angle and thread pitch) but not equivalent in strength or reliability due to stricter requirements on AN tolerances.

As stated above, the right flare tool is critical to getting a proper seal. You need a 37 degree flare tool, not a 45 like what you'll commonly find at a hardware store. Preping the end of the tube is also very important - it should be debured prior to flaring. How far you insert the tubing is also very important. I use a Rigid model 377 for flaring 3/8" (see picture below). The flaring cone on this tool rotates eccentrically, working the metal gradually as it makes its way around and around the flare. I've found it to produce exceptional results on par with the Swagelok tools I've used in the past, but for a lot less money. I have not done stainless with this tool yet, so I can't comment on what the quality would be in that case.

It also helps to have a good tube bender, although this is less critical. Some of the cheap benders you'll find at the hardware store tend to kink, dent and scratch the tubing. If you look at the bender pictured above, it has a long shoe that slides along the tube and swing-away hook arm to keep the tube against the die. The result is no kinks or scratches for a quality bend. I have also used a Swagelok bender that had roller dies and it worked well too without any scratching of the surface.

Whatever route you go, solid or flexible, be very aware of how and where you route your lines. Keep them away or shielded from exhaust. Use as few fittings as you can. If you cross mounting surfaces that can vibrate independently (like a frame mounted to a body with rubber bushings), use a flexible connection to bridge the gap. Fasten lines appropriately so they will not come loose or vibrate excessively. And inspect your work frequently to catch leaks before they become fires.

Here is an example of some hydraulic lines I made from 3/8". There are a lot of flare connections here, but no leaks at over 2000psi. This system uses JIC fittings which are very similar to AN (same flare angle and thread pitch) but not equivalent in strength or reliability due to stricter requirements on AN tolerances.

As stated above, the right flare tool is critical to getting a proper seal. You need a 37 degree flare tool, not a 45 like what you'll commonly find at a hardware store. Preping the end of the tube is also very important - it should be debured prior to flaring. How far you insert the tubing is also very important. I use a Rigid model 377 for flaring 3/8" (see picture below). The flaring cone on this tool rotates eccentrically, working the metal gradually as it makes its way around and around the flare. I've found it to produce exceptional results on par with the Swagelok tools I've used in the past, but for a lot less money. I have not done stainless with this tool yet, so I can't comment on what the quality would be in that case.

It also helps to have a good tube bender, although this is less critical. Some of the cheap benders you'll find at the hardware store tend to kink, dent and scratch the tubing. If you look at the bender pictured above, it has a long shoe that slides along the tube and swing-away hook arm to keep the tube against the die. The result is no kinks or scratches for a quality bend. I have also used a Swagelok bender that had roller dies and it worked well too without any scratching of the surface.

Whatever route you go, solid or flexible, be very aware of how and where you route your lines. Keep them away or shielded from exhaust. Use as few fittings as you can. If you cross mounting surfaces that can vibrate independently (like a frame mounted to a body with rubber bushings), use a flexible connection to bridge the gap. Fasten lines appropriately so they will not come loose or vibrate excessively. And inspect your work frequently to catch leaks before they become fires.

Last edited by -TheBandit-; 08-10-2011 at 10:22 AM.